A normally operating car power unit quickly responds to any changes in the position of the gas pedal. If necessary, it should almost instantly gain momentum if acceleration is required, or quickly release them if the accelerator is released.

If the operation of one of the power plant systems is disrupted, this will necessarily manifest itself in the behavior of the motor.

A sign of improper operation of one of the engine systems is the appearance of dips when you press the gas pedal.

“Failure” when pressing the gas pedal

A failure is a sudden interruption in the operation of a car engine.

A common problem. It can occur in different operating modes when you press the gas pedal. Accompanied by a drop in vehicle acceleration and even stopping. Possible - short failure (2-3 seconds), deep failure (3-10 seconds), jerk (1-2 seconds), twitching (series of jerks), rocking (series of failures).

This article discusses ways to independently eliminate the failure when pressing the gas pedal in the operation of a warm engine of VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107 - “Classic”, 2108, 21081, 21083, 2109, 21091, 21093 , 21099 - Samara-1 family, 2121, 21213 - Niva, 1111, 1113 - Oka, 2140, 2141 - Moskvich, GAZ Volga, etc., associated with one or another malfunction installed on them carburetors 2105, 2107 Ozone, 2108, 21081, 21083 Solex and their modifications.

And also the main reasons for its appearance related to carburetor malfunction are given.

Signs and causes of “failure” when pressing the gas pedal on a carburetor engine

All causes of “failure” are based on either over-leaning or over-riching of the fuel mixture entering the engine cylinders when the gas is pressed. As a result of such a violation, the engine either does not receive the required amount of fuel and operates with failures, or it is simply flooded with fuel with a similar result.

This should be taken as a starting point when diagnosing this malfunction.

An over-lean fuel mixture is caused by a decrease in fuel supply through the carburetor due to clogging of its jets and channels, “suction” of foreign air, gasoline leakage, and low level in the float chamber.

An over-enrichment of the fuel mixture is caused by a violation of the adjustment of the position of the carburetor flaps, or the leakage of the needle valve, connections and seals.

For example, if there is a “failure” (1-2 seconds) when you smoothly press the gas pedal when starting off or idling. Subsequent acceleration and dynamics, as well as idle speed are normal.

The reasons for this particular malfunction are that the outlet holes of the transition system of the first carburetor chamber are clogged and (or) the carburetor accelerator pump is faulty.

In detail about the signs and causes of failure in the operation of a carburetor engine of a car: “Signs and causes of failure in the operation of a carburetor engine of a car.”

Methods for eliminating failures in the operation of a carburetor engine when pressing the gas pedal

— Check the condition of the fuel filter at the inlet to the carburetor

A dirty and clogged filter makes it difficult for fuel to enter the carburetor float chamber, which leads to a decrease in its level, a leaner fuel mixture at different engine operating modes and, as a result, failures due to loss of power. Contamination of the strainer occurs due to clogging and corrosion of the fuel tank and fuel lines, and the use of low-quality fuel.

We remove the fuel filter of the Solex 21083 carburetor for cleaning

Cleaning the fuel filter on carburetors 2108, 21081, 21083 Solex and 2105, 2107 Ozone is almost identical. Unscrew the filter plug with an open-end or spanner wrench (2108 Solex – key to “13”, 2105, 2107 Ozone – key to “17”). Carefully remove it. Remove the mesh filter inserted into it. Clean it thoroughly (for example, with a toothbrush soaked in acetone), blow it with compressed air from a car pump and put it back. Also clean the filter hole in the carburetor.

Remove the carburetor fuel filter Ozone 2105, 2107

If you detect severe clogging of the carburetor fuel mesh filter, you should pay attention to the cleanliness of the entire fuel line: fine fuel filter, fuel pump filter, mesh filter on the fuel intake in the gas tank. It is worthwhile to inspect the entire fuel system of the car, and, if necessary, clean the fuel lines and gas tank.

— We check the connections for “suction” of foreign air into the carburetor

As a result of excess air entering the carburetor, the fuel mixture becomes leaner, causing a “failure” in the engine when opening the throttle and idling. Inspect the hoses and tubes leading to the carburetor. They should not be damaged (broken, worn out...), the fit on the fittings should be tight. Clamps should be placed where necessary (fuel pipes, pipes for supplying crankcase gases to the carburetor and to the vacuum brake booster).

