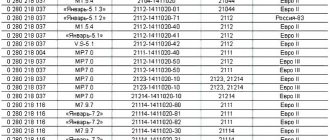

VAZ 2115 cars are the last link in the Samara family and inherited the range of engines from it. Accordingly, the engine ECU controllers and the mass air flow sensors combined with them are similar. Flow meter compatibility is determined by the ECU type, and is as follows:

- ICE VAZ 2111 - Mass air flow sensor 0 280 218 004 (obsolete) or 0 280 218 037, environmental standard Euro 2;

- ICE VAZ 21114 - MAF 0 280 218 116, environmental standard Euro 2;

- ICE VAZ 211183 - Mass air flow sensor 0 280 218 116, environmental standard Euro 3.

Actually, ecology is not related to the type of flow meter; exhaust toxicity is set by the settings of the ECU controller.

Mass air flow sensor on a VAZ 2110: how to check for a malfunction

VAZ 2110 injection power units are equipped with various kinds of sensors (including mass air flow sensors) that monitor the condition of the engine, control the quality of the fuel-air mixture, the CO content in the exhaust gases and much more. Data read from the sensors is transmitted to the electronic engine control unit (ECU), which checks and evaluates the received parameters, and then makes adjustments to the operating mode of the engine.

What is a mass air flow sensor and where is it located in the VAZ 2110

Mass air flow sensor is one of the devices involved in controlling an injection engine. The abbreviation stands for: mass air flow sensor. It is entrusted with the task of measuring the volume of air directed into the power unit. The mass air flow sensor works in conjunction with two other sensors: atmospheric pressure and air temperature.

In its modern version, the mass air flow sensor is a hot-wire flow meter. The working element is a thin platinum wire to which voltage is applied. The more air passes through the sensor, the more the wire cools. Therefore, to maintain a constant temperature, it is necessary to increase the voltage, by the value of which the ECU judges the volume of air entering the engine.

The mass air flow sensor notifies the electronic control unit about the amount of air directed into the engine

The serviceability of the device affects the optimal operation of the naturally aspirated engine. The mass air flow sensor is a small device. It is mounted on the air filter housing of the VAZ 2110. From the device there is a pipe to the throttle valve.

The MAF sensor is located on the air filter housing

PURPOSE AND PRINCIPLE OF OPERATION

The VAZ 2114 injection engine is a complex design capable of operating in different load modes. In order to ensure normal operation of the power unit and the optimal amount of gasoline consumed, the car’s electronic brains must determine as accurately as possible the ratio of gasoline and air in the supplied fuel mixture.

To determine the required ratio of fuel mixture proportions, the ECU uses the indicators of various measuring instruments - the main one is the mass air flow sensor.

Let's figure out what this DMRV is and what it is eaten with.

Mass air flow sensor (also known as a flow meter) is a sensor that determines the amount of air entering the car engine. Based on the obtained air consumption indicators, the ECU determines how much gasoline needs to be supplied to the combustion chambers.

The sensitive element of the sensor is represented by a thin platinum thread. During operation of the device, this thread heats up to a temperature of 1000 degrees and is cooled by the flow of passing air. The amount of air passed through is determined based on the temperature to which the sensitive element has cooled. The lower the temperature, the higher the conductivity of the platinum, and the greater the amount of current transmitted to the thread it conducts.

The cost of the sensor is about 2-3 thousand rubles. The products of the German company Bosch have proven themselves well, while the owners of the fourteenth, on the contrary, do not respond entirely positively to the domestically produced mass air flow sensor.

Mass air flow sensor device

Signs of malfunction and causes of its occurrence

The driver will learn about a breakdown of the mass air flow sensor by the following symptoms:

- The Check Engine light on the dashboard comes on.

- Fuel consumption increases sharply.

- The car slowly picks up speed.

- A hot engine has difficulty starting.

- The car's power has dropped.

The reasons for the breakdown can be different: from banal carelessness of the driver to mechanical damage. If the air filter is not changed in a timely manner, the air flow sensor becomes clogged faster and is unable to perform its functions. It is especially dangerous for it to get in contact with oil and condensate. The next time you replace the filter, be sure to check the condition of the rubber gasket between the sensor and the filter housing - it protects against the leakage of unfiltered air.

Connecting the MAF air sensor VAZ 2112

If the mass air flow sensor is operational, then when the engine is running at 900 rpm, the volume of air used will be at least 10 kg per hour. When the speed increases to 2 thousand, this figure will increase to approximately 20 kg. If the volume of air at such speeds drops, the dynamics of the vehicle will also decrease, and accordingly, this will lead to a decrease in gasoline consumption.

If these indicators increase, this will also contribute to an increase in fuel volume. Deviations of the parameter by 2-3 kg should not be allowed, since in this case the operation of the power unit may be incorrect.

Diagnostics

To check the air flow sensor uses several methods in garage conditions. They can be done by any car enthusiast and do not require special skills or knowledge.

Easy test of the mass air flow sensor

The easiest way to check functionality: disconnect the sensor and start the car. If there is no sensor in the electrical system, the electronic control unit switches the engine to a safe operating mode. The combustible mixture is prepared only based on the position of the throttle valve. Try driving a few hundred meters - if the car moves “faster”, then it is faulty. It should be replaced.

How to check with a multimeter

The second method involves measuring the voltage between the sensor contacts with a voltmeter.

On a note. Such diagnostics are only possible with a Bosch mass air flow sensor with original numbers: 0 280 218 004, 0 280 218 116, 0 280 218 037.

Step-by-step instructions for DIY diagnostics

- Turn on the ignition, but do not start the engine.

- Switch the tester or multimeter to voltage measurement mode. Set the scale limit to 2 volts.

- Connect the probe with the red wire from the voltmeter to the sensor terminal (the yellow wire goes to it).

To make it easier to measure the output voltage, use a pin. Be careful not to damage the insulation

The serviceability of the sensor is judged by the voltage value. To help the driver, below is a small table:

| Range of values | Air flow sensor condition |

| 1,01 — 1,02 | good |

| 1,02 — 1,03 | satisfactory |

| 1,03 — 1,04 | resource is running out |

| 1,04 — 1,05 | "near-death" state |

| 1.05 and above | it's time to change |

Help from a friend

The third unique way to test the sensor is to have a friend help you. If you have a friend who owns a VAZ 2110, ask him to borrow his working mass air flow sensor. If after replacement the car with the friend sensor behaves differently, then the mass air flow sensor should be replaced.

Important Information About the Throttle Controller

The throttle position controller in the Four is located on the same axis directly with the throttle. This controller performs one of the main functions in the operation of the motor control system. In accordance with the data that the regulator sends to the control module, the proportions of the combustible mixture are calculated. Also, the control module, referring to the sensor readings, adjusts the ignition timing.

Principle of operation

TPS works as follows:

- First, an electrical impulse is sent to one of the contacts of the device; the voltage value is 5 volts, while the other output is connected to the ground of the car, that is, the body. The TPS device involves the use of a third output - through it the signal is sent to the control unit. When the damper is turned, the voltage level that goes from the current collector slider to the output changes.

- When the ignition is turned off, you can measure the voltage supplied to the regulator; a diagnostic tester is used for this.

- When the throttle opening angle changes, the voltage parameter supplied to the control module from the damper also changes. In accordance with this, the control unit regulates the fuel supply.

- The throttle position controller is directly connected to the idle air control. When the car engine starts and if the throttle is in the closed position, then when a signal is sent to the control unit, the module activates the idle air control. In this case, an additional volume of air flow begins to enter the power unit, bypassing the damper.

Possible malfunctions and ways to eliminate them

The TPS, like any other regulator, cannot work forever, so over time, malfunctions may occur in its operation.

First, we recommend that you familiarize yourself with the signs of breakdown:

- floating engine speed when idling, in particular, most often the speed is increased;

- drop in power of the power unit, engine response will also deteriorate;

- when you press the gas pedal, you can feel dips and jerks appear, while the engine does not gain power;

- if the driver switches speeds, the motor may randomly turn off;

- even if the TPS breaks down at a certain throttle opening, power failures are possible.

For what reasons may problems occur in the operation of the TPS:

- One of the most common causes is contact oxidation. To fix this problem you will need WD-40. Using this liquid and a cotton swab, you need to clean the contacts on the device connector, as well as under the cover.

- Often the sensor breaks due to worn substrates. This problem often manifests itself in those devices whose design features include the deposition of a resistive layer.

- The moving contact of the device is broken. It is possible that the contact tip has failed, which leads to scoring and, accordingly, damage to other contacts.

- Another reason is that the throttle valve cannot open when idling. You can try using a file to file down the place where the regulator is installed - because of this, the damper should close (the author of the video is Ivan Vasilyevich).

