In addition to the fact that a car is a means of transportation, it is also a source of a wide variety of sounds. Sounds can tell a lot to an experienced owner. Many can easily make a diagnosis without even opening the hood or looking under the bottom. It is enough, as an experienced doctor, to listen to the nature of the noise, and the malfunction is clear in the palm of your hand. Some nodes cannot be diagnosed any other way. This is especially true for bearings. Today we will be interested in the generator bearing.

Correct replacement of generator bearings on a VAZ 2114

The generator on the car serves to ensure the normal operation of all elements of the electrical circuit in its composition, as well as to recharge the battery while the engine is running. All its malfunctions lead to the fact that the engine eventually stops starting, and it becomes impossible to move the car.

Replacing the generator bearing on a VAZ 2114

Other modification

As for the direct brother of the car mentioned above, replacing the generator bearings on a VAZ 2112 differs little from the process described. After all, the filling of these cars is virtually the same. Moreover, the marking number of the bearing for the VAZ 2112 is identical to what we mentioned earlier, both for the front and rear.

For repair actions you will need the same set of tools and accessories:

- spanners;

- round timber and block;

- puller;

- "Litol."

- We de-energize the car from the battery power.

- We dismantle the electric motor we need in the same way as for the “ten”, since it is mounted in the same way.

- In the sequence described above, we release the necessary parts from the assembly unit.

- Using thick lubricant, we install new parts.

We did not pay much attention to this instruction, since the VAZ 2110 engine and the VAZ 2112 engine are essentially the same, and the generator model used in these cars is the same.

Fourteenth model

Let's turn to another AvtoVAZ modification. Next, we will look at replacing the generator bearing in a VAZ 2114.

The reasons for the breakdown of parts here are similar to those given at the beginning of the article. Well, what will be useful to us for the next repair, we list here in a short list:

- set of wrenches;

- screwdriver;

- hammer and round timber;

- Litol lubricant.

Let's describe the repair technology point by point.

- Disconnect the terminals from the battery.

- We loosen the long adjusting bolt at the top of the unit being dismantled, then unscrew the lower mount of the electric motor, having previously treated the threaded connections with penetrating lubricant.

- Having disconnected all the wires, we remove the electric motor (you can try through the top), and also prepare new parts. Their numbers are 180302 and 180201.

- We unscrew the plastic cover of the electric motor, remove the brush holder and voltage regulator. At the same time we study the degree of wear of the brushes.

- Use a screwdriver to separate the stator from the cover. A hammer may come in handy here, but we do everything very carefully!

- Unscrew the nut from the pulley area and separate the impeller.

- We remove the bearings and install new ones, applying thick grease.

- Assembly is done in reverse

GENERATOR MODEL ON VAZ 2114 CAR

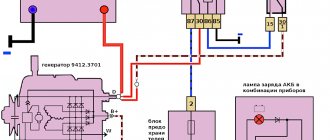

If on early VAZ 2108-09-099 models a generator of the 37.3701 series was installed, then on the VAZ 2110-2115 the brand 94.3701 began to be used. Generators of this series have significant power - the rated current (maximum output current) of such units can be 80A, 90A, 105A, and even 120A (manufacturer StartVolt). The price of the device starts somewhere from 3,500 rubles and can reach 5,000 rubles or more. The price depends on the manufacturer, the technical characteristics of the generator, the region of sale and the seller himself. Other main characteristics are:

- Rated rotation speed;

- efficiency;

- Rated voltage;

- The frequency at which self-excitation occurs.

Generator 94.3701 is an electrical machine that generates alternating current; direct current is obtained through a rectifier (diode bridge) located at the output of the electrical circuit of the machine. Type 94.3701 is used on VAZ passenger cars with an electronic engine control system (ECM), the units are capable of operating at temperatures from – 40º to + 45ºC, permissible humidity 90%. Products are sold both on the domestic market and exported to countries with different climatic conditions.

Generator set model 94.3701

BEARINGS

The generator on a VAZ 2114 car consists of the following main parts:

- A housing consisting of two aluminum covers (front and back);

- Stator (winding located inside the housing);

- A rotor rotating inside the stator;

- Diode bridge;

- Voltage regulator.

The armature (rotor) rotates in two bearings, which are installed: one in the front cover and one pressed onto the rotor. Both bearings are press-fit and therefore are not that easy to replace.

There are usually two main problems with a generator:

- Charging disappears;

- Noise occurs: whistling, grinding or humming.

If there is a whistling noise under the hood, a worn alternator bearing is often to blame. Due to such a malfunction, charging is not lost, but you still shouldn’t drive with noise, since as a result the generator will jam because the rotor will stop rotating.

