Dashboard lights indicate a problem

AvtoVAZ has long started installing engines with a fuel injection system on its cars. More than 10 years have passed since the first VAZs with similar engines appeared on our roads. Over the years, many changes have been made to the design and components. If at first only General Motors ECUs were installed, then later they began to use Bosch control units. And all sensors that were previously produced abroad are now produced in Russia. Our cars already largely meet European standards: the quality of engines is improving, the exhaust is much cleaner.

The consumer is afraid of modern microelectronics because he knows little about it. But it’s worth learning something about what symptoms appear when a particular sensor fails. The TPS has some symptoms, the speed sensor has others, and the lambda probe has others. And there is no need to panic when the “Check Engine” light comes on on your car’s dashboard.

If you look at the design of the Lada Kalina ignition system, you will see many incomprehensible elements, and they all affect the operation of the engine. To avoid getting into an unpleasant situation, it is better to know the location of all the car’s sensors and the main reasons for their malfunction.

Frequent injection system malfunctions

Symptoms such as spasms, dips, and jerking during acceleration often appear. In this case, the treasured indicator indicating an engine error does not light up. My first thought is that the spark plugs are faulty. And then the driver remembers that his Kalina has been driving for a year or more, and these important elements of the ignition system have not even been distorted. If after replacement there is no positive effect, then you should immediately pay attention to the type of gasoline that is poured into the tank. This is the most common cause of car breakdowns.

Ignition coils are Kalina’s sore spot

Pay attention to the ignition module. Perhaps this is the problem. But the module can only be checked using modern engine testers. Therefore, it is necessary to contact an experienced auto electrician who will quickly calculate the fault and replace or repair the module. If it is possible to install and test a work item, take advantage of it. The engine started working perfectly - run to the store for a new module. Repairing this unit is possible, but finding a professional technician is quite difficult.

No less often, the problem of speed fluctuations occurs on VAZ-2110, Priora and Kalina cars. The tachometer doesn't know where to go. The needle moves gradually from a minimum of 850 to a maximum of 1200 rpm. The malfunction is obvious, but the expensive lamp, which should indicate an error, does not light up! At the same time, the throttle position sensor is clearly broken, which is especially common in older models of VAZ cars of the 2110 family, as well as in modifications of the Lada Kalina. Recently, they have begun to install TPS of fairly high quality, so problems with them rarely arise.

A malfunction of the idle speed control can be determined by the following symptom: it is impossible to start the engine without pressing the gas. The sensor is located next to the TPS, right on the pipe. But don't change it right away, try rinsing and cleaning it first. Very often the regulator becomes dirty, so it looks like it has failed. The price of such items has now decreased, and their selection in stores is very large.

Dependence of the appearance of an air lock in the cooling system on the expansion tank cap

When the liquid in the cooling system is heated, it expands and pressure in the system increases. In order to prevent the system from rupturing, the cap of the expansion tank must release excess air when the pressure rises to 1.3 atmospheres. When cooling, the liquid and air compress and a vacuum appears in the system. To prevent air from being sucked in from under the pipes, the cover must freely allow air into the expansion tank.

Often these covers are of poor quality or simply oxidize and stop normally letting air in and out from outside, which causes air to be sucked in at weak points and, accordingly, the system is re-aired. It also happens that the cover valves freeze when the engine cools down.

To troubleshoot the lid, try sucking air out of it from the back side; if air does not flow in or it comes in with obvious force, then it’s time to change the cover. The presence of freezing is checked in the following way: leave the heated car until it cools completely, then unscrew the lid and look at the valves; if they are completely covered in ice, then the problem is condensation. In case of freezing, you can try treating the lid with silicone grease or VD-shkoy.

The last cover I took and it was the most successful:

Here's the other side:

There is also another option for dealing with bad caps - unscrewing them in winter to allow free air access in both directions through the threads. But keep in mind that in this case the maximum boiling point of the coolant will decrease.

General information about the control system

The speed began to fluctuate: this means that the DPS is faulty. It is necessary to determine the speed and degree of opening of the throttle valve. Its design is based on a simple potentiometer: when the damper position changes, the voltage at the sensor signal output changes. A potentiometer is a variable resistor, and is more often called that.

The sensor is installed directly on the damper shaft. The connection with it must be tight, so even the slightest kickback is unacceptable. Potentiometer pins:

- supply voltage, which is usually 5 volts;

- signal output connected to the vehicle's ECU;

- “Ground” (“minus” of the power supply, which is located on the car body).

This is what TPS looks like

The highest resistance of the sensor is observed when the damper is closed, while the voltage on the ECU is minimal. Press the accelerator pedal to open the shock absorber, at this moment the resistance changes and the voltage gradually increases to its maximum value of 5 V.

The electronic control unit contains firmware in which all important parameters are recorded. Depending on the opening value of the shock absorber, the ECU regulates the ignition timing, as well as the opening time of the injectors. Non-contact magnetoresistive type DPDZ can also be used. They consist of the following elements:

- electronic sensing element treated with special material;

- permanent magnet built into the throttle valve.

When you press the accelerator pedal, the permanent magnet rotates. At this time, the sensing element changes its resistance due to changes in the magnetic field surrounding it. Only in this case the ECU sees a change in angle, not voltage. If the sensor fails, problems arise with starting the engine, gasoline consumption increases, engine speed constantly changes, and vehicle acceleration becomes difficult.

Adaptation using the example of some cars

Another method, which we will consider using the example of one well-known German brand, also involves adaptation without a computer. Here you should warm up the engine to a temperature of approximately 70-99°C. The battery voltage must be at least 12.9 Volts when the engine is not running. The action plan for how to adapt the throttle valve on a Volkswagen will be something like this:

- After warming up and turning off the engine, you should wait a short period (5-10 seconds).

- With the gas pedal released, turn on the ignition and wait 3 seconds.

- After 3 seconds, you need to press the accelerator pedal all the way 5 times and release it back. Act quickly, as you only have 5 seconds to do this.

- After the 5th exercise, you should wait a pause.

- After 7 seconds, press the pedal all the way again and hold it in this position until the “CHEK” indicator starts flashing (≈ 10 sec.), then it should remain on continuously (≈ 20 sec.).

- When the indicator lights up constantly, count to three and only then release the pedal.

- Start the engine (repeat if necessary), wait 20 seconds, then lightly accelerate (2000-3500). If the tachometer shows 700 rpm at XX (+- 50), it means that the adaptation was successful.

Dismantling and repair of parts

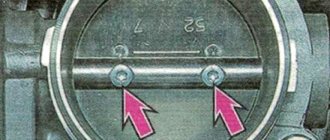

The sensor is fixed with two screws

On the Lada Kalina, the potentiometer is located directly on the throttle axis. To access it, you need to remove the decorative cover. On Lada Kalina cars, the minimum voltage at the control output is slightly less than 0.7 Volts. Fully open throttle is 4 Volts or more (up to 5 Volts). To check the operation of the sensor, you only need a multimeter, which must measure the voltage at the signal output. If the voltage constantly changes in the closed position, the throttle body and sensor contacts will need to be cleaned.

Often the cause of a malfunction is contacts and contaminated system elements. When a sensor fails, the following happens:

- a digital fault code is stored in memory by the controller;

- a warning light on the instrument panel lights up, indicating a malfunction;

- The throttle opening angle is calculated by the engine control unit based on air flow and engine speed.

Before starting work on replacing or repairing the sensor on a Lada Kalina car, you must disconnect the negative terminal from the battery. Then the plug is disconnected from the position sensor connector by pressing the plastic latch. The TPS is fixed with two screws, which can be unscrewed without much difficulty. Only after this the node is deleted. Carefully inspect it for damage, measure the width of the sensor rod (it should be 5 mm). The throttle body may need to be cleaned before installing a new potentiometer. If the axle is dirty, the sensor will be difficult to move.

If there is kickback in the unit, it cannot be eliminated in any way. Wrapping with tape or other material will not bring positive results. Only a complete replacement of the throttle position sensor will solve the problem.

