The car engine is switched to idle mode (idle speed) by command from the electronic control unit (ECU). This happens at the time of start-up or when it is necessary to warm up the engine. The engine is in this state when the transmission is turned off, when the car is stopped, for example, at a traffic light. The engine operation is controlled by a special idle speed sensor (IAC). Usually it does not cause any special problems, but its breakdown can cause a lot of trouble for drivers. That is why the performance of the DCS must be constantly monitored and, if defects appear, they must be promptly eliminated.

Design

Any DXH provides air flow inside the engine when the throttle valve is closed. Moreover, if previously the idle speed sensor of the carburetor VAZ 2109 functioned as a shut-off valve, the calibrated hole of which could only be either open or closed, then the new idle speed sensor VAZ 2109 injector is capable of independently, depending on the position of the throttle valve, reducing or increasing the amount air, which is needed at different periods of time. That is why experts consider the new version of the IAC not to be a sensor, but a measuring device, and recently it has received the name idle air controller (hereinafter referred to as IAC).

The idle speed control of the VAZ 2109 injector is structurally reminiscent of a miniature module; in addition to the stepper motor, its body contains a rod with a needle with a cone-shaped tip.

The IAC is secured to the throttle body housing with two screws.

The device is also equipped with a 4-pin connector designed to connect the device to the car's ECU.

Removing the device

If you nevertheless determine that the idle speed sensor is broken, then you will need to replace it with a new one. To dismantle this part, no special skills are required.

The above-mentioned VAZ 2109 and 21099 sensor is installed on the throttle body body and attached to it with two bolts, for example, like a fuel pump. In order to remove this device, it is enough to unscrew the two mounting bolts and remove the bundle of wires connected to the device. Before performing this work, it is recommended to disconnect the battery by removing both terminals from it.

Before installing a new part, be sure to sand the joint. Also, if necessary, you need to replace the gasket.

Principle of operation

The basic principle of operation of the IAC is reduced to changing the cross-sectional area of the calibrated hole in the bypass channel based on the current position of the throttle valve. This change begins with the translational movement of a needle connected to the armature of a stepper motor through a worm gear. Completely closing the bypass channel with the throttle valve fully open does not affect the operation of the power unit. When the needle moves back, the amount of air increases in proportion to the closing angle of the throttle valve. Due to this, it is possible to smoothly regulate the crankshaft speed during the transition from the operating state of the car engine to the idle mode.

How does the regulator work?

In everyday life, the IAC is often called a sensor, although in reality it is not one. The element is a stepper motor housed inside a non-separable housing. Only the spring-loaded rod with a cone-shaped tip protrudes outward. At the command of the ECU, the engine extends or retracts the rod to a certain distance.

The idle speed sensor is located in the throttle valve block, the working cone is extended into a small cross-section bypass channel. Since the engine starts and idles without pressing the accelerator pedal, the mentioned channel supplies air to the cylinders when the throttle is closed. The task of the IAC is to regulate the amount of air flow, blocking part of the flow area with a cone.

To better understand the issue, it is worth presenting the operating principle of the idle speed sensor in the form of an algorithm:

- After the driver turns on the ignition, the controller activates the governor motor, forcing the idle air passage to open. The ECU calculates the opening amount using a temperature sensor - if the engine is cold, the rod will move back more.

- At the moment of startup, the injectors supply an enriched mixture to the cylinders. Then the amount of fuel is reduced so that the engine does not “suffocate” and stall. The speed is monitored by the control unit using a crankshaft position sensor.

- The volume of air entering through the IAC is taken into account by the mass air flow sensor located on the inlet pipe, while increased crankshaft speeds are maintained (1200–1500 rpm).

- Using the temperature sensor, the control unit “sees” that the engine is warming up and gradually reduces idle speed, giving the command to the IAC to cover the cross-section of the bypass channel. When the temperature reaches an acceptable value (60 °C or more), the regulator maintains the speed at 850 rpm.

Note. If a warm engine is started, the controller immediately sets the IAC rod to the operating position corresponding to normal idle speed.

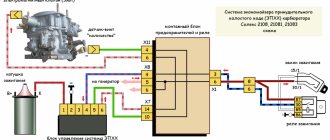

IAC connection diagram and its operation

The IAC is connected to the ECU control controller with a 4-wire harness through a standard connector.

The existing electrical circuit does not allow the driver to influence the operation of the IAC, since the control algorithm of the controller is reflashed exclusively on special equipment.

The IAC mechanism works according to the algorithm indicated below:

- When you turn the ignition key, the regulator rod moves to its extreme position and the calibration hole of the air pumping channel in the throttle pipe is completely closed.

- The IAC returns the valve to the primary position after starting to read steps. At this location of the rod, the motor starts and its operation begins in the XX mode.

Important! The basic position of the rod is determined by the ECU firmware - for example, it is equal to 50 steps for Bosch firmware, and for January 5.1 firmware it is 120 steps.

- When the gear is engaged, the throttle valve is open and the IAC does not take part in the operation of the engine - the valve position is closed, while the rod and needle are motionless.

- If the power unit enters idle mode (which means the throttle valve is closed), voltage is transmitted to the stepper motor.

- The needle opens the hole in the valve slightly after the stem begins to move.

- In a roundabout way, the required amount of air moves into the engine (through the slightly open hole of the additional pumping channel), preventing the latter from stalling.