Before changing or starting repairs, you need to buy the necessary spare parts. And before purchasing, you need to find out what bearings are on the VAZ 2114 generator. A bearing of brand 180202 (a foreign analogue of 6202-2RS) is installed on the rear of the rotor, and 180302 (an analogue of 6302-2RS) is installed on the front cover. The cost of Russian parts is low - in the range of 50-80 rubles per piece, imported spare parts are noticeably more expensive - from 200-250 rubles. Bearings are often sold as a set, that is, in pairs. Imported analogues are of much higher quality, so when choosing parts it is better to buy brand 6202-2RS and 6302-2RS.

Bearing 6302-2RS

Parts Specifications

To purchase new parts, you need to know which bearings are specifically installed in your unit in order to avoid mistakes. The VAZ-2110 generator has 2 supporting elements: front and rear. Their markings vary depending on the year of manufacture:

- in units produced in recent years, the rear part is marked 6203, the front - 6303;

- in older versions the number is slightly different - 6202 and 6302, respectively.

The bearing cages are sealed on both sides with plastic caps, which can be removed to add lubricant if necessary. The overall and internal dimensions of the rotating parts are the same for any marking; their exact values are indicated in the table.

| Bearing size | width, mm | by outer diameter, mm | by internal diameter, mm | Catalog number |

| Front | 14 | 47 | 17 | 180202 |

| Rear | 11 | 35 | 15 | 24940220 |

As a lubricating filler for cages, you can use thick lubricant “Litol-24” or another intended for rolling bearings. It is easy to identify the manufacturer by the additional symbols on the labeling.

The most popular parts of Russian production are from the following enterprises:

- Samara plant, marking - SPZ-4;

- Vologda plant - 23GPZ;

- Saratov plant - 3GPP.

Also, quite often, motorists install 2110 generator bearings from the Koyo, Kraft and LSA brands.

It is strictly not recommended to install elements without inscriptions and markings, manufactured in an unknown location, most often in China.

You may run into trouble with such parts quite soon due to the poor quality of the products.

REPLACEMENT

If there is a whistle coming from under the hood, and it turns out that the generator is the cause of the whistle, then it’s time to change the bearing on the VAZ 2114 generator. It is better to change them in pairs, because the second one may soon whistle too.

At a car service center, they will charge approximately 600-700 rubles for the replacement work, plus removal and installation of the generator - approximately the same amount of money. But you can change the bearing on the generator yourself; you only need minimal plumbing skills, tools and care when disassembling and reassembling. Alternatively, you can buy a new assembled generator, but replacing the VAZ 2114 generator bearings will cost much less.

So, let's look at how to change the bearing on a VAZ 2114 generator. To replace it, you will need the following tools:

- Set of combination keys;

- Screwdrivers – slotted and Phillips;

- Puller for pressing out the rear bearing;

- Hammer;

- Vise;

- A drill bit with a diameter of approximately 4 mm and a drill (not needed if the entire front cover is being replaced).

Replacing the generator bearing yourself is done as follows:

- We turn off the engine, remove the battery terminals;

- Loosen the belt tensioner nuts and remove the tension belt;

- We completely dismantle the belt tension bar, disconnect the wires, unscrew the mount and remove the entire device itself.

What problems may arise in the operation of the generator and options for solving them.

- If the brushes or voltage regulator malfunction, you will have to completely change the assembly due to the fact that it does not fold.

- Rotor bearings and their replacement. We've already discussed in detail how to change a bearing on a generator, so let's just remember that there are two bearings in a generator. One is pressed into the front cover, and in the event of a malfunction, it is very often replaced along with the cover assembly. The second bearing is secured, wound onto the rotor shaft, removed using a special puller, and a new one is pressed in its place.

- Additional diodes. If the diode malfunctions, its leads can be unsoldered, and then, being careful not to break the rectifier unit with impacts, pull it out of the holder. Clean the area of epoxy, then install the diode and solder it. After the entire procedure, the diode lead, which has a color mark, is soldered to the bus, and the diode body is fixed to the holder with epoxy resin.

- The generator tension belt requires adjustment. But this must be done competently and carefully, since excessive tension can quickly increase the load on the bearing and lead to its failure.

Many of these problems may seem trivial, but they may result in you needing a new generator. You can repair the generator yourself, but to do this you need to have certain skills, so we still recommend leaving this work to experienced craftsmen.

Instructions for replacing generator bearings on a VAZ 2114

The generator is an incredibly important component of the car, the functioning of which determines the performance of the entire car.

If you hear a grinding noise coming from under the hood, you can immediately suspect that the generator bearings are faulty. This metal element often becomes deformed during operation and loses its performance characteristics.

This may manifest itself as annoying grinding, ringing or whistling noises. If the situation is really bad, the bearing may be even louder than your running engine.

Generator bearing

Article on the topic:

Checking the overrunning clutch without removing the generator

When the engine is running, this part of the car should not make sounds such as creaks and noise. Experienced drivers can tell by sound whether the problem is mechanical or electrical. The generator should not become very hot during operation. If it emits heat, like a switched-on oven, it means it is not working correctly.

