Today’s post will be about How to remove the front axle on a Niva 21213. Some people don’t understand the difference between an axle and a gearbox, but in this case it doesn’t matter, you’ll still have to disassemble everything, since until you remove the wheels and drive, The gearbox cannot be removed.

For those who are interested, I can say: the axle - the wheels are rigidly connected to each other, and the gearbox with separate drives - the suspension of the wheels is independent of each other. But these are technical details, the essence is the same - the transmission of rotation from the cardan to the wheels. So this note can easily be called: “front axle Niva 21213”. Well, for those who need everything to be correct, let it be “removing the Niva front gearbox.”

General information

- A transmission is a set of mechanisms that connect the engine to the wheels.

- The front axle is the part of the transmission that connects the front wheels of the car to the frame or to the car body.

The latter will be discussed in the article. The front axle of a passenger car can be different in design, but in cars like Niva-Chevrolet, the front axle is continuous and rigidly connected to the crankcase, since the car is equipped with permanent all-wheel drive. The main advantage of a continuous axle is that due to the rigid fixation, the tires wear out much less, but at the same time all the vibration from the wheels is transferred to the car.

Even such an element as the front axle can help you stand out; Niva used all its resources - unlike the rear axle, the front axle is not only driven, but also steered. The cross-country ability of both cars under consideration, the Chevrolet Niva and Niva 2121, makes many prestigious “SUVs” envious, since many modern cars, although called SUVs, do not have permanent all-wheel drive.

Sequence of work

- We purchase (make) a tying kit. When making it yourself, we drill holes in the pan in accordance with the diameter of the studs.

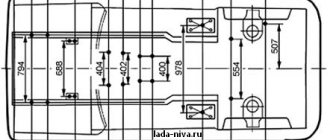

- We securely install the car on supports, preferably above the inspection hole.

- Drain the oil from the gearbox.

- We dismantle the CV joint drives, having first freed the steering knuckles of the wheels.

- Disconnect the front driveshaft from the flange.

- We remove the axle gearbox from under the car.

- On a flat working surface, separate the bottom tray and side covers of the RPM.

- On top of the CV joint drive covers, using elongated studs, we fasten the earring brackets. It is possible to replace the installation sequence of covers and brackets, depending on the kit you choose.

- Instead of a standard pan, we attach a reinforced one, with installed clamps for attaching the anti-roll bar to the beam. In addition to the factory gasket, we use sealant. The pallet will experience additional loads, so the tightness needs to be improved.

- We hang the RPM with the rear mount on the stabilizer beam. We center the axis of the propeller shaft and the axis of its flange in the gearbox.

- On the bridge beam we mark the fastening lugs for the brackets for the front suspension of the gearbox housing.

- We weld the eyes to the bridge beam and perform anti-corrosion treatment.

- We fix the earrings in the eyes using polyurethane or rubber silent blocks.

- We check the vertical alignment of the propeller shaft and CV joint drives.

- We attach the axle shafts and driveshaft, and secure the steering knuckles of the wheels.

- Fill the gearbox with oil according to the operating instructions.

- Without starting the engine or removing the car from its supports, check the free rotation of the wheels and the front driveshaft.

- We make a test drive, after which we re-inspect the car in the inspection pit.

The front axle decoupling is complete, your SUV has become much more comfortable on the highway and more reliable off-road.

Front axle device

In a Niva-Chevrolet car, the front axle has such a basic element as a differential box, since the vast majority of other components are endless gears, nuts, covers and bearings, which a person without specific training will not understand. It is worth pointing out that one of the elements of the front axle is the crankcase.

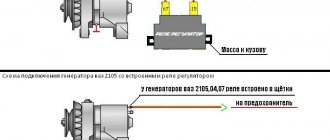

But the most interesting part is the front axle gearbox; the Niva has constant problems with it. Nowadays, almost no one does repairs; repairs are limited to installing a working element. When replacing a broken gearbox with a working one, you must remember that the new one must match the rear one, otherwise the car may break down much earlier than expected or refuse to move at all.

General rules for revision

- The untethered bridge must be fastened at three or four points that do not have a rigid connection with the engine.

- The front axle beam and anti-roll bar are used as supports.

- When determining the new position of the RPM, it is important to prevent horizontal displacement of the axes of the propeller shaft and axle shafts.

The bridge can be uncoupled using a gearbox suspension kit from Chevrolet NIVA.

Therefore, most car owners prefer steel brackets made independently or in the factory.

For cars taking part in off-road competitions, a version of the RPM steel body has been developed. This gearbox is structurally equipped with lugs for independent suspension.

There are also additional subframes for extreme conditions of use of the NIVA.

What is a differential?

The previously mentioned differential is a device that distributes forces to the wheels.

It works as follows - if one wheel slips, then when the differential is locked, the force is transferred to the other pair of wheels and at the same time the car drives out of deep mud, high snowdrifts, etc. Powerful cars are capable of driving out of deep off-road conditions with traction even of only one wheel, that is A Niva Chevrolet, whose front axle is buried in the snow and is slipping, can easily get out of the trap using the rear wheels. However, it is more convenient to drive out with the front wheels, since you can see where your front axle is pointing; the Niva 2121, for example, will not allow you to drive out in reverse comfortably - you can run into some tree or even a gas pipe.

Removing the front gearbox Niva 21213

After unscrewing the gearbox mounting bracket on the right side, it remained hanging on two studs on the left side of the engine:

I unscrew the front nut completely, and leave the second one a couple of turns unscrewed so that the gearbox does not fall out without my help!

I climb under the car, rest my right hand on the ground with my elbow and hold the gearbox, and with my left hand I first unscrew the fastening nut completely, then hold the gearbox so that it does not spin and lower it to the ground.

The weight of the gearbox is about 23 kilograms and if you don’t move it by weight, but like me, resting your hand on the ground with your elbow, it can be removed and installed without much effort.

Disabling the bridge

Some people have a passion for innovations in cars, including craftsmen who can change the front axle; Niva 2121 is the most common victim of this experiment. Disabling the front axle is done for many reasons, for example, to reduce tire wear, but the miraculousness of this method is questionable. In fact, the shutdown is carried out to reduce the fuel consumption of the SUV, while the car loses its increased cross-country ability. For this reason, the shutdown is used only on smooth and dry roads, otherwise a tall car can easily roll over when skidding.

Modernizing important elements has always been a very expensive pleasure. An important element is the front axle - the Niva can be equipped with the ability to disable it for an amount slightly less than seven thousand rubles. It is noteworthy that the amount paid for the purchase and installation of a shutdown may never be recouped - fuel consumption decreases slightly, and the Niva is rarely driven on a dry and level road.

Some useful tips:

• Since the engine no longer bears additional load, you can replace the standard hard cushions of the power unit with softer ones, from VAZ classics. • When attaching the lugs to the front axle beam, welding should be carried out by an experienced welder who is familiar with the technique, which allows not to “release” the metal. The beam is a load-bearing structural element of the car, and its strength should not be reduced. • The welding areas should be cleaned of scale, then the joints should be thoroughly primed and painted. • After untying, the RPM should not touch the engine and beam either in a static position or while the vehicle is moving. • If you are producing a suspension lift, you should select a decoupling kit that takes into account the increased angles of the CV joint and driveshaft. • The silent blocks of the brackets of the untethered gearbox are subject to wear in the same way as the cushions of the power unit or suspension elements. The replacement of these elements should be included in your list of operations during maintenance.

Leverage

All SUVs actively use all their resources, including the front axle.

At the same time, Niva manages to use such resources as people’s nerves. In addition to the familiar gear shift lever and handbrake, Niva boasts another lever that serves to control the transmission - downshift, return to upshift, lock and unlock the differential. At the same time, those who got behind the wheel of this car for the first time may have big problems - after engaging a lower gear, the lever does not want to return to an upshift! The secret is that return is only possible with the clutch depressed and at low speed. Some drivers neglect the instructions and remain unaware of the generally accepted method. Through trial and error, they figure out that shifting is possible when driving in reverse in a circle at extremely low speeds. And although this method works, its convenience is highly questionable.

Preparation

The main stage is preceded by preparation, including:

- Drain oil from the RPM through the drain hole.

- Disconnecting the driveshaft with a 13 key

- Removing the right wheel drive.

- Removing the lower ball joint on the left side.

- Removing the suspension extension.

- Removing the gearbox from the brackets on the right and left using a stop.

This is followed by disassembling the gearbox, thoroughly cleaning the surfaces from dirt and grease, and troubleshooting the components.

There was a breakdown

The front axle (Niva) often requires replacement, the price of which sometimes reaches 20,000 rubles, for those people who are constantly trying to improve their car or reduce its consumption. The actions of amateurs lead to increased wear of one or another bridge, and sometimes both at once. However, the bridge does not always fail due to human intervention, because no one has canceled simple breakdowns and wear of parts.

It's okay if you've never seen the front axle, Niva will forgive you for that. The sound will immediately let you know about a breakdown - increased noise, squealing and squeaking will be difficult to miss. Another common problem is oil leakage, but this problem can easily be identified during a technical inspection. It is easy to understand that noise occurs when there is poor engagement, wear of bearings and gears, as well as physical damage to the bridge, which is extremely unlikely, but still possible. Oil leakage occurs due to poor assembly and wear of the seals. At the same time, non-man-made transmission breakdowns are an extremely rare occurrence, since the Chevrolet Niva and Niva 2121 are extremely reliable and simple.

Removing and/or replacing the gearbox

Front

Regardless of what gearboxes are installed on the 2012 Chevrolet Niva, removal will require a lift or “pit”, disconnection of the suspension, and engine crankcase protection. Even the coupler of the exhaust pipe with the muffler will have to be loosened a little. Then we lift the engine and remove the front axle assembly with the front wheel drive. We return everything back in the reverse order.

Rear axle

The rear can be disassembled a little easier; we disconnect the rods and shock absorbers from the beam. To remove the gearbox, you will need to partially disassemble the bridge. After returning the bridge to its place, do not forget to adjust the brakes.

Why we don’t lay out all the operations from beginning to end is probably obvious. This text is still more of an educational program on how to choose a gearbox for a Niva, and not a book with step-by-step instructions for maintaining an SUV.

How to use all-wheel drive and transfer case on a Niva

Since we have already found out that when they ask the question “how to turn on 4VD on a Niva,” they actually mean how to turn on the center differential lock, let’s look at the instructions for using the transfer case.

For off-road conditions, Niv transfer cases have two options and two mechanisms. The first is a differential lock. The second is the reduction/increasing gear shaft.

On normal asphalt roads, an overdrive shaft is always used and the differential lock is turned off. This is the “normal” mode of operation of the car, when it should drive like any city car. How to install the levers correctly - read below in the section about the control of different Niva models.

The following modes are used off-road. A reduction gear without differential locking is needed when the car needs more traction - in sand, in mud, when driving downhill, when starting with a heavy trailer.

Shifting to a lower range of gears can only be done with the car stationary before starting to move through a difficult section or when driving at a speed of up to 5 km/h, because the Niva gearbox does not have synchronizers! But you can switch to a higher gear while the car is moving, with the clutch disengaged.

Blocking is used in the following cases - if the area becomes particularly difficult to pass and when a wheel slips/hangs on one of the axles. You can lock the differential while the car is moving, but before entering a difficult section of the road. Most often this function is used in conjunction with downshift. With overdrive, the locked differential can be used when driving on relatively flat sections of the road without asphalt.

Many sources write that you need to engage the differential lock when driving on slippery snow and ice. But there are no such recommendations in the user manual - they suggest, if necessary, using this function only if you are unable to move on such a surface. And “Behind the Wheel” journalists, during tests of the Chevrolet Niva, determined that on a slippery surface, the blocking only helps when driving downhill. During acceleration, this mode increases the risk of slipping, and in turns it worsens handling!

It is not recommended to make any shifts directly when the wheels are slipping. You should also not drive with the differential locked at speeds above 40 km/h . Including because such driving worsens the car's handling , increases fuel consumption and tire wear. And constant movement in this mode will generally lead to breakdown of mechanisms and transmission parts. Therefore, in all Niva cars and Chevrolet Niva, the all-wheel drive icon on the instrument panel lights up when the differential is locked. Even if you forgot to unlock it, the warning light will prompt you to correct the situation.

In practice, it can be very difficult to engage the differential lock. This happens because the coupling teeth of the units rest against the teeth of the gear. You should not apply force in such a situation - you can simply break the lever or mechanism! Such “sticking” is not a sign of a breakdown, but normal operation of the transfer case. This is a purely mechanical unit that works this way.

According to the instructions, the Niva differential lock at speeds up to 5 km/h , while pressing/squeezing the clutch twice. But the practice of car owners shows that it will be more effective to do this not while driving in a straight line, but by making a non-sharp turn. When the wheels are turned, the locking lever is easily engaged. A similar problem may occur with turning off the lock. The method is the same, but moving backwards with a slight turn of the steering wheel will be more effective.

How to control the Niva transfer case levers in all modes (detailed video)

Niva differential lock control (short video)

Does Niva have one or two transfer case levers and how to control them?

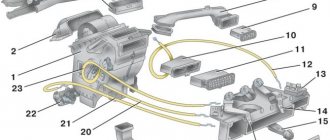

Different Niv models have different implementations of the mechanism for controlling the functions of the transfer case .

The VAZ-2121, VAZ-2131 and LADA 4×4 models (three- and five-door) use two levers. Front - differential lock. In the “pressed forward” position, the differential is unlocked. In the “pressed back” position, the differential is locked. The rear lever is an up/down gear series. Rear position - increased number of gears. The middle position is “neutral” (in this position the car will not move, even with the gearbox engaged). Forward position - downshift.

The LADA Niva, VAZ-2123 and Chevrolet Niva models use one lever. In the standard position, the differential is unlocked, and the neutral and up/down positions are the same as described above. The differential is locked by pressing the handle towards the driver and this can be done while the gear is in low/high gear or in neutral.

Control diagram with two transfer levers

Transfer case control diagram with one lever

How to adjust the gearbox

The issue of gearbox adjustment also relates to the area of deep technical knowledge, and most importantly, the skills of an auto mechanic. If, according to our records, a not very savvy driver tries, for example, to adjust the drive gear, set the side clearance of the main pair and the preload of the differential bearings, then the mechanics from the nearest service station will certainly say “thank you” to us. The car owner himself is unlikely to be happy.

You need not only knowledge, but also quite specific tools. And since we are not going to harm anyone, we strongly advise you to use the services of professionals, both in the selection of spare parts and in servicing the machine.