To ensure safe and stable thermal conditions of an internal combustion engine, precise operation of the cooling system is required. The slightest failure will lead to overheating of the engine, which can lead to burnout of the head gasket or failure of the piston group elements.

The radiator fan is one of the key components of the car cooling system. Its role is to promptly force cool the liquid in the radiator. Problems with turning it on are a common occurrence for our cars.

In this article we will talk about possible reasons why the VAZ-2110 cooling fan does not work, and also consider options for eliminating them. But first, let's understand its design and operating principle.

Fan connection diagram in carburetor and injection engines

The control of forced radiator airflow in carburetor and injection engines of the VAZ-2110 is significantly different. Firstly, the fan switch located on the radiator housing is responsible for everything. It is set to a certain coolant temperature. Usually it is 105-107 oC. When the coolant heats up to this temperature, the sensor is triggered, sending a signal to the fan relay. It closes the electrical circuit, driving the electric motor.

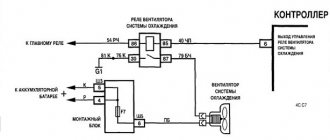

Turning on the cooling fan of a VAZ-2110 with an injection engine occurs somewhat differently. In engines equipped with an electronic control unit, there is no sensor on the radiator. Its place was taken by a temperature sensor located on the thermostat pipe. When the coolant heats up to a temperature of 105-107 oC, it sends a signal directly to the controller, which makes the decision to turn on the fan. It transmits an electrical impulse to a relay, which turns on the electric drive.

Operating principle and triggering requirements

So, the main element of the DVV is the contact group inside the node. When the desired temperature is reached, the sensor contacts begin to expand and at a certain moment close. After this, the signal goes to the ECU, which, in turn, gives a command to the fan.

What should the switch-on temperature be? You must remember that DVVs are available with different temperature limits.

Most often, switching on occurs when 92 degrees Celsius is reached, and switching off occurs at 87. Sensors are also sold with other temperature ratings, but for the VAZ-2110 the 92/87 option is most suitable - so give preference to it.

Possible faults

If the VAZ-2110 cooling fan does not work, do not rush to contact a car service center. You can determine the cause of the malfunction yourself. Moreover, it is not at all necessary to have special skills for this.

The cooling system fan may not turn on due to:

- electric drive malfunctions;

- blown fuse;

- faulty thermostat;

- a failed fan switch (temperature);

- faulty relay;

- broken electrical wiring;

- faulty expansion tank plug.

Fuse

The elementary rules of physics state that the water contained in the coolant boils at a temperature of 100 degrees.

If the fuse valve, which is located on the expansion tank, fails, and the pressure inside the tank increases, then the liquid will boil, but the fan will not start working. The cooling element will not turn on even if the electrical circuit is working properly. This all happens because the component switching sensor on the injection VAZ-2110 has a startup temperature of more than 100 degrees.

To solve the problem with the fuse, you will need to replace the cap of the expansion tank. The new part must correspond to the possible pressure inside the system and operate in a situation where the fluid temperature reaches 105 degrees. This will result in the fan blades turning on.

How to check the thermostat

The function of the thermostat in an internal combustion engine is to regulate the flow of coolant, directing it in either a small or large circle. While the engine is cold, its valve blocks the flow of coolant into the cooling radiator. This allows the engine to warm up faster.

When the coolant warms up, the thermostat valve opens, directing it to the radiator for cooling. If the valve jams, the coolant constantly moves in a small circle, not reaching either the fan switch sensor or the temperature sensor. In this case, the liquid may even boil, but the sensors, being uninvolved in such a circuit, will not work.

Check the thermostat by determining the temperature of its pipes by touch. When the engine is warm, they should all be hot. If the pipe leading from the thermostat to the cooling radiator is cold, the locking device is faulty.

How to check the sensor

One of the most common reasons why the VAZ-2110 cooling fan does not turn on is a non-working sensor for its activation (for carburetor engines) or a temperature sensor (for injection engines). Let's consider ways to check them for different engines.

In a car with a carburetor engine, you must turn on the ignition and short-circuit the two wires going to the sensor. The fan should turn on. If this does not happen, the problem is definitely not with the sensor.

For injection cars, it is necessary to warm up the engine to operating temperature and disconnect the sensor connector, disconnecting it from the vehicle’s on-board network. In this case, the controller must start the fan in emergency mode. The electronic unit perceives this as a failure in the cooling system and forces the fan drive to operate in constant mode. If the drive starts, the sensor is faulty.

Problems with the electrical circuit

If checking the reservoir cap does not reveal any faults, then the problem may lie in the circuit.

The search should begin by checking the serviceability of fuse F7. To do this, you need to gain access to the mounting block and check the contacts for the presence of oxidative traces. If nothing of the sort was noted, then proceed to the next step. Otherwise, clean the contact connections or simply replace the fuse with a new element. The part is inexpensive.

The next step is to check the fan switch sensor:

- Initially, warm up the car to 100 degrees.

- Turn off the engine and immediately start the engine.

- Open the hood and disconnect the terminal from the fan sensor.

- If, after disconnecting the contact, the fan starts working, then the unit is operational, but the sensor needs to be replaced.

- When the fan does not turn on after disconnecting the terminal, then the situation is the opposite - the sensor is working, but the fan is not.

Electric motor breakdowns are often the reason why the fan does not turn on. If all the previous measures did not help you find the problem, then you will need to dismantle the electric motor. The following problems can be identified in this node:

- The commutator brushes are worn.

