April 10, 2017 Lada.Online 181 679 9

Currently, all LADA models (Lada XRAY, Vesta, Largus, Granta, Kalina, Priora, Niva 4×4) without exception are equipped with ABS (anti-lock braking system). During the operation of the car, many owners notice that the ABS and ESC lamps (if this system is available) light up on the instrument panel. Let's figure out how to solve this problem and improve the design.

Correct braking without ABS

Every driver should be aware that it is not enough to simply use the brake pedal in time. Because if you sharply press the brakes at high speed, the car’s wheels will be blocked, resulting in no traction between the wheels and the road surface. The road surface may be different, so the sliding speed of the wheels will be different. As a result, the vehicle becomes uncontrollable and can easily skid. If the owner of the car is inexperienced, then controlling the direction of the car may be beyond his capabilities.

The most important thing in such braking is to prevent the wheels from locking rigidly, causing the vehicle to skid. To avoid such cases, it is recommended to use intermittent braking. To carry out such correct braking, it is necessary to periodically press and release the brake pedal at short intervals, and in no case should you keep the brake pedal pressed until it comes to a complete stop. With this simple braking technique, you can control the car regardless of the quality of the road surface.

However, it is necessary to take into account a simple human factor - a driver in an unforeseen situation can become confused and all the rules of braking can simply fly out of his head. To control the vehicle in such emergency situations, an anti-lock braking system was developed.

Purpose of ABS

The anti-lock braking system, based on its operating principle, imitates the actions of an experienced motorist who uses intermittent braking on a slippery road to prevent the car from skidding. And here the question arises: why do we need an electronic system when the driver himself can perform these actions? Cars that do not have ABS installed are quite difficult to control during heavy braking, and in many situations it is simply impossible to manage without it.

Note! The anti-lock braking system is automatically activated 15-20 times per second, resulting in minimal braking distance in the event of emergency braking. A person is physically unable to work at such a speed.

Perhaps the main advantage of ABS is that the driver, even under heavy braking, can make the car obey the steering wheel. When this device is absent, during the braking process the car will slide uncontrollably along a straight path, despite all the efforts of the driver to level the movement of the personal vehicle by turning the steering wheel.

When ABS , you can hear a soft cracking sound in the cabin, indicating the functioning of the executive unit, and feel gentle and frequent pushes on the brake pedal. Those motorists who have not previously dealt with such a system will need some time to get used to this innovation.

The car's anti-lock braking system has proven itself to be excellent, but, nevertheless, there were a number of dissatisfied motorists who claim that no electronics can replace an experienced driver, because he is much better able to navigate a difficult situation on the road and take the right actions.

Note! ABS does not interfere with the braking process at all, but serves as an indispensable assistant in preventing an irreparable traffic situation. Thanks to the anti-lock braking system, the uncontrollable mountain of iron into which the car turns during heavy braking begins to obey the steering wheel and is capable of performing at least some maneuvers.

What is the secret of how ABS works?

It is important to know by what principle the ABS works, because it has a close connection with the control system, which means that, accordingly, with the level of safety of the driver and passenger. So, the main idea of the system is that when the driver presses the brake pedal, instant control occurs, and the braking force is redistributed to the wheels. Through this, the car is controllable in any conditions, and the effect of reducing speed is achieved. However, one cannot rely only on various additional systems because the driver must master his own car - the length of the braking distance and behavior in emergency situations. It is recommended to test the car's capabilities at specialized racing tracks in order to prevent sticky situations on the road in the future.

There are also some peculiarities of ABS operation. For example, when a driver decides to stop moving a car equipped with an ABS system, when pressing the brake pedal, a slight vibration is felt on the pedal, and an accompanying sound similar to a “ratchet” can be heard. Vibration and sound are a sign that the system is working. Meanwhile, the sensors read the speed indicators, and the control unit monitors the pressure inside the brake cylinders. Thus, it does not allow wheel locking, but slows down with quick jerks. Thanks to this, the car's speed drops without skidding, which allows you to control the vehicle until it stops. Even on slippery roads, with ABS, the driver only needs to keep control of the direction of the car. Such perfect and controlled braking is only possible thanks to the ABS system.

The following steps should be emphasized:

- Relieving pressure in the brake cylinder.

- Maintains continuous pressure in the cylinder.

- Increasing the pressure to the appropriate level in the brake cylinder itself.

It is important to know that the hydraulic unit in a vehicle is mounted in the brake system in a row directly after the main brake cylinder. As for the solenoid valve, it is a kind of tap that allows in and blocks the flow of liquid to the brake cylinders themselves.

The control and operating processes of the vehicle braking system are carried out in accordance with the information received by the ABS control unit from the speed sensors.

During the braking process, ABS deciphers information from the wheel speed sensors, due to which the vehicle speed drops evenly. If any wheel stops, a signal is instantly sent from the speed sensors to the control unit. Having received such a signal, the control module removes the blockage by activating the release valve, which blocks the entry of liquid into the wheel brake cylinder. At this moment, the pump returns the liquid to the accumulator. When the wheel speed increases to the permissible speed, the control unit will give the command to close the exhaust valve and open the intake valve. After this, the pump is started, which will pump pressure into the brake cylinder, as a result of which the wheel will continue to brake. These processes are carried out instantly and last until the vehicle finally stops.

The essence of the ABS operation being discussed represents the newest four-channel system, in which all wheels of the vehicle are monitored.

Is it possible to disable ABS without negative consequences?

It should be noted right away that if you disable the factory-installed system incorrectly, the on-board computer will record the fact of outside interference, which can lead to unnecessary questions during maintenance. If you have to contact the service under warranty, the fact that the ABS is turned off on its own may well become the reason for denial of warranty, and therefore free repairs.

To temporarily disable ABS, you can use the following algorithm of actions.

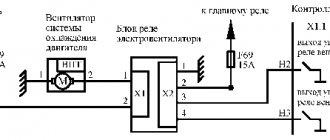

- Open the fuse box located next to the battery. In most cars, to disable the ABS, you will have to remove the 15-amp fuse, but before doing this, it is better to clarify this issue in the owner's manual for your specific car.

- After this, to check, you should briefly turn on the ignition - the brake and ABS lights should not go out, in addition, a sound signal will be heard. The ignition turns off.

- The mounting block itself is unscrewed and its bottom cover is removed.

- You will need to find the wire leading to the already removed fuse, cut it lengthwise and strip the ends by 1.5-2 cm.

- Before starting work, you need to purchase the simplest five-pin relay from a car store.

Before connecting, you should look at the contact diagram located on the case. You should start working with contacts 85 and 86, going to the winding. A wire leading to ground is connected to them, and the second will serve to supply a control signal from the ignition switch through the ABS switch off switch. Contact number 30 is connected to the wire coming from the fuse, and pin 88 is connected to the ABS. It is convenient to do this with wires prepared in advance, crimped on one side with the “mother” terminal. Subsequently, they will need to be installed in an empty relay block, and the switch off button is mounted anywhere in the cabin. How this is done in practice, and what the driver’s impressions are after this, can be seen in the video:

Other known types

- Single-channel consists of a sensor located on the rear axle, whose task is to distribute braking force synchronously to four wheels. This kind of system has only one pair of valves, due to which the pressure varies simultaneously throughout the entire circuit.

- Two-channel - it carries out paired control of wheels, which are located on one side.

- The three-channel one consists of three speed sensors: one is mounted on the rear axle, and the rest are mounted separately on the front wheels. In the mentioned type of system there are three pairs of valves (inlet and outlet). This type of ABS operates by individually controlling the front wheels and a pair of rear wheels.

Having compared different types of ABS, we can conclude that their difference is manifested only in the different number of valves and speed control sensors themselves. However, the essence of the system in a vehicle, as well as the order of the processes occurring, is identical for all types of systems.

Basic malfunctions of the ABS system

Any driver who has ever had an ABS light come on in a Priora will tell you about the sensor. But it could be worse - if the ABS in Priora does not work. There are several options in which to look for the source of the problem:

- wiring damage;

- mechanical damage to the brake fluid pressure valve block;

- failure of speed sensors.

The first thing you need to do when you see the light (ABS lights up) is to read the error symbols using a special diagnostic scanner. Each item in the ECU is indicated by a corresponding code:

- C0040 – the speed sensor (DSC) of the right front wheel is faulty;

- C0035 – DSC of the left front wheel is faulty;

- C0050 – DSC of the rear right wheel is faulty;

- C0045 – DSC of the rear left wheel is faulty;

- C0065 – front left valve (intake);

- C0060 – front left valve (exhaust);

- C0075 – front right valve (intake);

- C0070 – front right valve (exhaust);

- C0085 – rear left valve (intake);

- C0080 – rear left valve (exhaust);

- C0095 – rear right valve (intake);

- C0090 – rear right valve (exhaust);

- C0161 – the braking signal does not turn off;

- C0121 – power to the valves does not turn on;

- C0110 – electric return pump.

- C0550 – error in the “brains” - ECU;

- C0245 – error in receiving data from sensors;

- C0800 – power surges.

The solution may be simpler: an ABS sensor is installed under the fender liner. Dirt often gets into this area; an unprotected piece of wiring near the DSC connector can be damaged. Replacing it will help.

History of system implementation

Engineers from leading automobile companies worked diligently to develop ABS in the first half of the 70s. Even the very first systems were quite successful, and already in that decade similar systems began to be installed in mass-produced cars.

Initially, mechanical sensors were installed on cars only on one axle, which sent data to the control module about changes in pressure in the brake circuits. Developers from Germany took this area one step further and began to use sensors without contacts, and this, in turn, catalyzed the transfer of information to the logic block. In addition, the number of false alarms has decreased, and due to the elimination of rubbing surfaces, wear has disappeared. The modern system works on the same principle that was used in the first anti-lock braking systems.

