Most of the VAZ-2107 cars that came off the production line were equipped with a carburetor power system, although injection versions were produced for export. “Sevens” with an injector appeared on the domestic market only in the last years of production. Therefore, most VAZ-2107s have a carburetor power system, which is already outdated.

But outdated does not mean bad; according to some criteria, the carburetor “bypasses” the injector. Positive qualities include a minimal amount of electronics, which affects the reliability of the power system, high maintainability, and unpretentiousness to the quality of gasoline.

But in order to maintain the VAZ-2107 power system in working order, some of its components require periodic maintenance. This primarily concerns the carburetor. The VAZ-2107 uses an Ozone carburetor, unlike, for example, the Solex carburetor of the VAZ-2109. The Ozone carburetor is distinguished by a relatively simple design and unpretentiousness, which allows you to carry out maintenance of the unit yourself, without resorting to the services of a service station. But we note that on the VAZ-2107 of various years of production, which were equipped with a carburetor power system, modifications of “Ozone” were used, although the difference between them is insignificant and it comes down to the use of auxiliary components that are different in design, but the general design is the same.

Main types of carburetors

The Seven engines are equipped with both a carburetor and an injector. The operation of the injector does not depend on weather conditions. But the carburetor is much simpler in its mechanical structure, which makes its repair and tuning more accessible.

Not all carburetors are designed to do the same thing. For example, there are models on the market that reduce fuel consumption or, on the contrary, increase fuel consumption, which in turn allows you to maximize the dynamics of vehicle acceleration. Such different models of carburetors were produced for different engine sizes, so it will not be possible to rearrange them so easily. If you suddenly decide on such an experiment, then you cannot do without alterations. And all this is true when it comes to standard models. But what if the car owner decides to install a non-standard carburetor?

However, first, let's turn our attention to the standard classic models.

Have you drained gasoline on your VAZ 2107 again?

If you have once again had gasoline drained from your VAZ 2107 and the secret caps with a key and caps with a code do not help, it’s time to think about a sensor for the gas tank.

The gas tank cap with the key is opened with a “roll” or a powerful screwdriver, inserting them instead of the key and turning them with force. It doesn't take that long to find a gas cap with a code (two rotating plates with numbers), especially if the attacker has the whole night ahead of him. At best, they will pour out the gasoline and break the cap; at worst, they will tear apart half the car.

So how to deal with thieves?

If you have an alarm installed on your car, you can put a sensor on the opening of the gas tank flap so that the alarm warns you that gasoline is being drained.

Attention! You cannot put a regular limit switch (limit switch) in the gas tank flap - it can give a spark and gasoline vapors will ignite. There is a way to install a non-contact sensor (reed switch) in the VAZ 2107 hatch, which is completely sealed and cannot be neutralized from the street and will allow you to protect your car from gasoline drainage

If you install a regular limit switch, then in addition to the fact that it can spark, it is very easy to notice it from the street and press it with some kind of wire, then open the hatch, tear off the wire from the limit switch and calmly drain the gasoline

There is a way to install a non-contact sensor (reed switch) in the VAZ 2107 hatch, which is completely sealed and cannot be neutralized from the street and will allow you to protect your car from gasoline drainage. If you install a regular limit switch, then in addition to the fact that it can spark, it is very easy to notice it from the street and press it with some kind of wire, then open the hatch, tear off the wire from the limit switch and calmly drain the gasoline.

A sealed, non-contact hidden sensor will save you from many problems, namely, it will sound an alarm when the gas tank flap is opened. If you have a feedback alarm, the key fob will work and you can (if you hurry) pay your respects to the thieves. If the alarm system is cheap and ordinary, it will still be somehow inconvenient to drain gasoline from a flashing and howling car, especially at night.

Description of models

The first VAZ 2107 was standardly equipped with a DAAZ carburetor In Russia, they were modified to meet the needs of the local automobile industry. DAAZ products had simple assembly, which subsequently affected their price. The given carburetor model was characterized by maximum simplicity and made it possible to provide good acceleration characteristics to the car. Initially, the space in the engine compartment was created specifically for DAAZ.

The VAZ 2107 carburetor is a complex, high-precision device, consisting of two chambers, one of which - the first is equipped with a special mechanical damper drive. It can be installed on any domestic rear-wheel drive car. The volume of the model in question is 1.5 and 1.6 liters.

Gasoline consumption when using DAAZ increases noticeably. But this is consistent with the car’s speed indicators, which are also increasing. And this is especially important when overtaking.

Drawing our attention to the model - “Ozone” - it is worth noting that this is a more modified version of the standard DAAZ. The new optimized mechanism had better environmental performance. Thanks to this, “Ozone” received its environmentally friendly name. In addition, it consumed much less fuel than the previous version, so for such an economical car as the VAZ 2107, the Ozone carburetor was considered the most optimal option of all possible.

Good maneuverability and speed of the car were given by a pneumatic valve located in the new carburetor and ensuring the efficiency of the second chamber. However, there was one “but” - even if the valve was slightly dirty, the second chamber stopped working. The speed of the vehicle immediately decreased. This was noticeable in the acceleration dynamics of the car and when the engine was running at medium speeds.

The Solex 21053 carburetor is no less popular among VAZ 2107 owners. At the moment, it is the latest development. Solex has a rather complex assembly, but at the same time it has a fuel reverse supply system, which makes this carburetor the most economical among the entire DAAZ line.

The carburetor mechanism has a larger volume compared to other models: 1.8 Solex versus 1.5, 1.6 other DAAZs. All these features tell us that this carburetor model is simultaneously designed for economical and fast driving.

Initially, Solex was created for cars with front-wheel drive. And yet, this carburetor can be installed on a VAZ 2107 without special modifications. Solex is picky only about the quality of fuel.

Important! The system may malfunction! In most cases, this is due to the fact that the air and fuel channels are clogged with dust. The solution to this issue will be timely maintenance of the carburetor.

All of the carburetors we list are installed on classic engines. If the size of your engine is not designed for the existing carburetor, then you will need to select and replace the jets. It is also worth adjusting the carburetor.

On the issue of non-standard carburetors, it is worth saying that in some cases, owners of “classics” resort to just such a solution. Without alterations and adjustments there is no question here.

“Solex” 21073 is a model designed for engines with a volume of 1.7 liters. The carburetor differs from previous versions by large channels and jets. Dynamic growth is guaranteed! But so does the subsequent expense.

The following non-standard model is installed on cars of the VAZ 2108 and 2109 series. “Solex” 21083 for installation on version 2107 will require certain modifications. Also, installing it will lead to the fact that at about 4000 rpm the engine will not be able to spin up any further. To install this carburetor model, you need to drill out the chamber diffusers. Then expand them. During the modification process, large jets are also installed. The result of such work can please you: fuel consumption will be lower, and the dynamics will exceed those of other models.

The smell of burning

Be that as it may, if there is a burning smell in the interior of the VAZ 2107, then this clearly indicates a malfunction. But the scale of the breakdown may vary. You can remove the root cause of this odor yourself by digging around in the car a little. And in some cases you will have to take your horse to the workshop, since you can’t do anything with your own hands. Of course, there is no need to panic if the smell of smoke or burning enters the interior from the street and not from under the hood. Close the air intake damper and forget about the problem. The main thing is to open it in time.

Be sure to check if there is a filter for cleaning the air entering the cabin. If it is, then evaluate its condition. It is quite possible that it is already so clogged that it is simply unable to let air pass through it. Often the cause of a burning smell on a VAZ 2107 car, and on others as well, is dirt on the engine. You can improve the situation a little by thoroughly washing the engine. And after such a procedure, when heated, it will not emit a fetid odor.

But if there are deposits on the exhaust manifold or exhaust pipe, then it will be much more difficult to get rid of them. There is often a burning smell in the cabin if there is an oil leak. As you understand, the engine heats up to high temperatures during operation. And when oil gets on it, it instantly boils and gives off an unpleasant odor. As a rule, the culprit of this phenomenon is always the rubber gasket installed under the valve cover. And the last reason is severe burnout of the gasket under the exhaust pipe. But at the same time an unpleasant sound is also heard.

Design and principle of operation

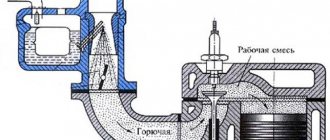

Despite the fact that the carburetor performs a well-known function in a car, the structure and principles of its operation require detailed consideration. After all, the amount of fuel consumed by the machine, as well as its dynamic performance, depends on this mechanism. “Solex” are two-chamber carburetors with a balanced float chamber, with sequential forced opening of the throttle valves and heating of the coolant of the idle channels.

