It's easy and interesting to communicate here. Join us!

Fan switch sensor, see

if the wire after the fan is shorted to ground

Is the check engine light on? If so, then most likely there is a break in the wiring to the sensor at the sensor connector. Tester in hand and forward. to check the circuits.

they have a single-contact sensor, 2 pieces, one for the brains and the fan, the second shows the temperature on the panel, they are located at the thermostat, swap them, if that doesn’t help, then look for a break in the wiring. You can’t short-circuit the sensor to ground, your brain will die.

Alena, the problem is most likely in the connector of the fan sensor, if after the connector is pulled out of the sensor and the fan still works, then it is the connector, or maybe the wires have rubbed together somewhere and the screw is bypassing the sensor.

The brains receive a signal from the sensor and control the turn-on relay. Perhaps the brain is to blame.

This is the temperature sensor that goes to the brain. either closed or the terminal is removed. The two-pin sensor is located below the camshaft sensor

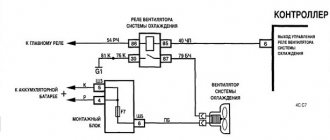

For injection, control of the fan comes from the brain (supplies -12V on). On, occurs when the antifreeze temperature reaches about 100-103 degrees Celsius and opens. at 96-97 degrees. Occur on so: +12V, fan winding -12V from the brain. Disconnect from the brain should be off. fan. If off It's the fault of the brains, if not, THEN look for a short circuit to the case from the fan to the brains.

It is not the temperature sensor that needs to be replaced, but the temperature sensor, which is located on the radiator.

Tips for motorists

If the owner of the VAZ-2114 wishes, it can be equipped with an air conditioner, allowing everyone to feel comfortable in the cabin of this passenger car on these hot summer days. Then, when the air conditioner is turned on, the fan of the engine cooling system must also turn on, regardless of what temperature the coolant is. Because this is how its electrical circuit is designed when there is an air conditioner.

But, on those VAZ-2114 cars where there is no air conditioning, the engine cooling system fan should operate when the antifreeze heats up to a temperature of 101 degrees. If the fan electric motor turns on and starts working even when the engine is not warmed up, the driver will need to solve this problem.

First, you need to check the integrity of the insulation of the wires going to the coolant temperature sensor (DTOZH), which is located in the cylinder head, on its inlet pipe. If, for some reason, they begin to short to ground, then the fan must turn on, since this false signal tells the controller that the temperature of the antifreeze in the engine cooling system has risen to 130 degrees. Since the controller does not know that this signal is false, he naturally turns on the fan.

Reset errors

Sometimes after repairs have been carried out, error codes still remain in the memory of the electronic control unit. They may interfere with the normal operation of the fan and may also be displayed on the on-board computer. In order to restore the functionality of the element, you need to remove them. This can be done in two ways.

1 way. To do this, you will need an OBD scanner and a laptop or smartphone with the appropriate application. Errors are reset in the following sequence:

- Connect the scanner to the diagnostic connector of the car and a laptop or other gadget.

- Turn on the ignition.

- In the program, press the READ key and press ERASE. Sometimes you need to select YES or CLEAR to clear errors in an application.

Method 2. If you don’t have a diagnostic scanner, you can use another error removal algorithm:

- Turn on the ignition without starting the engine.

- Open the hood and loosen the negative terminal of the battery.

- Wait approximately 1 minute.

- Place the terminal in place, securing it securely.

- Close the hood and turn off the ignition.

After clearing the fault codes, you need to turn on the ignition and check for errors. You also need to make sure that the fan is functioning properly. If resetting does not solve the problem, the problem may have been identified incorrectly.

You can drive with a constantly running fan, but provided that the antifreeze temperature is normal. If it is high, then you need to stop and not use the machine until the problems with the cooling system are eliminated.

How to check the cooling system thermostat

Testing it is quite simple. To do this, you need to start the engine and warm it up to such temperatures when the valves of this mechanism operate. You can find out the temperature threshold directly on the device body. Usually it is 72 or 80 degrees. Then you need to check the temperature at the lower and upper pipes. If both are at approximately the same temperature, then the reason why the cooling fan is constantly running has been found. It is recommended to carefully inspect the thermostat valves after removing it. It is useless to repair this unit (it is easier and cheaper to buy a new one). By the way, if this element is dismantled, it can be checked without installing it in the car. To do this, the thermostat is placed in a container of water, which is then heated. Increasingly, the valve should open. If this does not happen, the device is faulty.

ECU

If the diagnosis of all other elements did not help, then the cause of the breakdown is a malfunction of the electronic control unit. But this doesn't happen often. It is not always possible to determine this malfunction on your own. Therefore, if an independent check does not give positive results, you should contact a car service center.

If the ECU fails, it is flashed to remove all existing errors or the unit is replaced. These procedures should be performed by an auto electrician. It is not advisable to do such work without experience. This device is not cheap, but, fortunately, it is replaced quite rarely. There are also several other very rare reasons why the cooling fan may not turn off. Unlike the malfunctions described above, they can usually only be identified and eliminated at a service station.

Cooling pump

Sometimes the reason why the cooling fan keeps running and won't turn off is the water pump. The temperature of the coolant in the radiator rises because its speed is slowed down. When liquid enters the cooling radiator, the antifreeze simply does not have time to cool to the required temperatures and passes to the next round. At the same time, the liquid heats up even more.

When does the radiator fan turn on on a VAZ-2110

To really understand how to change the fan switching temperature on a VAZ-2110 injector, you need to know exactly the factory design parameters and the principle of fan switching itself.

In carburetor engines, the fan turned on at about 100 degrees.

On old-style 2110 carburetor engines, the fan was turned on using a thermobimetallic sensor. It was installed directly in the radiator bank and set to a certain temperature. Since the normal operating temperature of antifreeze is 80-90 degrees , the bimetallic plate made contacts at approximately 100-105 degrees .

In injection tens, the fan starts in a completely different way. There are two temperature sensors installed near the thermostat - one with one wire, the second with two. The first one is responsible only for the temperature indicator needle, so there is little demand from it. The second sensor with two wires is working. It is he who supplies the impulse to the electronic engine control unit, which then supplies power to the fan motor network.

Features of the temperature sensor

However, one must understand that a temperature sensor is a conventional converter of thermal energy into a variable electrical pulse. More precisely, when the temperature of the antifreeze changes, the resistance of the sensor changes approximately in this mode:

Now the principle of operation of the fan activation system becomes clear - the ECU receives a certain electrical impulse when the temperature reaches 110 ° C (133 Ohms) and supplies power to the fan motor.

As soon as the resistance of the sensor element rises to 187 Ohms (which corresponds to 97 °C), power is removed from the fan and the engine cools down.

Pump faults

Often, the pump does not stop working suddenly. Initially, the pump gives various signals about breakdowns - for example, the engine cooling fan is constantly running or turns on frequently.

The main reason for pump failure is the bearing - it jams or collapses. You can tell that the pump has failed by the characteristic sounds coming from under the hood. They sound like some kind of howling or knocking. These sounds can be heard even at idle. Novice motorists often do not pay attention to these noises. Pump knocks are mistaken for camshaft malfunctions. To fix the problem, you need to replace the pump. Depending on the model, it is possible to install only the front part of the pump and replace the bearing.

Additional recommendations

If desired, you can install an additional button that will forcefully start and stop the fan.

VAZ 2114 fan diagram with a button

In order to do this, you will need:

- purchase a button (or toggle switch) and mount it in any convenient place (you can even under the hood);

- make a branch from the wire coming from the battery positive to the fan relay, soldering another wire to it;

- connect this wire to the first contact of the button;

- connect the second contact of the button to the relay leg, from which the “positive” wire goes to the fan.

Thanks to such a simple circuit, it will be possible to control the operation of the fan manually.

Clogged cooling system channels

Often the engine overheats due to congestion in the cooling system. The situation is further complicated by the fact that diagnosing this problem can be quite difficult. Therefore, if the cooling fan constantly works or turns on more often than usual, it would not be superfluous to flush the SOD channels. In most cases, these activities are more than enough to ensure everything works correctly. Experts also recommend not limiting yourself to just flushing, but also additionally venting the radiator.

