If instability occurs in the idle speed, the first thing car owners are advised to do is check the condition of the idle speed sensor. Instability of the operation of the DXX or the XX regulator is manifested in the following:

- When driving, the car stalls when changing gears;

- The revolutions then drop sharply, then begin to increase again.

If you find one of these problems, the IAC will most likely have to be replaced. But first, let’s figure out what kind of device this is.

How to determine the malfunction of the IAC VAZ-2110: signs

Every car, without exception, needs timely maintenance.

This is quite normal, because different components have certain operational properties. And the breakdown of any device causes a lot of inconvenience to the driver. However, you shouldn’t give up right away. Every problem can be resolved if the right approach is taken. Thus, it will be quite easy to explain the reasons for each breakdown. One of these troubles that prevents the driver from driving a VAZ-2110 normally is a breakdown of the idle speed sensor (IAC or IAC).

A little theory

A sensor is an element that belongs to the category of measuring instruments. Basically, such a node is used to analyze, process and convert incoming information with subsequent output to a display board.

Among car owners, the idle speed sensor is called the abbreviation IAC. This is one of the most important parts in the internal combustion engine, which is responsible for the stable operation of the vehicle.

This regulator is an actuator, and it is not easy to identify problems with its operation. All this is due to the fact that VAZ cars do not have self-diagnosis. For example, if the IAC breaks down, the “check engine” error will not appear.

How does IAC work?

The functional unit regulates the volume of air supplied to the engine when the throttle valve is closed. This is necessary to ensure automated control of engine speed at idle.

The sensor is also involved in the process of warming up the internal combustion engine to operating temperature in cold weather. IAC operating range is from -40 to +130 degrees.

When the ignition in the car is turned on, the rod on the regulator extends all the way and rests against the calibration point of the throttle pipe. The IAC counts the steps and the valve returns.

When the motor is on, increasing/decreasing steps changes the amount of passing air masses. The required amount of air mass is supplied to the engine, which will ensure normal operation at idle speed.

The IAC on the VAZ-2110 is small in size and consists of three units:

- Stepper motor.

- Springs and rod.

- The needle is cone-shaped.

The device is secured to the throttle body using two threaded screws.

What could be the sensor malfunctions?

Failures in the functioning of the regulator cause a large number of problems for the car owner.

Accordingly, ignoring the problem for a long time can provoke an accident. Therefore, you should not neglect your own safety and it is advisable to identify the malfunction in the early stages. Signals of a faulty regulator:

- The engine speed constantly fluctuates. You may notice a sudden increase/decrease in this indicator.

- When the engine is cold started, there is no increase in speed.

- When you turn on additional electrical appliances (headlights, stove, etc.), the idle speed decreases noticeably.

- The internal combustion engine stops at idle and when the gear is engaged.

In practice, there are other signs of IAC malfunctions, but in order not to make a mistake and not confuse a sensor malfunction with other failures, it is important to know how the unit in question is checked.

Symptoms and causes of IAC malfunction

Signs of a malfunctioning idle speed sensor appear as follows:

- during a cold start, the crankshaft speed does not increase, which is why the engine runs unstable and tends to stall;

- there is a drop in the number of idle revolutions after a significant increase in the load on the generator - turning on headlights, electric heaters, and so on;

- the engine periodically stalls when any gear of the manual transmission is switched off (the symptom manifests itself while driving);

- The speed “floats” - it spontaneously increases and decreases.

Important point! There is a misconception that a regulator failure is necessarily accompanied by the inclusion of the Check Engine indicator on the dashboard. Since the element is an actuator, the light warning option is not provided in all cars.

If the car shows signs of IAC malfunction in the form of floating engine speed at idle, advanced diagnostics may be needed. A spontaneous change in the crankshaft rotation speed occurs for many reasons - failure of a sensor, air leaks, gas distribution malfunctions, and so on. It is better to start troubleshooting by checking the regulator.

IAC failure occurs for three main reasons:

- Open or poor contact in the power supply circuit. Simply put, there are problems with the wiring.

- Breakdown of the stepper motor due to natural wear and tear. In this case, only replacing the idle speed sensor will help.

- Contamination of the rod and cone with oil deposits.

There is a fourth reason - problems with the electronic control unit.

The problem is quite rare and is accompanied by additional symptoms - increased gas mileage, unstable operation in all modes, difficult starting, and the like. Oil deposits reach the rod thanks to secondary gases sent by the crankcase ventilation system for re-combustion. The more worn out the engine, the more deposits accumulate on the working cone. As a result, moving the rod becomes difficult; in advanced cases, the mechanism simply jams.

Checking the serviceability of the IAC

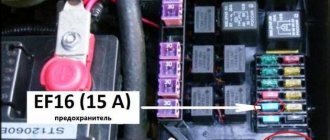

Initially, put the car on the handbrake and place wheel chocks under the wheels. Next, gain access to the device, disconnect it from the supply wire block. The next step is to check the voltage using a regular voltmeter. Contacts to be checked: minus of the internal combustion engine and plus on the contacts of the wire block A, D.

To perform a proper check, turn on the ignition and evaluate the information you receive. The voltage on the device should be no more than 12 Volts. If the indicator is less, then there may be problems with the battery. If there is no voltage at all, then you need to check the electronic control unit and the entire circuit.

Next, carry out the inspection with the ignition on. Check pins A:B, C:D. The optimal resistance should be around 53 ohms. With the sensor removed and the ignition on, if you connect a power supply to it, the conical needle should move. If nothing like this happens, the node is faulty.

Otherwise, the malfunction lies in the operation of the regulator, but do not panic and immediately go to a service station. You can replace the unit in question or clean it yourself.

Checking the sensor yourself

The sensor is located in the throttle body and to remove it for inspection, you just need to unscrew two screws.

To dismantle the IAC, you need to disconnect the block and unscrew two screws.

Before dismantling, you need to thoroughly clean the place of its attachment from dust and dirt and remove the negative terminal from the battery. But first, a check.

Sensor connection diagram.

We look at the connection diagram and check the sensor using a conventional multimeter in the following sequence:

- Checking for power supply to the sensor. To do this, measure the voltage at the two outer contacts of the block, A and D. Turn on the ignition, place the black probe of the multimeter on the engine ground, and the positive probe on the contacts one by one. The voltage should be within 12 Volts. If it is less or absent altogether, we look for an open circuit or blame the electronic control unit for everything. But first, we check the voltage at the terminals from ECU 4 and 54. Here, naturally, there should also be 12 V.

The voltage is normal.

- We switch the multimeter to ohmmeter mode and measure the resistance between contacts A-B and C-D on the sensor itself . As can be seen from the diagram, we are checking the resistance of the winding of the stepper motor of the regulator. Between the indicated contacts, the nominal resistance is from 40 to 80 Ohms, according to the factory rating - 53 Ohms.

- We check the electric motor for short circuit of the windings . To do this, measure the resistance at terminals A-D and B-C. The resistance should tend to infinity, that is, there should be no contact between the two windings. If there is resistance, no matter what the value, we conclude that the windings are short-circuited. This cannot be cured; we replace the sensor with a new one.

It cannot be said that this testing method 100% guarantees the functionality of the sensor; we only checked its electrical part. The mobility of the cone valve and the magnitude of its stroke are of great importance. And this can only be checked either at a special stand or with a special tester.

Checking the operation of the mechanical part of the sensor

To check, remove the sensor from the throttle assembly.

However, if the electrical part is in order, you can check the mechanical part of the regulator by eye:

- Unscrew the sensor and remove it from the throttle body.

- We connect the contact block to the sensor.

- Turn on the ignition. When turned on, the valve should move forward. If this does not happen, the rod is coked or the stepper motor is not working properly.

- We measure the distance between the sensor body and the conical valve - nominal 24 mm.

We measure the distance with a caliper.

If we removed the sensor from the car and the electrical test passed, but we still did not achieve mobility of the cone valve, we try to clean the regulator using a soft swab, a cotton swab and WD-40 penetrating lubricant or an aerosol carburetor cleaner. Good luck to everyone and stable idle speed in any weather!

Sensor with carbon deposits.

Soak the valve in cleaner.

Cleaned sensor.

Idle speed regulator VAZ-2110

On VAZ-2110 equipped with engines with an injection power system, the crankshaft speed of the power plant at idle is maintained by the XX (IAC) regulator.

The task of this element is to stabilize and maintain crankshaft speed at a given level under different conditions - abruptly releasing the gas pedal, creating a significant load on the on-board network (when the heater, headlights, etc. are turned on). A malfunction of the VAZ-2110 idle speed control does not affect the performance of the engine, but the lack of idle speed causes a number of inconveniences when operating the car.

IAC cleaning

It is recommended to wash and clean any non-working idle speed sensor on the VAZ 2110 to make sure it is faulty. The process is very simple and will not take much time. To do the job you need: carburetor cleaner, WD-40. The following actions are performed:

- The block is removed from the sensor;

- Apply any of the listed cleaning liquids to a regular cotton swab and carefully treat the contacts;

- Unscrew the screws securing the idle speed sensor;

- Remove the IAC from the seat;

- Inspect the idle speed sensor. If black dirt, oil, or IAC are detected, it is necessary to clean the entire throttle assembly. If not, spray WD-40 or cleaner onto the needle with a spring, thereby cleaning it. Dry the idle speed sensor VAZ 2110, 2112;

- Before reinstalling, measure the distance between the idle speed sensor housing and its needle, which on a working regulator is 23 mm.

When the IAC VAZ of the tenth family did not work normally, the guide needles wore out and the wire inside the housing broke. In these cases, the idle air regulator must be replaced.

On a VAZ 2110, the idle speed sensor is mounted in the reverse order of dismantling.

On the VAZ-2110, equipped with engines with an injection power system, support for the crankshaft speed of the power plant at idle is carried out by the XX (IAC) regulator. The task of this element is to stabilize and maintain the crankshaft speed at a given level under different conditions - sharply releasing the gas pedal, creating significant load on the on-board network (when the heater, headlights, etc. are turned on). A malfunction of the VAZ-2110 idle speed control does not affect the performance of the engine, but the lack of idle speed causes a number of inconveniences when operating the car.

Operating principle of IAC VAZ-2110

Let's consider the principle of operation of the XX regulator. This element is part of the design of the throttle assembly, which dispenses the air entering the cylinders.

When the gas pedal is released, the throttle valve closes the main air intake channel. To ensure the engine operates in this position of the damper, an additional channel of small cross-section is made in the throttle body, through which air is supplied to the cylinders, bypassing the damper. The idle speed control is designed to change the cross-section of the additional channel, which allows the ECU to maintain speed regardless of conditions.

It all works like this: when the throttle valve is closed, the XX regulator slightly opens the bypass channel. Using the mass air flow sensor, the amount of air entering through the additional channel is determined. Based on this information, the ECU regulates the amount of fuel injected. Using data from other sensors, the control unit determines the crankshaft speed and, if they do not correspond to the norm, sends an impulse to the IAC in order to stabilize the engine operation by changing the channel cross-section.

Replacement

To work you will need:

- New regulator suitable for your VAZ 2114;

- Rags;

- Crosshead screwdriver;

- 13mm wrench;

- Carburetor cleaner;

Having the necessary tools and materials available, you can get to work.

- Place the car on a level surface and turn on the handbrake.

- Raise the hood and secure it firmly to avoid unnecessary injury.

- Disconnect the negative terminal from the battery. IAC is an electrical device, therefore this event is mandatory.

- Remove the protective casing from the power unit.

- Loosen the clamp slightly to disconnect the rubber tube from the air filter connection. This is necessary so that the tube does not interfere.

- Remove the clamp that holds the air filter pipe. The corrugation is disconnected and moved slightly to the side.

- The fastening screw of the cable going from the gas pedal to the throttle valve needs to be loosened slightly.

- Use a rag to remove all dirt near and on the throttle assembly itself.

- Treat the throttle assembly mounting nut, as well as the IAC mounting screws, using the almighty WD40. This will make dismantling easier.

- Remove the throttle assembly completely. To do this, unscrew two nuts using a 13 mm wrench.

- Remove the sensor connector from the terminals.

- If there is dirt at the contact points between the DHH and the throttle assembly, be sure to remove it with a rag.

- Using a screwdriver, unscrew the two fasteners that connect the throttle assembly and our desired sensor.

- Remove the regulator from the mounting socket.

- Clean the entire throttle body with carburetor cleaner.

- Install the new regulator in the same position as the newly dismantled DXH was in.

- Use engine oil to treat the new rubber gasket, which should come with the IAC.

- Replace the two screws and make sure the adjuster is firmly seated in the throttle body.

- Return the remote control to its place and check how securely the nuts are secured.

- Connect the connector to the device terminals.

- Reinstall the cable, pipes and tubes. Tighten all clamps properly.

- Reinstall the engine protective cover.

Replacement procedure

After assembly, a very important stage remains - calibration of the new IAC. To do this, you need to connect the battery and turn on the ignition. 10 seconds is enough. During this time, the electronic control unit will perform calibration on its own.

That's it, the new regulator is ready for use. To avoid problems with replacement, watch the training video.