DIY replacement instructions

How to replace the TPS:

- Before replacement, prepare a new controller, seal, and a Phillips-head screwdriver. Turn off the car's ignition, open the hood, and then disconnect the terminal from the battery to de-energize the car's on-board network.

- Find the regulator, disconnect the clamps, and then disconnect the connector with the wires connected to the device. Using a screwdriver, you will need to remove the two screws that secure the regulator to the throttle body. When the bolt is unscrewed, remove the device, as well as the seal.

- Replace the worn seal with a new gasket. The seal itself is located between the damper pipe and the regulator. Securely fix the device to the throttle body by tightening the screws as tightly as possible. If the bolts are not fully tightened, this may cause the sensor to operate in vibration conditions, which will quickly damage it.

- Then connect the connector with wiring to the device. Having done this, you can replace the car battery terminal. Make sure the replacement procedure was completed correctly. Try to open the valve itself with your hands, and then turn the drive sector of the device; to do this, you can pull the gas pedal cable. If, as a result, the sector does not rotate, then the regulator must be reinstalled, in particular, dismantled again and turned 90 degrees relative to the throttle axis.

Is the air flow sensor covered? Don't rush to buy a new one

A new sensor costs from 2 to 3.2 thousand rubles. But before we run to the nearest store or car market, let’s try to bring the old one back to life. This method of resuscitation does not provide a 100% guarantee of restoration of functionality. But it's worth a try.

First, disconnect the negative terminal on the battery. Remove the sensor from the vehicle. Remove it from the air filter housing. Disassemble the device using a Phillips screwdriver. Be careful with platinum threads, do not touch them with your hands or other objects. Clean with carburetor cleaner. Spray the liquid 3-4 times onto the areas indicated by arrows in the photo. Assemble the mass air flow sensor and install it on the car.

Accompanying photos to the process

If you are a little lucky and act carefully, you will be able to save a couple of thousand rubles.

In conclusion, I would like to note that a drop in power and an increase in fuel consumption do not always indicate a malfunction of the mass air flow sensor. But if such symptoms appear, check the air flow sensor first. Its initial diagnosis can be performed independently. An accurate check is carried out using special equipment at a service station. Be careful with your car - it will save your money and time.

Source

Crankshaft Position Controller Basics

Now we suggest that you familiarize yourself with the basic information regarding the crankshaft sensor. Where is this device located, how to check the device, what types are there? Find the answers below.

Installation location, purpose and device

The crankshaft sensor or crankshaft sensor is a small device designed to transmit information about the position of the crankshaft. The information is sent to the control module, that is, the block. The regulator is responsible for injection. The correct operation of the engine injectors, which are responsible for supplying fuel, depends on the performance of the DPKV. DPKV also affects the performance of the ignition system as a whole. As for the location, the controller is not difficult to find - it is located in the engine compartment, next to the crankshaft pulley, the sensor is fixed to the oil pump with a bolt.

Principle of operation

It is necessary to take into account that the Fours can use different DPKVs and they differ from each other not only in design features, but also in their operating principle. For example, if we are talking about an inductive type controller, then it is equipped with a steel rod with a magnet that is used to magnetize the sensor. On top of the rod there is a winding of copper wire. In this case, the operating principle is based on delivering an impulse if a metal object is located nearby.

There are also sensors whose operating principle is based on the Hall effect; the Hall controller itself is located inside the structure. If you bring a metal device to the DPKV, the state of the sensor will change. In addition, the “Fours” also use pulse devices, which are designed to generate signals of a certain frequency.

Possible problems and methods for eliminating them

How to check and determine if the regulator is not working? There are many reasons why a DPKV can break, ranging from contamination of the device to failure of the device itself or damage to the wiring.

First, let's look at the main symptoms of a breakdown:

- the car's power unit has become unstable at idle speed - the speed can increase and decrease arbitrarily;

- the power of the car engine may also decrease;

- when the driver presses on the gas, dips may occur in which the car’s power does not increase;

- there are difficulties starting the engine;

- computer diagnostics may show errors 0335 or 0336; with such problems, most likely the cause should be sought in a damaged electrical circuit near the connector.

