Lada Largus (2019). Gears are difficult to engage

Reasons for difficulty shifting gears

| Possible causes of malfunction | Troubleshooting |

| Clutch faulty | Carry out diagnostics |

| The selection cable or gear shift cable is faulty (broken, torn, stuck in the sheath) | Replace the faulty cable |

| The gearbox control mechanism is worn or damaged | Replace mechanism |

| Worn or damaged gear shift mechanism | Repair or replace transmission |

| Worn gear synchronizers | Repair or replace transmission |

- Clutch malfunction. In this situation, the gears will engage either poorly or not completely.

- Problems in the drive of the switching mechanism. Broken traction leads to difficult engagement of 1st and reverse gears. -Jet thrust is faulty. -Wear of plastic parts in the box control drive. -The slide is set incorrectly. A weighty element, incorrect adjustment leads to malfunctions. - Wear of bearings. This is a fairly rare occurrence; anyone can experience this, especially when you have a manual transmission. In such a situation, it is usually difficult to engage first gear. -The box shaft is faulty. By itself, it is not subject to heavy loads, which could lead to wear. A factory defect may cause the entire unit to be replaced. -Failure of clutches. Often found among owners of cars with an automatic transmission. The malfunction is eliminated by replacing the clutches. -Failure of synchronizers - the problem most often occurs among gearbox breakdowns. They are made of brass, and this metal itself is quite soft. During use, it wears out and wears out. —-

-The breakdown is usually accompanied by a grinding noise when switching to another speed.

Manual transmission (gears are difficult to engage)

There are also several clutch malfunctions that cause manual transmission gears to shift poorly:

- Airing of the clutch release hydraulic drive or leakage of fluid from it. The malfunction is eliminated by replacing failed components of the hydraulic system and pumping it. - Worn or broken clutch release fork. The part requires replacement or repair. - Warping (runout more than 0.5 mm) or the thickness of the new driven disk is too large. -Failure of the basket (temperature deformation of the pressure plate or its distortion). -Loss of mobility of the support bearing of the gearbox input shaft (at the end of the crankshaft to which the flywheel is attached). - Jamming of the clutch driven disc hub on the splines of the gearbox input shaft. To eliminate the defect, clean the splines of the gearbox hub and input shaft. It wouldn’t hurt to lubricate them a little with lithol. -Too much free play of the clutch release fork. Its value needs to be clarified with the manufacturer, since it is slightly different for different cars. Until you find out the value of this parameter for your car, set it from 5 to 8 mm. Too little free play of the fork is also undesirable, as it leads to clutch slipping and increased wear of the release bearing. -Excessive wear of synchronizers mainly occurs in those gears that are engaged more often: these are usually first, second and third. The rear one is not included in this list because it does not have a synchronizer. When your gear shifts poorly, and you assume that the reason for this is wear of the synchronizers, firstly, you should only have difficulties with this while driving. Secondly, in this case it switches better if you use double squeeze.

(What is a double squeeze. To shift into an upshift: squeeze the clutch, put it in neutral, release and squeeze the clutch again, shift into gear)

To switch to a lower gear: double squeezing must be combined with re-engaging, that is, when the clutch pedal is released and the gearbox is in neutral, you need to press and release the accelerator pedal. This is how gears are changed in cars that do not have synchronizers. If the gearbox shifts easier using double squeezing, then the culprit for poor gear shifting is most likely worn synchronizers.

A malfunction in the vehicle's clutch mechanism can also cause poor gear engagement:

- the tightness of the hydraulic clutch circuit is broken. As a result, when you press the clutch pedal, the required pressure is not created in the hydraulic circuit. Accordingly, the clutch disc is not released completely, which does not allow the required gear to be engaged. Leakage points are eliminated by replacing the rubber seals or by additional tightening the connecting nuts of the hydraulic circuit. - fracture or wear of the clutch release fork. The problem is solved by replacing the plug. If it is not possible to replace the part with a new one, the old fork is restored. - runout of the clutch driven disc (more than 0.5mm) as a result of overheating or manufacturing defects. - breakage of the clutch basket spring petals or their deformation as a result of overheating (manual transmission gears are difficult to engage); - failure of the manual transmission input shaft bearing. Eliminated by replacing the bearing. - the stroke of the clutch release fork is not adjusted; the cable connecting the clutch pedal to the fork has broken.