Carburetor design

The structure of the mechanism includes:

- float chamber. It is needed in order to maintain a given fuel level. The supporting device consists of floats and a valve;

- the idle and transition system works when the main dosing system can no longer work (cannot work due to low vacuum, since the throttle valves are either closed or slightly open);

- the accelerator pump injects fuel in order to smoothly transition to the increased load mode;

- starting system. For stable engine starting, an over-enriched mixture is needed. It occurs when the air damper closes and the throttle opens slightly. To prevent the engine from stalling from the resulting mixture, the air damper is opened slightly again due to the force of the diaphragm in the main dosing system;

- The econostat only works at high speeds, when fuel passes through the nozzle and delivers it to the nozzle hole, which is located in the low-pressure area;

- The power mode economizer saturates the mixture at full load to achieve maximum power.

The two main parts that make up the Solex are the cover and the body. The cover is secured to the body with five screws. There is a gasket between the screws and the housing. The cover itself contains: fittings and studs for fastening the air filter, an EPHH solenoid valve, channels through which air is delivered to the main air jets, a needle valve, an air damper and an econostat sprayer.

The Solex carburetor body contains: emulsion wells, an accelerator pump, throttle valves, their drive mechanism, a starting device, an econostat, a float chamber, an economizer and an accelerator pump.

The design and operating principle of this carburetor are not fundamentally different from devices of a similar type.

What else you should know

A mesh filter is installed in the fuel pipe of the carburetor to clean the incoming gasoline, which should be washed periodically. Some owners install an additional filter before the fuel pump, or between the pump and the carburetor.

Sometimes the idle speed “floats”, this can be caused by “excess” air passing through the gasket in the forced idle economizer, which needs to be replaced. You can use the car for some time if you insert a spring of a suitable diameter between the valve cone and the valve body, and then set the idle speed.

“Loss” of idle speed can occur after a failure of the solenoid valve. Often this can happen after the nozzle of the tip of this valve is clogged; after cleaning it, functionality is restored.

Please rate the article

I couldn't adjust the idle speed no matter what. I took the car to the workshop, it turned out that I didn’t know anything about bushings at all) but now there are workshops that basically don’t know how to do this..

Cars without an injector are still relevant on our roads. Moreover, their owners usually like to repair breakdowns themselves, which are already quite common with long service life. Among these breakdowns there are malfunctions of the most complex air and gasoline supply unit. Therefore, many car enthusiasts are faced with the question of how to repair a carburetor with their own hands.

Basic faults

Solex carburetors are the same technology as other mechanisms in a car, so even with proper operation, it can wear out and eventually fail. Some of the faults can be determined by the way the machine operates. But there may be something hidden from your eyes inside the carburetor body. In this case, diagnosing the breakdown will be much more difficult.

The owner of a VAZ 2107 can judge the incorrect operation of the Solex by the following signs:

- jerks and jolts when the vehicle moves;

- increased fuel consumption;

- problems starting the ignition;

- engine failures;

- decreased acceleration dynamics;

- idle failures.

Faulty operation of the VAZ 2107 carburetor when it wears out has a bad effect on engine power. Some things can still be cleaned, but somewhere else a full replacement of parts will be required. Any problems associated with misalignment of parts or associated with changes in the operation of the power unit are a clear knock on the door of the repair room.

Let's look at the most common problems that arise when a Solex carburetor wears out:

Gasoline is not supplied

The reasons that fuel does not enter the carburetor may be: lack of pressure in the fuel supply system, faulty fuel pump, dirt in the supply hose from the gas tank, or an outdated gas filter. In this case, it is recommended to try to blow out the fuel line or change the fuel filter.

Pouring gasoline

If you find leaks of gasoline (especially in winter they are very easy to notice - small puddles of gasoline in the snow), then be careful! This may cause a fire . Therefore, this problem must be resolved immediately! Most likely the solution lies in the depressurization of the hoses. The operation of the accelerator pump also needs to be checked, since if the problem is related specifically to it, then the cause of gasoline leaks may be excess fuel that is formed during accelerated operation of the pump.

Shoots

“Shooting” in the carburetor can be caused by a severe leanness of the fuel mixture, incorrect connection of high-voltage wires, a timing belt that is displaced by two or three teeth (when you change it completely, the belt must be tensioned well, and over time, tightened when displaced) and incorrectly installed ignition moment. The malfunction is detected when you press the gas pedal. As a result, you see the car jerking jerkily, after which it begins to stall.

The second camera does not work

Often the second chamber on Solex carburetors reminds of itself by breaking down. To eliminate it, we need to establish the cause of its occurrence. There can be as many reasons as with “shooting”. Here are all kinds of malfunctions: flooding of the carburetor chamber, incorrectly set gap, problems with opening the damper, lack of the proper amount of fuel, some components of the chamber have failed. You can determine the cause of the malfunction by unscrewing a couple of spark plugs. If the carbon deposits on the spark plugs are abnormal (black), this may indicate either a mixture that is too rich or too lean. Ideally, it is necessary to check the operation of all elements of the system.

Accelerator pump does not work

This problem can occur if the accelerator pump does not operate correctly. Because of this, the volume of fuel may be too large or too small, since the required pressure in the system is not provided. To solve this problem, you will need to remove the carburetor, disassemble the pump device and diagnose its operation. Most often, the malfunction may be due to wear of the rubber parts of the pump.

The engine stalls when you press the gas

One of the most common problems that VAZ 2107 owners face is the engine’s refusal to start. This can happen even after the car has been started. All this tells us that the fault lies in the float chamber. There may simply be no fuel in it or its level may be extremely low. Most often, engine starting problems occur due to the mixture being rich or lean. To deal with this problem, you will need to disassemble the carburetor and check the functionality of individual elements. (float, jets, dispenser)

If the car is only idling and the same problem occurs, then the malfunction may be hidden in such components as: control unit, solenoid valve mechanism, idle jets.

Regardless of what the problem is, you will need to inspect all parts of the idle system, adjust their quality and quantity with screws, tighten them, blow them and wash them.

What is

The operating principle of internal combustion engines is based on the combustion of fuel, which is used for carburetor engines. The engine will not work if gasoline is simply poured into the combustion zone. Its operation is possible only when the fuel mixture enters the combustion chamber, which is formed in a ratio of 15:1 parts of air and gasoline. The carburetor just forms the composition of the fuel mixture.

New cars today are no longer produced with carburetors in the power system; they have been replaced by injectors, but the demand among car enthusiasts has remained. The production of these devices continues in many countries around the world, including the Russian Federation. During operation, these devices wear out, their adjustments are lost, so they need maintenance, adjustments, and repairs. Before we start talking about this, we should consider the design of these devices.

Carburetor adjustment and tuning

You will need to adjust the VAZ 2107 carburetor and configure its systems just when you begin to notice such defects in the operation of the mechanism. What to do if your car can barely start, even when the frost has not yet arrived and the temperature outside does not drop below zero, and the tachometer needle does not float, but jumps? Or when you press the gas, the engine stalls and stalls.

There are problems such as, for example, the problem of the ignition system, where when a spark is formed, the mixture in the cylinders ignites. In older “classic” models, the ignition coil breaker is responsible for this. In more modern cars, a contactless ignition system is installed, where the ignition switch (distributor) is responsible for the appearance of the spark. But even this seemingly complex problem can be resolved manually. Many carburetor problems can also be adjusted manually. Let's try to figure out some of them...

Adjusting the float system

Any carburetor adjustment begins with adjusting the float chamber. Fuel consumption and engine stability will depend on this part of the mechanism. It is important to follow technology! We start the engine for 3-4 minutes. Then turn off the power. We remove the air filter housing, as it interferes with access to the carburetor unit. Remove the supply pipe from the surface of the carburetor. Then remove the lid from it. We measure from the edge of the float chamber to the level of the remaining fuel. The distance between them should not be more than 25.5 mm. If you find that this is not the case, then it will be necessary to adjust the position of the float. Depending on whether you decrease the distance or, on the contrary, increase it, the bracket on which the float is held will need to be bent to one side. The float axis must be positioned so that it moves freely.

Idle speed adjustment

Adjusting the idle speed of the car is carried out without disassembling the carburetor. However, before making adjustments, you will need to warm up the engine to 90 degrees. Remove the air filter housing. Take a screwdriver and tighten the quality screw until it stops. Then unscrew the screw 4 turns. We start the engine and turn on everything at once to increase energy use. We use the quantity screw to set the optimal speed for the VAZ 2107 - this number does not exceed 800 revolutions. Next, use the quality screw to achieve the maximum value - 900 revolutions. Then we unscrew it in the reverse position until the motor jerks. At this moment we stop twisting and make 1 revolution back. At the end of the work done, turn off the engine.