- The brushes are stuck.

- There was a short circuit in the armature winding - the problem is identified by a characteristic smell.

Problems with the relay. Sometimes a situation arises when the cooling system fan start button simply fails. In this case, you will need to carry out the following work:

- Remove the trim on the right side of the dashboard inside the passenger compartment. To do this, you need to unscrew two screws.

- Under this panel there are three relays.

- The required relay is usually located on the side in relation to the front of the car.

- To be sure to act correctly, find the car's operating manual and check the wires that go to the relay we need.

- To solve the problem with the relay, you just need to install a new element. You should not skimp on this component. Cheap models break down very quickly.

Checking the cooling fan relay

The most difficult step in troubleshooting a fan is determining the functionality of its relay. It is only relatively possible to establish its serviceability at home. But you also need to know where the cooling fan relay is located.

And it is located in the additional mounting block of the center console. On the lower left side of the front passenger side there is a plastic cover covering the console. To open it, you need to unscrew four screws. There are three relays under the cover. The leftmost one is responsible for turning on the cooling fan. You can check it only by installing a known-good device in its place. After the engine has warmed up to the sensor response temperature, wait for a characteristic click. If the cooling fan relay does not work, you need to check the wiring.

Design Features

The cooling system, as a rule, consists of a large number of components. In a situation where the fan is not working, we will need to be aware of the following components:

- Actually an electric fan, which is triggered when the antifreeze heats up to a temperature in the range of 100-105 degrees.

- Fan trigger sensor. This unit is configured from the factory so that the device begins to operate under specifically established conditions. The sensor is fixed on the inlet pipe of the cylinder block. The housing is marked with the following code: LS0112.

- Fuse F7, located in the mounting block.

- Fan relay. The component is located in the cabin under the right dashboard panel.

How to check wiring

Finding a broken conductor in a car's electrical circuit yourself is not at all difficult. It is necessary to check (ring) all wires in the indicated areas with a tester.

For carburetor engines:

- from the switch on sensor to the fan;

- from the fan to the mounting block (fuse);

- from the mounting block to the relay.

For injection engines:

- from the main relay to the fan switch relay;

- from the switching relay to the fan and controller;

- from temperature sensor to controller;

- from the fan to the mounting block (fuse).

If a wiring break is detected, it must be restored, as well as the possible cause of the circuit break must be identified and eliminated.

Expansion tank cap

The last reason why the VAZ-2110 cooling fan does not work may be a malfunction of the expansion tank cap. The fact is that when the engine is running, a pressure above atmospheric pressure is created in the cooling system, due to which the water, which is part of the coolant, does not boil at 100 ° C. The expansion tank cap valve is designed to maintain the required pressure. If it fails, the pressure in the system will be equal to atmospheric pressure. This will cause the coolant to begin to boil already at 100 degrees. A sensor designed to turn on at a higher temperature will naturally not work.

It is unlikely that you will be able to check the operation of the cover at home, so if during a visual inspection you have doubts about its functionality, it is better to replace it immediately.

VAZ 2110 engine operating temperature

Normal operating temperature of internal combustion engine: +90. +95, if above +97 then the internal combustion engine will be slightly dulled, but this t is also considered normal, up to +110 is also normal, but the radiator fan should already turn on. If t is below +90, this is not overheating. We look at the thermoelement for grinding into the thermostat cover (so that when closed it does not etch into a large circle) and the serviceability of the thermoelement itself by boiling it in the thermostat cover. If the lower pipe is cold, this is not a fact that it does not poison the large circle.

I purchased a 6-hole thermostat assembled, sealed, with an Quality Control Department stamp, t 85, PRAMO, for 505 rubles. I also had a thermocouple from a viburnum, also at t 85, lying around for a long time. ___________________________________________

Kalinovsky thermoelement: ___________________________________________________

Thermostat with thermocouple: ___________________________________________________

I boiled both thermoelements in this one housing of the new thermostat, the result:

1. Thermoelement from viburnum: opened slightly at +92 (began to let water through at atmospheric pressure) at 96 opened slightly by 5 mm +100 opened by 8-9 mm diluted the water to +83 - almost instantaneous slamming.

2. Stock thermocouple Pramo: opened slightly at exactly +85 and went at atm. pressure +86 hole mm 2-3 +88 hole approximately mm 5 diluted the water to +83 - it slows down for about a minute.

Now do you understand why your operating temperature in winter is +88 and below?

There was a thermoelement left from the new PRAMO thermostat, which turned out to be a little longer (rod) and did not fit tightly into the cover of the Priora thermostat. The cover of the Priorov thermostat was drilled out a little and the thermoelement sat tightly, now it is not blown through. (before these actions I thought about it, I didn’t sit down by two mm)

via FTP video 5:52, 24.4 MB _______________________________________________________________

And now the sea trials of the Kalina thermoelement with the Pramo cover:

In weather -15, VideoAdded t coolant on the move, t air in the driver's compartment, t air flow at the carrier's feet (16.6 MB)

Via FTP, 16.6 MB ________________________________________________________________

Warming up from a cold start, with on. stove, -16 on the street, -15 coolant, -15 in the cabin, at XX, 24 minutes: here is the video, 63.4 MB:

Warming up from a cold start, with off. stove, -19 on the street, -18 coolant, -17 in the cabin, at XX, 23 minutes: here is the video, 30.4 MB: