As practice shows, failure of the speedometer and tachometer is a fairly common occurrence.

On the one hand, such breakdowns do not affect the basic functions of the car, but on the other hand, the driver does not receive important information, which can lead to more serious malfunctions or even an accident.

Therefore, if your speedometer stops working or the tachometer needle begins to “take on a life of its own,” you need to urgently take some action.

In this article we will look at what and how to do.

Why the tachometer does not work on the VAZ 2114

Quite often, in domestic cars equipped with ECUs, there are malfunctions in the operation of the dashboard instruments. These include the tachometer.

Many drivers, especially beginners, ask the question why the tachometer on the VAZ 2114 does not work ? There may be several reasons for this.

First, let's check the serviceability of the indicator itself; to do this, we carry out diagnostics on the instrument panel by clicking on the odometer reset, with the ignition off, turn on the ignition, as a result of which all the instrument panel arrows should rise to the maximum level and return back. If the tachometer needle does not respond during diagnostics, the pointer is most likely faulty; the remedy is to replace the instrument panel. It’s even easier to check the indicator, if the car has an on-board computer and it shows the revolutions, it means the problem is in the indicator.

Sometimes a malfunction occurs, expressed in jumps in the tachometer needle, or periodic shutdowns (works, does not work), most likely the fault here is poor contact in the wire blocks that supply and control the tachometer, or weak ground contact, on the tachometer or on ECU. It is also possible that the control circuit from the computer to the tachometer may be broken. The solution is to check the quality of the contacts on all tachometer wires. Also, the tachometer may not work together with all the other devices; the reason here is most likely in the supply of power to the panel, or rather its absence or not constant contact. The elimination method is to eliminate the cause of the lack of power - a blown fuse or an open circuit.

So, why does the tachometer on the VAZ 2114 not work? It does not work because either the device itself is faulty, or the circuits that supply and control it have a break or unauthorized contact, i.e. short circuit.

Source

diagram, icons, shield and repair

The instrument panel of the VAZ 2114 is designed to inform the driver about the condition of the vehicle components. Beginning motorists should find out more about the functions and capabilities of the panel, as it allows timely detection of some serious breakdowns. In addition, some users may be interested in tuning the panel, so below are tips on what should be changed in the interior and how.

Main information devices

The instrument panels of the VAZ 2114 show information about the status of important operating components of the car. The main part is an information block with two round scales and several smaller indicators.

- The speedometer is the right round scale on the panel with marks from 0 to 200 km/h, which shows the speed of the car. The device sensor is located in the transmission assembly and is connected to the display in the cabin. Below the scale there is a window that displays the vehicle's mileage.

- The indicator to the right of the speedometer shows the level of gasoline in the tank. It has three main divisions - 1, ½ and 0. One - the tank is full, zero - empty. When the fuel is running low, the orange fuel icon lights up.

Indicators

The VAZ 2114 injector dashboard indicators play an important role in informing the user about malfunctions. They help prevent errors in the system, so it is important to know which indicator means what. How does the panel work? If any problem occurs, the sensor immediately sends information to the panel, and the driver will see an orange signal light up.

- The first icon is an oil lamp, which indicates a drop in the oil level in the crankcase of the engine assembly. If there is not enough oil, this indicator will light up. An icon that looks like a fountain indicates that there is insufficient coolant. If it lights up, there is less than 1 liter in the tank.

- Dome with a key - if it lights up, it means there is not enough coolant in the expansion tank.

- The icon looks more like a belt buckle and indicates that the car doors are not completely closed.

- A light bulb crossed out with a cross indicates that the parking lights or brake lights are faulty. Most likely, one of the devices will need to be repaired.

- A circle with six dotted symbols is a graphical indication of a malfunction in the brake system. Most likely, the pads are worn out and need to be checked and replaced.

- An icon with a man and seat belts is an indicator indicating that the driver has not fastened his seat belt.