Adjusting the starting system

We carry out the adjustment on a not warmed up engine. The carburetor is not removed from the engine. First we connect the tachometer. Then pull out the carburetor choke control handle all the way. Let's start the engine. Using a screwdriver, open the edge of the air damper by one third. Rotate the throttle position adjusting screw under the choke control lever with an open-end wrench to 7mm and set the crankshaft speed to 3200-3400 rpm. Release the air damper. We rotate the trigger screw with a slotted screwdriver, loosening its lock nut with an 8 mm wrench. Thus, we reduce the rotation speed to 2800-3000 rpm. Finally, tighten the locknut again.

Setting the “choke” (air damper drive)

To begin setting up the air damper drive, remove the air filter from the carburetor. Open the air damper. On the damper control lever, loosen the locking screw of the drive rod end. Loosen the screw with one key, and use another 8 mm key to hold the screw bushing. We also loosen the tension of the rod sheath clamp screw. The choke handle must be recessed all the way. After making sure of this, turn the air damper control lever all the way by hand. The distance we set between the edge of the rod shell and the angle of the lever should be 10 mm. Turn the air damper control lever back clockwise. Finally, tighten the shell locking screw and the rod locking screw. Don't forget to make sure that the damper opens and closes completely.

If you are clearly confident that you will undertake the repair of your carburetor yourself, then additional information about the problems associated with it will definitely be useful to you. Well-known carburetor expert Nail Poroshin can share advice on this topic on the Internet.

Carburetor filter

The carburetor strainer is responsible for the normal flow of gasoline from the fuel line into the float chamber. Therefore, in order to avoid the problems that its contamination can bring (and this means improper operation of the entire fuel system!), it is recommended to carry out periodic cleaning.

Cleaning the strainer

Using a 13 key, unscrew the filter plug and remove it along with the mesh filter. Then we clean the cells of the mesh filter (a toothbrush will do) and blow them with compressed air. In the same way, we clean the removed filter plug and its seat in the carburetor cover. And be sure to blow everything out with compressed air.

Troubleshooting nodes

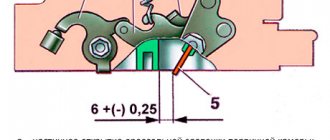

Measure the distance using a previously prepared piece of cardboard. The gap should be in the range of five to five and a half millimeters. If it is larger or smaller, make an adjustment. Using a flat-head screwdriver, you need to unscrew the plug on the adjusting bolt, which is located on the starter. Using a screwdriver, you need to rotate this adjusting screw to set the required gap

Please note that the width of the flathead screwdriver should be a maximum of 3.5 millimeters. But the tuning of the VAZ-2107 carburetor is not completed.

Then the damper gap in the first chamber is adjusted. To carry out this work, you will need to completely remove the carburetor. The lever, on which there are three arms, must be turned counterclockwise until it stops. In this position, it is necessary to measure the gap using a previously prepared wire. There should be no more than 0.8 millimeters from the chamber wall to the edge of the damper.

To make adjustments if necessary, you will need to rearrange the throttle and air damper drive rods. You can also bend the rod a little. All work that needs to be done on the starting device has been completed. Install the power system in reverse order. Then check the operation of the power system. But keep in mind that the VAZ-2107 ignition must be adjusted. The carburetor will function perfectly, but if the ignition timing is set incorrectly, you will not get efficient engine operation.

Carburetor cleaning

Carburetor cleaning is carried out during a routine inspection of the car, which is done once a year.

Important! Before you begin cleaning, you must dismantle the device. Care must be taken to ensure that foreign particles and bodies do not enter the intake manifold. The cleanliness of the workplace must be ensured!

- First, clean the outer surface of the mechanism. Carefully remove adhered dirt.

- We disassemble the float chamber and wash it with clean gasoline. When doing this, we try not to disturb the setting of the float, otherwise they will have to be adjusted again.

- We disassemble the vacuum accelerator and remove the strainer.

- It's time to remove all the jets. Since they are made of soft metal, it is recommended to clean them using a stiff fishing line or soft wood chips.

- Provided that the carburetor is completely disassembled, you can completely purge all fuel and air passages. In this case, you will need a compressor with a thin nozzle.