Turn off the engine, take a thin screwdriver and turn the generator armature. If everything is in order, it should only spin well in one direction.

If the overrunning clutch does not work properly, the alternator belt may become dislodged.

Ways to solve the problem

If such a malfunction occurs, you need to solve the problem as quickly as possible. Basically, there are three main ways to do this.

- Seek assistance from specialists at the nearest service station.

- Replace the complete prefabricated generator, rather than trying to solve the issue with a more budget-friendly method.

- Purchase a new bearing for the generator and replace it yourself.

What nuances does one or another method presented above have?

- The first option is reliable, but requires costs not only for the part itself, but also for the expensive services of craftsmen.

- The second option is more financially accessible, but you will have to do quite difficult work.

- Option number three is the most difficult from the point of view of independent execution, but is the most budget-friendly. Consequently, you will be able to save an impressive amount of money.

Should I contact service or replace it myself?

Having problems with your generator?

Most likely, you will need to replace the alternator bearing that produces an unsightly grinding noise from under the hood. During operation, a metal bearing can become deformed or fail, causing it to produce unpleasant sounds in the form of squealing, whistling or ringing. Sometimes the power of such sound can drown out the sound of a running engine. There are only three options:

- seek help from the nearest service station;

- replace the generator by purchasing it as a complete set;

- We get a new bearing for the generator and solve the problem ourselves.

Considering the first method of solving the problem, it is worth noting that it will be quite expensive, because you will have to pay for both spare parts and labor, and at the same time the simplest, because you will not have to do anything yourself.

The second option is simpler from a financial point of view, but you still have to make an effort yourself. Well, of course, the third solution to this problem seems quite complicated, because you need to understand how to independently replace the bearings on a VAZ 2114 generator; this option is much more complicated than others, but it will save you a lot money.

Of course, if you had a car not a VAZ 2114, but some kind of Mercedes or BMW, then you, of course, would not do such repairs, since if you had enough money for an expensive car, then there would also be repairs. But, unfortunately, not everyone has this opportunity, so domestic car enthusiasts prefer to solve such problems on their own. This is not bad, since the motorist will also gain technical skills, and the money will be safer. How to remove a bearing from a generator? This requires detailed instructions, so it’s worth going into more detail.

Repair

So, you have decided to purchase new bearings and follow a difficult but fairly economical path. For cars like the VAZ 2114, self-repair is a common thing. Such work, even in the absence of impressive experience and knowledge, is not difficult to do. Simple follow the instructions.

- Disconnect the generator from the battery to deprive it of power.

- Remove the timing belt.

- Using wrenches of the appropriate size, remove the fastening nuts.

- The film is removed, after which the sleeve is removed.

- The generator itself is carefully removed from its seat.

Subsequent work is more subtle and complex. After all, you have to disassemble the generator in order to get to the bearings. The task is not an easy one, but you can handle it yourself.

- There are nuts on the generator housing that need to be unscrewed;

- Remove the cover and remove the regulator from under it. This element is responsible for brushes and tension;

- Disconnect the stator from the cover. This operation should be done as carefully as possible so as not to damage the copper winding;

- Sometimes the housing can become rusty, making the stator difficult or even impossible to remove. In such a situation, arm yourself with a hammer and an impact screwdriver. With the help of these tools it is necessary to deliver the most accurate blows. This way you will be able to divide the element into blocks;

- Separating the generator from the stator, you will see both bearings - front and rear;

- Remove the damaged component and install a new alternator bearing in its place. Don't forget that there are two of them. For prevention, you can replace both at once, even if one of them is in completely good condition;

- Assembly is performed strictly in reverse order.

Generator bearing VAZ 2115

The generator on the car serves to ensure the normal operation of all elements of the electrical circuit in its composition, as well as to recharge the battery while the engine is running. All its malfunctions lead to the fact that the engine eventually stops starting, and it becomes impossible to move the car.

Replacement

How to remove the generator bearing?

On devices from different manufacturers, this process is carried out in different ways, and the bearings of the Bosch generator are most easily replaced. Car enthusiasts often ask the question of how to change a bearing in a generator. So, this is done in the following way:

Do-it-yourself repair versus service repair

Of course, contacting the service is always safer, and the driver will be more confident that everything will go right. But it is precisely for this confidence that you often have to overpay, and by very substantial amounts. As already written, even some of the parts that do not need to be replaced, like the top cover of the generator, often also become a reason for extra payment (especially in non-professional service stations).

Of course, doing a DIY repair is not an easy task, especially when you get to parts like a generator. But sometimes everything is done for the first time. And the significant amounts of money to pay for the robotic service can be spent on more pleasant things. In addition to economic indicators, a clear advantage will be the fact that the car owner will be able to feel like a real professional, realizing that he is the one who is able to repair his own car.