The earlier version of the 2114 instrument panel had some other symbols, such as emergency oil pressure, handbrake engaged, Chek Engine light, and several others that indicate minor operating errors, but which are no longer used.

Pinout

The VAZ 2114 instrument panel pinout shows the correct order of connecting the wires of measuring and information devices, in other words, this is the electronic circuit of the instrument panel. You will need it if you want to make any changes to the standard panel configuration or carry out repairs and replacement of parts. For each car model and specific dashboard, the diagram will be slightly different; for example, the diagram on the VAZ 2115 has significant differences from the 2114 model.

The circuit consists of 26 connections, which are made according to an electronic circuit. Usually the diagram should come with the car manual. It’s not a problem to get a description of her work now.

There are two pads inside the panel - one red and one white. The devices will be connected to them in a certain sequence.

There is nothing complicated in the pinout if the user has basic knowledge of the rules for connecting wires - plus to plus, minus to minus. If you have a diagram of the instrument panel on hand, you can start tuning individual devices or the entire set so that the instrument panel of the 2114 model becomes more visually pleasing.

Tuning options

The instrument panel of the 2114 looks rather dim, so the first option for tuning it may be to install a backlight. This is done quite simply:

- We replace dim lamps with small LED lamps. If you want the light from them to fall evenly, install heat shrink on the lighting elements.

- The wires for the new lamps are connected to the power supply of the stove. You should not use a lot of bright colors, but red and its shades are best for arrows. An excellent analogue would be the blue color of LEDs.

In order for the instrument panel on the VAZ to have a clearer visual perception, the buttons should also be backlit.

Conclusion on the topic

The 2114 dashboard is quite simple in terms of both operation and repair.

Of course, her appearance leaves much to be desired, but this can be changed by adding a little visual effects. The last tuning option is to completely replace the panel with a European version. Everything you need is already installed, all you have to do is connect a few wires and turn on the new display system.

Why does the tachometer not work on a VAZ-2114 car with an injector?

VAZ cars never cease to be improved. Now the latest models come off the assembly line with injection power units. Such engines are built according to a complex scheme of interaction between many sensors and an on-board computer. The article will reveal a number of reasons why the tachometer on the VAZ-2114 does not work.

The purpose of the tachometer, symptoms and causes of malfunction of this device will also be described. At the end of the article, a schematic diagram of connecting the engine revolution counter will be given.

Analogs

Original speed sensors for injection VAZ-2114 are marked with article number 2111-3843010. This is a part in a plastic case, with a drive gear made of the same metal. The German analogue in a metal case is also suitable for this car model, but to install it you will have to redo the electrical contact socket.

Domestic EMFs are quite reliable. Their declared service life is up to 100–150 thousand kilometers. Rapid wear occurs due to dirt or damage to the housing itself during the repair of other components. You just need to monitor the condition of the part during operation.

Purpose

A car's tachometer is necessary to visually monitor engine speed. This control is very convenient for novice car enthusiasts and owners of cars with a manual transmission. On fuel-injected cars, the tachometer is also an additional means of monitoring speed for the on-board computer. Together with the crankshaft position sensors, speed and detonation sensors, the hog computer compares the received electrical impulses, thereby regulating the injection and oxygen saturation of the fuel.

Camshaft position sensor

This mechanism is located near the cylinder block. The main task is to transmit data to the ECU regarding the current operating cycle. Among specialists, the mechanism is called a Hall sensor. The operation of the device is based on the following principle: in accordance with the location of the crankshaft, the position of the gas distribution mechanism is determined. The data received by the sensor is reported to the electronic unit. Fuel is injected and the mixture is subsequently ignited.