Radiator clogged

The radiator can be clogged from the outside and inside. External contamination is associated with dust and other debris, as well as insects, entering the honeycombs. This worsens heat transfer and is manifested by frequent operation of the fan and a long operating time.

Clogged engine radiator honeycomb

A good high pressure washer solves the problem. If the radiator has been in use for a long time, the car cools and heats up worse due to deformation of the honeycombs. You can “cure” this problem by replacing the radiator.

Air locks in the cooling system

For experienced car owners, air locks are not a secret at all. They arise due to some errors during the process of replacing the coolant. Leaks in the system are also the cause. Antifreeze cannot warm up evenly. This leads to instability in the fan operation. It often turns on or even works without interruption - hot coolant enters the radiator. Before you try to eliminate these same traffic jams, you need to check the system for leaks. If they are found, then they should be eliminated. Next you need to remove the plugs. For this you need a compressor. One tube is unscrewed from the throttle, which supplies fluid. Then a compressor is connected to the neck of the expansion tank and the air supply begins. Two to three minutes will be enough for all traffic jams to go away.

Leaking cylinder head gasket

This problem is one of the rarest causes of engine overheating in VAZ 2114 cars. When it occurs, overheating is a secondary symptom that may be accompanied by a number of others:

- oil leaks from under the cylinder head;

- uneven engine operation and low compression;

- increased oil consumption, noisy engine operation and gas flow, black exhaust.

In this situation, at best, the solution would be to replace the cylinder head gasket. At worst, a major overhaul of the engine with cleaning of all internal cooling channels.

When the engine gets hot, it is dangerous not in itself, but because of its consequences. Long-term driving at elevated operating temperatures first leads to loss of properties of elastic parts: valve stem seals and piston rings. Because of this, oil consumption increases, and engine operation becomes uneven and dirty. All this leads to expensive major repairs.

The consequences of severe overheating are even more severe: the cylinder head and cylinder block are deformed and sometimes crack. An engine that has survived this can no longer be repaired.

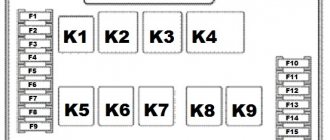

Relay

Often the cooling fan does not turn off due to a failed fan relay. It is installed in an additional mounting block “four”. This block is located near the front passenger's feet and is covered with a decorative trim.

It is not necessary to use a tester to detect its breakdown. It is enough to take a similar element from the owner of the same car for a couple of minutes and replace it with your own. If the fan operates normally, the relay has failed and needs to be replaced. It is inexpensive, and you can replace it yourself.

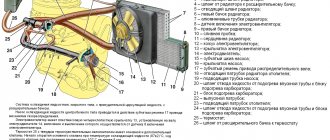

Design and principle of operation of the fan

Before you move on to repairing the fan, you should understand the principle of its installation on the cooling system. To do this, it is better to use the following simple diagram, on which the following main parts are indicated by numbers:

- — cooling radiator.

- - cork.

- - electric fan motor.

- - protective casing.

- - fan impeller.

- — damper pillows.

- - coolant drain plug.

In addition, a diagram of the electrical equipment of the cooling system, which looks like this, will also be very helpful in repairs:

As you can see, the start of the cooling fan is controlled by a relay, which starts after receiving a signal from the temperature sensor.

Once the liquid in the radiator reaches a certain temperature, the temperature sensor closes and thus triggers the fan to start.

Once the temperature of the liquid in the radiator drops below a certain point, the sensor will open and the fan will automatically turn off. But, as already mentioned, sometimes this does not always happen.

What measures to take in case of problems

Self-repair is possible only if you have the skills to work with tools and knowledge of the design of your model. With your own hands you can:

- Replace the door seal. The type of part is indicated in the technical documentation. Repair occurs strictly according to the manufacturer's instructions.

- Install the thermostat and temperature sensor. The circuit is pre-tested with a multimeter. The components are selected only for a specific refrigerator model.

- Replace the compressor. Repairs are only possible if the user fully understands the design of the parts and has experience.

- Top up the refrigerant, but only with special equipment and professional skills.

- Having your refrigerator repaired under warranty will save you money or get your equipment repaired for free.

- Call specialists from the brand’s service center who will professionally eliminate simple and complex faults.

Watch the video why the compressor on the refrigerator does not turn off