What you can do yourself

Like I said: no need to panic. Let's look point by point at what you can do yourself.

- Open the hood and disconnect the battery. The electronic control unit is located under the hood, usually in the same housing as the hydraulic modulator (brake force distributor). An article on the ABS device. You can recognize it by the large number of brake pipes suitable for the block (usually 6) and a bundle of wires with a connector. So, disconnect this connector and carefully inspect for water or mechanical damage to the contacts. If there is moisture, blow and dry.

- Check the fuses, this should have been done first. Well, never mind, wipe your hands and move on. The ABS system can be supplied with several fuses, which are usually located in the engine compartment mounting block.

- Well, then it’s a little more complicated. If there is a car lift, then look at it. If not, you can lift it with a jack. Your task is to inspect the wires that go to the wheel sensors (usually screwed into the hub) for damage. Because often these wires fly off the mounts and rub against the wheel.

- Wheel sensors are designed with a wire and a connector at the end. The length of the wire can reach 1 meter. Your task is to find these connectors and check the quality and presence of contact. Make sure there is no moisture or rust.

- If everything is in order, but the abs light is still on, then you have a direct route to a car service center. Moreover, it is not always possible to clear an error in the locking system by simply removing the battery terminal.

But in most cases, after eliminating the malfunction, you should drive the car a little and brake once or twice. The abs light goes out.

Everything written here concerns independent searches. A good service center will connect a scanner to your car, which will tell you exactly what is broken.

Some disadvantages of ABS

One of the biggest disadvantages of the anti-lock braking system is that its effectiveness depends on the quality and condition of the road surface. If the road surface is not good enough, the braking distance is much longer. This is due to the fact that from time to time the wheel loses contact or traction with the asphalt and stops rotating. ABS detects this kind of wheel stop as blocking and thus stops braking. At the moment the wheels engage the asphalt, the programmed command does not agree with what is needed in this case, and the system itself needs to be rebuilt again, which takes time and increases the braking distance. This effect can be minimized only by reducing the speed of the vehicle.

In the case of a non-uniform road surface, for example, snow - asphalt or ice - asphalt, if you encounter a wet or slippery section of the road, ABS evaluates the surface and adjusts the braking process to the given road. At the same time, when the wheels hit the asphalt, the ABS is rebuilt again, which again increases the length of the braking line.

On unpaved roads, the conventional braking system works much better and more reliably than the anti-lock braking system. After all, during normal braking, a blocked wheel pushes the ground, creating a small slide that prevents the vehicle from moving further. Thanks to this, the car stops very quickly.

Another flaw of the anti-lock braking system is that at low speeds, the system is completely disabled. In cases where the road is downhill and at the same time slippery, you need to remember that a reliable handbrake may be required for braking. Therefore, it must always be in working order.

There is no provision for regularly disabling the anti-lock braking system in cars. Sometimes drivers want to disable this system. To do this, you need to pull the plug out of the block. It is also necessary to take into account that in new cars the redistribution of inter-axle braking forces also depends on ABS. Therefore, by braking, the rear wheels are completely blocked.

It is important to note that the ABS system is an excellent addition to the car’s braking system, thanks to which you can control the car in the most difficult and unusual situations. Despite this, we should not forget that it is impossible to completely rely on the machine. The driver also needs to make great efforts to keep the situation under control.

How to replace Grant rear brake pads without ABS

Let's look at the whole process step by step. To work you will need

:

- New pads (choose depending on whether the car has ABS or not);

- Keys 13: open-end and ratchet with long head;

- Wheel key;

- Head E-8;

- Head for 7;

- Screwdrivers for removing and installing springs;

- Pliers.

A long 13 socket will be needed if you are going to adjust the handbrake. It is not needed for simple pad replacement.

Delamination and severe wear of the rear pads = the handbrake does not work, noise and the car pulls to the sides when braking.

Preparing to replace pads

Getting ready to remove the brake pads. For this:

- We park the car on a flat surface

; - Remove the handbrake

and put it in neutral; - We support the wheels

with wheel chocks (you can use bricks, bars, etc.); - We pump out the brake fluid

to the MIN level - use a syringe or an enema bulb; - We remove the wheel bolts;

- We hang the rear wheel

(jack up the car) and remove it.

We support the wheels, remove the handbrake and wheel.

There are Ladas with disc brakes all around. They are often changed as needed, but sometimes re-grooving the brake discs also helps. If you don’t know what to choose, ask a diagnostician for advice.

How to remove a brake drum on a Lada Granta

The drum on the Grant is removed like on any other VAZ model. To do this , unscrew the key to 7

guide pins and remove the drum.

If the drum is soured and cannot be removed, the same pins can be screwed into adjacent holes as shown in the photo - they are made for mechanical removal of the drum.

Unscrew the pins and remove the drum.

It is not recommended to knock the drum with a mallet or hammer - there is a risk of damaging it.

Replacing pads yourself

Attention

– from this moment on, you cannot press the brake pedal. Otherwise, the brake pistons will extend and removal/installation will be difficult.

Step 1

: To weaken the springs, press the pads inward.

We press them out with a pry bar, focusing on the brake shield. Move the brake pads.

Step 2

(based on the figure below) – remove:

- upper spring No. 5;

- expansion bar No. 6;

- lower spring No. 13;

- guide springs No. 7 (available on both pads).

At this stage we need springs 5, 13, 7 and bar 6.

Step 3

: Freely remove the left block.

The handbrake lever is attached to the right one - so we pull out the block itself and use pliers to remove the cotter pin securing its finger to the block. We remove the handbrake lever from the cable, remove the cotter pin and disconnect the handbrake lever from the block.

Step 4

: Assembly with new pads is carried out in reverse order.

For ease of assembly: the retaining springs 7 can be put on using a thin wire or wire.

If new shoes make it difficult to put on the drum, they can also be tightened

inside using pry bars.

Video

Modern cars are equipped with a significant number of active safety systems, the task of which is to prevent the driver from losing control of the car in different driving situations. These include the anti-lock braking system (ABS).

Note that ABS is the first among active safety systems that began to be widely used on cars. At the same time, it also acts as a basis for other systems.

The first working samples on cars began to be used more than 40 years ago. As technology developed, it was improved and refined. For example, the first systems included more than a hundred components, but the latest versions of the ABS system consist of only 18 elements.

Is it possible to do without the ABS system?

As you can see, the ABS braking system is smart enough to manage our braking force optimally, because the electronics are responsible for this. Hence, by the way, the braking distance is shorter, thanks to the laws of physics, the system calculates the optimal dose of sliding and resting friction forces, provides blocking in time and releases it in time so that you don’t even feel these transitions, but simply hold the brake pedal almost to the floor. But these are all the machinations of technological progress, but what about those who have an older car and have not yet been equipped with such “intelligence”?

Previously, they coped something like this: they pressed on the brake, then released it, pulled the steering wheel in the direction of avoiding the obstacle, pressed the pedal again, etc., creating an anti-blocking effect, roughly speaking, manually. But this is fraught with the same drifts, and therefore not all drivers cope successfully with emergency situations. And braking efficiency also suffered, the braking distance was even longer and the trajectory was not always adequate. So there was a chance to avoid an accident, but it was significantly less than with ABS on a modern car.

The Anti-lock Braking System (ABS) is an electro-hydraulic active safety system that helps maintain vehicle control and stability when braking by preventing wheel locking. ABS is especially effective on road surfaces with a low coefficient of adhesion, as well as in bad weather (snow, ice, rain). The abbreviation ABS stands for Antilock Brake System, which literally translates as “anti-lock braking system”. Let's consider the principle of operation of the system, its main components, generations, as well as the pros and cons of use.

Features of the system

ABS is installed on the braking system and makes its own adjustments to its operation. From the name itself you can understand that its task is to prevent wheel locking during braking.

The peculiarity of car wheels is that their rolling friction force is higher than sliding friction. That is, a wheel that rolls has better adhesion to the road surface than a wheel sliding along the road surface, which happens if it is completely blocked. As a result, the braking distance of the car increases.

Also, wheel sliding does not always occur in a straight direction, since lateral forces can prevail over longitudinal ones, which is why the trajectory of movement of such a wheel changes. The result of this is unpredictable and uncontrolled movement of the machine.

But if you create a force on the braking mechanism that will slow down the rotation speed as much as possible, but without blocking it (keeps it on the edge), then the braking distance will be shortened and the car will not lose control.

In cars without this system, experienced drivers use the method of repeatedly pressing the pedal (intermittent braking) to obtain maximum braking effect. To prevent the wheels from becoming blocked, the driver presses the pedal when braking, then releases it and repeats this many times.

The essence of this method is very simple - to catch the moment on the brake mechanisms when they slow down the wheels as much as possible without causing them to lock, but this is not always possible, especially if the wheels are moving on different surfaces.

Intermittent braking (press and release) does not allow the wheels to completely lock, since the driver simply periodically loosens the force on the brake mechanism. ABS uses the same principle.

The need to replace the device

Malfunctions in the ABS system are indicated by a warning lamp located on the dashboard of the car. In normal mode, the indicator lights up when the engine starts and goes out after 3–5 seconds. If the controller behaves incorrectly - it turns on while the engine is running or blinks chaotically when the car is moving - this is the first sign of a sensor failure.

The ABS indicator should go out 3-5 seconds after starting the engine

Also, a possible device malfunction is indicated by:

- an error code appears on the on-board computer display;

- continuous wheel locking during heavy braking;

- absence of characteristic vibration on the brake pedal when it is pressed;

- the parking brake indicator lamp has been activated when the handbrake is off.

