How to disassemble and reassemble the front brake mechanism of a VAZ-21213 car

Disassembling the front brake mechanism

We hang and remove the front wheel.

Using a 10mm socket, unscrew the bolt securing the hose guide brackets

Using a 14mm socket, unscrew the bypass bolt of the brake hose of one circuit.

We remove the hose with the bypass bolt.

The hose fitting is sealed on both sides with copper washers

Similarly, disconnect the brake hose of the other circuit.

Remove the cylinder block with the brake caliper (see Replacing the front brake pads).

We take out the brake pads.

Clamping the brake caliper in a vice with soft metal jaw linings, use a drift to remove the cylinder block retainer.

At the same time, we recess the cylinder block retainer with a rod with a diameter of 3–4 mm and, hitting the cylinder block with a hammer with a plastic striker, we begin to move the block along the guides of the brake caliper.

After moving the cylinder block by 1.5–2.0 mm, remove the rod. Using a hammer with a plastic striker or mallet, knock out the cylinder block from the caliper guides.

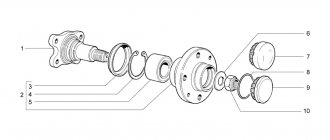

Cylinder block and brake caliper.

We remove the clamp and its spring from the socket of the brake cylinder block

The retainer fits into the caliper hole and limits the movement of the cylinder block

We assemble and install the front brake mechanism in the reverse order.

To facilitate assembly, use a file to remove the chamfers from the guides of the cylinder block.

Having sunk the latch into the block socket, insert the block into the grooves of the caliper. Using a hammer with a plastic striker, hammer the cylinder block until the retainer fits into the caliper hole.

To remove the pad guide, remove the upper clamping lever in the same way as the lower lever (see Replacing the front brake pads).

Using a 10mm socket, unscrew the bolt securing the front casing to the pad guide

Using a chisel, loosen the two bolts securing the shoe guide to the steering knuckle.

Using a 17mm wrench, unscrew the bottom bolt.

It is more convenient to unscrew the top bolt with a head

Remove the pad guide.

The brake disc and its protective casing can be dismantled only after removing the hub (see Replacing the hub bearings). When tightening the bypass bolts, note that the position of the brake hoses is determined by the guide brackets.

We carry out the assembly in the reverse order and bleed the brake system (see the article - “Bleeding the brakes”).

Source

Tips for caring for brake pads

The service life of brake pads is influenced by many factors: the condition of the brake discs, the driver's driving skills, the operation and quality of the pads, climatic and weather conditions, as well as the storage conditions of the vehicle.

Tips for caring for brake pads

To extend the life of the pads you must:

- Adhere to the schedule for checking the vehicle and all its systems, including the braking system.

- Use spare parts from the original manufacturer, and also use “original” consumables.

- Adhere to an adequate driving style. Use the vehicle only in areas suitable for it.

- Replace brake fluid at appropriate intervals.

- You must use the brake fluid specified in the vehicle manual.

- Regularly check for leaks under the car.

- Monitor the wear of the gaskets.

Replacing cylinder caliper 2121

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

It can be repaired, even if there is caries on the piston, with a bang. The task comes down to simply cleaning the parts from dirt. As for where it gets into the system, who knows. Wash only with brake fluid, blow with air, use clean and dust-free rags. It is necessary to disconnect the cylinder from the hoses, otherwise sand will pour in during assembly. Rubber bands must be changed if damaged, removed, washed and wiped with a cloth. Do it carefully and everything will work out. The slightest grain of sand or piece of rust, and all the work is in vain. My old woman has USSR cylinders, I cleaned them a couple of times, the last time about 6 years ago.

Caries is a complete f#@a, since it always means fistulas and cavities of the working surfaces. And if so, I consider all the masturbation of disassembling, reassembling, cleaning a waste of time, the result is always the same - replacing the assembly. I am not a theorist and I am 100% sure of what I am writing, I have done it repeatedly, in different interpretations and with the same result. As for moisture getting into the brake system, this is inevitable. Either due to torn anthers, or, more likely, getting there condensation. Which is formed when positive and negative temperatures change. Brake fluid is hygroscopic, the quality of the metal parts of the brake mechanisms is below any criticism. It is also possible that the controversial three-piston caliper design plays a role. As a result, we have hemorrhoids every 2-3 years..

When to replace pads

The main signs of brake pad wear include:

- Increasing the duration of the braking distance. This occurs when the friction material is depleted, friction between the pad and the discs occurs with the metal part, leading to a decrease in braking coefficient.

- Not linear braking. This happens if one of the discs is clamped tighter during braking.

- Brake pedal damping. When the brake pads are completely worn out, the brake pedal loses its shock-absorbing properties and does not return to its original position.

