Throttle valve malfunctions externally can be determined by the following signs of engine operation - problems with starting, decreased power, deterioration of dynamic characteristics, unstable idling, increased fuel consumption. The causes of malfunctions may be contamination of the damper, air leaks in the system, incorrect operation of the throttle position sensor, and others. As a rule, repairing the damper is not difficult, and even a novice car enthusiast can do it. To do this, it is cleaned, the TPS is replaced, or the leakage of external air is eliminated.

Malfunction of the Lada Vesta throttle assembly

Throttle assembly problems are a common phenomenon on all modern cars, and Lada Vesta is no exception. The reason lies in the fact that this unit includes many components that are influenced by external and internal factors. It is important to make sure that the problem is a malfunction of the throttle assembly. Below is a list of elements whose damage can lead to similar symptoms:

- Accelerator pedal position sensor

- Throttle Motor

- Idle speed control

- Damper position sensor

- Mechanical elements of the case

- Air filter and air intake elements

- Electronic engine control unit

If any of these parts are damaged, signs of a malfunctioning throttle assembly may appear. Therefore, before rushing to the auto store for a new throttle assembly, it makes sense to conduct a detailed diagnosis of all the elements associated with it.

Sensor types

There are several types of TPS, but there are only two main differences. The conventional throttle position sensor, used by all car manufacturers, has resistive tracks and a slider in its design. Such a regulator is rigidly fixed to the pipe of the air supply system and connected to the axle. The shutter opens when the driver presses the gas, which naturally turns the axis and moves the slider.

Non-contact sensors are produced as an alternative to the contact potentiometer. Devices operate due to dynamic changes in the magnetic field. The slider here does not directly contact the working part, everything is tied to the electronic component.

Non-contact TPS

Such regulators are less likely to break down, but are noticeably more expensive.

Read more about the types of potentiometers in the table.

| Indicators | Magnetic | Inductive | Resistive |

| Resource | normal | normal | short |

| Price | big | average | low |

| Dimensions | average | big | big |

| Type | analog, digital | analog, digital | analog |

| Voltage ratio | good | excellent | excellent |

| Ways to improve reliability | possibility of installing 2 backup sensors | additional tracks | practically absent |

Signs of a malfunctioning throttle valve Lada Vesta

There are a number of indicators that indicate a malfunctioning throttle valve. Symptoms may vary depending on the part that fails. To understand which direction to move, you need to familiarize yourself with the list of possible symptoms of damage to the throttle of your Lada Vesta:

- Uneven idle speed

- Stopping the engine, both at idle and when pressing the gas

- The engine does not start or stalls immediately after starting

- Loss of engine power

- Jerks when accelerating

- Check Engine Light Is Intermittently or Constantly Illuminated

As you can see, there are quite a lot of signs indicating throttle valve problems and all of them can indicate many other malfunctions. Therefore, before repairing the throttle assembly, you need to rule out possible malfunctions of other parts of your car. To do this, use the algorithm of actions given below.

General information about the control system

The speed began to fluctuate: this means that the DPS is faulty. It is necessary to determine the speed and degree of opening of the throttle valve. Its design is based on a simple potentiometer: when the damper position changes, the voltage at the sensor signal output changes. A potentiometer is a variable resistor, and is more often called that.

The sensor is installed directly on the damper shaft. The connection with it must be tight, so even the slightest kickback is unacceptable. Potentiometer pins:

- supply voltage, which is usually 5 volts;

- signal output connected to the vehicle's ECU;

- “Ground” (“minus” of the power supply, which is located on the car body).

This is what TPS looks like

The highest resistance of the sensor is observed when the damper is closed, while the voltage on the ECU is minimal. Press the accelerator pedal to open the shock absorber, at this moment the resistance changes and the voltage gradually increases to its maximum value of 5 V.

The electronic control unit contains firmware in which all important parameters are recorded. Depending on the opening value of the shock absorber, the ECU regulates the ignition timing, as well as the opening time of the injectors. Non-contact magnetoresistive type DPDZ can also be used. They consist of the following elements:

- electronic sensing element treated with special material;

- permanent magnet built into the throttle valve.