Another reason for unclear gear shifting may be a malfunction of parts and mechanisms in the gearbox:

- wear of synchronizers. Excessive wear of synchronizers occurs in those gears that are engaged more often, namely in the urban cycle these are first, second and third gears.

- manual transmission shaft bearings. The breakdown occurs mainly on cars with very high mileage or on cars that, by the nature of their activity, transport heavy loads. In both cases, manual transmission bearings are subject to increased wear. At the initial stage, bearing wear is manifested by the appearance of a monotonous howling sound from the box. If no measures are taken, then a wear appears in the worn bearing, which leads to axial runout of the bearing, followed by jamming. Parts of a loose bearing can get into the gears of the manual transmission and completely damage it.

-destruction of gearbox gear teeth due to physical wear or manufacturing defects. When operating a vehicle with a manual transmission, the teeth of one of the gearbox gears may “fall out” with subsequent possible destruction of the gearbox.

Automatic transmission (gears are difficult to engage)

An automatic transmission is much more demanding in terms of accuracy in maintaining the oil level in it than a manual transmission. Both too low and too high oil levels are very harmful to her. Both of these can lead to serious damage. In both cases, oil foaming occurs. When there is a lack of oil due to the fact that the oil pump begins to capture air along with the oil. When there is excess oil, it foams on the rotating parts, which in this case are immersed in it. Foamed oil compresses better and has low thermal conductivity. Therefore, if you operate a machine with such oil, the pressure in its control systems will be low. Which will lead to slipping of the clutches and their intensive wear. Deteriorated thermal conductivity will not allow all excess heat to be removed. Which, together with low pressure, will lead to the machine failing and requiring serious repairs.

At first, I didn’t want to make this entry at all, because I wasn’t sure that I diagnosed the problem correctly, or that it was my treatment method that helped. But, after thinking about it, I decided to write it, in case it would be useful to someone. This trouble happened at the beginning of December. The weather outside was damp, the temperature was about zero, it was snowing and raining. Everything was in water, the humidity was off the charts. In the morning, as usual, I got ready for work, started the car, drove out of the yard - but the back wouldn’t turn on... What nonsense? I turned it off, started it, played with the clutch, tried other speeds - everything was fine. The fifth and rear ones do not turn on. The impression is that the lever simply does not reach the extreme position to the right. There was no time to figure it out, I had to go to work, fortunately there was a place to leave without using the rear one. On the way, about 5 minutes later, after the engine warmed up, the glitch disappeared. The fifth one turned on without problems. When I arrived at work, I tried the rear one - everything was fine, no questions. It was as if nothing had happened... The next morning the problem repeated itself. It was Saturday, I was in no hurry, I began to look for the reason. Playing with the clutch and other gears didn't help either. I turned off the car and opened the hood. I examined the switching mechanism and cables - no visible problems. I tried to engage the gears by hand from under the hood - all six engaged without problems, in any sequence. Using the lever from the cockpit - no way... I had the feeling that something was simply preventing the lever from reaching the extreme right position, from which the fifth and rear are engaged. After warming up the engine to operating temperature, the problem disappeared again - the gears were engaged and continued to be engaged without problems. Studying the forums did not bring any clarity. Basically, people wrote about the fact that one gear, most often the third, would not engage, and double squeezing and re-throttle helped. I didn’t find any symptoms similar to mine. Meanwhile, the next day the problem repeated itself... I was already wondering how I could present this OD, because everything worked perfectly when it was hot... It was necessary to bring the car, leave it overnight near the salon, and show them in the morning when it was cold. I categorically did not like this option, but nothing smarter came to mind... Meanwhile, the weather changed, the rains and snowfalls stopped, it got colder and dry. And the glitch disappeared. Just disappeared. Both cold and hot everything turned on clearly. This gave me an idea, and I once again reached under the hood. And I found what I was looking for. Water was seeping and dripping onto the engine from the washer nozzles. Right on the valve cover

And on the left... exactly the gear shift mechanism! The guess seemed absurd, but there were no other options. In those days when this glitch appeared, snow and water lay on the hood all night. Apparently, water was slowly seeping under the nozzle and dripping onto the cable, freezing it. The result is that some of the gears did not turn on. After the engine warmed up, all this melted and began to work as expected. The next weekend I took silicone sealant, degreased and coated both injectors.

When the speed of the car begins to turn on heavily, it not only causes an unpleasant feeling, but also makes the operation of the car unsafe. In this article we will analyze the reasons why gears are difficult to engage or do not shift at all, which is usually associated with this.

The gearbox is a complex mechanism that requires constant maintenance. Including regular diagnostics and gearbox oil changes. Ignoring these measures often leads to problems with gear shifting.

What are the reasons for poor gear shifting?

Difficulty shifting gears can occur as a result of improper operation of the gearbox, or due to operation of the vehicle on bad roads. Problems with the gearbox sooner or later occur in used cars.

If you have difficulties when trying to switch to another gear, you cannot shift or it takes a lot of effort, then there is clearly a malfunction. Most often, car owners turn to a car service when they have difficulty engaging first or reverse gear. A fairly common problem on VAZ and Ford Focus cars.

Let's look at the faults that lead to difficult gear shifting:

- Clutch malfunction. In this situation, the gears will engage either poorly or not completely. A common occurrence in VAZ cars that have fur cables. the clutch is moving away from the mount.

- Problems in the drive of the switching mechanism. Broken traction leads to difficult engagement of 1st and reverse gears.

- The jet thrust is faulty.

- Wear of plastic parts in the box control drive.

- The slide is incorrectly positioned. A weighty element, incorrect adjustment leads to malfunctions.

- Bearing wear. This is a fairly rare occurrence; anyone can experience this, especially when you have a manual transmission. In such a situation, it is usually difficult to engage first gear.

- The box shaft is faulty. By itself, it is not subject to heavy loads, which could lead to wear. A factory defect may cause the entire unit to be replaced.

- Clutch failure. Often found among owners of cars with an automatic transmission. The malfunction is eliminated by replacing the clutches.

- Faulty synchronizers are the most common problem among gearbox breakdowns. They are made of brass, and this metal itself is quite soft. During use, it wears out and wears out. The breakdown is usually accompanied by a grinding noise when switching to another speed.

Diagnosis of manual transmission faults

The main malfunctions of a manual transmission can be determined auditorily and visually: noise, knocking, vibration under load, oil drips, defects (cracks) on the housing. Also during operation, you may notice difficulty engaging the gear or failures. The gearbox body may overheat, self-shutdown or poor gear shifting.

These malfunctions can be the result of either untimely or poor-quality transmission maintenance, or a consequence of wear and tear on the unit’s parts.

Why is it difficult to engage manual transmission gears?

Problems with manual gear shifting most often occur for the following reasons:

To prevent possible gearbox malfunctions, perform regular maintenance, change the oil on time, and in case of minor failures, rush for diagnostics. This will save you time and money in the future.

Watch the video for what not to do with a manual transmission:

What to do if it is difficult to engage reverse gear?

If you have difficulty engaging reverse gear, do one of the following:

- When you feel that the gear has not reached the end, release the clutch slightly, and the gear will be inserted all the way.

- Fully depress the clutch and only after a few seconds engage reverse gear.

- Depress the clutch, set the gear to neutral and release the clutch. After this, press down and engage reverse gear.

- Shift into reverse through another gear. For example, first engage 4th and then shift to reverse.

How to properly engage reverse gear on a Hyundai Solaris, watch the video:

It's hard to engage first gear

Many drivers who encounter this situation try to force the gearbox selector to engage 1st speed. But this is fundamentally wrong and should not be done this way.

In this situation, it is necessary to use the regas method. Its essence is as follows:

- While driving in second gear, depress the clutch and set it to neutral and then release the clutch.

- After this, you need to press the gas pedal, increasing the speed to 2.5 thousand.

- The next step is to engage the clutch again by pressing the pedal all the way and turn on the first gear on the gearbox. If you still have difficulties with this, then you need to repeat it, because... You gave too little gas, there were too few revolutions.

- If all the steps are performed correctly, the first speed will turn on without any difficulties or sounds.

However, this method should not be used on an ongoing basis when it is difficult to engage 1st gear. This method is temporary in order to at least get to the service station without any problems. In any case, the box will have to be repaired.

What to do when it’s hard to engage 1st gear on a car, watch the video from a driving instructor:

The procedure for replacing synchronizers requires experience, relevant knowledge and special tools, so it is better to contact professionals. Automotive technicians will perform the replacement quickly and efficiently, and will also advise you on further operation and maintenance of the box.

"LADA-LARGUS": CHANGING THE FIFTH GEAR GEARS

We hang the car on a lift or on stands and remove the left front wheel.

1. Dismantle the plastic mudguard, carefully freeing it from the pistons and latches.

2. Unscrew the upper bolt of the subframe bracket, loosen the lower one and move the bracket to the side so that it does not interfere.

3. Unscrew the fastening of the power steering pipeline to the gearbox and remove the connector from the reverse switch.

4. Unscrew the drain plug, drain the oil and screw the plug back. Unscrew the three bolts of the rear transmission cover.

5. and carefully remove it so as not to damage the lubricant groove. Use a rod to knock out the pin that secures the fifth gear fork.

6. Move the fork towards you and engage first gear with the lever: the primary and secondary shafts are blocked - this makes it easier to unscrew the gears. Unscrew the input shaft nut.

7. Remove the synchronizer fork and clutch, the driven gear and the fifth gear synchronizer hub. It is more convenient to use a two-jaw puller with thin legs.

8. Having unscrewed the bolt of the secondary shaft, remove the drive gear.

9. Change the gears and assemble in reverse order. A few notes about the assembly. We recommend applying a few drops of a fixative (for example, Frenetanche) to the splines of the drive gear. We tighten the nut of the primary shaft to a torque of 190 Nm, and the bolt on the secondary shaft to 80 Nm. Don't forget to fill the box with oil, preferably fresh.

And most importantly. We changed the gears ourselves, fortunately we were not opening the first box and we also have the appropriate tool. If you don't have enough experience or courage to replace it yourself, leave the job to professionals.

' w /> LADA Largus

, Discussing

Posts: 3,714 crossover

Has anyone encountered such a problem. When the box warms up, the rear one starts to stick in normally. Maybe it’s worth changing the oil in the box, it may have been filled with crap from the factory. Or maybe something else is the problem?

PS As in the joke, even if you make a Mercedes at AvtoVAZ, the Lada is still produced by the crooked hands of AvtoVAZ workers. Damn place.

Post edited by konstantin5

– Oct 27 2014, 09:14

Posts: 4 905 From: Erzya mazychinamobile 4x4

On a cold box in cold weather, the reverse gear stopped sticking in, only after some shamanic movements, which I myself haven’t really understood yet, at some point, it sticks in, then everything becomes normal. I read on the forums that the disease of all Logans has migrated to Largus. However, it's a mistake of the developer. And crickets appeared in the cabin under the windshield in cold weather, but the seats stopped squeaking

PS In search of a solution to the problem, I mastered double squeezing and re-gasping. Now I will use it, it’s a handy thing in some cases, especially when downshifting

Posts: 3,714 crossover

The question is what to do? I read third-party forums, some advise adjusting the cable, some the rocker, some changing the oil. Meanwhile, the rear one does not stick to a cold box either when the engine is off or on, as if this rear one is not there at all, and the gears are not felt. By the way, in the Murzilka it is written that the box is filled with oil: ELF TPM 4501 (semi-synthetic ).

Post edited by konstantin5

– Oct 27 2014, 10:22

Problems with automatic shifting

An automatic transmission is very demanding in maintaining the oil level and its condition, unlike a manual transmission. Too high or low oil level can lead to machine malfunction. In addition, due to a lack or excess of oil, difficulties may arise in switching gears.

The most common automatic transmission faults:

- Forward gears do not engage.

- There is no reverse gear, forward there is only 1st and 2nd.

- All speeds are engaged except reverse.

- The gears don't engage at all.

The oil level in the automatic transmission is checked using a dipstick. If the oil level is low, add.

Lada Largus

Over time, you get used to the shortcomings of the car you drive all the time. But there are exceptions to the rules. For two years now I have been using the Lada-Largus editorial station wagon and still cannot accept the heart-rending roar of its engine on country roads. On a long journey, you get tired of this tedious monologue, and the rising tachometer needle puts pressure not only on the psyche: you constantly think about increased fuel consumption. Judging by the numerous unflattering comments on thematic Internet forums, I’m not the only one who doesn’t like the too short fifth gear. Moreover, this problem mainly concerns the most popular passenger version with a 16-valve 1.6-liter K4M engine. Different boxes and main pairs are installed on Largus (see table). And in a passenger car with a sixteen-valve engine, fifth gear turns out to be the most high-torque. Even the van speeds faster in fifth gear. Although logically it should be the other way around.

Theory of gearbox operation

At the moment, all modern gearboxes are equipped with synchronizers, which are important elements of the gearbox. The essence of how synchronizers work is that they equalize the operation of the gearbox shafts.

Every driver, when switching from second to first gear, has encountered a situation where some kind of obstacle was felt. What prevents you from engaging first gear while driving. This is the synchronizer.

If you have a fairly new transmission, then when switching from an upshift to a downshift you will not find yourself in such a situation. Switching will be carried out without problems. This manifests itself as the components of the unit are used and worn out.

Watch a video about the design and operating principle of the gearbox:

One of the fairly common problems in cars is difficult gear shifting on a manual transmission. Inexperienced drivers do not always pay attention to this. Or, on the contrary, they begin to worry a lot in advance. Let's figure out what is the reason for the tight shift and what needs to be done, as well as what every car owner should know regarding this issue.

Methods for engaging first gear

So, if the modes in your vehicle are difficult to engage and you have already understood the reasons and theory, then let’s move on to the most important thing - methods for engaging first gear. The simplest method in this case would be to activate first gear while driving the car. You need to push the unit selector forward without any effort and do this until the corresponding synchronizer comes into operation. However, it should be noted that this method is relevant for most passenger vehicles and some trucks.

It should be taken into account that this cannot be done in most old trucks, since the design of the unit itself does not allow this, since they simply do not have synchronizers. In addition, you need to take into account that this method of activating the first speed is hardly relevant if the synchronizer on your vehicle has already exhausted its service life. This will simply be impossible.

Double car re-gas

Then the driver will only have to wait a while until the car practically stops in order to turn on the desired speed. Or use force to engage the gearshift lever. In principle, neither the first nor the second method can be called the optimal solution to such a problem. As practice shows, it is best to use the same old-fashioned method with re-gasping.

You can find out how to do this below:

- So, while driving in second gear, start depressing the clutch pedal.

- When you press the pedal, move the gearbox selector to the neutral position. Having done this, you can disable the clutch pedal.

- Then, when the pedal is completely lowered, you need to lightly press the gas with your right foot, pressing the pedal. In this case, pay attention to the tachometer, which shows the number of revolutions. You need to increase the revolutions to two and a half thousand per minute, that is, the needle should be at the number 2,500. Here, pay attention to one important nuance - the greater the difference in angular speeds of the mating gears of the box, the higher the number of revolutions needs to be raised. That is, 2,500 is the minimum, add gas if necessary.

- Then depress the clutch pedal again.

- Next, the box selector should be moved to the initial mode activation position, that is, first speed. Here, also pay attention to the fact that if the selector does not enter the required position correctly, then most likely you simply did not give enough gas. If this is the case, then repeat the steps, only add more gas.

- As a result, you need to release the clutch pedal smoothly, not abruptly. If you did everything correctly, the gearbox lever will move to the required position without any problems, shocks or extraneous sounds.

If you were unable to do this, then do not be discouraged - rarely does anyone manage to perform a double gas change the first time. By repeating the procedure several times, you will be able to remember everything that needs to be done to correctly engage the first speed. Actually, the same methods allow you to activate first gear when driving in third, for example, if in an emergency you need to brake the engine. In this case, the higher the driving speed, the longer you will need to wait for the synchronizers to help you. Or you need to press on the gas more.

But do not regard double throttling as a way out of the situation. This method can be called a temporary solution, but the unit will still have to be repaired. Since replacing synchronizers is a rather complex process, we recommend that you seek help from specialists. If you still decide to perform this procedure yourself, then the instructions provided below will be useful to you.

Loading …

Changing synchronizers

Replacing gearbox elements is carried out in several stages. We will not describe them in detail, since all actions are individual for each individual car.

Moreover, if you have never encountered such a procedure, you are unlikely to be able to perform it yourself:

- First you need to remove the gearbox from its installation location. To do this, use the recommendations in the service manual or search our resource - here you can find several instructions. The dismantled gearbox is thoroughly cleaned of dirt and dust.

- After this, you should remove the clutch cable retainer.

- Next, unscrew the four nuts that secure the rear cover of the unit; move it to the side.

- After this, unscrew the screw securing the fifth speed fork. Then turn it on, to do this you need to move the synchronizer clutch down with the fork. This must be done in such a way that the coupling splines are together with the gear. Having done this, you should activate either the third or fourth speed.

- Then you need to unscrew the nut that secures the input shaft. To be able to move it out of place, pull the key firmly, since it is most likely tightened with force. Carry out similar actions with the nut that secures the secondary shaft.

- Next, lift the fifth speed gear and remove it with the synchronizer and the secondary shaft fork. Please note: the clutch should not move from the hub at this point. Installation of new elements is carried out in the reverse order. You need to be as careful as possible. As you can see, in general the process is quite complex and responsible, so do not bother replacing synchronizers without experience.

Gears engage with effort: gearbox malfunctions

In cars with a manual transmission, gear shifting is done by the driver himself. Using a lever from the interior, it acts on the rocker and then on the entire gearbox mechanism. Simply put, the driver moves the gears on the shafts.

Since the shafts rotate at high speeds, cooling is required. This is done using special gear oil. Oil also protects the surfaces of rubbing parts from premature wear. The lubricant must be changed on time. On average, this is done after every 40-50 thousand kilometers.

We also recommend reading the article about why gears do not engage when the engine is running. From this article you will learn about the reasons for the difficulty of switching gears after starting the internal combustion engine.

As for the reasons for tight gear engagement, there may be several of them. However, most often they are associated with problems in the clutch or the gearbox itself. If you study the list of the most common breakdowns, then you can highlight the following:

- . In particularly difficult cases, it may be necessary to replace the plastic bushings. This procedure, like adjustment, can be done on your own;

- hydraulic drive failure. If it leaks, you may not be able to engage the gear at all, since it is impossible to disengage the clutch;

- the clutch cable has broken or fallen off (in a cable clutch);

- The clutch basket has failed.

The exception is reverse gear, since it does not have synchronizers; By the way, when the reverse gear is difficult to engage, extraneous noises, clanging, and crunching often occur. Such phenomena directly indicate wear of the gear teeth.

What's the result?

So, the main reasons why gears are difficult to engage are problems with the clutch mechanism and gearbox. However, most of them can be eliminated yourself if you have tools, spare parts and certain skills.

We also recommend reading the article about why gears do not engage after replacing the clutch. From this article you will learn about the main reasons why, after replacing the clutch, engaging gears is impossible or very difficult.

Why may it be difficult to engage gears or why first gear, second, reverse, etc. may not engage? The main causes of gearbox malfunctions, recommendations.

Reasons for difficulty shifting gears with the engine running. Transmission oil and level in the gearbox, wear of synchronizers and gearbox gears, clutch.

How to change gears without a clutch: driving a manual car without a clutch in case of malfunction. Tips and tricks.

Manual transmission gears (speeds) do not engage after replacing the clutch: main reasons, settings and adjustments. Diagnosis of problems, useful tips.

Clutch: basket, release, clutch disc. Purpose and design, principle of operation of the clutch basket. How to increase clutch life.

The automatic transmission does not change gears: the car does not move forward or backward, the automatic transmission does not switch to individual gears, reasons.

The reason for unclear switching and extraneous sounds when changing gear levels does not always lie in the gearbox itself. Much more often, gears shift poorly due to wear/breakage of the clutch or play in the gear selection mechanism. In this article we will look at common faults that cause problems with gear shifting, and methods for diagnosing them.

Possible breakdowns of Largus manual transmission

LADA Largus is a family vehicle equipped with a transmission system that is well suited to work in difficult road conditions and when traveling over rough terrain.

With prolonged use of the Lada Largus, its owner may encounter problems such as unclear gear shifts.

Vehicles need diagnostics if there are problems with engaging reverse gear. In some cases, this is a consequence of the fact that the working properties of the filled oil have deteriorated. The transmission fluid must be replaced if it has changed color. The howling of the box may be the reason that there is insufficient oil in the gearbox. Gears must be subjected to mandatory inspection.

Diagnostics of the box is relevant if an increased stroke of the handle is observed. It should be noted that when undergoing diagnostics on a Lada, the condition of the spark plugs and filters is checked. When these consumables break down, the car starts to accelerate worse and fuel consumption increases.

If the Lada is frequently used in aggressive conditions, the functioning of the gearbox may deteriorate prematurely. In particular, extraneous noise and squeaks will appear as a result of bearing wear. These components must have a good level of lubrication.

Thus, Largus can be equipped with manual gearboxes JH3 and JR5 (5 steps), which include synchronizers for all forward gears. They differ in clutch release units. Malfunctions can occur due to many reasons, ranging from gear wear to spontaneous loosening of bolts. The use of non-original auto parts during repairs helps to reduce the service life of the gearbox.

Overhaul of a gearbox always begins with vehicle diagnostics. Thanks to computer diagnostics, it is possible to accurately determine the nature of the malfunction present. If it is necessary to repair these gearboxes, you should contact a specialized service.

- Scheme for connecting Webasto to the cooling system

- Where is the turn signal relay located on a Mazda Premasi?

- How to replace the battery in a Cherry Bonus A13 key

- Where is the computer located on a Nissan Liberty?

- Install Toyota Auris parking sensors

The box “crunches” when switching

Crunching is the characteristic extraneous sound that occurs when changing gears. Reasons for this phenomenon:

- and the drive to turn it off, due to which, when the pedal is depressed, the driven disk remains engaged with the flywheel (in such cases it is often said that the clutch “drives”). Sounds when changing gears are often accompanied by a tight movement of the rocker, so to change gears you need to apply quite a lot of force;

- insufficient amount of oil in the gearbox;

- incorrect adjustment of the clutch release cable drive;

- wear of synchronizers in the gearbox.

Selecting transmission oil

Tranself TRJ 75W-80

The transmission determines the dynamic and speed characteristics of the vehicle. When the gearbox fails, vehicles lose their driving performance. In some cases, this may be the result of the transmission fluid losing its quality. For Lada, it is necessary to select oil that must match the brand of the automotive system.

Transmission oil is poured into the box, which is designed for the entire operational life of the vehicle. However, a number of car owners decide to replace them at 60,000 km. As a rule, Tranself TRJ 75W-80 is used for the Lada Largus gearbox. The oil level should be checked every 15,000 km. Replacement should be done with the car warmed up. It is not recommended to mix different types of transmission fluid on Lada.

Synchronizers or clutch?

In the design of a manual transmission, synchronizers are necessary to equalize the rotation speed of the input shaft and the selectable gear mounted on the secondary shaft.

The hub is rigidly connected to the gearbox output shaft, while the helical gear of each gear rotates freely on the shaft. When changing gears, the sliding clutch moves, locking together a pair of hub and helical gear corresponding to the desired gear. Since the speed of rotation of the hub and gear will be different when moving to a higher/lower stage, synchronizers are needed for smooth and silent shifting.

In the design of a synchronized manual transmission, the clutch, when moving, presses the locking ring against the synchronizer cone. Due to the high friction force between the cone and ring, the speed of the output shaft and the helical gear are equalized. The sliding clutch then seamlessly engages the gear with the output shaft hub.

If the synchronizer malfunctions, due to different rotation speeds of the input shaft and gear on the secondary shaft, rigid engagement occurs, accompanied by a characteristic roar/crunch.

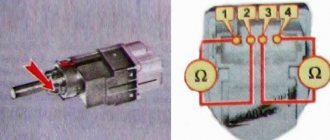

You can distinguish a synchronizer malfunction from a clutch failure by the frequency of sounds. If the problem is in the release drive or the clutch basket itself, then the gearbox crunches with every shift. In the case of burnt or worn synchronizers, the sound appears when changing to a specific gear. For example, on front-wheel drive VAZ cars, due to a design flaw in the domestic manual transmission, a characteristic roar most often occurs when switching from 1st to 2nd gear.

After disengaging the gear, release and then depress the clutch again before engaging the next gear. If after double squeezing the gears shift softer, the problem is clearly in the synchronizer.

A little about clutch operation

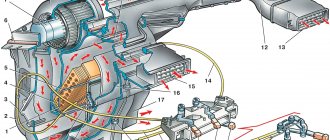

Difficulties with gear shifting due to a faulty clutch are associated with incomplete disengagement of the flywheel and driven disk. In this case, the synchronizers are not able to ensure smooth meshing of the gears, which is why the gears are difficult to engage and a characteristic crunching sound occurs. The cause of the malfunction can be either in the release drive or in the clutch basket itself. Manual transmissions are equipped with two types of clutch release drive:

- Mechanical (cable). The clutch pedal is connected by a cable to the clutch release fork. Moving the cable changes the position of the fork, which moves the release bearing towards the damper pressure plates.