Special attention to the integrity of the gaskets under the carburetor and (or) deformation of the carburetor flange (lower part). This is the most common place for leaks. To check with the engine running, spray the area of the gaskets under the carburetor with water (soap suds, spray). If the engine begins to run smoother (water has clogged the cracks), then check the gaskets and flange.

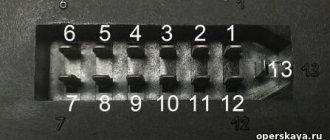

The image below shows the probable places where foreign air is “sucked” into the 2108 Solex carburetor (except for the gasket under the carburetor).

Places for “suction” of foreign air into the carburetor 2108, 21081, 21083 Solex

On classic VAZ 2105, 2107 cars equipped with a remote pneumatic valve of the carburetor EPHH system, often damage or loose fitting of the tubes leading to the pneumatic valve leads to the “suction” of foreign air and causes failure.

On carburetors equipped with an electromagnetic valve, extraneous air can be sucked in through its seat if the valve is not tightly screwed on or through its worn sealing ring.

You should also pay attention to the integrity of the rubber o-ring on the fuel mixture “quality” screw.

A noticeable failure when starting off is also possible if the tube of the vacuum ignition timing regulator is not sealed or has come off.

An article on our website on eliminating the “suction” of foreign air into the carburetor is “Suction of foreign air into the carburetor.”

— Check the fuel level in the carburetor float chamber

With an increased level of fuel in the float chamber of the carburetor, the mixture becomes very rich and, entering the engine cylinders, can “flood” the spark plugs, which causes “failures” in its operation.

At a low level, the fuel mixture, on the contrary, is lean and when pressing the gas pedal, instead of the expected acceleration, the driver feels a failure, since the engine does not receive fuel of the required quality.

It is necessary to let the engine run for a while and then quickly remove the carburetor cover (top part). As a result, you can observe the actual fuel level in the float chamber. You should measure it immediately. Until the gasoline evaporates. On the 2105, 2107 Ozone carburetor, the approximate fuel level passes through the middle of the inclined surface of the front wall of the float chamber (in the image it is marked with an orange line).

The fuel level in the Ozone carburetor float chamber should reach this line

On the 2108, 21081, 21083 Solex carburetor, the fuel level is 29±1 mm from the bottom of the float chamber (any, first or second). You can measure with a ruler or caliper.

We measure the fuel level in the float chamber of the Solex 21083 carburetor using a ruler

In the image, the fuel level is marked with a red line. This figure is very arbitrary, although many carburetor operators, when setting the fuel level in the carburetor float chamber, rely on it, not recognizing the adjustment by the position of the float.

Details of fine adjustment of the fuel level by float position:

— We check whether the fuel and air jets, emulsion wells, channels in the small diffusers of the main carburetor metering systems (GDS) are not clogged

Their purity directly affects the mixture formation process at different engine operating modes. Depletion or enrichment of the fuel mixture due to clogging of these jets leads to “failure” when you press the gas pedal.

It is necessary, with the carburetor cover removed, to unscrew the fuel and air jets of the main metering systems (GDS), clean them, rinse them, and blow them with compressed air. On the 2108, 21081, 21083 Solex carburetor, the GDS air jets are combined with emulsion tubes and are removed along with them. On 2105, 2107 Ozone, emulsion tubes can be removed by lightly screwing a self-tapping screw into them and pulling up with pliers. Clean and rinse the emulsion wells, clean the channels of the small diffusers of both chambers, pay attention to their markings and correct installation.

A little about the Solex carburetor

Initially, VAZ equipped its cars with carburetors of the Weber family. These carburetors were completely mechanized. They lacked any electrical wiring and were not very reliable. Practically, they constantly needed attention, since the main struggle of car owners was aimed at returning the engine to idle speed. Only rear-wheel drive cars of the Zhiguli family VAZ 2101, 2103 and 2106 of the early versions were equipped with it.

“Weber” was replaced by “Ozone”, which began to be successfully used on VAZ 2105-07 cars. It was a perfect design, which was equipped with idle economizers and an autonomous system. The idle problem has been resolved. Ozone was also used on Niva cars.

With the advent of the front-wheel drive VAZ 2108 on the assembly line, a perfect design was required, aimed at reducing exhaust toxicity and maximizing fuel economy. This is how Solex was born.

Initially, it was a French design, which was purchased under license and was successfully installed not only on Samaras, but also on Zhigulis. Its design took into account all the mistakes of previous units, and efficiency increased to the limit. A properly tuned mechanism lasts a long time, and maintenance and repairs are cheaper than many modern cars. Unlike the Ozone family, it uses a long rod drive or cable, which significantly softens the accelerator pedal when depressed.

Almost all domestic carburetors are called DAAZ, and an index is written through a dash, the beginning of which corresponds to the car model.

Causes of failures when pressing the gas pedal

Let's look at the main reasons:

- Spark plugs and high-voltage wires;

- Clogged fuel injectors;

- The throttle valve is dirty;

- The ignition is set incorrectly;

- Errors in the ECU;

- The air filter is clogged;

- Problems with the fuel pump.

Often, failures occur due to a breakdown of the power system . After pressing the gas pedal, the power system increases the volume of fuel supplied to the cylinders. Breakage causes a change in these proportions. Those. The motor just can't do its job.

In addition, it is possible that there may be a breakdown in the ignition system . It occurs much less frequently. It's either spark plugs or ignition wires. The spark plugs must be removed and checked. The presence of carbon deposits or too clean spark plugs indicate a rich or lean fuel mixture, respectively. This indicates that the ignition system is adjusted incorrectly.

To ensure that the fuel mixture ignites at the right time, read the article on how to set the ignition correctly.

Dips when pressing the gas pedal during acceleration

It is determined both using computer diagnostics and by the steps described below (some of the points below can be performed independently, but specialists in car services in Moscow will be able to determine the problem area more quickly and accurately):

- The first thing you need to do is inspect the spark plugs. To do this you need to remove them. The presence of carbon deposits on the spark plugs, poor contact with the wires, or an excessively lean or rich mixture lead to spark plug malfunctions.

- High voltage wires can also cause engine malfunction, as can ignition coils.

- The throttle needs to be checked. If it is clogged, this causes the engine to respond untimely when pressing the gas pedal.

- It is necessary to check the condition of the air, fuel and oil filters. They tend to get clogged, which worsens dynamics, increases fuel consumption and causes pedal failure. They need to be changed constantly, you can do it yourself, they are inexpensive and easy to install.

- The presence of errors in the ECU leads to failures.

- Clogged injectors. If necessary, replace or repair injectors .

The wires, as well as the rubber bands on them, should not be damaged and should not spark when the engine is running. If damage is found, this indicates that the engine is shaking and jerking begins. This may occur due to the age of the car, worn-out or low-quality spare parts, poor contact with the spark plugs, or due to the temperature of the engine.

The resistance of the coils and the temperature change together, as a result of which a gasoline car begins to jerk during acceleration. In diesel cars, jerking cannot be associated with the coils, since they are not present.

Dips when pressing the gas pedal at idle

Problems also occur at idle speed; of course, there will be fewer reasons. However, this is also a serious problem and cannot be ignored, because... The car will have difficulty starting and simply stall.

Troubleshooting is performed in the following order:

- The first thing to check is the spark plugs. If the spark plugs are faulty, they should be replaced. We recommend replacing all spark plugs at the same time. Buy spark plugs specifically for your engine. If necessary, adjust the gap; it should be 1 mm for 92 gasoline.

- The fuel filter and fuel pump diagnostics are checked. If a malfunction is identified, fix it.

- The breakdown may be in the idle speed sensor.

- Checking the injectors. If clogged, replacement or cleaning is necessary.

- Diagnostics of the ECU for errors.

- Checking the injector.

How to fix overclocking failures

- Check the ignition wires and coils. When a breakdown occurs, the spark plug wires spark and glow in the dark. The engine shakes and jerks. This happens due to age, poor quality parts or poor contact with the spark plugs. The malfunction may be related to the engine temperature. The interwinding resistance of the coils and the thermal operating conditions change together, which is why a gasoline car jerks during acceleration. If you have a diesel engine, jerks during acceleration are definitely not related to the operation of the coils, they are not there.

- Inspect the spark plugs. Poor contact with the wires, heavy carbon deposits, too lean or rich fuel mixture disable them. Unscrew and check each spark plug as in our article “Diagnostics of internal combustion engine operation using spark plugs,” where we gave examples of faulty spark plugs.

- Check the fuel, oil and air filters. Over time, they become clogged, which leads to deterioration in dynamics, increased fuel consumption and periodic failures. You can replace them yourself; they are inexpensive and easy to install.

If the tips above did not help, only diagnostics will solve the reason for this behavior of the gas pedal. Incorrect operation of systems, errors, composition of the fuel mixture - the diagnostician will name a specific malfunction.

Diagnostics

Checking the injector is faster because there is an electronic control unit. After reading the error codes, the source of the problem can be clearly identified. Carburetor cars do not have this option. Therefore, such a system is diagnosed in its own way.

First you need to check the coherence and correct operation of the fuel system. You have to probe all the places where air leaks may occur. The fuel pump and fuel line are also checked. There should be no deposits or blockages.

If the test results do not reveal any problems, the failure most likely occurs due to the carburetor. This is the main device responsible for mixture formation and intake into the manifold. When the carburetor is working properly, fuel flows evenly without interruption.

Checking the carburetor system

Initially, the operation of the fuel system is checked to see how smoothly and correctly it works. Every working unit and detail matters. Air leaks are checked, fuel lines are examined and the fuel pump is diagnosed. All blockages and deposits are removed.

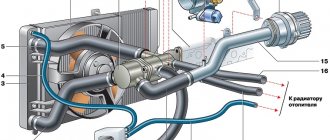

Fuel pump If the diagnostics do not reveal any problems, then the carburetor may cause a failure in the engine when the gas pedal is pressed. This part is responsible for supplying fuel. During normal operation of the carburetor, fuel is supplied without interruption, constantly and evenly.

To identify and eliminate the cause of the problem, you must proceed as follows:

- We exclude air leaks, which may occur due to a loose fastening on the exhaust manifold.

- We study the condition of the mesh-type filter, which is located in the area where the pipe from the fuel pump connects.

- We dismantle the EPH valve and the sealing ring and examine their condition. If the EPHH is working properly, then when you connect one side of the wire to the terminal, and the opposite end to the positive terminal of the battery, a clicking sound will be heard.

- Check the liquid level in the float chamber. To do this, start the engine, leave it to run for a while, remove the top carburetor cover and filter housing. Now let's evaluate the fuel level. In normal condition, it should be in the middle of the inclined wall.

- The dosing system may become clogged and this is a common problem. To eliminate it, you will need to remove the top part of the dispenser and the jets. We look for blockages and remove them using wooden parts. Emulsion tubes, which are often forgotten, also need inspection and maintenance.

- Special products are used to clean the carburetor channels.

Dips at idle

If the revolutions drop not when you press the gas pedal, but on their own - in the interval between starting the engine and completely warming up, you will need a good scanner to fully diagnose the cause. A problem that appears only on a cold or only on a hot engine may simply be a failure of electronic components. Among the sensors, the “champions” in terms of failures were: “brains” (control electronics unit), throttle position sensor, idle air control, intake air pressure and temperature sensors, flow meter.

Errors in the ECU are most often the cause of the gas pedal failing

Not all inconsistencies in indicators, loss of sensor signals, or open circuits cause errors on the instrument panel. Most pass without a trace, and only an experienced diagnostician will see them in the logs.

You can independently check for external air leaks, replace the air and fuel filters, change spark plugs, high-voltage wires, and coils. Measure compression in all cylinders. Inspect the engine head for oil leaks from under the crankcase ventilation valve - it may be clogged and will need to be washed or replaced. If you are not sure about the cleanliness of the tank and the quality of the fuel, drain it completely by washing the tank and the fuel pump sump.

Drop in injector speed

The characteristic “thoughtfulness” when vigorously pressing the gas pedal indicates incorrect operation of the injectors or fuel pump. You can check whether the quality and volume of the mixture your car “feeds” corresponds to the standard through detailed diagnostics. Separately, you need to remove the injectors and check their performance on a bench.

It’s easier to look for the cause in a sequence from simple to complex: change the fuel, flush the tank, replace the filters, check the pump mesh in the tank and the pressure in the rail, then test the injectors.

Some injectors can be restored, others will have to be replaced, correctly registering the replacement in the “brains”. Difficulties during acceleration can also be a sign of a malfunction of the electronic unit that controls the injection system. If it cannot be eliminated by chipping, the “brains” will have to be changed.

Causes of failures when pressing the gas pedal

Let's look at the main reasons:

- Spark plugs and high-voltage wires;

- Clogged fuel injectors;

- The throttle valve is dirty;

- The ignition is set incorrectly;

- Errors in the ECU;

- The air filter is clogged;

- Problems with the fuel pump.

Often, failures occur due to a breakdown of the power system . After pressing the gas pedal, the power system increases the volume of fuel supplied to the cylinders. Breakage causes a change in these proportions. Those. The motor just can't do its job.

In addition, it is possible that there may be a breakdown in the ignition system . It occurs much less frequently. It's either spark plugs or ignition wires. The spark plugs must be removed and checked. The presence of carbon deposits or too clean spark plugs indicate a rich or lean fuel mixture, respectively. This indicates that the ignition system is adjusted incorrectly.

To ensure that the fuel mixture ignites at the right time, read the article on how to set the ignition correctly.

Dips when pressing the gas pedal during acceleration

It is determined both using computer diagnostics and by the steps described below (some of the points below can be performed independently, but specialists in car services in Moscow will be able to determine the problem area more quickly and accurately):

- The first thing you need to do is inspect the spark plugs. To do this you need to remove them. The presence of carbon deposits on the spark plugs, poor contact with the wires, or an excessively lean or rich mixture lead to spark plug malfunctions.

- High voltage wires can also cause engine malfunction, as can ignition coils.

- The throttle needs to be checked. If it is clogged, this causes the engine to respond untimely when pressing the gas pedal.

- It is necessary to check the condition of the air, fuel and oil filters. They tend to get clogged, which worsens dynamics, increases fuel consumption and causes pedal failure. They need to be changed constantly, you can do it yourself, they are inexpensive and easy to install.

- The presence of errors in the ECU leads to failures.

- Clogged injectors. If necessary, replace or repair injectors .

The wires, as well as the rubber bands on them, should not be damaged and should not spark when the engine is running. If damage is found, this indicates that the engine is shaking and jerking begins. This may occur due to the age of the car, worn-out or low-quality spare parts, poor contact with the spark plugs, or due to the temperature of the engine.

The resistance of the coils and the temperature change together, as a result of which a gasoline car begins to jerk during acceleration. In diesel cars, jerking cannot be associated with the coils, since they are not present.

Dips when pressing the gas pedal at idle

Problems also occur at idle speed; of course, there will be fewer reasons. However, this is also a serious problem and cannot be ignored, because... The car will have difficulty starting and simply stall.

Troubleshooting is performed in the following order:

- The first thing to check is the spark plugs. If the spark plugs are faulty, they should be replaced. We recommend replacing all spark plugs at the same time. Buy spark plugs specifically for your engine. If necessary, adjust the gap; it should be 1 mm for 92 gasoline.

- The fuel filter and fuel pump diagnostics are checked. If a malfunction is identified, fix it.

- The breakdown may be in the idle speed sensor.

- Checking the injectors. If clogged, replacement or cleaning is necessary.

- Diagnostics of the ECU for errors.

- Checking the injector.

Failure - what is it?

Failure is an interruption in engine operation and an untimely response to pressing the gas pedal. If the driver needs to accelerate, he applies the accelerator, but the engine does not gain speed.

This interruption in operation is accompanied by a sharp drop in speed until the vehicle stops completely.

Interruptions in operation occur in all operating modes - smooth or sharp acceleration, when starting to move, at low, medium or high speeds.

Dips when pressing the accelerator manifest themselves in different ways; there is even a classification of this phenomenon:

- Short-term failures, in which the engine does not respond to pressure within 2-3 seconds;

- Long or prolonged dips, during which the power plant loses speed for 4-10 seconds, which is enough to stop completely;

- Jerks are very short-term dips, lasting 1-2 seconds;

- Jerking is a series of short-term dips that causes the car to either gain speed or slow down at the same position of the gas pedal;

- Swinging is a series of prolonged dips, it acts like a twitch, but the time it takes to gain speed and reset it is more than 4 seconds.

Causes of malfunction on an injection car

Let's move on to injection power systems, and consider the VAZ-2110 injector as an example.

As in the carburetor system, the cause of failures when pressing the accelerator can be fuel supply elements.

If the fine fuel filter is heavily clogged or the fuel pump is faulty, gasoline is supplied to the fuel rail in insufficient quantities, which leads to the occurrence of gas pedal failure.

Therefore, these elements are checked first. Also, do not forget about the mesh filter installed on the fuel intake in the fuel pump.

Why are the revs dropping?

There are many reasons that can provoke failure when pressing the gas pedal. This circumstance significantly complicates diagnosis.

- Spark plugs and high voltage wires are the first thing you need to pay attention to when this problem occurs. The problem with spark plugs is carbon deposits that occur during vehicle operation. Carbon deposits cause incorrect operation of the spark plugs, which in turn leads to engine failure. Wires do not often become the cause of such a malfunction, but still their condition is also checked without fail. During the diagnostic process, a fracture or poor contact may be detected.

Carbon deposits on spark plugs

Triple

This is the most common phenomenon that every vehicle owner, and even novice drivers, knows about. However, not everyone understands what exactly this term means. When experts talk about engine tripping, they mean that one cylinder (or several) is not functioning. The result is failure of the gas pedal. Moreover, this phenomenon negatively affects the power unit itself.

And if experienced drivers are able to easily identify the signs of tripping by ear, then beginners should rely on the following symptoms:

It is not difficult to determine in which cylinder the spark plug is not working (if the problem is in it) - you need to disconnect the high-voltage wire one by one, and then increase the speed to 1,500 each time. If the sound of the running engine does not change, it means that the “good” cylinder has been turned off, you should switch to the next one.

Drivers who independently disconnect high-voltage wires must exercise extreme caution, as there is a risk of electric shock. Often the contacts become oxidized and, as a result, no current flows. You can diagnose this problem with a multimeter.

VAZ 2109 carburetor malfunctions

The carburetor is one of the most delicate components of the VAZ 2109 car to configure. Its repair requires experience. The maximum that an amateur can handle is replacing the throttle cable of a VAZ 2109. Many subtle technologies interact with each other in the process of preparing the air-fuel mixture. By adjusting the operation in acceleration mode, you risk disrupting the idle speed adjustment, and vice versa. So you should start repairing the carburetor yourself with caution and without excessive self-confidence.

A significant volume of fuel with all impurities, chemical and mechanical inclusions, conceivable and inconceivable contaminants passes through the carburetor. This means that cleaning will never harm the carburetor. It is about total cleaning that we will talk about.

Everything is cleaned, including fuel injectors, air jets, transition channels, filter elements and metering wells. This is done like this:

- disconnect the mechanical throttle actuator;

- separate the inlet and outlet fuel pipes;

- wrap the freed carburetor with aluminum foil of sufficient width;

- place the wrapped carburetor in a plastic bucket to protect it from leaking;

- fill the carburetor with acetone or other strong solvent;

- leave the carburetor in a flooded state for a day.

Keep in mind that this should be done in a well-ventilated non-residential area. At the end of washing, drain the solvent, rinse the unit with a running stream of solvent, blow with a stream of compressed air, and dry. Install the carburetor in its original place. Try your "nine".

If a radical flush solves the problem, ride to your heart's content. If you haven’t decided, it’s time to turn to professionals. Forget about engine failures for a while and go to a car service center.