Device

The tachometer of the VAZ “fourteenth” model is very simple. Its basis is the car's ignition module. This device contains a Hall pulse chopper. Due to the rotation of this device, an electrical impulse is generated. For one revolution of the crankshaft, only 2 discharges are formed (for 1–3 and 2–4 pistons). These signals are transmitted to the on-board computer. The ECU calculates the speed and number of received pulses. Based on these data, the magnitude of the electrical signal and its duration are calculated, which will be transmitted to the tachometer receiving unit in the car. Also, an exactly identical signal, but with a higher frequency, comes to the ECU from the crankshaft sensor. The computer compares the number of pulses and transmits the result in the form of a pulse voltage to the tachometer itself, located on the dashboard of the car. Two completely different devices allow you to obtain the most accurate data on the number of revolutions of the power unit.

Classification by operating principle

- Mechanical or electromechanical tachometers with direct drive. The revolutions are transmitted to the dial indicator through a flexible shaft, which, through a worm gear, receives rotation directly from the crankshaft or one of the transmission shafts. The operating principle of the indicator is based on the phenomenon of eddy current induction. The operation and design of a magnetic tachometer are extremely similar to the operating principle of a car speedometer. In modern cars, a similar tachometer design is not used.

- Electric machine. A distinctive feature is the connection to a generator. It is used primarily on diesel engines, but for the purpose of unification, a device of this type can also be used on gasoline engines.

- Electronic. The signal can be taken either from the ignition system or directly from the computer. Installed on gasoline and diesel internal combustion engines.

Design and principle of operation

Main components of electric machine and electronic tachometers:

- measuring unit, or signal converter. It can be based on elements of analog circuitry or built using special microcircuits;

- display unit with analogue or digital display of the number of revolutions;

- auxiliary elements.

The operation of electronic tachometers is based on the conversion of individual signals or pulses captured from the computer, ignition system or generator into a signal “understandable” for the display unit.

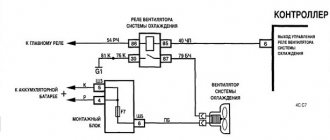

Connection diagram

When looking for the reason why the tachometer does not work, it is first of all important to understand the connection diagram and the type of signal. There are 3 typical connection schemes:

- to a contactless ignition system (the tachometer wire is connected to the primary circuit of the ignition coil). The operating principle is based on measuring the frequency of voltage surges in the primary circuit of the ignition system. Calculating the ignition angle is impossible without focusing on the number of crankshaft revolutions, therefore the sparking frequency directly depends on the crankshaft rotation speed. On 4-cylinder internal combustion engines, a full revolution of the crankshaft corresponds to 2 voltage pulses in the primary circuit. Accordingly, the higher the crankshaft rotation speed, the greater the frequency of voltage surges;

- connection to the contact ignition system. The operating principle and connection diagram are similar to the BSZ, but the design of the measuring unit will differ depending on the voltage of the input circuit;

- connection to the engine ECU. The principle of operation is still based on recording voltage pulses in the primary circuit of the ignition system, but the signal to the tachometer comes from the engine control unit;

- connection to the generator (the tachometer signal contact is connected to terminal W of the generator). The rotation of the generator pulley is carried out by a belt drive from the crankshaft, so the rotation speed of the generator rotor will always be proportional to the crankshaft speed. The change in the number of revolutions of the crankshaft can be calculated by constantly measuring the amount of EMF generated on the winding. According to its principle of operation, an electric machine tachometer resembles a regular one class=”aligncenter” width=”448″ height=”412″[/img]

Symptoms

Poor tachometer performance is due to several reasons. Symptoms of the malfunction are:

- Complete tachometer failure. The arrow completely or partially stops functioning. Often freezes in a certain position or trembles. The cause of the phenomenon may be an unstable contact connection in the power connectors.

- Poor start of a cold engine. The problem may be related to the connection of the autostart system to the tachometer. A connection problem or error disables the tachometer.

- Loss of power. Power is lost due to incorrect calculation of the fuel supply by the on-board system.

- Engine speed instability at low speeds.

- Increased fuel consumption.

- Complete loss of performance of the power unit. The cause may be a failure of the crankshaft sensor.