- Hydraulic drive. The design is based on the incompressibility property of the fluid, and the operating principle itself is similar to the operation of the brake system. By pressing the brake pedal, we move the pusher of the main hydraulic drive to release the clutch. Inside the hydraulic drive there is brake fluid, which, under pressure from the piston, flows through a pipeline to the working cylinder. As it extends, the piston presses on the clutch release fork.

Features of the JR5 gearbox

Gearbox JR5

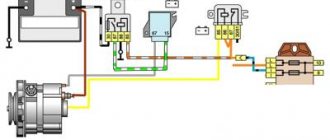

The budget transmission type category includes the JR5 gearbox, where control is carried out via cables and a hydraulic clutch drive. It should be noted that the connections of all internal transmission mechanisms are well sealed.

The advantages of the JR5 gearbox on the Lada Largus should be listed:

- reliability;

- long working life;

- maintainability.

In addition, all cycles consume little fuel. Smooth gear changes are ensured. The JR5 517 gearbox option can be equipped with the K4M (16 valves) and K7M (8 valves) engines. These engines have different power and gear ratios.

The cause of extraneous sounds in the clutch

We will consider only those cases in which improper operation of the clutch leads to extraneous sounds when switching and tight movement of the lever.

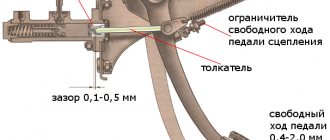

- Incorrect mechanical clutch adjustment. Over time, the cable stretches, causing the pedal travel to be insufficient to completely move the driven disc away from the flywheel. Adjusting the clutch release drive allows you to compensate for cable stretch and restore the working stroke of the clutch pressure plate.

- Play in the connections of the clutch release fork, rotary rod and release bearing.

- Breakage of one or several pressure damper springs. Fatigue of the metal “petals” also occurs. In this case, the springs lose their elasticity and do not provide the proper working amplitude for retracting the driven disk.

- Worn release bearing. If the release valve breaks, a characteristic rustling noise occurs only when the clutch pedal is depressed. The sound indicates dry friction of the bearing and the need to replace it.

- Air in the hydraulic circuit. The system must be ventilated after each intervention in the hydraulic drive, during which the system elements are disconnected.

- Malfunction of the clutch master or slave cylinder. Leaks in brake fluid compression result in insufficient pressure in the line. Because of this, the pushing force on the release bearing and, as a result, the amplitude of its movement decreases.

- Broken release bearing housing. This often happens with bearings in a plastic cage, which are partially destroyed under mechanical loads. In this case, the fork seat moves slightly relative to the bearing itself, which is why the amplitude of movement of the fork is not enough to completely disengage the clutch.

- Wedging of the input shaft needle bearing. It is installed in the flywheel and serves as one of the support points for the input shaft. In case of critical wear and increased friction between the rolling elements and the race, the primary bearing begins to jam. In this case, even after the clutch is completely disengaged, the torque from the flywheel will be partially transmitted to the input shaft. It is difficult to engage manual transmission gears due to jamming of the needle bearing, most often only at mileages over 400-600 thousand/km or due to a factory defect of the unit.

Why are gear shifts slow and unclear?

We looked at gear shifting faults related to the clutch and gearbox. But the condition of the backstage plays an equally important role in the smoothness of the change of steps. According to the type of design, all types of gear shift mechanisms can be divided into 2 types:

- hinged-traction type. The shift lever is connected to the gear selection lever inside the gearbox through a system of rods and articulated joints. In a rocker of this type, the bushings at the junctions of the elements and the liners of the base of the rocker often wear out. If the reaction of the gear selection mechanism under the hood is much less than the amplitude of movement of the lever, then the cause of the unclear shift should be sought in the cabin. Remove the casing and inspect the mechanism for worn rubber seals, plastic or metal bushings. Most often, the cause of tight and unclear shifts is the wear of the section of the rocker from the cabin rod to the gear selector lever inside the gearbox. The problem is solved by partially replacing the mechanism and installing a backstage repair kit. In critical cases, some gears are not engaged at all, instead of 1, 3 is engaged, and the 2nd stage is easily confused with 4;

- cable drive. The shift lever in the cabin is connected to the gear selection lever inside the gearbox through a system of rods and cables. If the cables become sour or freeze in winter, the gears are difficult to shift. When the cables are stretched, the lever stroke increases, so shifts become tight and unclear.

Each type of backstage requires proper installation, and often adjustment.