Description of the regulator

The idle speed control is one of the most important sensors in a car's injection system. It is he who corrects stable idle speed. The regulator is involved in engine operation only at idle.

The IAC is a cylindrical DC electric motor with a worm gear. A shut-off valve is installed on the worm shaft, which, when forming the air-fuel mixture, blocks the flow of air into the throttle valve.

The operation of the IAC is only mechanical by blocking the incoming air channel in the throttle valve. That is, when there is a need for increased speed at idle, the regulator closes the air channel, thereby forming a fuel mixture with a large amount of fuel, as a result of which the engine speed becomes higher.

How to clean the idle speed sensor?

Cleaning the IAC is performed after preparing the following tools and materials:

- Phillips head screwdriver;

- carburetor cleaner; regular alcohol, solvent or WD-40 will also work;

- spanners;

- Torx keys;

- lint-free rags, preferably light in color.

User Alexander Filimonov spoke about the nuances of cleaning the idle speed controller.

You need to clean the device like this:

- The car engine must be turned off and cooled down.

- The air duct connecting the filter element to the throttle body cover is dismantled. To do this, unscrew two clamps and dismantle it, this will make cleaning more convenient. The crankcase ventilation system line is disconnected and the throttle valve is removed. The cover itself is usually secured with a clamp, but access to it can be difficult. You may need several screwdrivers to unscrew it.

- The cleaning agent is sprayed onto the closed throttle valve. This is done carefully so as not to splash other parts of the device located nearby. It is recommended to spray the product with light, short-term pressure. After completing the task, you need to wipe the damper with a lint-free cloth, and then clean it again. Only now you need to spray the liquid onto the walls of the chamber; the remaining product is removed with a cloth.

- The unit is cleaned in the same way with the damper open. The steps are repeated until the device turns as smoothly as possible and without jamming. It should close as tightly as possible.

- Then the block with wires is disconnected from the idle speed controller. Using a wrench of the appropriate size, remove the bolts securing the regulator. The device is dismantled; during removal, the sealing element located on the mount cannot be lost. If the damper is open, the air channel hole must be plugged with a rag. All components are cleaned, including the seat of the control device.

- The controller is also cleaned using a cleaning agent. You must act carefully so that the rod does not move during the work. At the final stage, you need to wipe the throttle valve cover, after which all dismantled elements are installed. If the rod was displaced during the cleaning process, its position must be adjusted so that it returns.

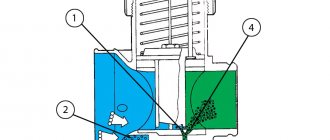

IAC device

As mentioned above, the IAC is a DC electric motor with a worm gear. The picture below shows a cross-section of the IAC with a description of all its elements located inside.

- Movable head (valve);

- Pressing plane;

- Stator winding;

- Worm shaft;

- Connector;

- Bearing;

- Frame;

- Rotor;

Signs of IAC malfunction

Since the IAC is an exclusively mechanical sensor, information about its malfunction will not be displayed on the dashboard in the form of a “CheckEngine” indicator

You can diagnose a faulty regulator using indirect signs:

- Stopping the engine at idle;

- XX speeds float (spontaneously rise and fall);

- On a cold start, the engine speed does not rise;

- The engine stalls when changing gears or moving in neutral;

WHERE TO FIND IT ON THE ENGINE

If someone does not know where the idle speed sensor is located, then we will tell you about its location. These devices are installed on the throttle bodies, fastened using two screws. There is also such a method of fastening as “landing” on the varnish. But it has not become widespread due to the complexity of such work. In the picture the arrow indicates the place where the pxx is installed on the VAZ 2114.

IAC check

Checking the regulator is carried out in two stages - visually and using a multimeter. Let's look at each stage in more detail.

Visual

It is necessary to check the visual condition of the sensor for damage, the integrity of the housing, and the absence of gaps between the connector and the metal part.

The condition of the rivets is also checked. Their absence indicates the presence of unaccounted air leaks.

Check the condition of the sealing ring; it must be free of nicks, damage and fit tightly to the IAC, otherwise the ring must be replaced.

Check the worm mechanism for contamination; there should be no traces of carbon deposits on it; the spring should be intact.

If the worm gear is dirty, it is necessary to wash the IAC with carburetor cleaner.

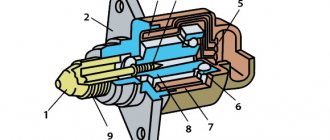

Multimeter

Testing with a multimeter is carried out by measuring the resistance between the contacts. This will determine the integrity of the motor winding and establish its suitability for further operation.

To check, you need to set the switch on the multimeter to the resistance measurement mode at 200 Ohms.

We connect the probes to the central terminals of the IAC. The resistance on the multimeter screen should be 50 ohms. If the multimeter shows 1, then most likely the IAC is faulty due to a break in the internal winding.

Checking the sensor yourself

The sensor is located in the throttle body and to remove it for inspection, you just need to unscrew two screws.

To dismantle the IAC, you need to disconnect the block and unscrew two screws.

Before dismantling, you need to thoroughly clean the place of its attachment from dust and dirt and remove the negative terminal from the battery. But first, a check.

Sensor connection diagram.

We look at the connection diagram and check the sensor using a conventional multimeter in the following sequence:

- Check for power supply to the sensor . To do this, measure the voltage at the two outer contacts of the block, A and D. Turn on the ignition, place the black probe of the multimeter on the engine ground, and the positive probe on the contacts one by one. The voltage should be within 12 Volts. If it is less or absent altogether, we look for an open circuit or blame the electronic control unit for everything. But first, we check the voltage at the terminals from ECU 4 and 54. Here, naturally, there should also be 12 V.

The voltage is normal.

It cannot be said that this testing method 100% guarantees the functionality of the sensor; we only checked its electrical part. The mobility of the cone valve and the magnitude of its stroke are of great importance. And this can only be checked either at a special stand or with a special tester.

Checking the operation of the mechanical part of the sensor

To check, remove the sensor from the throttle assembly.

However, if the electrical part is in order, you can check the mechanical part of the regulator by eye:

- Unscrew the sensor and remove it from the throttle body.

- We connect the contact block to the sensor.

- Turn on the ignition. When turned on, the valve should move forward. If this does not happen, the rod is coked or the stepper motor is not working properly.

- We measure the distance between the sensor body and the conical valve - nominal 24 mm.

We measure the distance with a caliper.

If we removed the sensor from the car and the electrical test passed, but we still did not achieve mobility of the cone valve, we try to clean the regulator using a soft swab, a cotton swab and WD-40 penetrating lubricant or an aerosol carburetor cleaner. Good luck to everyone and stable idle speed in any weather!

Although this device, even in specialized literature, is more often called a sensor, its more correct definition is a regulator. The fact is that the sensor, ideally, is a measuring equipment. In our case, we are talking, first of all, about stabilizing the speed of the engine operating in the idle mode by adjusting the air supply to the combustion chamber with the engine closed. So this is really a regulator, but since another definition of it has taken root, we will use both the first (DXX) and second (РХХ) designations.

So, we have already found out what this device is needed for, from which it follows that this component of the car’s intake system plays a significant role in ensuring the normal functioning of the power unit. In this article we will look at the principles of operation of this device, its possible malfunctions, and also how to check the idle speed sensor yourself, without resorting to the services of a car service.

Price

The table shows IACs, which, according to reviews from Lada car owners, are the most reliable and affordable.

| Manufacturer | vendor code | Price, (rubles) |

| LADA | 2112114830002 | 990 |

| AvtoVAZ | 21120114830004 | 600 |

| Standard | 21120-1148300-81 | 680 |

| Pegasus | 2112-1148300-03 | 805 |

| ERA | FJ480 | 370 |

Replacement

Replacement is quick and easy, just follow the instructions below.

- We remove the negative mark from the battery, since the work is carried out on the electrical equipment of the car

- Remove the connector from the regulator and unscrew the two screws using a Phillips screwdriver

- We take out the regulator and install a new one in the reverse order. Don't forget to install an O-ring between the IAC and remote control. It is recommended to lightly lubricate the ring with engine oil for easier installation into the throttle body.

We hope our article was useful to you.

Preventive measures

In order not to encounter a complete malfunction of the regulator in the future, it is worth periodically carrying out the cleaning process described above. How often to carry out the cleaning process depends on how actively you use your vehicle. If the car is a work vehicle, it is recommended to check and clean the sensor once a year; if you use it only for yourself, once every two years will be enough. But, of course, do not forget about the signs of a part malfunction; if they appear, do not delay. This will help you avoid complete failure of the part and enjoy a high-quality ride. Together with you, we come to the conclusion that the part is unpretentious, simple in its functionality and use. Don’t forget: timely detection of a malfunction is the key to overall vehicle productivity. The full operation of the engine depends on the serviceability of each of its components, and if you neglect any part, including the idle speed sensor, this can lead to more labor-intensive repair processes and failure of the entire car.

Checking the idle speed sensor

Diagnosing the part is quite easy, but pay attention to a few points. The first problem may be removing the part; most manufacturers attach the XX sensor to screws, and in extreme cases they can be drilled out, but in some variations the part is mounted on varnish

If your regulator is secured with varnish, be careful not to forcefully remove it, as this may damage the intake part of the car. In your case, it would be correct to completely dismantle the throttle assembly and only then disconnect the IAC.

The easiest way to check is, of course, visual inspection.

During a visual inspection, the first thing you should pay attention to is whether the needle is dirty. Also pay attention to the condition of the contacts and the throttle valve itself.

If broken wires are found, they must be returned to their place. Solder them and, to avoid corrosion, treat them with varnish.

It would be appropriate, if possible, to check the IAC with a multimeter or a homemade tester. You can check the resistance with a multimeter, and use a homemade tester (you can make one from a mobile phone charger) to check the stroke of the regulator rod.

If you find that the motor is damaged, the rod is completely worn out, or the cone needle is worn out, the part will need to be replaced. Don’t be too upset about this, the cost of the part will only be about 1000 rubles.