If any of these problems occur, the device should be fully diagnosed. It is not at all necessary to trust this question to highly paid car service technicians - checking the ABS sensor yourself takes little time and is done without expensive equipment. If diagnostics reveal that the device is broken, it will have to be replaced with a new one.

Design and purpose of components

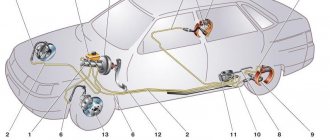

The anti-lock braking system consists of three main components:

- Wheel speed sensors

- Control unit (module)

- Actuator

Car ABS elements

As noted, this system is often used as a basis for others. At the same time, the components of a number of other systems are only an addition to the ABS.

Sensors

Speed sensors are very important components, since the operation of the ABS system is based on their readings. Based on the pulses they supply, the control module calculates the rotation speed of each wheel, and based on the calculations, the actuator is controlled.

Location of the speed sensor on the wheel hub

The ABS design uses two types of sensors. The first ones are called passive sensors. These elements are of the inductive type.

Their design includes the sensor itself, consisting of a winding, a core and a magnet, as well as a gear ring used as a driving element. The ring gear is mounted on the hub, so it rotates with the wheel.

Inductive type sensor

The essence of the functioning of the passive element is very simple - the winding generates a magnetic field through which the gear ring passes. The existing teeth, when passing through the field, influence it, which ensures the excitation of voltage in the sensor. The alternation of teeth with cavities ensures the creation of voltage pulses, which make it possible to calculate the speed of rotation of the wheel.

How to change

According to the ABS scheme, all wheels of the car are equipped with sensors. The peculiarity of their replacement is that the elements installed on the front axle of the car are removed from the bottom of the body or from under the hood of the car. The rear sensors can only be accessed from below. This instruction describes the general principles of replacing the device. Note that this method is applicable to many foreign and domestic cars.

Tools

To change the sensor you will need:

- reliable jack;

- wheel wrench;

- a set of open-end and socket wrenches;

- hammer;

- flat screwdriver;

- metal conditioner WD-40;

- tester (multimeter).

Phased replacement

We will consider the step-by-step execution of work using the example of replacing a device installed on one of the rear wheels of a car.

- Let's park the car on a flat surface and activate the parking brake (handbrake). We will place wheel chocks under the wheels that are not involved in repair work. Remove the negative terminal from the battery.

- We dismantle the rear row of seats, the plastic trim of the threshold and the rubber door seal.

- Let's get to the sensor connector - bend the clamps and pull out the plastic trim in the area where the shock absorber is mounted. Let's disconnect the device.

View from the interior: 1 — connector; 2 — clamp; 3 — overlay; 4 - sensor wire

The wheel must be removed by installing safety supports under the bottom of the car.

View of the rear part of the hub: 1 — bracket; 2 - mounting bolt

View of the arch: 1 and 2 — sensor wire fixation points; 3 - plug

Attention! Before installing the trim elements, turn on the ignition and start the car engine. Only after making sure that the ABS indicator lamp behaves correctly (it goes out 3-5 seconds after the start) do we continue to work.

As a visual aid to help you replace the device, we offer the following video.

Video: How to change the ABS sensor on Renault Logan

Generations and species

The modern system installed on a car is four-channel. It includes two valves for each wheel, as well as one pressure accumulator and shock-absorbing chamber per circuit (of which there are two).

In general, this system already has 5 generations. The first of them appeared in 1978, the second replaced it in 1980 and was installed until 1995, after which the 2nd generation replaced the 3rd. The modern 4th generation of the system appeared in 2003, and now the 5th generation is in use, which continues to be used to this day.

In terms of design features, the four-channel system is the latest and most technologically advanced. But it was preceded by:

- single-channel system (it used only two valves, which regulated the pressure in all lines simultaneously. It is noteworthy that in the single-channel type the system usually made adjustments only in the drive axle mechanisms, that is, the ABS worked only with two wheels);

- two-channel (in this type of ABS, the brake mechanisms are divided along the sides, each of which has its own set of valves. That is, one channel combines the mechanisms of the front and rear wheels of one side);

- Three-channel (it provided one set of valves for the wheels of the rear axle, and the front ones were each equipped with its own channel).

Nowadays, these three types of ABS systems are found only on older cars.

Replacing the “grenade” with the Lada Granta

1) First, you need to place the car on a hard, level surface so that you can jack it up.

2) Remove the wheel using a wheel wrench.

3) Loosen the hub nut with a 30mm socket. If it is difficult to turn, use the iron pipe as a lever.

4) Remove the brake caliper.

5) Remove the 2 bolts from the ball joint.

6) Unscrew the hub nut completely, take the mounting tool and remove the hub from the CV joint (and from the ball joint).

7) Pull off the boot and remove the grease, otherwise there will be a lot of dirt.

Using a hammer, carefully knock out the “grenade”.

Using a hammer, carefully knock out the “grenade”.

9) Don’t forget to remove the retaining ring with a screwdriver.

