Any car, from a pickup truck and flatbed Gazelle, to eight-axle dump trucks and road trains, has a generator. This device receives mechanical energy from the engine and converts it into electrical energy. After which it sends current to consumers. In particular, it charges the battery.

If everything is in order, then the battery is recharged as much as required, without undercharging or overcharging. But, in case of any problems, the battery may fail. Violations “in both directions” are harmful for her. If it is over-discharged, a constant discharge will occur. If overcharged, the jars will boil. In such situations, diagnosis is required.

How much should a generator produce?

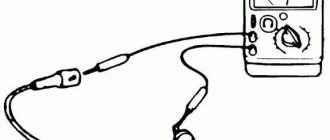

Using a voltmeter or multimeter, measure the current strength, its voltage and resistance. During normal operation of the generator, the battery should receive from 5V to 14.5V. If the charging current is outside the specified range, then you need to look for problems.

Because The battery and the generator are directly connected to each other, then the voltage can be measured in two ways - at the generator or directly at the battery. In the second case, it is enough to connect the multimeter to the banks in any sequence. If a load plug is used, the polarity of its connection to the terminals must be observed.

The normal network potential difference is considered to be 12 volts or higher. If you turn off the energy consumers and start the engine in idle mode, the device should show a voltage on the battery of 13.5-14V. Lower values (for example, 13.3-13.8V) indicate abnormalities.

It would also be a good idea to measure the current. The number of amperes that the battery receives from the generator is different for different cars and depends on the electricity consumers. For measurements, you need to start the motor and apply a load to the current source. With the engine running and consumers turned off, the charging current will be 6-10A. Then the battery will charge, the current will begin to decrease. After turning on the headlights, side lights and heating, the charging current should increase. If not, there is a malfunction in the system.

More accurate data on current strength at different loads at different engine speeds can be found in special tables.

It is also useful to measure the resistance of the generator elements: stator, rotor and diode bridge. The rotor resistance is measured on the winding. To do this, you need to connect the multimeter probes to the slip rings. With values of 2.3-5.1 Ohm, we can assume that everything is in order. The current in the winding should be in the range of 3.0-4.5A. Operating resistance – 0.2 Ohm.

When monitoring a diode bridge, you need to not so much measure the indicators as make sure that there is resistance at all. If only the device does not give zero values. Measure in pairs - “plus” and all the plates on its side, and then also “minus”.

What's the result?

Taking into account the above information, it becomes clear that if problems begin with the battery, often the cause of the problem is the generator, and not the battery. In this case, the generator needs to be checked comprehensively (alternator brushes, slip rings, windings, generator relays, wiring, terminals, etc.)

Please note that too high a load on the generator (for example, when installing powerful emergency power consumers) in many cases causes rapid failure of the generator. To avoid problems (especially when choosing a new generator), you need to separately take into account some features.

We also recommend reading the article on how to properly charge a battery with a charger. From this article you will learn about the features of charging a battery with a charger, as well as what subtleties and nuances you should pay attention to when charging a car battery.

Simply put, the charging current must be at least 10% of the battery capacity (manufacturers indicate on the generator body what current the generator supplies to the battery). The total consumption in the network is also taken into account separately (calculated based on the maximum performance of electrical appliances and vehicle systems). Also, installing a more powerful battery may require a more powerful generator.

As a result, we add that every 15-20 thousand km. mileage, it is necessary to check the tension of the generator belt, since loosening it reduces the performance of the generating device. It is also necessary to periodically check the diode bridge, voltage regulator, as well as a number of other elements. At the same time, the terminals are cleaned and the battery is serviced. This approach will allow you to maintain full functionality of the system and eliminate possible unexpected breakdowns.

Why does the generator not charge?

As mentioned above, if the generator is working normally, then the battery charge level is replenished to the extent necessary. Under load, the charge decreases. But there are many components in the scheme that can cause the process to go wrong. Problems arise both in the mechanical part (bearings, generator drive, etc.) and in the electrical part (wear of brushes, burnout of diodes, breakdowns, short circuit of windings or their breakage, etc.). The relay regulator should also be checked separately.

In the vast majority of cases, generator malfunctions are fixable. To restore the battery charging process, sometimes you only need to replace the drive belt. Perhaps for repair it is enough to put the terminals, contacts or other parts in order. Although, there are also such malfunctions when you have to change the generator assembly.

It is also not uncommon for a situation where, with a working generator and a normally functioning battery, the voltage is still unacceptably low. And during the diagnostic process no problems are detected. Then it is necessary to carefully examine the condition of the terminals. They need to be tightly seated, without oxidation. This also applies to electrical wiring. It is recommended to ensure that the contacts are clean and securely fastened, and that the wires themselves are intact. To prevent oxidation from appearing on the contacts, they must be cleaned from time to time. Otherwise, the flow of current will deteriorate.

There are also errors during maintenance. For example, due to incorrect connection of the contact group, the battery may discharge and the generator may begin to operate intermittently.

Important points

The voltage (U) and capacity of the car battery are the main parameters that need to be paid attention to when choosing and checking a power source.

The main purpose of the battery is to start the engine during the period when the car's generator has not yet been connected to work, and the battery is the only power source.

To eliminate operational problems, the car owner should know the following points:

- What does the battery life depend on?