It is not necessary to clean the unit with gasoline; there are also special products for washing carburetors for this purpose. If it is not possible to use a compressor, then we replace it with a conventional pump. Once you have completely cleaned the carburetor, you can begin assembling it and reinstalling it. It is worth drawing your attention to the fact that all metal components must be disassembled and washed separately. Special liquids for washing carburetors can damage them. Do not neglect all actions! First of all, they are aimed at maintaining the functionality of the system.

Troubleshooting methods

If you find that the leak is in the fuel tank, you must replace it. You can try to prevent troubles of this nature. To do this, it is advisable to periodically carry out preventive inspections of the fuel system of the car, as well as monitor the tension of the tapes securing the gas tank and the good condition of their fastenings to the body.

The most vulnerable part of the fuel tank is its filler neck. Malfunctions of this part can also cause a fuel smell in the car interior. This element can either be welded to the container or screwed using a special rubber gasket. The last method of fastening is considered the most reliable. Welding defects or violation of its integrity will quickly lead to destruction of the entire seam. And the flange mount will remain in place and hold the pipe for a very long time. If you smell fuel, the first thing you should do is inspect the weld.

The presence of a fuel smell in the car interior can be caused by damage to the flexible hoses that connect to the fuel pump. They act as adapters from the line to the tank and from the line to the fuel pump. During movement, the pipes may be damaged or broken. If you find faults in these elements, they must be replaced.

It is necessary to maintain not only cleanliness in the salon, but also a pleasant smell. But not everyone succeeds. There is also a weak spot in the fuel supply system - this is the hatch to which the fuel pump and sensors that monitor the liquid level in the fuel tank are attached. All this is assembled into one module and located in the internal volume of the tank.

This entire unit is mounted using bolted fastenings located along the contour of the cover. There is a special rubber gasket between the tank body and this cover. It is this seal that can be a weak point, because it is continuously exposed to fuel vapors. And after a certain period of time, the gasket material begins to deteriorate. The result is a loss of tightness and the appearance of a fuel smell in the car interior.

The fuel system, and more specifically the tank itself, is equipped with special ventilation. It consists of hoses that are connected to plastic pipes. These hoses ensure the removal of gasoline vapors from the tank. And the weak point here is the plastic pipes, which can simply crumble. You can eliminate the smell in the cabin by replacing this entire unit.

Removing the carburetor

However, before you start cleaning the carburetor, you need to disassemble it, following a sequential procedure.

Using an “11” wrench, unscrew the bolt securing the liquid chamber housing to remove the semi-automatic starting device. Remove it together with the sealing rubber ring. Using a screwdriver with a sharp tip, pry off the retaining ring of the air damper drive lever. Then we pry up and remove the locking wheel of the throttle valve of the first chamber. We press on the levers and rods, disengaging them from each other. Unscrew the three screws securing the starter housing with a Phillips screwdriver. Remove the starting device assembly. It is not recommended to disassemble this device.

You can disassemble the carburetor without removing the starter. To do this, you will need to disconnect the lower lever of the starting device, and then use a Phillips screwdriver to unscrew the five screws securing the cover.

Use a hammer to knock out the axle with a float using a drift. Remove the cover gasket. We turn out the needle valve body with a spanner “11”. We take it out and the copper o-ring. We unscrew the inlet fitting with a “15” wrench and remove it together with the sealing ring. Using a 13 key, unscrew the solenoid valve and remove the idle jet. Unscrew the screw securing the throttle body heating unit. We turn out the main air and fuel jets. Remove the accelerator pump nozzles. Fuel jets can simply be shaken out of the wells.

Using a Phillips screwdriver, unscrew the three screws securing the economizer cover. After removing the cover, take out the spring and diaphragm. Using a screwdriver, unscrew the economizer nozzle and remove it. Unscrew and remove the four screws securing the accelerator pump cover. Next, remove the diaphragm along with the return spring. Now you can unscrew the screw of the plastic wire holder of the EPHH screw sensor and remove the wire. Unscrew the throttle valve stop screw. Then unscrew the screw securing the sector and the damper control lever. We remove the unscrewed lever and, applying considerable force, the sector. We remove the rod by unscrewing the screw securing it. Using a narrow screwdriver, unscrew the mixture quality adjustment screw and remove it along with the rubber o-ring. Finally, remove the rubber o-ring from the fuel intake pipe of the idle system.

That's all! The carburetor is ready for cleaning, adjustment of individual parts and complete tuning.