These symptoms become the reason for checking and troubleshooting.

Crankshaft position sensor

You can often hear drivers with many years of experience calling this mechanism nothing other than a synchronization sensor. This name comes from the principle of operation of the device. The tasks of the DPKV are to synchronize the operation of the electronic unit and the gas distribution mechanism.

The VAZ-2114 is equipped with an inductive type DPKV. The cost of such a sensor is relatively small. If a vital controller for a car fails, most drivers prefer to immediately replace the device with a new one.

If the DPKV breaks down, further operation of the vehicle will become impossible. Without this mechanism, the fuel supply system will stop working, because the ECU will not receive information about when it is necessary to give a command to inject fuel into the cylinders. The location of the DPKV is in close proximity to the camshaft.

Electronics are responsible for fuel delivery in the VAZ-2114 car system. Without TPS, the control unit will not be able to determine the optimal time to supply gasoline. Deviations from the correct operation of the TPS lead to an increase in the amount of fuel consumed. The operation of many other car systems depends on the angle at which the remote control is located: cooling, fuel supply.

see also

The TPS is located near the idle speed sensor. In the “fourteenth” system, the work of these two devices is closely linked.

When the TPS breaks down, the car begins to twitch in a certain position of the damper, and instability of engine operation is also noted. All VAZ-2114 8 valve sensors are interconnected in their operation, so two different devices sometimes exhibit the same symptoms of malfunction. If symptoms of a breakdown occur, it is necessary to take a comprehensive approach to checking all controllers.

Malfunctions

There may be several reasons why the tachometer on a VAZ-2114 does not work. Malfunctions include:

- Failure of the fuse that protects the instrument panel from voltage surges and short circuits. In this case, the entire panel, its backlight and some auxiliary devices are disconnected from power.

- Failure of the ignition switch. Often the contact through which power is supplied to the tachometer burns out or there is no hard connection.

- Poor contact at the ignition module connector. Occurs due to oxidation, pollution, moisture.

- Breaker failure is a common cause. It lies in contamination or wear of electrical contacts.

- The crankshaft sensor is broken or there is poor contact on its connector.

- Malfunction of the module - the receiver of the device itself. Occurs due to a short circuit.

All described malfunctions require routine inspection and testing of each device. Methods for checking each element will be described below.

Replacement

Practice has shown that the weakest unit in the speedometer system is the EMF. The plastic parts of this unit are very fragile and quickly wear out from friction. A faulty sensor will have to be completely replaced. To do this you need:

- Disconnect the “+” terminal from the battery.

- Remove the air purification filter and its pipe.

- Disconnect the current-carrying EMF connection.

- Using the “22” key, unscrew the part.

- Wash the sensor installation area thoroughly with solvent.

- Replace the rubber seal ring.

- Install a new EMF analogue.

- Reinstall previously dismantled parts.

Attention! Devices with gears have different numbers of teeth. If you install a part that differs from the original, a problem may arise in the accuracy of the speed readings.

Examination

You need to start checking from the tachometer itself. For a quick test, you need to reset the odometer - hold down its button and turn on the ignition. If the tachometer and speedometer needles react to the supply of voltage, then both of these devices are working. If there is no reaction, then you will have to continue the search.

Fuse

The tachometer does not have a direct connection through the fuse. It connects via a common dashboard control system. Fuse “F16” is responsible for protecting this system. In order to check it, you will need a tester in dial mode. Both tester probes must be connected to the contacts of the protective device. An audible alert will indicate integrity. If the fuse is blown, then it must be replaced with an analogue 15 ampere.

More complex breakdowns

When, along with the tachometer, absolutely all the electrical equipment of the panel fails, you will have to look beyond the fuses. There is a risk that the problem lies in the ignition system. In particular, here the contacts on the lock are often charred or the track on the board of the VAZ-2114 mounting block is damaged. In the first case, the mechanism must be removed and cleaned, and in the second, the element is replaced with a new one.