As for the main breakdowns:

- the device case is damaged, then the only solution is to replace the sensor;

- there is a short circuit of the turns on the winding itself, due to which the control module receives incorrect signals - the device will also need to be replaced;

- natural wear and tear of the sensor - there is no escape from this, the sensor will have to be replaced;

- The teeth on the crankshaft pulley are damaged; in the event of such a malfunction, the pulley itself must be replaced (author - AUTO REPAIR channel).

How to change the DPKV yourself?

The easiest way to check the functionality of the controller is by replacing it with a known working device. If, as a result of replacement, the symptoms of malfunctions become more pronounced, then we can say for sure that the previously installed crankshaft sensor is inoperative.

How to change the device yourself:

- First, turn off the ignition and open the hood of the car.

- Find the location where the controller is mounted, look for it on the oil pump, next to the crankshaft pulley.

- If the sensor seat is dirty, it should be cleaned before dismantling the device. Make sure that the surface around the device is as clean as possible.

- Then disconnect the connector with wires connected to the sensor, unscrew the screw that secures it and remove the controller from the mounting location. Visually check for possible damage to the device body, as well as the toothed pulley.

- Before installing a new DPKV, clean the seat again. Install the new controller, tighten the screw that secures it. When tightening, be careful not to over tighten.

- Using a feeler gauge, you should also check the gap between the pulley and the controller core. Ideally, this gap should be no more than 1 mm; a slight deviation of 0.4 mm upward is allowed.

- When the DPKV is installed, it is necessary to start the power unit and check its operation. If you notice that the engine started quickly and confidently, then the replacement was performed correctly (the author of the video is the IZO channel)))LENTA).

Checking the air flow sensor VAZ 2110, 2111, 2112

The mass air flow sensor serves to transmit data about the air flow into the engine to the control unit. The sensor converts the volume of air passed through itself into digital data and, using an ADC code, transmits it to the engine control unit. Over time, the sensor wears out and transmits incorrect values.

In this article, we will step by step analyze the process of checking the mass air flow sensor using the example of a VAZ 2110. We will check it using a multimeter and computer diagnostics. Let's compare verification methods and find out which one provides more accurate information. We will also analyze the symptoms of sensor failure and tell you about choosing a new one.

conclusions

Checking the camshaft position sensor of the VAZ-2114 is quite easy and simple. Almost every motorist can cope with this task. But, it is still recommended to start diagnostic operations by connecting to the ECU and identifying error codes.

Author:

Maxim Markov

To achieve maximum fuel economy, many injection cars are equipped with a number of special mechanisms, a phase sensor is one of them. Such a device appeared on modern domestic vehicles in 2007 and is still used today. It can be found on Kalina, Ten, Priora and other masterpieces of the Togliatti plant. For those who are not in the know, I’ll tell you right away that it’s impossible to find the device on carburetor cars because it’s simply not there. All because of the vacuum-mechanical principle of ignition timing into which it is impossible to integrate the controller. It is this procedure that our today’s “hero” is responsible for, but first things first. Do you want to know how the VAZ 2114 camshaft position sensor functions and what the mechanism affects? How to identify a device malfunction and fix it? Then you have come to the right place, because this is exactly what we will talk about.

Symptoms of a problem

- Increased fuel consumption;

- Black velvety soot on spark plugs;

- Check-Engine may light up on the instrument panel;

- Poor starting of a hot engine;

- Floating speed in idle mode;

- Loss of power and dips during acceleration;

- When the speed drops sharply, the engine stalls;

If any of these signs are detected, immediately check the mass air flow sensor, as an incorrectly formed air-fuel mixture significantly reduces engine life.

How to understand that a breakdown has occurred

There are various signs of malfunction that will be noticeable even to novice car enthusiasts:

- The engine begins to operate unstably when idling. This is felt especially well when it is not warmed up.

- The revolutions begin to “float” after starting, and if you sharply press the accelerator pedal, the mechanism will stall.

- When a sharp release of gas occurs, the speed will not decrease, but will remain at 2000-3000 for some time.

- Even after warming up, the power decreases noticeably.

- If the load is full, the driver will need to engage a lower gear. In addition, it will be difficult to climb uphill and accelerate on highways.

In addition to those indicated, you can notice other “signals” that will also indicate that it is time for the technician to check the air flow sensor.

Thus, cracks may appear on the surface of the corrugated hose connecting the device to the throttle valve.

In addition, it is worth checking how the power supply works, and also inspect the wiring for damage.

The car service also diagnoses the signal level. So, if it is low, then the following options are possible:

- Mass air flow sensor 037 is disabled;

- there is a break in the circuit;

- wires are not connected correctly.

