The clutch is one of the most important mechanisms in a car. This mechanism ensures that the torque of the car engine is transmitted to the driven disc through the clutch basket. The clutch disc is in constant contact with the flywheel using a spring mechanism. It is affected by the release bearing, the function of which is to disconnect the torque of the motor from the driven disk when you press the pedal. Like all elements of a vehicle, the clutch is subject to wear and various types of problems.

Car owners often do not take into account the existing creaking of the clutch pedal. In fact, this may indicate a number of serious malfunctions. Photo: autoskipper.ru

Causes of a squeaking clutch pedal

The causes of squeaks are different for everyone, but you can identify the most common and common ones that are found everywhere.

- The first and main reason why a pedal squeaks is wear on the pedal pad . Cars with high mileage often suffer from this disease. The pedals have a rubber pad that has convex shapes and a pattern; with high mileage, this pad wears off and when you press the pedal, the sole slides over the pedal and makes a creaking sound.

- When you press the pedal there is a squeaking sound, no matter what shoes you are wearing. Most likely, the mechanism that makes the pedal a pedal—the spring—has worn out. A pedal may have two springs, one below it and one above it. Some cars only have one spring above or below it. The appearance of a squeak is associated with wear of this mechanism.

- It is worth noting that the clutch pedal mechanism is not complicated and is heavily loaded. Dirty shoes and moisture on the soles get into the pedal assembly. Therefore, pedals often squeak, moisture and dirt get into the pedal mount and displace the lubricant.

- Not an obvious reason. For example, it happens that after soundproofing a car, the floor level has risen. The clutch pedal may touch the rubber mat and make strange sounds, as well as squeaking.

Answers (3)

- Lubricate the clutch pedal cable, or change the cable itself. Or do nothing. My pedal squeaked on my Opel. I sprayed WD-40, but it didn't help for long.

08/07/2019 at 13:20

- Lubricate these places on the clutch pedal assembly with lithium grease - look at the photo

08/07/2019 at 13:42

- What helps is to place a piece of hose under the cable. Only 5-6 cm of hose. There is one in the photo.

Where to put the hose

Space for hose08/07/2019 at 13:45

Similar questions

Solution

In almost all cases, the problem of a squeaking clutch pedal can be eliminated with the help of lubricant. To do this, you need to lubricate all intensively rubbing parts.

Experts recommend using thick grease (CV joint or something like that) as a lubricant. If the car was designed in such a way that it is impossible to get to the pedal elements or spring, do not despair - there is a way out. Use a slotted screwdriver for this. Apply a little lubricant to its metal part, after which you can reach the necessary places with a screwdriver.

There is also a possibility that the squeak does not come from the pedal, but from the clutch fork. During operation, it serves as a place for dirt and used lubricant to accumulate. Because of this, this unpleasant sound appears.

In order to eliminate squeaking in the clutch fork, it must be washed from dirt. Naturally, it is very difficult to reach it, so this must be done through the engine compartment. To clean, you can use carburetor cleaner - it will do the job perfectly. Once you have removed all the accumulated dirt, apply a coat of thick lubricant to the fork.

Other possible squeaks

In addition to the clutch pedal, the reasons for the appearance of squeaks we have already figured out, the reason may lie elsewhere. For example, if the clutch mechanism uses a cable drive, then it is often the cause of unpleasant sounds. If this is the case, simply changing the lubricant will not help solve the problem. To do this, it is necessary to replace the clutch cable.

If you hear a squeak somewhere from the engine, this indicates a faulty release bearing. To fix this problem, you will most likely need to replace the release bearing.

The clutch pedal may make peculiar noises due to the clutch actuator. This is due to the fact that all the work of the clutch is mechanical friction of the working parts. Naturally, the appearance of noise cannot be avoided. In order to get rid of annoying sounds, you will need to periodically lubricate the rubbing parts. Because you will not be able to control a constant level of lubrication - everything is washed off during operation.

There is a more difficult way out of this situation. Using a skilled turner, turn the bushing between the rubbing parts from a softer metal or polycarbonate. In this case, the occurrence of unpleasant sounds will stop, because the friction of different materials will not create such noise as two materials of the same density and structure create.

Published: August 25, 2015

Advertisements on NN.RU – Auto

Extend the chassis (frame) on Gazelle Next, Gazelle peasant under a body of 4.2 m, 5.1 m and 6.2 m. Extend the frame on Gazelle Next, Gazelle Gas 3302. Cost: 25,000 rubles.