- Low brake fluid level.

- Extraneous sounds during braking. A sign of complete wear of the friction linings.

- Dust on wheel rims. The dust can be dark or metallic. Dark dust occurs as a result of abrasion of the friction material, metal dust is a sign of abrasion of the discs.

The best replacement for standard brakes on Niva - calipers 2108

In this article we will talk about why Nivavods began to actively use 2108 calipers on Niva, why this is good or bad and how much it costs.

Currently, cars of the Niva family use front brake calipers, which have not undergone any significant changes since 1976. Many motorists operating this car are faced with problems such as uneven wear of the front brake pads, jamming of one or more brake pistons on the front brake cylinder, “clunking” and other unpleasant moments. Undoubtedly, those who monitor and promptly service the brake system encounter these problems much less often. But if you overlook it, you'll be on your way to the store for spare parts and service for a replacement.

If, when repairing front brake elements, it is necessary to replace one of the elements, for example, only the front brake cylinder, the cost of a spare part can average from 1000 to 1800 rubles, depending on the modification and the manufacturer of the brake cylinder. And if you need to replace the brake caliper assembly, the cost can range from 4,000 to 5,000 rubles.

But recently, replacing the standard front brake calipers with a brake system from 2108 has been gaining popularity.

This kit includes:

- Adapter plates with fasteners for installing brake cylinders from 2108 to 2121*, 2123 Chevy Niva

- Caliper 2108-09 left

- Caliper 2108-09 right

- Brake hose for caliper 2108. 2 pcs required.

- Front brake pads 2110-12, 1118-19, 2170, 2190 (4 pcs.)

Now let's look at the "pros"

- Caliper 2108 has a guide apparatus - these are wells in the caliper bracket and guide pins, this ensures minimal movement of the pads from the brake disc. On uneven roads it does not “clunk”, because the device is pressed by springs on the brake pads. For comparison, the Nivsky pad clamping mechanism does not have a guide apparatus, but rests freely on the caliper bracket and is pressed by two earrings through four springs. This design allows the caliper to move relatively freely in all directions, while producing clunking sounds. The consequence of these movements is excessive movement of the brake pads from the brake disc. As a result, when braking, increased idling of the brake pedal.

- The brake pad 2108 is wider than in the Niva, so the brake disc lasts longer.

- The weight of the left and right caliper 2108 complete with hoses, brake pads and adapter plates with fasteners is less than in the Niva.

- The 2108 caliper consists of one cylinder and a piston, diagonal wear of the pads is excluded, and souring or jamming of the piston is easily diagnosed by the behavior of the car. For comparison, the Niva cylinder has three pistons. Two are connected to the front circuit, one to the rear circuit. Often, when the front and rear circuits of the master cylinder operate unevenly, diagonal wear of the pads occurs. The same thing happens when one of the cylinders becomes sour.

- The area of one cylinder 2108 is 14% less than the total area of three cylinders 2121. Therefore, caliper 2108 develops pressure on the pads 14% less than caliper 2121. The rear brakes on the Niva are from the VAZ 2101, and with 16 wheel radius they are less effective than with 13 wheel radius. After installing front calipers 2108 on the Niva, the braking force is redistributed by 14% in favor of the rear brakes.

Recommendations for the driver

To prevent sticking of the friction linings, sudden braking should be avoided after installing new pads, since they are deformed and subsequently make the normal braking process impossible. Smooth braking is recommended during the first half a thousand kilometers after manipulating the brake pads.

The lifespan of brake pads is affected by many nuances. Performance depends not only on the skill and driving style of the vehicle owner, but on weather conditions. Remember, brake pads should be checked at least once a year.

Do-it-yourself VAZ 2121 caliper repair video

The front brake mechanism on the VAZ 2121 and Niva 2131 is dismantled for repairs. Remove the caliper, prepare a standard set of tools and perform the following sequence of actions:

- Fix the mechanism in a vice, having first cleared it of dirt and rinsed it with clean kerosene.

- Next, use a drift to pry the cylinder block retainer out of place.

- While simultaneously recessing the latch, using a hammer with a rubber or plastic striker, push the cylinder block along the caliper guides.

- After the cylinder is slightly moved along the guides, remove the rod.

- We finally knock out and remove the cylinder block from the caliper.

- Using pliers, remove the block retainer and its return spring from its seat.

- We assemble the mechanism in the reverse order. For convenience, it is recommended to process all chamfers on the new cylinder block and caliper with a fine-grained file.

At this point, the repair work on dismantling the front brake mechanism on the VAZ 2121 and Niva 2131 has been completed. Carry out installation in reverse order.

International NIVA Club

- Unanswered topics

- Active topics

| Photo gallery | NIVA-SHOP | Files | Video |