The disadvantage of the VAZ 2109 injector idle speed sensor and its connection to the ECU is the lack of a self-diagnosis system. In case of malfunctions and errors in operation, the driver will not receive any useful information about this. The Check Engine light on the dashboard will not illuminate. Therefore, the driver must independently guess about the malfunction of the regulator based on his own analysis of randomly appearing indirect signs that affect the operation of the engine.

Basic faults

Since the idle speed sensor has many moving mechanisms, it is prone to breakdowns. But, since it relates to the engine power system, the symptoms of its malfunction will be very similar to other devices of this unit. How can you determine that the idle speed sensor is faulty?

If, when the VAZ 2109 and 21099 injector is idling, the speed fluctuates and the engine does not operate stably, or even stalls, then this is the first sign of a malfunction of this device.

The second sign is when the engine is VAZ 2109, 21099, the idle speed is kept in the range of 600 - 800 rpm, and does not rise higher, and when you press the gas pedal, the engine stalls completely.

The last symptom that the idle speed sensor is faulty is that the injector stalls during operation, when the gear is turned off. If the speed fluctuates, or the engine stalls completely during operation, in gear, then the reason is clearly different.

Signs of IAC malfunction and ways to eliminate them

If the engine begins to malfunction or previously unidentified symptoms are observed in its operation, then they may indicate malfunctions in the regulator, for example:

- idle speed is unstable;

- when changing gears or by itself, the engine begins to stall;

- there is no increase in speed when starting the car, which is typical for the primary mode

- warming up;

- When various additional equipment is turned on, the speed decreases.

Similar symptoms are also observed if:

- the bypass channel of the throttle assembly is clogged with dirt;

- there is damage to electrical wires (breaks, broken contact connections, etc.);

- The installed IAC variant does not match the ECU firmware type.

Before starting diagnostics of the regulator, it is recommended to make sure that the above defects are absent.

Idle speed sensor for VAZ 2109 injector

The car engine is switched to idle mode (idle speed) by command from the electronic control unit (ECU). This happens at the time of start-up or when it is necessary to warm up the engine. The engine is in this state when the transmission is turned off, when the car is stopped, for example, at a traffic light. The engine operation is controlled by a special idle speed sensor (IAC). Usually it does not cause any special problems, but its breakdown can cause a lot of trouble for drivers. That is why the performance of the DCS must be constantly monitored and, if defects appear, they must be promptly eliminated.

Dismantling the IAC

Dismantle the regulator as follows:

- Block the car with a handbrake or wheel chocks.

- Remove the terminals from the battery.

- Disconnect the connecting connector from the IAC.

- Clean the area around the IAC from contamination.

- Unscrew the 2 mounting screws.

Having completed all these operations, the regulator is removed from the mounting socket.

Replacement or cleaning

Practice shows that in a fairly large number of cases, simply cleaning the idle air regulator allows you to restore its functionality. Therefore, we advise you to try this method first. And if it does not give results, then it will not be difficult to replace the device.

Disassembling the unit for cleaning or replacement

The main thing here is to act carefully and not to overdo it with the carburetor cleaner if you first decide to try cleaning the device. Otherwise, replacing the IAC does not cause problems even for beginners.

Source

Checking the serviceability and restoring the functionality of the IAC

Check the functionality of the regulator as follows:

- Connect the battery to the vehicle's on-board network and, holding the IAC in your hands, put the power supply block in place.

- Turn on the ignition. In this case, the regulator rod should retract inward and then extend back to a certain distance. If the IAC acts this way, then it is operational. Otherwise, it must be replaced.

Sometimes the functionality of the regulator is restored after cleaning the spring, valve hole and needle.

Clean the IAC with a cleaner like WD-40. In this case, there is no need to disassemble the device - just treat the rod, needle and spring with a solvent. It also doesn’t hurt to spray the cleaner inside the XX channel, which will clear the valve hole of any contaminants. As soon as the cleaner dries, the functionality of the regulator is checked again and only after that a decision is made on the advisability of replacing it.

IMPORTANT! Before installing a newly purchased or repaired IAC, it is recommended:

Make sure the product matches the vehicle ECU firmware; check functionality; Lubricate the spring and rod with grease.

When choosing an IAC VAZ2109 injector, avoid purchasing counterfeit products. A fake is distinguished by the following characteristics:

- information on the packaging does not allow identifying the manufacturer;

- yellow color of the sticker on the product body;

- dark tip of the locking needle;

- thin sealing ring.

The figure below will help you distinguish the old-style sensor (on the right) from the new-style sensor (on the left):

Lada 2109 1992, 71 l. With. — self-repair

Comments 6

Participate in the discussion can only registered users.

All this is in vain, you just had to replace the xx system if it failed, but most likely just clean and adjust the carb YOURSELF.

Kalkhoz is not Kalkhoz, I don’t know, but I still have problems in my car and there is no point in solving this every time... regarding setting up the carb, I go to carburetor specialists and I don’t know how to set it up.

In my opinion, this is a collective farm solution to this problem. The carburetor needs to be adjusted. Have you tried turning the quality screw, it also affects xx. Maybe you even have a buggy system epkhh.

I suffered for a long time with magnetic valves (I changed 4 pieces) In the end I bought an expensive one (170 rubles) - as they said, “factory”)) Pah-pah it works for now, but when it “cracks” I’ll probably do the same as you. I won’t buy another valve) )