Preventative work

There are quite a few components in 2107 that require attention. In order to prevent the operation of the carburetor, it is cleaned and all systems are adjusted. For ideal operation, the VAZ 2107 carburetor setting itself must be ideal! It is not surprising that the mechanism quickly becomes clogged. This occurs when dust particles passing through the air filter collide with oil droplets. This mixture very often settles on the carburetor body. Dirt flakes can get into the float chamber and also clog the jets. Try to check the carburetor from time to time.

To prevent this problem, they came up with one way. To prevent dirt from getting into the balancing holes, they need to be raised a couple of millimeters higher. For this you can use polyethylene tubes with a thickness of 1 mm and a diameter of 5 mm. They must be inserted into the holes so that their protrusion on the side of the floats reaches 2-3 mm. Using a soldering iron, you need to flare them. The second end of the tubes may coincide with or be higher than the cap.

This modification ensures that now large enough dirt particles will not be able to get into the camera. The jets will also not become clogged with them.

Repair kit

In order not to worry once again that your carburetor may be damaged in the most inopportune place, it is recommended to always have a repair kit with you. It will help you easily and cost-effectively repair a faulty element. Most often, problems can be caused by wear of gaskets, valves, and diaphragms. Many of the car parts are subject to wear: battery, timing belt, cylinder head parts, hydraulic compensator, generator (brushes), muffler, panel. Even if it is a miniature device, like the ignition relay, which is used to turn on the starter, it still plays an important role. And usually all repairs boil down to the fact that these parts are successfully replaced. In most cases, these kits contain everything you need.

How to set idle speed

First, make sure that the ignition system is set correctly, all wires are in order and the engine is warmed up to operating temperature.

For this:

- Turn the “mixture quality” screw (counterclockwise) to maximum speed, this will enrich the mixture with fuel;

- Turn the “amount” counterclockwise, while the speed should still increase.

- Perform a quality check to see if you can still increase the speed.

The meaning of this operation is to tighten the “quality” screw with the “quantity” screw unscrewed to 850-900 rpm.

You can determine the revolutions by the tachometer on the dashboard, and if you are skilled, by ear.

Why should a car's fuel system be sealed?

Currently, the VAZ 2107 car has been discontinued, so it has now become a domestic automobile classic. Despite this, a lot of people drive “Sevens” in our country. The tightness of the fuel system in these cars has always left much to be desired. This applies to both early carburetor “sevens” and later injection ones.

The tightness of the VAZ 2107 fuel system is the key to clean air in the cabin

Meanwhile, the fuel system of any car must be absolutely sealed, and here’s why:

- fuel consumption increases. It's simple: if the car smells like gasoline, it means gasoline is leaking from somewhere. And the larger the leak, the more often the car owner will have to refuel;

- risk of fire. If there is a high concentration of gasoline vapors in the cabin, the risk of fire increases significantly. One stray spark is enough and the interior will be engulfed in flames. And the driver will be very lucky if he survives;

- harm to health. When a person inhales gasoline vapors for a long time, this does not bode well for him. This may cause nausea and dizziness. In some cases, a person may lose consciousness. In addition, systematic inhalation of gasoline vapors can lead to the development of cancer.

Considering all of the above, if the smell of gasoline appears in the cabin, the driver must do everything possible to eliminate this problem, no matter how insignificant it may seem.

Why should a car's fuel system be sealed?

Currently, the VAZ 2107 car has been discontinued, so it has now become a domestic automobile classic. Despite this, a lot of people drive “Sevens” in our country. The tightness of the fuel system in these cars has always left much to be desired. This applies to both early carburetor “sevens” and later injection ones.

The tightness of the VAZ 2107 fuel system is the key to clean air in the cabin

Meanwhile, the fuel system of any car must be absolutely sealed, and here’s why:

- fuel consumption increases. It's simple: if the car smells like gasoline, it means gasoline is leaking from somewhere. And the larger the leak, the more often the car owner will have to refuel;

- risk of fire. If there is a high concentration of gasoline vapors in the cabin, the risk of fire increases significantly. One stray spark is enough and the interior will be engulfed in flames. And the driver will be very lucky if he survives;

- harm to health. When a person inhales gasoline vapors for a long time, this does not bode well for him. This may cause nausea and dizziness. In some cases, a person may lose consciousness. In addition, systematic inhalation of gasoline vapors can lead to the development of cancer.

Considering all of the above, if the smell of gasoline appears in the cabin, the driver must do everything possible to eliminate this problem, no matter how insignificant it may seem.