A wide selection of hydraulic pumps and hydraulic motors of all series: spline hydraulic pump of right rotation. It is used in road construction and... Cost: 1,000 rub.

A special enterprise for the conversion of cargo vehicles produces extensions of the man man, iveco iveco truck tractor.

A special enterprise for converting cargo vehicles into a tow truck invites you to install a tow platform on.

Source: www.nn.ru

Symptoms of malfunction, diagnostics, solutions

| Sign | Cause and remedy |

| Short pedal stroke | Adjust the length of the cable. Check the integrity of metal fibers. Most likely delamination or bending. |

| The clutch drags at speed, it is difficult to shift into higher gears. | The flywheel is bent or damaged. The gripper teeth are worn. Replacing the flywheel and related consumables. |

| Slipping when activating first gear and increasing speed with the accelerator pedal. | Replace friction linings, disk, clean the drive from old grease |

| Sharp jerks when turning on / changing gears. | The pressure plate is damaged, replace the basket. |

| Whistle when activating first and subsequent speeds | Install a new release bearing |

| Crackling, knocking, crunching noise when shifting into up/down gears | Wear out the damper spring, replace it with a new one, lubricate the entire drive mechanism. |

| The lever falls, falls, rattles | Excessive stretch of tensioner. Replace with a new one, install bushings. |

Transmission cable: replacement

When using a manual transmission correctly, it is necessary not only to monitor the technical condition of this unit, but also to competently handle the gear shift lever directly. Since the main malfunctions in a manual transmission occur when the driver operates the shift lever incorrectly (sharp engagement or “jerking”).

In this case, switching mechanisms, synchronizers, shafts, gears, cables, etc. may fail. We must not forget that over time, the gear shift system, subjected to heavy loads, can also fail. As a result, there is unstable gear shifting, difficulty with shifting, etc.

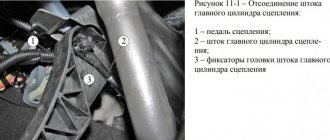

So, let's look at how to change the manual transmission cable. By the way, replacing manual transmission cables is practically no different from replacing automatic transmission cables. The only difference is the number of cables. The sequence of actions when removing manual transmission control cables is as follows:

- disconnect the wire from the negative terminal on the battery;

- remove the floor tunnel lining, then use special pliers to grab the bent edge of the cable sheath fastening bracket and remove the bracket;

- disconnect the gear shift cable end from the rocker lever pin;

- Grab the spring cotter pin securing the cable tip with pliers and remove it from the hole in the rocker arm;

- remove the battery mounting shelf;

- Squeeze the cable end clamps with pliers and disconnect it from the lever on the manual transmission;

- Remove the end of the cable sheath from the groove of the bracket on the mechanical box;

- Disconnect the end of the gearshift cable from the manual transmission lever and remove the end of the cable sheath from the bracket;

- Remove the “thermal shield” of the additional muffler and remove the cable holder from the hole in the base of the car body;

- Remove the cables under the car;

Read more: How to remove a box on a Matiz

Installation of new cables is carried out in the reverse order of removal. Also, upon completion, it is necessary to adjust the gearbox control drive. Please note that adjustments to the rocker and other mechanisms must be performed as efficiently as possible in order to achieve clear and easy gear engagement.

Creaks in the clutch mechanism

In cars of the VAZ family, the creaking of the clutch pedal can be caused by the clutch fork on the bushings in the crankcase

If everything is more or less clear with squeaks in the pedal block, then with squeaks and rattles in the clutch mechanism everything can be somewhat more complicated. On Grant, Kalina and similar cars, as well as VAZ 2108, 2109-2114, the clutch fork itself on the bushings in the crankcase can creak. The problem is that it is quite difficult to lubricate it without removing the clutch. And for this purpose, many people have WD in their trunk. But we are adults, and we don’t solve problems with half measures. Therefore, you need to try to lubricate it with oil, without removing the gearbox. Otherwise, such a lubricant is worthless. Although if you are not sure that it is the fork on the crankcase that is creaking, then disassembling the entire mechanism may well be required. Creaks don’t just appear and indicate either increased wear, a lack of lubrication, or both.

To lubricate the fork in front-wheel drive cars, you need to remove the rubber plug, if any, and use a syringe to apply lubricant to the clutch fork axle. Sometimes it may be necessary to drill out the housing where the axle is mounted. This way the lubricant will work more efficiently and accurately reach the fork axis.

https://youtube.com/watch?v=1YbOGBZgu1w

In the same mechanisms where the fork does not have an axle, but simply rests against the rod, as in the VAZ 2107, you just need to use a strong screwdriver or pry bar to move the fork to the side, and then lubricate the contact point of the fork with the rod with Litol. It's a two-minute job, but you'll have to crawl under the car. But nerves are more expensive. Therefore, do not be lazy, and your nerves will be stronger and the car will be quieter.

Number of guests with me:

Squeaks when using the clutch pedal

As mentioned above, the Lada Granta clutch cable drive has a circuit that provides for the presence of a wear compensator (automatic tensioner). Its participation in the work process significantly simplifies the operation of the vehicle, since it eliminates the need to independently adjust the clutch fork gap or adjust the pedal. However, shortcomings in the production assembly (some of which we mentioned above) reduce the functioning of the wear compensator to nothing.

The solution to the problem involves a complex that includes several, not technically complex, measures:

The initial step is to adjust the clutch fork clearance. This process involves two options:

a) With removal of the air filter housing. We dismantle the (cold) air intake pipe, the air supply pipe to the receiver, and the wiring of the (mass) air flow sensor one by one. We disconnect the electrical harnesses attached to the filter housing, release the housing from the grip of the rubber stops, and then remove it.b) Without removing the air filter. This method is less common because it requires quite a lot of effort to perform manipulations in the limited space of the engine compartment.

To set the clutch fork gap to 27 millimeters, we perform the following manipulations. Pull the clutch cable all the way (in the direction of vehicle movement) and by twisting (unscrewing) the plastic “lamb”, set the required gap (L) between it and the fork.

The next stage (after setting the working gap on the fork) of a set of measures to eliminate the causes of extraneous noise during operation of the clutch pedal will be lubrication of the elements of the pedal assembly. As a lubricant, experts recommend using a substance that is extremely popular among car enthusiasts - WD-40. Lubricant is supplied not only to the clutch bushing, but also to the plastic ratchet that compensates for wear. Applying lubricant to the cable sheath won't hurt either.

In addition to the information presented above, let's look at a few more reasons that cause squeaking clutch pedals.

One of these reasons may be the friction of the plastic bushing, which is one of the parts of the pedal mechanism, on the bracket. This happens when the pedal is pressed on the microswitch of the mechanism that automatically tensions the clutch cable.

Review of Manufacturer Prices

| Manufacturer | Price, rub.) | Resource (Thousand km) |

| LADA 21901-1602210 original | From 634 | 100 |

| ASPCC260210 | From 465 | 75 – 80 |

| BRAND 219011602210 | From 300 | 75 — 80 |

| Plastic cable lead 21901-1602266-00 | From 150 | 40 |

| 21901-1602210-00 clutch cable assembly | From 550 – 600 | 75 |

| 21901-1602210-00 clutch cable assembly | —/— | 75 |

| JSC "ProSport" 26594516 | From 500 | 80 – 85 |

| JSC Vortex 5465465 | From 550 | 80 — 85 |

*prices are current as of October 29, 2018.

Recommendations for the selection of parts and components

The vast majority of spare parts for the Lada Granta are domestically produced. Foreign analogues are not in demand due to their high cost. Compared to “our” products, imports are 10–15% more expensive. The workmanship is at the same level.

When purchasing spare parts and components, always give preference to high-quality, original parts. Check the correspondence of catalog items with the actual data specified in the operating instructions for the technical device.

If you have no experience in car maintenance, seek qualified assistance from service station specialists.

Step-by-step instruction

Now we will analyze the whole process step by step. Stock up on a caliper or at least a ruler in advance.

- Open the hood and disconnect the negative terminal on the battery. Now we need to remove the air filter, which hides the components we need

- We remove the mass air flow sensor connector, the adsorber coupler, the rubber supports and tilt the VF housing to the side

- Our clutch fork is located next to the crankcase. On some cars on the secondary market you can also find a sensor moved there by the driver

- Using a tool, say, pliers, we pull the tip towards ourselves in order to free up more space for work

- We take a caliper and measure the distance from the leash to the fork. According to Grant's technical documentation, it should be exactly 27 millimeters

- We adjust the leash according to the thread if the distance does not match

- Then we press the pedal a couple of times, look at the result, and repeat the setting

- Next is the travel of the pedal itself. It should be 14.6 centimeters (+ - centimeter). As already said, it is better if it is flush with the brake

- If even after several adjustments the pedal does not fall into place, then it would be logical to deal with the unit itself

Clutch pedal creaking - causes

The main reason in the vast majority of cases is the drive, which can be either mechanical or hydraulic. The force you exert on the pedals is transmitted to the clutch fork via a cable or hydraulic system. Despite the fact that hydraulic and mechanical drives have different designs, they have the same squeaking noise. On models such as: VAZ 2110, 2112, 2114, 2115, a mechanical cable clutch is installed. In some models, in order to compensate for friction lining wear, the manufacturer installs a mechanism that does not require adjustment. This clutch is equipped with: Priora, Granta, and also Kalina.

When the driver notices that the clutch pedal is creaking, this already indicates that the problem has reached a certain point. Creaking is associated with increased wear of working parts (for example, the fastening mechanism), moisture on the rubbing surfaces, as well as with other reasons for which increased friction occurs. Often pedal squeaking occurs due to the return mechanism.

Such sounds most often occur not when pressing, but when releasing the pedal, just at the moment when the clutch mechanism is released from the load. If we talk about the pedal assembly, then only the mechanical connections, as well as the return spring, can creak there. The problem of squeaking itself is unpleasant because it is extremely difficult to get to the pedal unit. Working in a confined space is not easy, so the work requires a lot of strength and patience.

The clutch pedal squeaks due to wear on the mounting mechanism. For most VAZ models, the pedals are mounted on suspension brackets and axles. Either a plastic bushing or lubricant is responsible for the pedal sliding on the axle. By and large, plastic bushings do not provide for the presence of lubricant, but if you add it, it will not be worse. A squeaking clutch pedal can occur even on new cars in which everything is working properly. You can remove squeaking and grinding noises by applying lubricant or replacing the bushing and spring; the most important thing is to find out exactly where the creaking is coming from. The lubrication itself is carried out after complete dismantling of the pedal block along with all mechanisms. The work is complicated by the fact that the dismantling process takes a lot of time and is considered very labor-intensive. If you don't want to remove all the pedals, you can try lubrication using a syringe. Apply oil to the rubbing parts, inside the bushings, and also where you think it is necessary. We remove the remaining lubricant with a rag, after which we check whether the clutch pedal squeaks or not.

If nothing has changed after lubrication, we can assume that the reason is the return spring. The spring may hit something or squeak on its own. We lubricate the spring, if necessary, with silicone grease or WD-40, but the effect will most likely be short-lived. Therefore, it is better to use more serious lubricants such as graphite or CV joint lubricant.

The cable creaks. In some cases, creaking, grinding and clicking noises are associated with malfunctions of the mechanical drive. The trouble in this case is that the cable can creak both outside and inside the cabin. Full lubrication of the cable along its entire length will help correct this situation. The procedure is not complicated and does not take much time, so if this is the reason, then you can consider yourself lucky. For convenience, the cable is disconnected from the clutch fork, after which it is lubricated from the engine compartment. If the cable is old and shows signs of wear, lubrication is hardly advisable, it would be better if you completely replace the clutch cable. Unprotected working surfaces of the cable that are outside the protective casing should be lubricated with waterproof grease.

The creaking of the compensating mechanism. If your car has such a mechanism (it is located under the hood or near the pedal), the new cable may make unpleasant sounds and clicks, similar to squeaking or grinding. The problem in this situation is due to the fact that the mechanism is not worn in and requires lubrication of the compensation mechanism.

If the creaking of the VAZ clutch pedal is not associated with any of the above problems, there is a suspicion that unpleasant sounds are generated in the crankcase area. Such a squeak can be produced, for example, by the clutch fork. The difficulty in this situation is that you can check whether the problem is or not only after completely dismantling the clutch. There are indeed some tricks, such as lubrication without removal, but they require certain skills and accuracy. The trick and dexterity lies in the ability to lubricate the fork with oil without removing the gearbox. However, if it is not the fork that is creaking, but another mechanism, most likely you cannot do without removal.

The fork is lubricated as follows. We take out the rubber plug, then fill the syringe with lubricant and carefully apply a few drops to the clutch fork axle. For cars whose forks do not have an axle, lubrication occurs a little differently. Using a powerful screwdriver or mounting tool, the fork is moved to the side, after which it is lubricated with a thick Litol-type lubricant at the point of contact of the fork with the rod.

Recommendations

Comments 25

Now I tried it, it didn’t help (( Granta Drive Active 60,000 mileage

A week later I started clicking again. Not so long ago I was driving a Datsum taxi, it clicks like crazy and I sold it to Grant for fuck's sake

There is an opinion that after such improvement the clutch cable breaks after a certain time. I don’t understand whether it’s a coincidence or not, but my cable broke in this particular place, a couple of months after installing a piece of metal-plastic there. Although I can say in support that there are no more clicks. And at the moment, even the newest one does not crunch))

Crunched up to 47 thousand km. Later, it can crunch and there are no more clicks or crunches. Everything became soft and quiet on its own

Curious... My mileage is 43 thousand km. It was necessary to wait))) for the sake of enthusiasm, I’ll take it out in a month and check it.

I’m not saying anything)) it happened to me personally)) I don’t even understand whether this will happen to you or not)))

There was also such a failure. I changed the spring to a stiffer one. It's been quiet for six months now

Yesterday I set the gap to 27 mm and everything worked. It works unsurpassed

I will inspect the gap and pull it out for testing.

I had enough for a week

A week has passed, everything is ok. I read reviews of people who have been riding for 2 years and everything is ok. You will also need to check the 27mm gap.

I generously lubricated the ratchet mechanism with graphite lubricant from Oilwright. Contributed

Lubricated it didn't help. But it slightly relieved the squeak; after all, the hose does not eliminate the squeak, but eliminates the clicks and gives softness to the pressure because the angle of travel of the cable changes.

This method is not for everyone, it didn’t work for me, I changed the cable to a new one, after 3k the same picture happened again. In the photo, 3 machines click, and the 1st one has an automatic machine.

I read your review. Well, the video helped me. Apparently it works for someone and everything is ok, for someone it doesn’t work and there’s no way to fix it.

Before I got behind the wheel of the Granta, I read the primer for it. The clicking noise is produced by the automatic wear compensator for the disc linings and the cable pull. It clicked once a day for about two weeks, at the moment if it clicks once every six months that’s all. Did not do anything!

I read your commentary before installation. Specifically, clicks and not clicks, I have one now and listen to the video, but earlier everything creaked and clicked. I've been driving for 2 months and it's constantly clicking and from time to time it even feels like the plastic is breaking with a crunching sound being squeezed out. At this point, a week has passed and everything is ok. And one of the main advantages was the soft pedal. We simply change the angle of travel of the cable, but not the most.

My pedal was always soft, there were clicks (on the newest one) once per squeeze. When I worked as a driving instructor, there were also clicks all the time, but one at a time, not the most.

Right now I also have one for the squeeze. Well, I heard it myself.

I set the gap to 27 mm and filled the ratchet mechanism with oil from a syringe and silicone from a balloon. There were no clicks at first, and there was no creaking.

Source: www.drive2.com

Why does a squeak occur when the clutch is released?

Very often, along with a squeak, other problems associated with the clutch pedal may arise. Basically, the pedal can be hard to move and is pressed jerkily.

Why does a squeak occur when releasing the clutch:

- In this case, it is necessary to urgently undergo diagnostics, since with further operation of the car, the fork or the cable that connects the clutch pedal to the car parts under the hood may break.

- Most often, the squeak appears when the clutch pedal is released, that is, at moments when there is no pressure on it. When all the mechanisms are under pressure, they work more smoothly. As soon as the pressure decreases, a squeak occurs.

- There are several options to solve the problem. Of course, it is best to remove the pedal, disassemble it and lubricate all the components. However, this manipulation takes a lot of time; even experienced car enthusiasts can do the job for half a day.

Consequences

This operation does not cause any negative consequences. As the clutch discs wear, the rod will gradually come back out. However, when new clicks begin, the time will come to change the clutch itself.

The design of the Priora clutch drive cable can be seen in the video:

- Vehicle track width: determine correctly

- Homemade strobe for setting the ignition

- How to make a car strobe light with your own hands

- Vehicle understeer and oversteer