Operating principle of the sensor

The Kalina throttle sensor is used to transmit a signal to the engine ECU. This part is a potentiometer, the maximum output voltage of which does not exceed 5 Volts. The element consists of a housing, inside of which there is a variable resistor. The positive power wire is connected to one of the contacts of the product, and ground to the second. An output conductor is connected to the third terminal, the voltage of which depends on the angle of the throttle valve. The potential difference is changed by moving the moving part of the third contact along resistive tracks.

The moving contact of the potentiometer is installed on the throttle valve axis, so a change in the position of this element is instantly responded by a change in voltage at the output contact.

Installation and causes of sensor failure

Installation is carried out in the reverse order of removal. Note the foam ring required for sealing. Damage to it is unacceptable. Therefore, it is recommended to replace the broken ring with a new one. The better the ring, the better the TPS will perform and the lower the likelihood of new failures. But then the question arises: why could such a simple sensor break? There can be many reasons. The most common:

Location by car

- partial or complete wear of the support;

- dust removal;

- hacking mobile kernel with contacts.

As a result, it is impossible to achieve a linear increase in voltage across the signal pin. Once assembled, no adjustments or adjustments are required: the microcontroller system takes the closed throttle valve as its reference point.

Repairing the sensor is extremely difficult, since it becomes necessary to spray a new contact layer. It is impossible to do this at home, and not all gas stations have such capabilities. If you look at the cost of such sensors for a Lada Kalina car, it turns out that it is easier to buy and install a new one. Another advantage (besides the low price) is that replacement takes no more than five minutes. And it is expected that you clean the contacts and the throttle valve at the same time.

It’s up to you to decide which TPS to install on your Lada Kalina car. But it’s worth talking about which designs are preferable. I want to install the sensor once and forget about problems with it for a long time. The simplest and cheapest potentiometers can boast only of their price. But their duration is not very long. These sensors were installed on the AvtoVAZ assembly line. But contactless devices, even if they cost twice as much, have a much longer lifespan. Therefore, from a reliability point of view, it is better to use magnetoresistive sensors.

VAZ electronic throttle: design, diagnostics, flushing and repair.

In this material I want to talk about the design, diagnostics and repair of an electronic throttle valve (injector) from Delphi, installed on VAZ cars in combination with the M74 engine management system. The reason I wrote this article was a typical malfunction on a VAZ 2115 car with an atypical cause, which I will talk about a little later. I would like to warn you right away that the author of this article is not responsible for unqualified intervention and repair of the electronic throttle valve in the event of its failure and emergency situation on the road, since repair of this unit is not provided, but only replacement.

Design. The electrically actuated throttle body (tube) is designed to measure the amount of air entering the intake manifold. Changing the amount of incoming air is achieved by rotating the damper using an electric motor, which is controlled by a controller. Main parts of the throttle body: All photos are clickable!

1. Placement 2. Damper 3. Gearbox 4. Electric motor 5. Throttle position sensors.

The connection diagram is shown below:

Removing the throttle valve: 1. Turn off the ignition, remove the negative terminal from the battery. 2. Unscrew the clamps and remove the inlet hose from the accelerator. 3. Disconnect the wiring clamp. 4. Unscrew the 4 bolts securing the throttle valve to the intake manifold and remove it.

Typical faults and their diagnosis. The childhood plague of early departures from the car, error P2135 (mismatch of signals from throttle position sensors A and B) manifests itself in the form of unstable idle, speed limit 2000, loss of traction. It can be successfully treated by crimping, bending and soldering the contacts of the throttle valve block or replacing all the wiring. Most cars have been looked after for a very long time; you won’t find much on new ones. Sailing modes and irregular idling. Here we will go into more detail, since this phenomenon is common and sooner or later appears in almost all cars. The main reason here is the mismatch between the throttle opening angle and the amount of incoming air. Most cars are washed. It is advisable to wash the throttle valve at least once every 20-30 thousand km, otherwise carbon deposits and oil particles create obstacles to the movement of air in rest mode with all the ensuing consequences. Therefore, the throttle valve assembly must be kept clean and tidy - this is an axiom. The second reason for free floating is free movement of the throttle valve. How does it manifest itself and how to diagnose it. Below is a screenshot of the SMS Diagnostic Tool. The parameters are taken from a VAZ 2115 car with an M74 engine management system.

Here it is worth paying attention to the high air consumption, the time of its filling and injection. At the same time, the throttle opening angle is very small, and the controller, trying to stabilize the idle speed, reduces the ignition timing. This is because the actual throttle position angle does not match the angle calculated by the ECU due to backlash. Also, if you initialize the throttle, the engine may run fine for a while, but after a while or after a restart, the situation repeats with fluctuating rpm. It is worth remembering here that if the throttle valve is dirty, the parameters will also differ from the norm, with the only difference being that the opening angle of the shock absorber will become larger than usual. As an example, here is a screenshot with normal parameters:

How to get rid of throttle valve play. To do this, you need to disassemble the throttle assembly. From the gearbox side, unscrew the 4 screws (torx 15) that secure the cover.

Here we see the gears of the transmission mechanism.

The sun gear is simply removed.

On the other side are the throttle position sensors and the electrical connector. Attached with very rare pentagonal star screws. Photo below:

We're shooting. The electric motor in the housing and the damper axis are visible.

Next, you need to use a press or vice to press the throttle valve from the DPS side towards the gears.

Remove the axle.

The electric motor must not be removed unless it is damaged. You can check this by simply measuring the contact resistance. The resistance should be about 10-30 ohms.

And also a photo of all the disassembled components of the throttle valve in disassembled form.

The throttle position, when the electric actuator is not engaged, is determined by the position of the spring bars between the flap stops in the throttle body and is approximately 10% open compared to the closed position.

Play along the axis of rotation of the throttle valve occurs due to the development of the spring on the aluminum clamps. Marked with a red arrow:

There are 2 options: either replace the throttle valve, and this is not cheap, at the time of writing (September 2013) it is about 2500 rubles. Or you can eliminate the play by eliminating the space between the spring tabs and the boss body. The essence of how I propose to eliminate the backlash is to lightly press the spring antenna to the amount of the gap, for example with a file, whisker-shaped grooves in the plastic stops on the gear itself.

After the review, we check the game manually. However, keep in mind that a small play, about 0.1-0.2 mm along the axis of rotation, will still be due to weak spring adhesion on the axle bushings.

If everything is in order, reassemble in reverse order. The throttle shaft is secured against displacement with a sealing washer, photo below:

You can press this washer onto the shaft using a suitable tube or a 10 deep socket for example.

Important note! After repair, replacement of the electronic throttle valve or replacement of the engine control unit, it is necessary to adjust the zero position of the throttle valve. This is done quite simply. The first switching on of the ignition after repair must be accompanied by a delay of at least 30 seconds. During this time, you will hear the damper electric drive turn on, turn the damper until it is completely closed and return it to its original position. After this procedure, throttle valve adaptation can be considered complete and the engine can be started. If you did everything correctly, the idle will be stable and smooth. Download movies dle 10.6 for free

Causes of pollution and how to deal with them

There are several reasons why the throttle body becomes dirty over time. By avoiding their appearance, you will automatically extend the time between cleaning it. Reasons mentioned include:

- Using low-quality gasoline . If there is sediment in it, it will definitely get into the throttle assembly, where it will turn into carbon deposits. Therefore, try to fill in high-quality gasoline and refuel at proven gas stations.

- Clogged fuel filter . If you do not change the fuel filter in time, then there is a possibility that pieces of dirt from it will get into the fuel system, including the throttle assembly.

- Dust and dirt getting into the intake system . This can be caused by various reasons - clogged air filter, damage to the integrity of the air duct, various mechanical stress.

- Crankcase gases with oil dust . They are the main cause of oil deposits on the valve. They can enter the combustion chamber through the valve cover from the crankcase ventilation system. The situation is aggravated by the fact that they carry oil dust. It is this that burns and remains as sediment on the surface of the throttle valve.

Clogged fuel filter

Change the air and fuel filters on time, fill with high-quality gasoline, and prevent dust from getting into the car's fresh air ventilation system. All this will save you from the need to clean the throttle valve ahead of schedule.

Malfunction of the Lada Vesta throttle assembly

Acceleration problems are common to all modern cars, and Lada Vesta is no exception. The reason lies in the fact that this node includes many components that are influenced by external and internal factors. It is important to make sure that the problem is precisely a malfunction of the throttle assembly. Below is a list of elements whose damage can lead to similar symptoms:

- Accelerator pedal position sensor

- Throttle motor

- Idle speed control

- Damper position sensor

- Mechanical elements of the case

- Air filter and air intakes

- Electronic engine control unit

Damage to any of these parts may indicate a faulty throttle assembly. Therefore, before rushing to the workshop for a new throttle assembly, it makes sense to conduct a detailed diagnosis of all elements associated with it.

The influence of the fuel vapor recovery system on the operation of the Lada Kalina engine

Modern technologies are developing, equipment is becoming more complex and sophisticated, and progress does not bypass vehicles. Carburetor cars were very simple, and any driver could figure them out, but on cars with injection engines, new components were added, in particular, a fuel vapor recovery system appeared, the main element of which is the adsorber. The main task of this circuit is to remove fuel vapor from the tank into the intake manifold at the time the internal combustion engine is started, and the adsorber purge valve plays an important role here. This article will discuss the operating principle of this system, the procedure for replacing the valve, and possible malfunctions that may arise during the operation of a Lada Kalina passenger car.

How does the Lada Kalina gasoline vapor recovery system work?

The EVAP system in question was created to prevent the release of harmful gasoline vapors into the surrounding atmosphere resulting from fuel evaporation; it includes:

- fuel shut-off valve;

- adsorber;

- solenoid valve for purging the absorbent element;

- connecting pipelines.

The most important component in the system is the adsorber (also called a carbon filter), the basis of which is activated non-edible carbon, enclosed in a plastic housing. The resulting gasoline vapors are absorbed by the carbon of the absorbent element, gradually accumulating in it. When the engine starts, the canister purge valve (KPA) is turned on, and due to the vacuum, all accumulated vapors enter the intake manifold and then burn out.

On the Lada Kalina, the adsorber is located in the gas tank area, and getting to it is very difficult. To dismantle this EVAP element, it is necessary to remove the fuel tank, but the control unit is located in an accessible place - the valve is located in the engine compartment, in close proximity to the battery, on the rear wall of the air filter housing. It should be noted that for turbocharged engines, a vacuum is not created in the intake manifold, and in order to force the vapors in the desired direction, an additional two-way valve is included in the circuit.

Design of the VAZ Kalina adsorber purge valve

KPA is present on all modern injection internal combustion engines, and Lada Kalina is also no exception. The purge valve (another name is Evap-Solenoid) is connected on one side to the carbon filter, on the other to the intake manifold, when there is no electrical signal to the control unit, the pipeline channel is closed, and vacuum is not created in the system. When an electrical signal is supplied while the engine is running, the valve is activated, the channel opens, and gasoline vapors freely pass from the adsorber into the intake manifold.

Malfunctions in the fuel vapor recovery system Lada Kalina

Since the solenoid valve itself is not a complex device, it has few malfunctions as such - it may not open or close when necessary, or may freeze in a certain position. But the culprit of the breakdown may not only be Evap-Solenoid; the gasoline vapor recovery system does not work correctly for other reasons:

- connecting pipes are pinched or clogged;

- normal vacuum is not created in the system;

- due to an open circuit, there is no voltage on the valve;

- the carbon filter is completely clogged (which is rare);

- The control unit malfunctions.

Signs of a malfunctioning throttle valve Lada Vesta

There are a number of indicators that indicate a faulty throttle body. Symptoms may appear differently depending on the part that is broken. To understand which direction to move, you need to familiarize yourself with the list of possible symptoms of an accelerator failure on your Lada Vesta:

- Irregular idle speed

- Stopping the engine at idle or by pressing the throttle

- The engine does not start or stops immediately after starting

- Loss of engine power

- Sprint when you pick up speed

- Check Engine Light Is Intermittent or Constant

As you can see, there are several signs that indicate problems with the throttle body, and all of them can indicate many other problems. Therefore, before repairing the throttle assembly, it is necessary to exclude the possibility of malfunction of other parts of your car. To do this, use the algorithm below.