The tachometer needle began to twitch - such a malfunction is far from uncommon. To find the cause, it is recommended to use the self-diagnosis mode of the standard on-board computer. It will show a list of errors, and all you have to do is start fixing them.

If there is no ECU, then first check the wiring, since a jerking arrow often indicates poor contact.

Also carefully inspect the mass of the VAZ-2114. This is all the more necessary to do when other panel devices are functioning with obvious disturbances.

Be sure to find out whether the contacts of the distributor are clean and whether the capacitor installed in its cover is still working. The latter loses capacity over time, which disrupts the operation of the entire vehicle ignition system.

Sometimes problems arise immediately after replacing the old tachometer of the 2114 model with a new one. Usually this is not a malfunction, but a bad setup. Do this:

Connection

Connecting a tachometer to the electrical circuit of a VAZ-2114 car is not difficult. It is necessary to be guided by a clear connection diagram.

Below are step-by-step instructions explaining the diagram:

- Terminals “2” and “8” go from the white power connector on the dashboard to the tachometer.

- Terminal “2” is connected to the pulse, central contact of the tachometer. Connects directly to the ignition unit, and in parallel to the router and ECU via terminal “7”.

- Terminal “8” is connected to terminal “3” of the ECU.

- Terminal “1” is “ground” and is connected to terminal “6” of the ECU.

When connecting, you should especially carefully inspect all plug connections for contact rigidity. All contact connections from the instrument panel go through the safety block; without it, connection is prohibited.

Tuning the dashboard of Lada 2114

To make their car distinctive, many motorists resort to tuning.

Although this is a troublesome task, it is worth it. Everyone strives to make the salon spectacular and cozy. The dashboard is a favorite place for tuning.

Backlight tuning

To make the panel devices look stylish and modern, they can be modernized. Let's look at how backlight tuning is done.

You can improve the appearance of a vehicle yourself, since the process is not at all complicated.

Everything you need for tuning:

The first step is to replace regular yellow light bulbs with bright LEDs. Chinese diodes are cheaper, but they will not last long. To ensure that the light comes directly from the diodes, heat shrink is put on them, and the arrows will be clearly visible even in the dark.

The diode wires are connected to the backlight from the machine stove. To change the color of the arrows, a red diode is placed under each arrow. The light from the arrows will acquire a rich, bright red color, which will noticeably update the panel.

Blue light bulbs are popular. The central panel is also subject to tuning, respect is guaranteed. The glow becomes soft and irritates the eyes when driving.

Europanel

To give a modern aesthetic look, you can install a europanel. The material of the panel is soft, rich, and less noisy. The original warning lamps and odometer make the panel modern and fashionable. It is equipped with many signal sensors. A special feature of the Europanel are sensor signals and airbags. White-blue LEDs also look beautiful. Typically, up to 50 LEDs are needed for tuning. If the glow of the diodes is very bright, then you can try to adjust it. Some VAZ components have this capability.

You can also tint the instrument panel, which will also look great. Improving the panel offers ample opportunities for creativity among car enthusiasts and designers. As a tuning option, you can install a start button, which will give the interior a distinctive style and modernity.

By the way, if the modernization will be carried out with your own hands, in order to avoid problems with the traffic police, you need to write a statement about the planned changes in the design of the car and wait for permission from the traffic police. After making changes, you need to undergo a technical inspection, where appropriate changes will be made to the registration documents.

FakeHeader

Comments 7

Try the test, if it doesn’t help, then take it off and put the arrow back on

Oddly enough, the test helped, thank you! I didn't even know about him.

Do a tidy test, it should go down

The test helped, the arrow went down.

Hi, after I re-lit the tidy, the tachometer column did not move at all. At the back of the dashboard there are 4 motors from the arrows, you carefully pry them up with a knife and there will be gears, one small one falls out, perhaps there is a jamb in it. Find a video on YouTube like repairing vdo arrow motors)