When you press the accelerator pedal, the permanent magnet rotates. At this time, the sensing element changes its resistance due to changes in the magnetic field surrounding it. Only in this case the ECU sees a change in angle, not voltage. If the sensor fails, problems arise with starting the engine, gasoline consumption increases, engine speed constantly changes, and vehicle acceleration becomes difficult.

Algorithm of actions for identifying a throttle malfunction

It is important to understand that the most reliable way is to download error codes to a smartphone or PC using the diagnostic connector. But, if this is not possible or the connector does not work, you can verify that the node is faulty using the following algorithm:

- Check the air duct for foreign objects, dirt, water, etc. If necessary, clean the channels.

- Make sure the air filter is suitable.

- Use a tester to check the functionality of the accelerator pedal position sensor.

- Test the functionality of the idle air control.

- In the same way, rule out malfunction of the damper position sensor, as well as the electric motor.

- If everything is in order, then it makes sense to disassemble the assembly and verify the integrity and functionality of the damper itself.

All measurements with the tester must be made with the ignition on and at different positions of the accelerator pedal.

TPS and problems with it

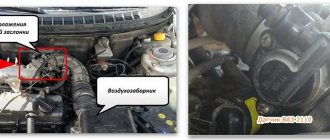

Location

The sensor is a device that determines the angle at which the throttle valve is turned. This is a sensor without which your engine would not be able to operate correctly. To put it simply, we can say that it shows whether the damper is open or not.

In addition, it should be taken into account that the sensor largely determines at what point the ignition will occur, and if you have an automatic transmission, how correctly it will work. That's why you need to monitor this sensor.

The problem with the sensor is that when there is a fault in the sensor, it can be closed, but the brains consider it open, accordingly, they begin to supply more fuel, which will correspond to a suitable air-fuel mixture. As a result, the engine begins to overflow and it stalls.

TPS on a removed throttle valve

Of course, it’s not very pleasant when the engine constantly stalls. Besides that, there is another problem. When the engine operates in this mode, it can cause engine failure. If this happens, the breakdown can be very costly. But even if a malfunctioning throttle valve does not lead to more serious problems, it will still hit your pocket, since the engine will begin to consume much more fuel than necessary.

If you want to check if the sensor is ok, then you need to know where it is. To find it, first trace the throttle body. The sensor connected to the damper axis is located on it.

DIY throttle valve repair

The throttle assembly of a Lada Vesta car can be replaced without much difficulty with your own hands. To perform a procedure such as replacing a throttle assembly, you only need a standard set of wrenches and hexagons, as well as a screwdriver. So, follow the steps in the following order:

Thanks for subscribing!

- Remove the negative terminal from the battery.

- Disconnect the air duct from the damper body by loosening the clamp

- Disconnect the wires going to the sensors.

- Unscrew the 4 bolts securing the throttle body and remove it.

- Use a clean rag or other plug to cover the intake manifold opening.

Installation of a new part is carried out in the reverse order of removal. If you need to carry out such an action as replacing the throttle sensor, then there is no need to remove the entire assembly - just disconnect the wires from the sensor and dismantle it, and then install the new sensor in the reverse order.

Adjustment

The adjustment process may vary on different car models, since different manufacturers use mechanisms of different designs. But the same principle can be applied for configuration. As for a specific model, it is better to find information on it in advance.

To begin the adjustment, the first step is to remove the pedal from the holding bracket. Next, loosen the screws securing the cover. One screw holds the cover in a certain position - it must be completely unscrewed. The cover is turned to the side clockwise until the end, then the screws are tightened again.

This is interesting: How to make a foam generator for a car wash with your own hands

This adjustment will reduce pedal response time. Some car owners note that after such adjustments, the response speed can even be compared with a mechanical pedal. Adjustment allows you to improve engine performance and improve the start of movement from a standstill.

In cases where a pedal with low sensitivity is needed, it is necessary to rotate the cover in the opposite direction - counterclockwise. The machine begins to respond to presses not so quickly.

Sometimes you can come across harmful adjustment tips - drivers advise placing shims under the lever. This is the wrong approach. Sometimes the pads get caught under the contact pads in the potentiometer, and the machine may lose control as a result.

Cleaning the damper

If the cause of poor engine performance is contamination of the throttle, it is necessary to clean it. To do this, you need to purchase a special engine cleaning product and start doing the work:

- Remove the valve body in the order indicated above

- Spray with the product and leave for a while (as indicated on the package)

- Using a clean napkin or other cloth, remove the layer of dirt and carbon deposits.

- Repeat the procedure several times until all parts are shiny.

It is also recommended to remove and clean the idle speed control and the channel in which it is located. Be sure to check the condition of the air filter, since an unsuitable filter can not only cause contamination of the throttle body, but also affect the operation of the engine as a whole and cause you a lot of trouble. Good luck on the roads!

How to check

Block

There is nothing complicated in checking, but it is worth noting that you need to strictly adhere to a certain sequence, and you will also need an additional device - a tester.

Device indicators

A little information about the check engine light: it reminds you that there is some kind of malfunction in the engine and you need to check or repair the engine. In theory, it should light up when the ignition is turned on and then go out immediately. If it does not go off, it means that the computer has detected some problems. In this case, most likely, you need to contact specialists.

- First of all, turn off the ignition. Once again, make sure that the check engine light on the dashboard is not on.

- If the light goes out, you can safely open the hood and start checking the sensor.

- First check if there is a minus.

- Next, check if there is power to the sensor (note that the values may vary depending on what voltage is used in the car).

- Without removing the sensor from its place, connect the minus to ground and the plus to the output contact that goes to the ECU.

- Without touching the damper in any way, turn on the ignition. The device should show a voltage of up to 0.7 volts.

- After this, turn the knob to fully open the throttle. In this position, the device should show at least 4 volts.

- Turn off the ignition.

- With the ignition turned off, you need to connect to the sensor again.

- Then rotate the sector smoothly and without jerking, at the same time look at what readings the device gives.

- If they grow slowly without any sudden jerks or fluctuations, everything is fine.

- But if not, then this indicates that worn spots have formed on the resistor track.

Damper sensor circuit

Please note that these indicators are very important, because they affect whether the control unit responsible for the level of fuel supply to the injectors will work correctly. After all, there may be situations when the throttle valve is closed, but the computer perceives it to be completely open, or vice versa. Both have a negative impact on the engine.

Causes

Usually the reason for carrying out work is interruptions in the functioning of the power unit - idle speed “floats”, or even the engine stalls or does not start.

IMPORTANT! The manufacturer states that the throttle assembly is non-separable, and therefore its repair in case of damage is excluded. A new component needs to be installed.

As for the regulations, it is recommended to clean it once every 50,000 km.

Breakdowns

The most common signs of throttle valve failure in budget cars (VAZ 2114) are:

- Lack of response to pressing the gas pedal . This effect in mechanical versions is associated with a break in the gas pedal cable, its jamming due to clogging. On electronic versions that are on models produced in 2011 and 2012, this symptom is associated with the failure of the data transmission unit (in this case, a warning about the malfunction should appear on the dashboard, and the on-board computer, if there is one, should display an error and its code) ;

- Engine problems at idle . Another sign is “floating” speed, which means that the engine cannot receive optimal load and the driver cannot move normally;

On the video of a malfunction of the throttle valve of a VAZ 2114:

- RPM freezing at a certain speed when shifting gears . Although this problem may not only be a faulty throttle valve, most often the symptom is located there. This happens due to clogging of the mechanical cable of the gas pedal or the information transmission unit (in the electronic version);

- Also, one of the signs on a VAZ 2114 car is the failure of the IAC and DPZD sensors . If these sensors malfunction, the damper receives incorrect information or does not receive it at all. Also, the on-board computer, without data on air consumption and the presence of an air mixture in the combustion chambers, cannot correctly optimize engine operation.

Such signs are common and characteristic of the entire budget segment, both in the presence of a mechanical damper and an electronic unit.

So in a Renault Logan car, the signs of a malfunction can be the same reasons, to which can be added the defect of the control unit on the first generation of the car as its disease. In subsequent versions, the reliability of the block was increased and this problem disappeared as a symptom.

Features of work

The supply of the air mixture should be carried out in doses, with greater force (pressing) on the gas pedal, accordingly, the damper opens by a larger amount and a larger amount of the mixture enters the combustion chamber, thereby activating the process of gasoline processing and increasing the speed and traction capabilities of the car. Therefore, timely care of this part is important for the correct operation of all systems.

The video shows signs of a malfunctioning throttle valve:

Electronic device

Modern cars have been equipped with electronic throttle over the last few years. The functions on such an element are the same, but the mechanism structure is somewhat different in complexity and design.

Compared to its mechanical counterpart, such a unit has a number of significant differences:

- The main and most significant difference is the absence of a gas pedal cable on the electronic analogue. In a mechanical device, this cable transmitted the impulse from pressing the accelerator pedal directly to the damper and regulated the degree of its opening. In the electronic version, a block is installed in place of the cable, and the signal is transmitted through a system of sensors, which is why the electronic system received the name - electronic gas pedal (among most owners of old cars with a mechanical throttle drive, this type of pedal is notorious - as the owners consider it reaction is quite slow). Perhaps the absence of a cable reduces the response to the gas pedal, but the absence of a cable makes the design quite reliable;

- Availability of IAC and DPZD sensors . Such sensors are installed on all variants of injection models, however, on the market you can still find cars without them with a mechanical drive. For cars with an electronic version, the presence of such sensors is mandatory in any case;

- The presence of an additional electronic side . Through this unit, in the version with an electronic damper, all information about the position of the damper and commands for its additional opening are sent to the car’s on-board computer and directly affect the response of the accelerator pedal. This unit, being in the engine compartment, is exposed to increased environmental influences and therefore may fail over time.

Removal

Cleaning the Lada Kalina throttle assembly begins with its dismantling.

Note. There is an opinion that it is not necessary to remove the component. This is true, but in this case all the carbon deposits will pour into the engine!

First of all, you need to turn off the engine, let it cool, and then remove the terminal from the battery.

Then the clamps securing the hoses and pipes are unscrewed:

- Small – 4 units;

- Large – 1 unit.

The plugs are disconnected from two sensors - TPS and IAC.

The accelerator cable is removed.

To prevent antifreeze from leaking, the hoses must be fixed at the top. In addition, you can insert M12 bolts into them.

In the end, all that remains is to unscrew the 2 nuts using a 13mm socket and remove the remote control.

E-gas (electronic gas pedal) and its adaptation

The first thing you need to do when buying this machine is change it (I flashed the software from Icebreaker) and everything works smoothly.

But there is one problem, e-gas is a rather delicate thing, if for some reason the car starts once on the 4th or 5th (for me this was caused by frosts of -30), then the operation of the e-gas is disrupted, resulting in floating rpm from 800 to 1000, or Even worse, the car will simply stall or idle at 2000 rpm.

Now let’s talk about how to cure this, that is, ADAPT E-GAS; there are sites to peel off, but there is no detailed description, I’ll share!

There are 2 ways to solve the problem:

- Find a good electrician and he will adapt you to e-gas for 1000-2000 rubles.

- Carry out the adaptation yourself!

I’ll tell you everything point by point, if you find that the speed has dropped after the engine has started, say, 5 times, then you need to:

- Not to worry.

- We turn off the car, remove the negative terminal and smoke for 3-4 minutes.

- We put the terminal back on, get into the car and turn the ignition key, the instruments turn on, the pump starts pumping gasoline, and we wait 40 seconds, after which we start the car! Most likely the situation will be the same! Getting ready for the most interesting things! Direct adaptation!

- The car is started, we drive out to a section of the road where we and no one will bother us!

- We get underway and engage second gear, press the gas pedal and spin up to 4000 rpm, and then release the gas pedal (that is, we brake the engine with the gear engaged) and wait for the rpm to drop to 1200-1000, and do the same thing 6 times.

- We park.

- We turn off the car.

- We remove the negative terminal, smoke again for 3-4 minutes, then put it back on.

- When you get into the car, insert the key, turn everything works, wait 40 seconds and start it!

The tachometer shows 800, nothing floats, the owner is happy!

I adapted my car in this way 3 times, I taught it to my friends, and they couldn’t be happier.

Source