Algorithm of actions for identifying a throttle malfunction

It is important to understand that the most reliable way is to download error codes to a smartphone or PC via the diagnostic connector. But, if this is not possible or the connector is not working, you can verify that the node is faulty using the following algorithm:

- Check the air duct for foreign bodies, dirt, water, etc. Clean the channels if necessary.

- Make sure the air filter is suitable.

- Use a tester to check the operation of the accelerator pedal position sensor.

- Check the operation of the idle air control.

- In the same way, fix the malfunction of the damper position sensor, as well as the electric motor.

- If everything is in order, it makes sense to disassemble the block and verify the integrity and functionality of the shock absorber itself.

All measurements using the tester must be made with the ignition on and at different positions of the accelerator pedal.

Tips and tricks

If the sensor is being replaced for the first time, it is possible to make some annoying mistakes that can lead to rapid failure of the new sensor or make the replacement and diagnostic process less comfortable. Experienced craftsmen advise when performing such work to pay attention to the following features:

- There is too little space in the engine compartment, so a shortened Phillips screwdriver should be used to remove the TPS.

- After removing the sensor, you should carefully inspect the foam gasket located in the seat. If there is severe wear or damage, it should be replaced.

- You can check the TPS of the Lada Kalina without an assistant. In order to independently change the position of the throttle valve with a multimeter connected, you should increase the length of the wire with which the measuring device is connected to the sensor output. After that, you should install the tester in the direct line of sight of the driver, and smoothly press the gas pedal yourself.

The cost of a new throttle position sensor is relatively inexpensive. If this part is the culprit for the unstable operation of the internal combustion engine, then after replacing it, fuel consumption will be reduced, that is, the costs of operating the car will be significantly reduced. In addition, wear will be reduced on many parts that were overly stressed when the machine jerks. The comfort of driving a car, which is completely free of any problems in the operation of the engine, is significantly increased, which makes it possible to preserve nerve cells, which, unlike car parts, cannot be restored.

DIY throttle valve repair

The throttle assembly of a Lada Vesta car can be easily replaced with your own hands. To perform a procedure such as replacing the throttle body, you will need a standard set of wrenches, hex keys, and a screwdriver. Then follow the steps in the following order:

Thank you for registering!

- Remove the negative terminal from the battery.

- Disconnect the air duct from the damper body by loosening the clamp

- Disconnect the wires going to the sensors.

- Unscrew the 4 screws securing the throttle body and remove it.

- Cover the intake manifold opening with a clean rag or other plug.

Installation of a new part is carried out in the reverse order of removal. If you need to do something like replacing the throttle sensor, you don't need to remove the entire assembly - just disconnect the wires from the sensor and disassemble it, then install the new sensor in the reverse order.

How to replace

If there is a high probability that the throttle position sensor is the cause of the engine malfunction, it should be replaced.

This procedure on a Lada Kalina car is carried out in the following sequence:

- Unscrew the filler plug.

- Remove the casing.

- Remove the plug.

- Using a Phillips screwdriver, unscrew the 2 bolts holding the sensor.

- Remove the sensor.

Installation of a new TPS is carried out in the reverse order of removal. When installing, you should twist the sensor slightly so that this part aligns with the holes at the mounting location.

Cleaning the damper

If the cause of poor engine performance is a dirty throttle valve, it should be cleaned. To do this, you need to purchase a special engine cleaner and get to work:

- Remove the shock absorber in the above order

- Spray with the product and leave for a while (as indicated on the package)

- Remove the layer of dirt and carbon deposits with a clean napkin or other cloth.

- We repeat the procedure several times until all the details shine.

It is also recommended to remove and clean the idle air control valve and the channel in which it is located. Be sure to check the condition of the air filter, as an unusable filter can not only contaminate the throttle body, but also affect the overall performance of the engine and create many problems. Good luck on the roads!