10) On the left in the photo is a CV joint made by AvtoVAZ, and on the right is Belmag. As you can see, of these particular samples, the VAZ one is preferable, since it has better calcination.

11) Take grease and fill the entire grenade bearing with it.

12) Put on a new boot and put lubricant in it. Then install a new retaining ring.

13) Screw the hub nut onto the CV joint.

14) Using a hammer on the nut, hammer the “grenade” into place

During the process, it is extremely important to keep the CV joint level in relation to the drive

15) Tighten the boot clamps.

16) Unscrew the nut, then reassemble everything in the reverse order of removal. We recommend coating all bolts with graphite to prevent them from souring.

17) Do not forget to move the ABS ring from the old CV joint if it is not on the new one, otherwise problems with its operation may arise.

Replacing a CV joint is a difficult and quite responsible undertaking, since if you do something wrong, there is a risk of damaging other components and assemblies.

The scheme described above is valid only for an external “grenade”. To get to the inside, it is advisable to put the car on a lift, drain the oil from the gearbox, perform a series of manipulations to remove the hub from the CV joint, and then, using a mounting tool, carefully, trying not to damage the protective ring, pull the drive out of the gearbox.

After that, holding it in a vice, you can comfortably begin replacing it. That's all for today, good luck on the roads!

Operating modes

The anti-lock braking system can operate in three modes:

- Pumping. In this mode, the brakes operate as usual. After pressing the pedal, the fluid goes to the mechanisms, the wheel slows down its rotation. In this mode, the inlet valve is open and the outlet valve is closed, that is, the liquid moves only along the supply line;

- Hold. If the unit calculates from the signals that one of the wheels is reducing rotation faster than the others, it will close the intake valve. As a result, the force of the mechanism will stop increasing, so the deceleration of the wheel stops at a certain level. On other mechanisms, the force will continue to increase;

- Pressure release. If, even after switching to the holding mode, the wheel still continues to slow down, the control unit activates the exhaust valve (closes the inlet valve) and part of the fluid goes into the pressure accumulator, thereby reducing the pressure in the mechanism (the wheel is released and begins to increase speed). As stated above, one battery is intended for two brake mechanisms (part of the circuit). There are situations when the pressure is released from both of these mechanisms at once, so the volume of the battery may simply not be enough. And then the pump starts working, pumping the excess into the main line.

ABS system diagram

During braking, the system changes its operating mode many times, which ensures effective braking. At the same time, the driver does not need to “play” with the pedal to prevent wheel locking; the system does everything itself.

How to properly and quickly bleed ABS brakes with your own hands

The procedure for bleeding the brakes is influenced by the design of the system, the location of components and the presence of additional electronic modules. The correct sequence is important. You need to start by relieving the pressure in the hydraulic accumulator. To do this, you need to turn off the ignition (it is not necessary to start the engine) and pump the pedal.

A simple secret to quickly pumping brakes. Video:

Read how to bleed ABS brakes and stock up on the following materials, parts, accessories and tools:

- spanner;

- a rubber (possibly plastic) hose with a diameter corresponding to the thickness of the fitting tip;

- brake fluid;

- container (necessarily transparent). This is where you will drain the old brake fluid.

You cannot do without an assistant who must press the pedal on command. You will perform manipulations with the fittings that ensure the removal of liquid.

Bleeding ABS brakes, where the components are located in one unit, differs little from the standard procedure. The only thing you need to do is turn off the system by pulling the fuse. This method works on domestic Ladas.

You can take advantage of the built-in pump. Then you will have to pump with the ignition on or even with the engine running. The sequence and order of bleeding the brakes starts with the right front cylinder and looks like this:

- disconnect the terminal of the level control sensor fixed on the expansion tank cover;

- remove the cover;

- open the brake reservoir;

- fill the reservoir to the brim with brake fluid;

- put the hose on the tip of the fitting;

- lower the end of the hose into a container to collect liquid;

- open the fitting by turning it a quarter or half a turn;

- to activate electronic systems, turn on the ignition;

- release the brake;

- wait until the pump expels the airy mixture;

- release the brake pedal;

- Tighten the fitting with a wrench.

The brake bleeding scheme is no different on any car, be it Patriot, Lacetti, Ford, Passat, Gazelle. First, air is removed from the “far” circuit (for “left-hand drive” cars it is on the right), then from the “near” circuit.

Important: When bleeding, keep an eye on the brake fluid level. If it falls below the minimum, the system will fill with air. Then the work has to be done again.

To bleed a system with components located in different places, a diagnostic tester is needed. It connects to the car and allows you to control electronic components using a smartphone or computer. In this case, you will also have to unscrew the fittings and drain the airy liquid. However, no manipulation of the pedal is required. Instead, the valves and electric pump must be activated using the appropriate menu items. This way you can bleed the systems on the VW Passat B6 and other modern cars.

Bleeding the brakes using the Priora as an example

Before you bleed the ABS brakes, you will have to drive the car into a pit. This will help you gain convenient access to the fittings on the rear cylinders and will allow you to avoid removing the discs during operation. On the Priora, the procedure for pumping brakes with ABS does not differ from that adopted on simpler models. The only difference is that the work must be performed by first turning on the ignition. In this case, the solenoid valves will be in the open position.

How to properly bleed the brakes on a Priora with abs with your own hands, video:

The work starts from the right rear and is done like this:

- disconnect the wires from the tank lid;

- unscrew the lid;

- Fill the reservoir with brake fluid to the brim;

- remove the protective cap;

- loosen the fitting using a spanner wrench;

- connect a tube to the tip of the fitting;

- lower the tube into the container;

- pump the brake pedal;

- press and hold it in this state (you need an assistant for this);

- open the fitting by turning it with a key;

- wait until the fluid flows out (the brake pedal goes down);

- tighten the fitting;

- pump up the pedal and release the “brake” until liquid that does not contain air bubbles comes out of the tube;

- tightly tighten the drain fitting;

- remove the tube with the spanner;

- put on the cap.

After this, it is necessary to repeat the work on the remaining three cylinders. To access the fittings on the front cylinders, you will have to jack up the car and remove the wheel rim.

Pumping the brakes using the example of “Grants” and “Kalina”

The technology for pumping brakes with ABS on the Kalina and Granta models is no different from that described in the section for Priora. Therefore, you can safely use it1, it is suitable for the entire model range of the VAZ brand.

Advice: after bleeding the brakes, do not rush to leave the garage immediately. It is necessary to check their system functionality. Make sure there are no pedal dips or leaks.

Advantages and disadvantages

Other advantages of this system also include:

- maintaining the trajectory of movement during braking when entering a turn;

- maneuvering is allowed when braking;

- convenience for novice drivers.

But ABS is not perfect. Under certain conditions, this system may not function correctly and may make errors. And this affects the effectiveness of braking and can somewhat disorient the driver.

These conditions are:

- road with problematic surface;

- sand;

- ice;

- surface with bumps, “comb”.

In general, ABS works great only on a flat road with good wheel grip. In other cases, the ABS system may make errors.

For example, on a problematic highway with frequently alternating surfaces (the asphalt alternates with crushed stone or other bulk material), the system will not be able to select the optimal force on the mechanisms, which is why the braking distance increases.

When flying off the road, ABS is also not a “helper”. Here, blocking is the best way to stop the car as quickly as possible.

The peculiarities of the anti-lock braking system also include some delay in activation when driving at high speeds (over 130 km/h). It’s just that under such conditions the control unit needs some time to make calculations and engage the valve body.

At low speeds (10-15 km/h), the system turns off completely. If this is a stop on a flat surface, then turning off the ABS has no effect, but when braking on a descent, deactivating the system can have a negative impact.

Note that disabling ABS is a relative concept, since the system operates constantly and cannot be turned off. Here, deactivation should be understood as a transition to “standby mode”. That is, it is activated again and will begin to perform its function the next time you press the brake pedal. The only time it won’t turn on is when braking when driving at low speeds.

Signs of a malfunctioning speed sensor

Malfunctions of the Lada Granta speed sensor are associated with its location near the road surface, which causes intense exposure to water, dirt, sand and reagents that are sprinkled on roads in winter. Speed sensor malfunctions manifest themselves as follows:

- when driving, the speedometer needle does not deviate from the initial mark or works only periodically;

- the speedometer readings are very different from the actual speed;

- the engine is idling unsteadily;

- engine thrust decreases;

- fuel consumption increases.

The last three signs may be a symptom of other malfunctions, for example, a broken oxygen sensor. In this case, the engine ECU incorrectly determines the composition of the air-fuel mixture.

Improvements and improvements

Engineers have brought the ABS design to a high level and there is practically nothing to improve. Only some components are subject to modifications. Thus, wheel sensors now not only measure rotation speed, they additionally integrate G-sensors and accelerometers.

Improvements also include increasing the functionality of the electronic unit (that is, the use of ABS as a basis for other systems). For example, the ABS control unit is used in the traction control system and brake force distribution.

Causes and their elimination

If you have repaired the ABS problem yourself, in most cases the light will go out after a few trips with the brake pressed. If everything is in order, the system will see this and turn off the lamp.

This is all the information related to self-diagnosis. It’s unlikely that you’ll be able to find anything else on your own. A good car service center will connect a scanner to your Lada Granta, which will be able to read the system and identify the cause. Most often the sensors or control unit are to blame. Subscribe, good luck to everyone on the roads, look forward to many more interesting things!

Source

What brake fluid should be used on the Lada Granta

In order to replace the used fluid with a new one, it is recommended to purchase “ROSDOT”, produced in the city of Dzerzhinsk, or “KAPROS-DOT”. The volume of the replacement reagent must be at least 450-550 milliliters. According to consumer reviews, most of them prefer to use ROSDOT brake reagent for replacement. According to research by the magazine “Behind the wheel”, the brand of brake fluid in question occupies the best place in the ranking. This may be a significant reason for choosing this particular brand for replacement.

Studies were carried out on the composition of DOT-4 working fluids. All of them can be combined with each other. True, there are slight differences between the substances and each other.

Modern classes of brake fluid differ from each other in purpose:

| Brake fluid | Description and purpose |

| DOT-3 (glycol based) | Used for vehicles traveling at moderate speeds. These vehicles are equipped with drum brakes or front disc brakes. |

| DOT 4 (mostly glycol) | It is widely used on new generation cars that develop high speeds and are mainly equipped with disc brakes for all wheels. |

| DOT 5.1 (mostly glycol based) | Used on fast racing cars that have high thermal overheating of the brake system. |

| DOT 5 (base consists of silicone) | It is almost never used on common cars. |

It is not recommended to mix the working reagents listed above. The only exception is that good mixing is possible if the color scheme of the reagents used is not particularly different from each other. If the Granta has ABS, then the on-board computer installed on it controls all the actions of the anti-lock brake.

In other words, ABS is built into the braking system of the Lada Grant. In the presence of such a system, the computer regulates the opening and closing of valves, pressure, and a jerk for pumping is organized.

Self-correction of ABS light coming on

Let's consider what measures need to be taken to fix the problem without going to a car repair shop:

- Lift the hood, disconnect the wires leading to the battery.

- The ABS electronic control unit is located directly under the hood. As a rule, it is located together with a hydraulic modulator, which distributes braking forces. This element can be recognized by the large number of brake pipes connected to the block and a bunch of auto wires with a connector.

- Next, you need to disconnect the connector and carefully examine whether there is any damage or liquid on its surface. If necessary, you need to blow out the connector and dry it thoroughly.

- Check the fuses. It's better to do this first, but it's okay if you take such actions at this stage.

The anti-lock braking system is controlled by several fuses. They are most often located in the mounting block located under the hood.

Then everything is a little more complicated:

- It's good if you have a car lift to look at. If there is no such installation, you can use a jack. The main thing is to first look at the wires that are connected to the wheel sensors to avoid damage. In most cases, the wiring rubs against the surface of the wheels or flies off the retaining mounts - this leads to the light bulb coming on.

- The design of the sensor on wheels involves connecting it to a wire with a connector attached to the end. The wire can be up to 1 meter long. You need to locate these connectors, check whether they have contact and what quality it is. Inspect the connector surface for moisture or rust.

- If your efforts have led nowhere, and the ABS light is still on, a visit to a car repair shop is necessary. It happens that it is not possible to eliminate the error by “rebooting” (by removing the battery terminals).

Above we described the steps for independently detecting a malfunction in which the ABS light is on and eliminating it. Car service specialists will connect your car to computer diagnostic equipment, and with its help they will determine the cause of the breakdown. From time to time, quite serious cases arise that require immediate professional help.

Why is the ABS light on and what should you check immediately?

Firstly, in these circumstances, you need to go to a car wash and thoroughly wash the wheel rims. It often happens that after the high-pressure wash is completed, the ABS sensors, which are located near the brake discs, are cleaned. While you're heading to the car wash, test the brake system again. Pick up speed 80 km/h, close the windows in the cabin, turn off the sound of the tape recorder. If the wheels (front or rear) make a barely audible or annoying hum while driving, then most likely the light indicates a wheel bearing failure.

In addition, additional activities can be carried out:

- inspect the fuse box, change the module responsible for the functioning of the anti-lock braking system;

- if possible, recognize the error code and inquire about it on online forums;

- contact a specialist who needs to describe the situation in detail, and then try to fix the error yourself;

- jack up the car, unscrew the wheels and see if the ABS sensors are dirty;

- examine the electronic control unit located under the hood (if there is moisture on it or inside);

- Still, the best way out of this situation is to have the car’s anti-lock braking and electrical systems diagnosed at a service station.

Without a doubt, the last option is the most reasonable, since you can get specific information about the causes of the breakdown (why the ABS light is on), find out whether the problem is serious, and also determine the cost of repairs. Only in this way will you get rid of the problem associated with a burning ABS light and other troubles in the operation of the vehicle.

It will be enough to connect computer diagnostic equipment with the latest program for the most complete and accurate testing of the car and identifying errors. Spend just a few minutes and you will be given the information you need to fix the problem yourself or have it professionally repaired.

We recommend

If you belong to the category of people who are used to coping with difficulties themselves, we will tell you how to properly correct the problems that have arisen.

Brake fluid for Lada Granta

A modern car produced by VAZ, the Lada Granta brand, is characterized by the presence of a functioning brake system, equipped with a hydraulic vehicle driving system. It is necessary to change used brake fluid according to the existing conditions specified by the manufacturer: according to the time passed, the time it was used and the kilometers traveled.

The technical operating conditions indicate how much brake fluid should be available to be used for replacement, and what brand of brake reagent is most suitable.