- What should the voltage be (in normal mode, after starting the engine and under load);

- What causes the decrease in capacity during the cold season and other issues.

Let's consider these questions in detail.

Engine running

on the battery with the engine running (less than 13) - evidence that the battery charging mode does not correspond to the norm. What could be the reasons?

Firstly, in the battery itself. Resource depletion and sulfation are the main problems that car owners most often encounter.

Secondly, either the generator is not working well, or there is a malfunction in the electrical circuit. For example, increased leakage current with decreased insulation resistance. As a rule, defects in the braiding of wires that lead to breakdown and short circuit.

Thirdly, there is a problem with contacts. This should be checked immediately. Remove the terminals, inspect them and the battery terminals for oxidation. If necessary, clean and tighten fasteners tightly.

Rectifier module

The rectifier module is designed to convert alternating current into direct current. It is based on six silicon diodes (gates): three positive and three negative. They are located on two horseshoe-shaped plates. To smooth out voltage surges, the terminals of the positive and negative diodes are connected through a 2.2 μF capacitor.

How to check the generator on a VAZ-2110 for the functionality of the rectifier unit with your own hands? To do this, you will need a regular car tester or test lamp. The essence of the test is based on the ability of diodes to pass current in only one direction. A faulty valve either does not pass current at all, or passes in both directions.

So, first you need to remove the casing of the rectifier unit. Next, connect the first wire of the test lamp to terminal “B” of the generator, and the second to the ground of the device. If the unit is working properly, the lamp should not light up. If it lights up, there is a short circuit in the rectifier and it needs to be replaced.

Don't be lazy to check the capacitor as well. Turn the tester into ohmmeter mode (1-10 MOhm) and measure its resistance. For a working capacitor, it should first take a minimum value and then gradually increase. If this does not happen, replace the capacitor.

Recharging the battery

Sometimes a generator malfunction is associated with overcharging the battery. It can be identified by its characteristic signs: the headlights shine brighter than usual, the battery charge indicator is constantly on. If the voltage exceeds the norm, this may cause the battery to boil over. Overcharging is most often caused by a broken voltage regulator. In a VAZ 2115 car, this part can be easily replaced by yourself.

How to avoid serious damage

To minimize the risk of generator and wiring failure, scheduled maintenance should be carried out on time.

- Replacing generator brushes.

- Timely tension of the belt.

- Bearing inspection and replacement.

- Be careful when carrying out repair work.

- High-quality insulation of contacts and twists.

- The use of crimp terminals and terminal contacts when repairing wiring.

To carry out routine maintenance, it is advisable to contact a specialized service that can check the condition of the electrical wiring and promptly carry out maintenance.

Malfunctions of the generator or electrical wiring can cause many unpleasant moments for the car owner. Difficulties with starting, dim headlights, slow wiper blades... Gasoline engines cannot go very far without a generator - it takes a lot of energy to form a spark on the spark plugs. At the first signs of malfunctions, it is better to carry out a full diagnosis and maintenance of the vehicle’s electrical systems.

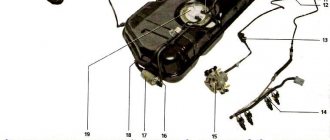

Disassembly

This section describes a step-by-step process that will help you correctly disassemble the Gazelle generator.

So, first you need to remove the plastic protective cover from the case. Then unscrew the brush block and the voltage regulator, having first disconnected the wiring from it. Next, you should unscrew the four tie rods of the generator housing and remove the housing cover together with the stator. Then, having disconnected the winding terminals from the diode bridge, you need to remove the stator, and, if necessary, the

You can carry out the process of diagnosing generator parts using measuring instruments: E236 or a special test light.

Other causes of low voltage

A small potential difference in the system is not always associated with a breakdown of the generator or a bad battery. If the diagnosis of these elements does not reveal any problems, then you should pay attention to the following:

- condition of the battery terminals - connection density and oxidation;

- electrical wiring problems - oxidation, violation of its integrity;

- output contacts to electrical appliances;

- correctly selected energy consumers.

Each contact must be tightly adjacent and intact, that is, there must be no formations (for example, sulfation) that will disrupt the flow of current. Incorrect connection of contacts leads to accelerated battery discharge even when the car is not running.

To improve the connection of the elements of the car's electrical system, it is necessary to clean all contacts and restore the integrity of the wires by replacing them or connecting them and wrapping them with insulating tape.

In conclusion, I would like to repeat that stable operation of the car requires constant monitoring of all elements, and the generator should attract special attention. The battery is charged from it and provides electricity to the entire car system. Pay attention to all elements: generator brushes, slip rings, voltage regulator, equipment winding.

The most correct measurements should be carried out when the battery is fully charged and in various modes. Remember that the manufacturer links the characteristics of the generator to the number of engine revolutions - they help produce a certain current.

Detailed video on how to check the generator:

Do you have experience diagnosing an alternator and solving problems in a vehicle's electrical system? Please share your experience and opinion with our readers in the comments. If you have questions about the topics covered, we will be happy to answer them.

What voltage should the VAZ-2114 generator produce: how many volts are needed to charge the battery

The purpose of any generator, including the one installed on the VAZ-2114, is to transform the energy produced by the car’s engine into electronic current, which is needed to power all systems and parts that need it.

The video shows how to check what voltage the generator supplies to the battery: