The rear wheel bearing is one of the weakest links in almost all domestic cars.

And the point here is not the low quality of components (although this aspect also plays an important role), but the terrible roads of the country.

Therefore, a good driver must promptly replace the faulty element. Otherwise, this may not only lead to more serious costs in the future, but also to an accident. Let's look at the main nuances of this work.

Symptoms of a problem

So, replacing the rear wheel bearing of a VAZ 2109 may be necessary:

- when noise appears (usually manifested in the form of a strong hum) or knocking in the rear of your car;

- the appearance of play in the bearing.

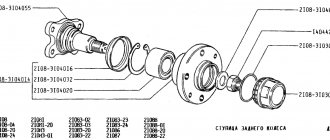

Rear wheel hub VAZ 2109

.

If you have one of the above symptoms, you need to lift the rear wheels one by one and make sure that there is a malfunction or not:

- Spin each of the suspended wheels thoroughly and listen to whether any extraneous noise appears. The presence of a clear hum indicates problems with the bearing;

- be sure to check for play (done with the wheel hanging). To do this, grab the top of the wheel and pull it away from you and towards you. If the bearing is intact, then the wheel should not play. Otherwise, you need to prepare yourself for serious work.

There are situations when there is no time for repairs. Try to lightly tighten the hub nut. Such a trick sometimes helps to remove the backlash, but not for long. In the future you will still have to make a replacement.

Structure

The part has a fairly simple structure. Essential elements:

- outer rim (used for screwing in bolts);

- internal part (for bearings);

- holes with slots (for CV joint);

- protective caps;

- sensor (it is sometimes included in the design).

CV joints are constant velocity joints; their main task is to transmit torque.

Note! The set of fasteners for this part consists of two nuts and one washer.

Hubs for different purposes have different technical characteristics. Hubs for passenger cars have the form of a hollow, lightweight cylinder, while for “heavyweights” the diameter of the part is larger.

Why is inaction dangerous?

It is better not to ignore a malfunction of the rear wheel bearing for several reasons:

- firstly, in the presence of noise and hum, driving a car is not nearly as pleasant as it might seem at first glance. To get rid of unnecessary sounds, car enthusiasts are ready to endure any costs;

- secondly, ignoring a bearing failure may lead to the need to replace the entire strut (which, naturally, entails more serious costs);

- thirdly, malfunctions of the chassis system are dangerous due to the unpredictability of the car on the road and an increase in the likelihood of an accident. Therefore, it is highly undesirable to joke with this.

How to remove a rear wheel hub and install a new one

The replacement procedure looks like this:

1. The car is installed on a lift. 2. Next, unscrew the nuts and remove the caliper. 3. Remove the hose, brake disc, and steering lever. 4. Release the hub from the ball joints and remove the strut fasteners. 5. Install a new bearing, return all parts to their place.

Important! For diagnostics, you can contact a service station, but according to reviews from car owners, the quality of the repair will depend on the responsibility and skill of the specialist, so in some cases you can repair the part yourself, but you should be extremely careful.

What brand should the bearing be?

In order for the replacement of rear wheel bearings on the VAZ 2109 to be as durable as possible, it is necessary to choose the right part.

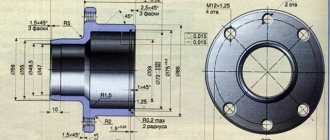

So, the design features of the part are as follows: the bearings have a closed shape (double-sided seal). Type - angular contact, ball, double row.

You can also find a roller version on sale - 537906. Its features include a lower rotation speed and a higher load capacity.

Bearings are produced at four factories - at the Saratov Bearing Plant (SPZ), in Vologda (23 gas processing plants), Samara (SPZ-4), Kursk (20 gas processing plants). By the way, bearings are no longer produced in Kursk.

As for quality, the best are the first two options. As for Samara, bearings are produced there for those who like to save money (that is, you should not expect high quality).

The nominal parameters of the rear hub bearing are as follows: diameter (inner - 30 mm, outer - 60 mm), width - 37 mm, weight - 400 grams, number of balls - 28 pieces.

Causes of problems

The hub is a very durable part of a car disk, so breakdowns rarely occur. But still sometimes deformation of the spare part occurs. In addition, the rear hub is more wear-resistant than the front hub, since it is less subject to heavy loads.

"Road factors"

Ingress of moisture and dust eventually displaces the lubricant, and the disc begins to overheat as a result of excess friction.

Insufficient lubrication

It ranks first among the causes of failure of this spare part.

Important! Sometimes it is caused by poor-quality lubricant material.

Excessive loads

In the average area this is unlikely. Usually found in mountainous areas.

Strong “tightening” of fasteners

It often happens that the bolts are screwed in more than necessary - this is how the threads wear out.

Important! If the hub and bearing are an inseparable connection, then there is almost no risk of wear of such a structure.

Required Tools

To complete the work, nothing unusual is required - most of the tools are already in the car enthusiast’s garage:

- pliers (with their help it will be necessary to dismantle the retaining rings);

- socket wrench. If you have the whole set, great, but for this work, number “30” is especially necessary;

- spanner wrench Again, you can use a set, but one “12” key is enough for the job. Without it, it will not be possible to remove the guide pins from the brake drum;

- special puller (necessary for pressing out bearings);

- Additional tools that may be useful are a hammer, a small wooden block, a pry bar and a chisel.

TABLE OF RECOMMENDED MANUFACTURERS

| No. | Manufacturer | Catalog number | Price 2022, rub. | Equipment | |||

| Retaining ring | Dirt cap | Lock-nut | Instructions | ||||

| 1 | VBF Russia | 2108-3104020 | 500 | – | – | – | – |

| 2 | SPZ Russia | 2108-3104020 | 520 | – | – | – | – |

| 3 | SKF Sweden | VKBA1307 | 1900 | 2 | – | + | + |

| 4 | FAG Germany | 545312A | 600 | – | – | – | – |

Bearing replacement instructions

To quickly and accurately complete the job, follow these recommendations:

First, remove the protective cap and unlock the rear wheel hub (this can be done with a hammer and chisel).

Loosen the bolts on the hub and wheel. Please note that the tightening torque of the hub nut is very serious, so it would be useful to increase the “shoulder” of the wrench with an additional pipe.

Put the car in first gear and secure the car (this can be done by installing special “shoes” under the front wheels). Do not use the handbrake.

Finally unscrew all the bolts and remove the rear wheel.

Unscrew the guide pins.

And remove the brake drum.

If it cannot be removed, you can use a block (as a spacer) and a hammer. By tapping on it, or turning the drum, you can easily blow it up from its “home” place.

Now move on to the main part. Completely unscrew the hub nut and remove it from the axle.

If you have a puller, use it.

If not, then you can use a simpler method.

Or use a pry bar.

Put the wheel back in place, screw it to the hub with bolts (you don’t have to tighten it all the way). After this, sharply move it towards you (the hub should come off).

Please note that this work does not always go smoothly. In particular, the inner ring of the bearing may remain on the journal. If you are unlucky, you will have to remove it with a chisel and a pry bar.

Or you can use a puller.

The bearing in the hub will be fixed by a special retaining ring - remove it. To do this, you can use special pliers or a regular screwdriver.

Now use a puller to press the bearing out of the hub. If you don’t have a puller at hand, then you need to find a pipe with a suitable diameter, place it and beat until “victorious”.

Or so.

Clean the inside of the hub and lubricate it well.

Press in the new bearing. There are several options here - do the work using a puller, a vice, or a hammer and a wooden or metal spacer, as in our case.

We return the locking ring to its place using a screwdriver and pliers.

We install the hub on the axle. If you can’t get the part into place manually, you can carefully tap the bearing from the inside.

Important points

- The method proposed above for replacing a wheel bearing is considered the easiest, but it has its drawbacks. The main disadvantage is that when removing the knuckles, the alignment of the car's wheels will inevitably be disrupted. In order to avoid camber violations, before removing the steering knuckle, you should put a couple of marks (this can be done with a chisel, for example). The first mark shows what position the adjusting bolt was in the rack. The second mark shows what position the steering knuckle was in. Of course, these marks will not allow you to achieve an accurate initial camber of the wheels, but the deviation from the original camber when using them will be minimal.

- New wheel bearings almost never fit into place the first time, even with the use of a puller and a vice, so they will have to be “re-fitted” by hand, that is, driven into the fist. To do this, you will need to cut a steel pipe (and the diameter of the pipe must exactly match the diameter of the outer ring of the bearing). The attachment is installed on the ring, after which it should be carefully struck with a hammer. In this case, the fist must lie on a flat, hard surface, and the adapter on the bearing must be positioned accurately, without distortions.

- It can be difficult to unscrew the 30mm nut that holds the wheel bearing. That is why it is best to put a long metal tube on the socket wrench and use it as an additional lever.

- It is best to clean the wheel bearing housing from rust using a wire brush. If you don't have a brush, you can use a regular kitchen knife. It is better to lubricate the seat before pressing in a new bearing not with oil, but with grease.

- After installing the bearing, you should check whether it is seated correctly. The easiest way to check: after the wheel is installed, you should jack up the car a little higher and lightly rock the wheel with the new bearing (away and towards you). The wheel should not wobble. If play is felt, it means the bearing is installed poorly. Be sure to spin the wheel as hard as possible and listen to the sound it makes as it rotates. It should be a very quiet, monotonous hum. If you hear some kind of creaking, or worse, clicking, it means the bearing is installed incorrectly.

As can be seen from the article, replacing wheel bearings is a rather labor-intensive task, even taking into account the fact that the article provides the simplest method (an alternative replacement method allows you to do without removing the steering knuckles, but in this case the car owner will definitely need an inspection hole, which is far from available everyone has). In the method proposed above, a hole is not needed, and the main difficulty is not to disturb the camber of the car’s wheels. If the alignment still turns out to be damaged, there is only one way out: go to the nearest car service center and adjust the alignment again.

Kinds

The following types of hubs exist:

- driving unsteered wheels;

This type is suitable for rear-wheel drive cars and is installed on the rear wheels.

- driven uncontrolled;

Designed for the rear wheels of front-wheel drive vehicles.

- leading managed;

Used in the front wheels of front-wheel drive cars.

- slave managed;

This type is needed for the front wheels of rear-wheel drive cars.

Selection of spare parts

To replace the bearing, we naturally need the bearing itself and the hub nut.

They can come either as a set or separately. Replacing the bearing is allowed on one wheel, but still, it would be better to change the axles on both wheels. The table below shows the main manufacturers of spare parts, indicating their catalog numbers.

| Manufacturer | Parts catalog number |

| LADA | 21083104020 |

| Complex | CX 081 |

| AUTOKIT | 01.280 |

| Euroex | 2108-3104020 |

| ABS | 200068 |

| FEBEST | DAC30600037 |

| BORG & BECK | BWK468 |

| CORAM | CR001 |

| BENDIX | 050841B |

| BREDA LORETT | CR 2552 |

| FIAT | 4178737 |

| BREDA | C171 |

| CORTECO | 19017731 |

| Finwhale | 2108-3104020 |

| Marketoem | 2108-3104020 |

| FINWHALE | HB321 |

| FIRST LINE | FBK468 |

| FLENNOR | FR891547 |

| IPD | 309110 |

| KAWE | FR891547 |

| Kemp | 77644281 |

| LEMFOERDER | 2006801 |

| LONGHO | 8751615_ |

| LSA | 21083104020 |

| SNR | R17204 |

| Mastersport | 2108-3104020 |

| MEYLE | 2146330001 |

| M.G.A. | KR3106 |

| MOOG | LA-WB-11604 |

| SBS | 1401762312 |

| N.K. | 762312 |

| SCT GERMANY | SCP 1307 |

| OPTIMAL | 802658 |

| SPIDAN | 26727 |

| SKF | VKBA 559 |

| TRISCAN | 853070201 |

| ZKL | 2108-3104020 |

Methodology and algorithm of repair work

Replacing a hub or bearing on a VAZ-2108 car is a clear technological process in which certain procedures will have to be followed. The first stage in the replacement process is preparatory. It is necessary in order to correctly assess the upcoming scope of work, prepare the site and the appropriate tools.

- Jack. In order for the problem unit to be replaced, you must first hang the wheel, removing the weight load from it. To do this, the vehicle is raised with a jack. If the replacement is carried out in a car service center or a specially equipped garage, then use a lift that will allow you to raise the car to a comfortable height.

- Puller. Replacing a hub or bearing on a VAZ-2108 requires the use of two different pullers, the sizes of which - 3 and 6 cm - correspond to the diameters of the rotation support races.

- Pliers.

- Wrenches for 12 and 30.

Under any conditions, replacing the rotation support begins with dismantling the hub unit.

- The front wheel is removed from the side of the defective unit. To do this, the car is secured with the handbrake and the mounting bolts are loosened. Then, on a jacked-up VAZ-2108, the bolts are completely unscrewed and the wheel is removed.

- The brake disc is removed.

- The caliper does not unscrew completely. It will have to be secured in this position, for example, with wire.

- After this, using a puller, we dismantle the hub along with the bearing.

The algorithm for further actions depends on which of the two units requires repair. In any case, the bearing will have to be pressed in, otherwise manipulations with the hub are impossible. Assembly of the unit occurs in the reverse order.

Diagnostics of VAZ 2108 car

Superficial diagnostics are quite easy to do. After a long journey, or after suspicious sounds have appeared, you need to touch the wheel disk from which the knocking came. A wheel with a broken bearing will be very hot, it will be impossible to touch it.

For a more detailed check, you will need a lift. If it is not there, then you can use a regular jack. First remove the mounts from the wheel, as this will be very problematic later. Lift that part of the VAZ 2108 car that bothers you. Don't forget to place supports and wheel chocks under the rear wheels. Then everything is even simpler, you need to take the wheel with both hands and try to rock it with maximum force. If the knocking noise repeats, this is a clear sign of a problem, and if the sound disappears when the brake is pressed, then the wheel bearing on your VAZ 2108 urgently needs to be replaced.