Types of engines for Lada Vesta

Both domestic and imported engines are installed on the car. Such engines have characteristic features, advantages and disadvantages.

Domestic

The car was initially equipped with three different power units: two 1.6-liter engines and one 1.8-liter. The 27th and 29th engines were designed at the AvtoVAZ plant, their full markings were 21127 and 21129. The first option had to be abandoned over time.

The VAZ-21127 engine had a long service life and good technical characteristics, but its non-compliance with Euro-4 standards forced AvtoVAZ engineers to look for a way out of this situation. The solution to the problem was found in the following - to bring environmental performance indicators to perfection by upgrading the engine.

Main changes:

- the compression ratio was reduced from 11 to 10.45 in the 29th engine;

- the control unit controllers received new firmware with a completely different algorithm;

- the exhaust and resonant starting system has undergone modernization;

- The parts of the connecting rod and piston group have been lightened.

The 21129th engine joined the ranks of 16-valve engines. The manufacturer managed to technically improve the Lada engine without changing the displacement or loss of power.

Starting from February 2016, AvtoVAZ is launching a 1.8-liter engine (21179) into series for the first time. The new proprietary engine is designed for the following models: Vesta, XRAY and Largus.

From Nissan's foreign partners

You can also find a modification with a Nissan-Renault HR16DE-H4M 1.6 liter power unit under the hood. It was designed with the participation of foreign engineers. The Nissan engine works great on both AI-92 and AI-95. At the same time, the internal combustion engine (ICE) was equipped with a chain instead of a timing belt, which allowed it to outperform its counterpart somewhat in terms of actual service life.

Real fuel consumption

According to AvtoVAZ: Fuel consumption depends on the vehicle and transmission.

But we immediately note that in some operating modes the 21179 engine turned out to be much more economical than all 1.6 liter engines. What is the real fuel consumption on the West? Real fuel consumption: After talking with car owners, it becomes clear that fuel consumption is not quite as economical as the factory tells us:

Vesta sedan + robot

- mixed consumption - 7.3 l per 100 km

- city - 9.3 l

- track - 6 l

(with a loaded weight of 1230-1380 kg depending on the configuration)

Vesta sedan cross + manual transmission

Vesta sedan cross + robot

Vesta SW + robot

Vesta SW Cross + robot amt

Vesta SW Cross + manual transmission

Xray + manual transmission

Xray + robot

Xray Cross + mechanics

- mixed consumption - 7.5 l per 100 km

- city - 9.7 l

- highway - 6.3 l

Based on the power characteristics, it becomes clear why Vesta 1.8 has a decent amount of fuel. The reason for this is high torque at low speeds. The power unit has high efficiency, “Locomotive traction” starts almost from 1500 rpm.

Engine 21179

AvtoVAZ was the first to introduce variable valve timing and use selective assembly on a conveyor belt. The 1.8-liter engine (122 hp) is not very different in appearance from the current VAZ sixteen-valve engines.

Updated engine parameters 21179:

- Throttle valve without mechanical drive.

- The cylinder head has additional oil channels for the phase regulator and lightweight Mahle valves.

- The catcollector is supplied by Russian, the diameter of the input channels is increased to 39 mm, the oxygen sensor bears the Bosch emblem.

- Crankshaft with increased crank radius.

- The working volume of the cylinders has “increased” due to the larger piston stroke.

- A reliable high-performance water pump is purchased from the Korean company GMB.

- For the first time, a VAZ has installed an imported GMB oil pump with increased performance.

- A new automatic timing belt tensioner with two rollers from the German company INA was used.

- Lightweight connecting rod and piston group manufactured by Federal Mogul.

- The fuel rail, injectors with increased productivity, and the spray pattern are optimized for the workflow of the new engine.

Specifications

Making the right choice when buying a car will be much easier with a deeper knowledge of the characteristics of this engine.

Features of the power unit 21179:

| Engine capacity, cc | 1774 |

| Maximum power, hp | 122 — 145 |

| Maximum torque, N*m (kg*m) at rpm. | 170 (17) / 3700 187 (19) / 3600 |

| Fuel used | Gasoline AI-92 Gasoline AI-95 |

| Fuel consumption, l/100 km | 6.8 — 7.9 |

| engine's type | In-line, 4-cylinder |

| Add. engine information | Electronic fuel injection |

| Number of valves per cylinder | 4 |

| Maximum power, hp (kW) at rpm | 122 (90) / 5900 122 (90) / 6050 145 (107) / 6200 |

| Supercharger | No |

Advantages and disadvantages

Even the leaders of the global automobile industry do not have ideal cars. Potential buyers will be interested in what the main advantages and disadvantages of this car are compared to old AvtoVAZ models and other cars presented in this price category. It is the ratio of pros and cons, expressed by differences in technical characteristics and convenience parameters, that primarily influences the consumer’s choice.

Positive features of the engine:

- Oil pump with increased power.

- Imported camshafts are lightweight.

- The cylinder head received additional oil channels that deliver fluid to the new phase shifter.

- The cooling system has been improved, an imported water pump of greater power with high reliability indicators has been used.

- The systems are controlled similarly to the VAZ 21127 model through DBP and DTV, and not through the previously familiar mass air flow sensor, which also has a positive effect on the reliability and stability of operation.

- The domestically produced intake tract was made specifically for the characteristics of the new power unit.

- The new engine is adapted for the use of cheaper fuel with an octane rating of AI-92.

- Maximum power - 122 hp. s., torque - 172 N/m. The engine received a flat torque plateau, which allows it to achieve a torque of 127 N/m at 1000 rpm, which is 7 N/m higher than the maximum performance of the base VAZ 11183 engine.

Despite the positive aspects, the engine of this car has its disadvantages.

Engine disadvantages:

- The engine is a modification of the 16-valve Priora engine. For some, it rattles when not warmed up or at idle, and often whistles. Such a whistling sound is generally characteristic of such a motor, so you can simply ignore it.

- The weak link of such engines remains the electrics: some complain about the gas pedal, starts on the 2-3rd attempts, even when it’s warm, and unstable idle. A Vesta with a Euro-5 engine only needs high-quality gasoline; bad fuel can cause hang-ups and bent valves.

- The new 1.8 engine for Vesta may surprise you with increased oil consumption at the start of driving. There was a theory that the cause could have been poorly processed Chinese valve stems, which AvtoVAZ quickly replaced with others, thus eliminating the problem.

Design nuances

Engine Nissan YD25DDTi

The 21179 engine bears little resemblance to the basic version 21127, as both the design and appearance have changed:

- phasing of intake valves within ±30 degrees;

- hollow camshafts with cams using powder metallurgy;

- vortex air supply into the combustion chamber;

- cylinder cooling system (jacket);

- improved configuration and cylinder head gasket volumes;

- ShPG Federal Mogul;

- Korean pump;

- inclined drilling of oil channels in the crankshaft journals;

- polymer cylinder head cover and solid aluminum pan;

- flywheel for clutch 215 mm, which is recommended by the manufacturer.

Motor gaskets

ShPG from Federal Mogul

Motor 21129

The new VAZ 21129 engine is based on the 21127 model, which is installed on cars: Granta, Kalina, Priora. Both engines feature a modernized air intake system. Instead of a mass flow measuring device, absolute pressure (AP) and air temperature (AT) sensors are used. A system of dampers is used to regulate the length of the intake manifold, which allows the engine to operate optimally at both low and high speeds. The new power unit is designed for Euro-5 and adapted for manual transmission from Renault.

For engine 21129, the changes affected:

- cylinder block - increased rigidity;

- lubrication systems;

- fuel injection;

- attachments of additional units;

- engine suspension;

- exhaust system and a set of engine control elements.

21129 uses a lightweight connecting rod and piston group. Short skirt pistons are cast from aluminum alloy. There are four small recesses in the bottom of each piston for the valve plates, but they do not prevent the valve from contacting the piston in the event of a timing violation or a broken timing belt. Each piston has two compression rings and one oil scraper ring. They are thinner than previous models to reduce internal friction losses.

Tuning a VAZ-21129 (using the example of the sports version of Vesta) without installing a turbine and compressor allows you to increase power from 106 to 150 hp. With.

Specifications

The Lada Vesta engine is a familiar engine, which received the index 21129. The technical characteristics of the VAZ 21129 power unit differ from the VAZ 21179 engine in some respects.