At the same time, experts do not advise limiting yourself only to these signs. To make sure what condition the mechanisms are in, a full inspection is carried out, since such breakdowns may occur against the background of malfunctions of other devices (for example, the air filter may become clogged, etc.). Repair work may be needed to restore the vehicle.

Spare part selection

There are sensors on the market in three price categories:

- Inexpensive. Typically these are Chinese-made sensors priced up to 1,200 rubles.

- Average. This category includes sensors from AvtoVAZ and foreign analogues of approximately the same quality. Their price ranges from 1400 to 2600 rudders.

- Expensive. High-quality and reliable mass air flow sensors from manufacturers Bosch or Siemens. Their price can reach 5,000 rubles.

We recommend giving preference to original sensors from AvtoVAZ or foreign analogues in this price category.

Checking the mass air flow sensor with a multimeter

- Set your multimeter to voltage measurement mode with a limit of two volts.

- Connect the positive probe to the fifth contact on the mass air flow sensor connector. The fifth pin produces an ADC signal. To make contact when the connector is connected, insert a pin without damaging the wire.

Connect the second probe to the negative on the battery.

- Turn the key in the lock to the ignition position.

- Place the positive probe on the pin and record the reading.

In our case, the multimeter showed a voltage of 1.02V. The table below shows data on the ADC in volts and the state of the sensor.

Most of the resource has been exhausted, collect money to buy a new sensor.

The sensor has served its purpose and it is time to replace it.

ADC (V) Air flow sensor condition 0.0996-1.01 New sensor. 1.01-1.02 A working sensor with a large remaining life. 1.02-1.03 Acceptable condition, but the sensor is far from new. 1.03-1.04 1.05 and higher The sensor is the source of problems in engine operation.

Checking the operation of the camshaft sensor

So, when all the questions have been considered, you can proceed directly to diagnostic operations.

The first method is manual diagnostics . How is it carried out? Let's consider this issue step by step:

- We dismantle the sensor.

- The first diagnosis is visual. It is worth inspecting the condition of the case, the presence of damage and cracks.

Sensor wire pinout

Multimeter to help

Now you need to check the contact group using a multimeter. First, we inspect the contacts for the presence of moisture, and then “ring” them. If the tester does not respond, then the sensor is faulty.

Diagnostics is carried out as follows: the “minus” probe of the tester is connected to the left contact on the sensor, and the “plus” to the central one. Next, we bring the metal plate to the sensor. A change in the voltage reading on the sensor will be immediately visible on the multimeter.

Replacing the mass air flow sensor

- Loosen the clamp securing the corrugated pipe to the mass air flow sensor.

Remove the pipe from the sensor and move it to the side.

Unscrew the two bolts securing the sensor to the air filter housing. The fastening bolts are located diagonally. Ten head bolts.

After unscrewing the fastening bolts, remove the sensor.

After dismantling the sensor, pay attention to the condition of the sealing rubber. If the rubber band is damaged, it must be replaced. You can install a working sensor with a damaged rubber band and the replacement will have no effect. The speed will fluctuate due to air leaks.

Replacing the camshaft sensor on 8-valve engines

- The sensor is attached with one bolt and a 10mm nut; by unscrewing the first two parts, you can painlessly dismantle the spare part.

- After removing the spare part, it is necessary to close the open part with the component in order to prevent dirt and dust from entering.

- If the device did not work properly due to dirt and moisture getting on the main components of the mechanism, you must remove them with a brush or rag and put them back in their place for further work. You can also use a special compressor that will supply pressurized air to remove particularly difficult clogs and components. If the camshaft malfunctions when removing the blockages, then it is worth replacing it with a working component.

- Sometimes it happens that even after replacing the camshaft, problems do not disappear. These types of problems are very rare, but it could be a sign that the gear has moved out of place and is not working properly. It will be quite difficult to eliminate this defect yourself, which is why you should seek the help of specialists.

Let's summarize

From the above, we can conclude that you can check the VAZ 2110 mass air flow sensor using a multimeter yourself. By comparing the ADC readings with computer diagnostics, we can say that the test with a multimeter is correct.

It is also worth noting that if you want to maximize the life of the air flow sensor, change the air filter more often. The manufacturer recommends replacement every 30 thousand kilometers. We recommend reducing this interval to 20 thousand kilometers, and if you mainly travel on dusty roads to 15 thousand km. mileage

The process of replacing the MAF VAZ 2110, 2111, 2112 is clearly shown in this video:

Source

Verification methods

The DPRV of the VAZ-2115 car is located under the air filter, installed near the cylinder head. In order to check its functionality, it is necessary to remove the power socket and dismantle the part.

Visual inspection

The first way to check the performance of the DPRV is a routine external inspection. The causes of the malfunction are the following:

- Cracks and chips on the body can cause penetration. A complete replacement of the part is required.

- Oxidation or breakage of contacts in the connecting socket is the reason for the lack of connection between the DPRV and the ECU. Cleaning the contacts will fix the problem.

Checking with a multimeter

In order to check the phase sensor with a multimeter, you must:

- Dismantle the part.

- Connect the multimeter terminals to terminals 1 and 3 of the sensor.

- Place the device in the resistance determination position.

- Apply a metal screwdriver or knife to the tip of the DPRV.

The device should react to metal, and the multimeter should show the working resistance of the part. Lack of response indicates damage.

Checking with a voltmeter

To check you need:

- Dismantle the part without removing the current-carrying socket.

- Turn on the ignition.

- Connect the voltmeter terminals to terminals 1–3.

- Bring a metal object to the tip of the part.

A working part should react to metal and produce a voltage of 0.7 to 0.9 V. High readings or their complete absence indicate damage.

Mass air flow sensor (MAF) 2110: symptoms of problems, diagnosis and repair

DMRV VAZ 2110 (mass air flow sensor) is an electronic device of a VAZ car, with the help of which the amount of air entering the cylinders is calculated. The MAF 2110 transmits the measurement data to the vehicle's electronic control unit, which, based on this information, determines the air-fuel ratio in the air-fuel mixture using a pulse signal.

It is not difficult to guess that the VAZ 2110 air sensor, which is responsible for the composition of the air-fuel mixture, is an important element; the fuel consumption and power of the internal combustion engine depend on the efficiency of its operation. For this reason, it is very important to monitor the condition of the sensor and correctly diagnose the malfunction. Next, we will look at what are the signs of a malfunction of the mass air flow sensor, as well as how to check and how to replace the mass air flow sensor on a VAZ 2110.

What's the result?

As you can see, if there are signs of problems and the first symptoms of the DMVR VAZ 2114 or another car appear, you should check the device as soon as possible for possible breakdown. In this case, you can quickly diagnose the air flow sensor with a multimeter in a regular garage.

We also recommend reading the article about what a car engine knock sensor is. From this article you will learn about the purpose, design, as well as signs of malfunction or malfunction of the engine knock sensor.

Based on the readings obtained from the device, it is possible to determine the malfunction (if a breakdown is confirmed) or to exclude the mass air flow sensor from the list of possible problem elements. One way or another, it is important to understand that this sensor is actively involved in mixture formation and affects the operation of the engine as a whole.

For this reason, it is necessary to perform regular checks of the ECM, scan for errors, and also pay attention to any failures and symptoms of malfunctions of the sensors of the electronic engine control system (TSP, DPKV, etc.).

When you need to change the DFID sensor 2110: symptoms of sensor malfunction and check

During the operation of a vehicle, the mass air flow sensor 2110 can fail for various reasons, one of which is the long period of use of the device. When a sensor fails, it is usually not repaired; it is simply replaced with a new one. The following symptoms may indicate that the sensor is not working properly:

In fact, the VAZ 2110 mass air flow sensor can be checked for performance using three methods: in motion, with a multimeter, visually. Checking the mass air flow sensor 2110 experimentally (in motion) is the easiest and fastest way. It consists of analyzing the operation of the vehicle’s internal combustion engine when the sensor is forcibly turned off.

- opening the hood, disconnect the mass air flow sensor connector;

- start the car engine;

- since the car will operate in emergency mode, the “Check Engine” light will come on and the amount of air in the fuel mixture will be determined depending on the throttle position;

- Having driven a car operating in emergency mode, you need to pay attention to its dynamics and compare them with the dynamics before the sensor was turned off;

- If the car accelerates faster with the sensor turned off, the air flow sensor is faulty.

What air flow should be on a VAZ 2114?

A 1.5 liter VAZ 2114 engine with a working mass air flow sensor at 850-950 rpm consumes from 10±0.5 kg of air per hour of operation, and at 2000 rpm - from 19 kg to 21 kg. If the amount of air consumed at the same speed decreases, the dynamics of the car also decreases, but fuel is saved. Conversely, increased air consumption leads to increased dynamics and higher fuel consumption. In this case, it may be difficult to start the engine in cold weather. If the sensor readings deviate from the real ones by 2-4 kg, the engine will begin to become very capricious and “dull”. Disabling the sensor will force the motor to continue operating in emergency mode.

Replacing the air flow sensor

To replace the VAZ 2110 mass air flow sensor, you need a part suitable for this model (the new sensor must have the same markings as the old one). In terms of selection, there are three price categories:

- Chinese-made sensors (relatively inexpensive);

- mid-price sensors from the manufacturer AvtoVAZ and some foreign manufacturers;

- high-quality and reliable, but quite expensive imported sensors;

Replacing the mass air flow sensor itself involves dismantling the old device and installing a new one. The procedure is quite simple, accessible to every car owner and can be done with your own hands. Before replacing the sensor, it is necessary to carry out a number of preparatory work:

- buy a mass air flow sensor with the same markings as on the body of the old sensor;

- prepare the necessary set of tools, screwdrivers of different sizes, wrenches or socket wrenches or wrenches with socket heads;

- multimeter (if necessary).

- Place the car on a level surface, lift the hood, remove the negative terminal from the battery;

- disconnect the mass air flow sensor connector;

- loosen the fastening screw of the corrugated hose with the mass air flow sensor housing;

- using a “10” wrench, disconnecting the hose, unscrew the two mounting bolts of the sensor with the air filter housing;

- Remove the old sensor housing and replace it with a new one, installing it in the reverse order of removal.

Please note that after the repair it is necessary to make a test drive to check the dynamics and power. You may also need to replace the air filter if the existing filter element is too dirty. It is also recommended to blow out the air filter housing with a compressor before assembly.

Replacing the camshaft sensor on 16-valve engines

- For easy installation, you will need to remove the radiator grille. To remove the radiator grille, it will be enough to lift the hood and unscrew the mounting bolts. Once the bolts are removed, the grille can be easily removed.

- Using a special wrench, you need to unscrew the two fixing bolts. When dismantling, it is advisable to unscrew the bolts gradually so that there are no distortions when removing the part. First you need to tighten one screw a couple of turns, and then another, and so on until the very end.

- Check the DPRV for deficiencies, clean all components, and then install it again. If these frauds do not help, you should start replacing parts.

- To install a new DF, do not use sealant, because during operation of the cylinder head, the temperature regime of the area may change. If there are signs of a faulty VAZ camshaft sensor, replacing the part on VAZ 2114 cars with a 16-valve engine will be more difficult, but the dismantling mechanism itself is similar to an 8-valve internal combustion engine.

Let's sum it up

As you can see, the VAZ 2110 mass air flow sensor is a fairly important component of the car in the ECM device. This sensor closely interacts with the computer and determines the degree of enrichment of the fuel mixture with air.

Finally, we note that if the sensor is dirty, it is not necessary to immediately resort to replacement. At the initial stage, it is cleaned, as well as the pipes are treated to remove accumulated debris, dust and dirt, and at the same time, all components of the sensor are inspected. However, if there is no positive result, it is necessary to purchase and replace the device.

Source

How to properly clean the mass air flow sensor?

The cost of a new sensor sometimes reaches 4,000 rubles. When identifying its breakdowns, you cannot do without these expenses. But if the device gets dirty, you can clean it yourself. To do this, use special chemicals that are sold in car dealerships. For example, chemistry from Liqui Moly. A mixture of 30% distilled water and 70% isopropyl alcohol works well. To wash the part, it is not advisable to use carburetor cleaners, WD-40, dishwashing liquid or window cleaner. Cleaning is done like this:

- Remove the device and its housing from the car;

- Separate the sensor from the housing. You can use pliers to unscrew the fasteners;

- Wash the resistors and channels of the part with chemicals. When using the product, you need to warm it up with a hair dryer to about 70 degrees.

- Dry the device sensor;

- Wash the body with soapy water, and then with water and dry it;

- Assemble the element and install it in place.

In order to save money, some drivers try to restore the functionality of a broken mass air flow sensor by installing additional resistors, changing the ECU firmware, or blocking part of the air supply channel with aluminum. These methods may be dangerous or ineffective. Therefore, in the event of a breakdown, the part must be replaced.