Motor parameters 21129:

| Production | AvtoVAZ |

| Brand | 21129 |

| Years of manufacture | 2015-present |

| Cylinder block material | cast iron |

| Supply system | injector |

| Type | in-line |

| Number of cylinders | 4 |

| Valves per cylinder | 4 |

| Piston stroke, mm | 75.6 |

| Cylinder diameter, mm | 82 |

| Compression ratio | 10.5 |

| Volume cc | 1596 |

| Power hp/rpm | 106/5800 |

| Torque, Nm/rpm | 148/4200 |

| Fuel | 92-95 |

| Environmental standards | Euro 5 |

| Weight, kg | 109 |

| Fuel consumption, l/100 km (for Vesta) city highway mixed | 9.0 5.3 6.6 |

| Oil consumption, g/1000 km | up to 200 |

| Oil | 0W-30 0W-40 5W-30 5W-40 10W-30 10W-40 15W-40 |

| How much oil is in the engine, l | 3.2 (AMT) 4.4 (manual transmission) |

| Oil change carried out, km | 15000 (better 7500) |

| Operating temperature deg. | — |

| Lada Vesta engine life, thousand km according to factory data in practice | 200 — |

| Tuning potential without loss of resource | 150+ — |

| Installed on: | Lada Vesta Lada X Ray |

Advantages and disadvantages

The list of qualitative changes could take a long time, but it will hardly be of interest to the average user, so we will focus on the main aspects - advantages and disadvantages.

The advantages of the 21129 engine are:

- Economical consumption of coolant, engine oil and fuel.

- Compliance with Euro-5 standards.

- Improved attachments.

- Do-it-yourself overhaul.

- The declared resource is 200,000 km.

- No periodic adjustments of valve thermal clearances.

To ensure the specified motor life, the manual recommends using only high-quality lubricants from reliable manufacturers.

The disadvantages of the power unit design are:

- Expensive maintenance due to the need for high-quality oil in hydraulic lifters.

- High overhaul budget due to the use of ShPG and timing belt kits from foreign companies.

- There is a danger of bending the valves if the timing belt drive breaks.

The compression ratio has decreased by 0.5 units, which allows the fuel octane number to be reduced. In practice, the quality of domestic gasoline is unsatisfactory. Experts do not recommend experimenting in order to achieve questionable savings in the operating budget.

Change of oil

AvtoVAZ recommends using synthetic oils for its internal combustion engines. The choice of which oil to pour into the Lada Vesta engine should be based on the season: the oils recommended by the factory are synthetic 5W-30 and 5W-40, they are poured when the car is released from the assembly line, and they provide optimal conditions in average Russian conditions.

Oil selection diagram based on ambient temperature:

The oil manufacturers recommended by AvtoVAZ are Rosneft and Lukoil; their lubricants have factory approvals, which guarantees full compatibility and reliability of the lubricant. Among foreign ones, we can recommend the products of Mobil, Shell (Helix HX8 oil) and Motul (Specific DEXO s2 fluid).

For the Lada Vesta, changing the engine oil is standard and can be done by yourself:

- the engine filler plug is unscrewed (with the internal combustion engine switched off);

- the crankcase protection is dismantled, if any (you need to remove 13 bolts);

the drain plug is unscrewed (you should first place a waste container under it);

after draining, the oil filter is removed (in this case, you will most likely have to disconnect the plug from the crankshaft sensor and remove the sensor itself), using a special puller or by piercing it with a screwdriver, which then serves as a lever for rotation;

Puller:

Removal with a screwdriver:

- Next, you should wait for the remaining oil to drain, install a new filter (after pouring about half the oil into it), return the sensor and plug to their place;

- After this, the required amount of oil is poured into the filler neck, the level of which is controlled by a dipstick.

This is followed by the engine starting and control measurement after several minutes of idling. If necessary, oil is added or, conversely, excess is removed.

Cylinder block

The block is cast from high-strength cast iron. Cylinder numbering is carried out on the installation side of the crankshaft pulley. Each cylinder, based on the results of measuring its diameter, is assigned a size class.

Block 21126 is painted gray. Wall processing is carried out in accordance with the requirements of Federal Mogul. Block 21126 has three classes every 0.01 mm (A, B, C). The cylinder class mark is located on the bottom plane of the block.

AvtoVAZ pleases us with its innovations from time to time. For a long time, the VAZ series, from the cheap Lada to the stylish S7, was very popular. Later, the Lada Samara line appeared, represented by the VAZ-2108, VAZ-2109 and VAZ-21099. They were supplemented by the model range of cars of the 10th family. Now we are content with Kalinas, Grants, Priors and Vestas. Some of these models began to be equipped with a new power plant - engine 21127.

What prompted you to take such a step? And how can the new engine surprise domestic car enthusiasts now?! Let's try to answer these and other questions.

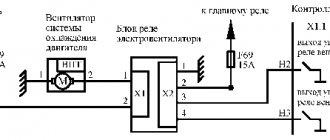

Electricity supply

The power plant is controlled by an electronic unit. The microprocessor of the unit receives information from sensors, on the basis of which it controls the power plant. The engine is powered by a battery and a DC generator.

When the engine is switched off, the power supply is supplied by the battery. The battery voltage is 12 volts. The negative wire is connected to the motor housing. After starting the engine, the consumers are powered by a DC generator.

The DC generator powers the engine ignition system and charges the battery. The generator is driven by a belt, from a pulley mounted on the crankshaft. To avoid voltage surges, a regulator relay is included in the circuit.

Pistons that do not bend valves

Such pistons exist, but not for all cars. Sometimes the automaker modifies the pistons and installs plugless ones. Third-party companies make non-original components. But such pistons have 2 features:

- non-optimal shape of the piston bottom and, consequently, the combustion chamber, reduced compression ratio;

- they are heavier.

These factors reduce the efficiency of the motor by 5-10%.

After replacing the piston group with a non-standard one, mechanics modify the engine software to compensate for the change in the shape of the piston bottom. It may also be necessary to increase the thermal gap in the CPG.

Gas distribution mechanism

The intake of the working mixture and the release of exhaust gases is carried out by a valve mechanism. Each working cylinder is equipped with two inlet and two exhaust valves. To control the valves, two cam-type camshafts are provided. The camshafts are driven by a belt, from a pulley mounted on the engine crankshaft.

To prevent lubricant from entering the cylinder during operation of the power unit, the valves are equipped with valve stem seals. To improve gas distribution, the manufacturer provides hydraulic compensators.

Cylinder head repair

We mark all hydraulic compensators with numbers using an ordinary clerical touch and put them away. An ordinary magnet will help you pull them out. We dry out the valves and remove the oil seals (valve seals), the valves into scrap metal, the oil seals into the trash. We clean all channels. We take the head for grinding, just in case. After washing it again with kerosene after sanding and blowing it with air, we begin to assemble it.

We arrange the freshly purchased valves in the sequence in which they will stand in the cylinder head and begin to grind in one by one. Lubricate the valve stem with clean oil and apply lapping paste to the edge.

We insert the valve into place and put a valve grinding tool on the valve stem. The stores sell a device for manual lapping, but since this is the twenty-first century, we are mechanizing the process. We take the old valve and cut off the rod from it, select a rubber tube for it of such a diameter that it fits tightly. The rod is in a reversible drill, one end of the tube is on it, the other is on the valve being ground in. At low speeds we begin to grind the valve, constantly change the direction of rotation and periodically press it to the seat or weaken the force. On average, the valve takes about twenty seconds. We take it out and wipe it. The valve is considered ground in if a uniform gray strip of at least 1.5 mm wide appears on the chamfer.

The same stripe should appear on the valve seat.

Tuning

Thanks to the standard design, the 21129 motor has a potential of 150 hp. The most popular modernization of internal combustion engines is in the following ways:

- tuning of the block and cylinder head - boring the cylinders up to 88 mm maximum, grinding the head channels, installing lightweight pistons;

- tuning of the intake tract – 54 mm damper instead of the standard one, filter with zero air resistance;

- tuning of the exhaust tract - spider at the exit;

- timing modernization - modification of 8.9 Stolnikov camshafts with mandatory phase adjustment.

VAZ engines are turbocharged with rotary compressors, superchargers or mechanical turbines. However, inertial mechanical pressurization is already present inside the standard receiver, so this option is not economically viable.

Thus, the Euro 5 standard has been achieved in the 21129 engine without increasing power and making special design changes to the basic version 21127. The M 86 control unit of the next firmware version is used. The valves are not protected from bending by the pistons, the overall user rating is +4.

Signs of the need for internal combustion engine repair

The reasons why the operation of the engine is disrupted are arranged in a small list, starting with refusal to start and ending with floating idle speed (this problem was removed on the 127 “engine”). Not all breakdowns end in capital damage - sometimes it’s enough to add oil, sometimes it’s enough to adjust the ECU settings.

Compression reduction

A decrease in cylinder compression below 16 atmospheres is a bad sign. Such a high limit corresponds to a compression ratio of 11.

Knocks in the engine

Engine knocks can come from several points. These could be hydraulic compressors, timing belt rollers or pins. The knocking noise could also be caused by low oil level. The answer to the question will be given by a thorough detailed inspection of all parts of the unit and checking the oil level.

History of origin

Motor 21179 was already in the minds of the engineer much earlier than you can imagine. Even at the end of the USSR, developers began to think about the Lada C project and its power units. Even then, engineers “knew” this motor by its features and power characteristics. But the difficult economic situation of that time and the collapse of the USSR forced the engineers to completely forget the Lada-Ts project.

And now, after a long time, when Boo Anderson comes to the post of general manager of AvtoVAZ, the project is raised and developed again.

The main task was to create an engine with good low-end torque, which AvtoVAZ lacked for a confident, comfortable ride. “Tractor” 8-cl engines have long since become obsolete, but the new 16-cl engines had a more “sporty” character. The situation was corrected by the then 21127 engine, now 21129, which is installed on Vesta, Xray, and other AvtoVAZ models. Due to the intake receiver with variable geometry installed on it, the torque from the bottom began much earlier, unlike the Prioromotor (21126), and its shelf was much further, right up to the cutoff. But with the start of production of a sedan with a larger mass - the Vesta, and the Xray hatchback - the need for low-end engines reappeared.

The engine was run in and tested for a long time. As a result, during the testing process it turned out that the rings were already stuck at 4t.km., as a result, the heat zone was increased and the problem disappeared.

Nissan HR16DE engine with 110 hp power. It copes well with its task on front-wheel drive. But if you have all-wheel drive, it will strain, get hot, eat a lot and not drive.

Another factor in the creation of the 21179 motor is economics and politics. Because the Nissan engine, although it is assembled here, still belongs to Nissan. And in the event of an unfavorable economic situation, an increase in exchange rates, the cost of its production and sale may simply be unprofitable.

Start of production of motor 21179

Back in 2014, there were rumors about the possible production of a 1.8 liter engine with phase shifters. And yet it became a reality. Previously, OPP and its subsidiary Super-Auto were already engaged in the construction and installation of a 1.8 liter engine with index 21128, which was installed in Priora Sport. But that engine did not have a special resource.

One of the differences

The new engine is based on the previous version of the internal combustion engine - VAZ-21126. The company did not plan to make any fundamental changes, however, there are serious differences.

The main feature is the use of a modern intake system with flaps, thanks to which air enters the cylinders a little differently. When the engine revs high, it travels a long way. At idle or low speeds, air first enters the resonance chamber. As a result, the fuel burns completely, which leads to improved performance of the VAZ-21127 engine.

Now under the hood of the car there are already 106 “horses”, although the engine volume remains the same – 1.6 liters. Moreover, this applies not only to high, but also to low speeds. And here you might think that with an increase in power, fuel consumption also increased. In fact, the efficiency remains the same. This is the same 6.7 liters per hundred kilometers.

Public opinion

As many owners of 2nd generation LADA Kalina cars equipped with the new engine note, they actually felt an increase in power. This was especially noticeable at low speeds. It takes 11.5 seconds to accelerate a car to a speed of 100 km/h, and this is a great merit for domestic transport.

As other reviews show, the 21127 engine worries a number of owners, which is associated with an already pressing problem - a high risk of timing belt breakage. But here you need to either come to terms with this state of affairs, or replace the pistons, as already mentioned above. A break is dangerous not only because of bent valves; other parts can also receive serious damage.

Maintenance

In order to get the maximum engine life, new oil for the VAZ 21129 engine must be filled in after 15 thousand kilometers. As a rule, owners use 5W-30 or 5W-40 lubricant, which requires about 4.1 liters to replace, since there are 4.1 liters of it in the engine.

Since the gas distribution mechanism is driven by a belt, it should also be constantly checked. Despite the fact that manufacturers claim a service life of 180 thousand kilometers, it is recommended to change the belt along with the tensioner after 50 thousand to avoid unnecessary problems in the future.

Why does the break occur?

A broken timing belt or chain occurs for a number of reasons:

- defective or counterfeit belt/chain;

- poor maintenance, failure to meet replacement deadlines;

- Damage to the belt, chain or entire timing mechanism.

This can be avoided by timely servicing of the car at a dealer service station or in a proven service club (there is a risk of losing the warranty). A cheaper option would be to do it yourself.