Symptoms of a problem

The VAZ-2110 idle speed control is a structurally simple mechanism consisting of a stepper electric motor and a spring-loaded needle, the displacement of which leads to a change in the cross-section of the channel. But despite the simplicity of the design, this part often breaks. Symptoms of a broken XX regulator:

- Unstable “floating” crankshaft speed during idle operation;

- Inconsistency of speed with the normal indicator (800-850 rpm);

- Spontaneous stopping of the power plant when releasing the gas pedal;

- No increased speed when starting a “cold” engine (“warm-up” mode);

- Drawdown in speed after creating a load on the on-board network;

It is noteworthy that such symptoms are also caused by a malfunction of the damper position sensor (DPS). But it is not difficult to recognize which sensor is faulty.

The XX regulator is an actuator, and it has no “feedback” from the ECU. Therefore, this sensor does not fall under self-diagnosis. As a result, regulator failure occurs only in the engine. As for the TPS, this element is checked by the system, and if it malfunctions, the “Check engine” will light up.

Types of malfunctions of the idle speed sensor

The most common malfunctions of the inactive VAZ sensor are as follows:

- loss of contact or unstable contact. The main reason for this lies in the oxidation of the connector or moisture entering it. Often this malfunction occurs intermittently, which makes diagnosis difficult;

- contamination of the stem, which greatly complicates its movement. This usually occurs due to premature replacement of the air filter;

- failure of the rod motor. This is one of the symptoms of increased voltage in the on-board network. Or indicates the poor quality of the idle air regulator used, which is also not uncommon;

- air leaks due to destruction of the sensor o-ring;

- barrel wear. In this case, the rod may get stuck in one position, causing spontaneous movement, which negatively affects the quality of the fuel mixture.

The most typical malfunction that occurs not only on VAZ cars, but also on most modern foreign cars is clogging of jambs. The air filter only traps large dust particles, and microscopic dust particles that penetrate through it eventually settle on the throttle valve and governor rod. Premature filter replacement, use of the so-called “zero” and leaks only approach the point of regulator failure.

In turbocharged engines, another cause of malfunction is turbine wear: during this breakdown, oil enters the air tube, where it contaminates literally everything: the throttle valve, the regulator rod, the receiver itself, air ducts, etc.

One of the important points in preventing malfunctions is regular cleaning of the shock absorber - this will not only help prevent possible damage to the regulator, but also stabilize the operation of the engine and its response to pressing the accelerator pedal. For flushing, it is recommended to use a standard carburetor cleaner.

It is important to know that critical contamination of the sensor rod creates an increased load on the electric motor, which can lead to its failure. In addition, some ECU models have rather weak protection against increased consumption, which leads to burnout of the resistance of the electronic control unit. Despite the relatively low cost of the resistor itself, resetting the unit is a very expensive procedure, especially since identifying this malfunction requires diagnostics using special equipment.

Causes of failure. Node check

The reasons for the malfunction of the XX regulator are breaks in the electrical winding. engine and needle jamming due to dirt or corrosion. But the sensor is not always the “culprit” for missing idle speed. Therefore, before removing and checking the sensor, check its power supply circuit.

For all checks you will need a multimeter. The power circuit is checked with a device set to “voltmeter” mode. Diagnostics is simple - we disconnect the block with wires from the regulator, connect the “negative” probe of the multimeter to ground, and the positive one to the terminals marked with the letters “A” and “D”. With the ignition on, we take measurements. If the circuit is working properly, the readings should correspond to the rated voltage of the circuit. If there is no voltage, you should check the computer and relays responsible for powering the sensor.

Malfunctions

The peculiarity of the idle speed sensor is that it is impossible to trace the occurrence of a malfunction due to the operation of the on-board computer. The system does not recognize a breakdown, so everything has to be done manually.

There are several characteristic signs that can tell you about problems with the XX sensor:

- The car often stalls when idling;

- A phenomenon called floating speed occurs;

- There are no increased speeds when starting a cold engine;

- If the gear is switched off, the engine may stall spontaneously.

There are also a few errors on the on-board computer, but you shouldn’t rely solely on them.

| Error code | What does it mean |

| 0505 | DXX error |

| 0506 | Low idle speed |

| 0507 | Increased idle speed |

Many people confuse the signs of IAC failure with the throttle position sensor. The symptoms are indeed very similar. But the point is that the on-board computer signals a breakdown of the position sensor, but regarding the IAC it is silent.

Diagnostic methods

Before proceeding with the replacement, we recommend that you really make sure that the cause of all problems with your VAZ 2114 is the faulty IAC. To do this, there are two main ways to check the status of the device.

Explore both to see which diagnostic option is best for you.

First way

- Get a tester if you haven't had one before.

- Disconnect the DXX from the block with wires.

- If you have a 1.6-liter engine, then be sure to disconnect the throttle assembly fasteners and move it from the receiver about 1 centimeter.

- Use a voltmeter to check if voltage is being supplied to the regulator. The minus is connected to ground, and the plus goes to the block - use the AD pins.

- With the ignition on, the tester should show at least 12 W.

- If there is no voltage, then there is a problem in the power circuit or electrical unit of the car.

- If there is voltage, but it is significantly less than 12W, then this indicates a low charge level of your battery. Be sure to recharge the battery.

- After checking the circuit for efficient operation, proceed to study the DXR itself. At this stage the ignition is turned off.

- In turn, connect the terminals to the tester to pairs A-B and CD. The normal resistance should be approximately 53 ohms.

- Change the pairs to AC and BD. When measuring them, the resistance should turn out to be infinitely large.

If the check shows that the readings do not meet the standards, then several actions can be taken:

- Clean the contacts, throttle body, needle needle and other sensor components using carburetor cleaner. It is not difficult to find, and it is cheaper than specialized cleaners;

- If possible, try to repair the IAC;

- If it is impossible to carry out repairs, replace the old sensor with a new regulator.

Faulty sensor

Second way

For this testing option, you will need a simple tester that you can easily make yourself. We offer corresponding video instructions

Now we proceed as follows.

- Unscrew the fastening screws of the regulator and remove it from its seat. The location of the DXX is already well known to you.

- Disconnect the regulator from the main block, and apply the finger of your right hand. And the index finger. You don't need to put a lot of effort into creating a set.

- The nuance of placing a finger lies in the features of the regulator itself, at the end of which there is a cone-shaped needle.

- If the engine stops working, then if the IAC is working properly, the needle comes out completely.

- Your finger will allow you to feel a slight jolt when you turn on the ignition.

- If this push is absent, then the device has failed.

The maximum distance from the protruding rod head to the flange is 23 millimeters. When buying a new IAC, be sure to take this fact into account.

A Question of Choice

When checking the sensor, we found out that the device was faulty and needed to be replaced. But what should we choose in its place?

Today, two types of devices from different manufacturers are in particular demand for the VAZ 2114 - OMEGA and KZTA.

In the case of OMEGA, pay attention to number 2112-114830. If you decide to choose KZTA, then the option that suits you has catalog number 2112-1148300-04.

The last two digits may be different, and this is a very important point. If your IAC number ends in 01, you should not change it to 03, otherwise you will simply waste your money. The device is replaced with a similar one or with a subsequent number - 01 is changed to 01 or 02, etc.

The cost of the IAC is around 300-400 rubles, depending on the region and the specific store. Be careful, as there are now an impressive number of fakes on the market.

Choosing a replacement regulator

On the VAZ-2110 with both 8-valve and 16-valve injection engines, a sensor with catalog number 2112-1148300 is used. Additionally, at the end of the marking there is a prefix consisting of two numbers, for example, 01, 02, 03, 04. This index indicates the manufacturer of the regulator (01 and 03 - “Pegasus”, 02 and 04 - KZTA). When choosing a replacement regulator, pay attention to two nuances - the seal and the height of the needle protrusion above the body. Factory spare parts use a red seal, while counterfeits use a black rubber element. The height of the needle protrusion above the body is 23 mm.

Before installing a new regulator, it is recommended to coat the sealing ring with a thin layer of engine oil to ensure a tight fit of the part in the seat and eliminate the possibility of air leaks.

Video: Review of VAZ idle speed controllers

Source

General concepts

One of the most common troubles that prevents you from fully driving a car is the idle speed sensor of the VAZ 2110 and modifications. Although this device is called a sensor among drivers, it will still be correctly called the idle speed controller, abbreviated as IAC, because all automobile sensors are measuring equipment, and this product serves to automatically stabilize and maintain idle speed by supplying air to the engine VAZ 2110 with the throttle valve fully closed.

IAC is an important component of the engine and plays a significant role in the stable and uninterrupted operation of any VAZ vehicle.

The VAZ 2110 idle speed sensor (abbreviated DXX) is an actuator, simply a valve consisting of an electric motor, a spring, and a rod on which a shut-off needle is installed (you can see it in the photo). It is through which the volume of air is dosed. That is, when the throttle of a VAZ 2110, 2112 is completely closed, and the controller determines that the idle speed needs to be increased, the IAC generates a command to change the position of the needle. It moves, partially or completely opening the intake port, through which air bypasses the throttle and then mixes with fuel. As a result, the engine does not stall.

Why do you need a sensor?

DXX, also called idle air control, is one of the elements of the intake system of a fuel-injected internal combustion engine. Its purpose is to stabilize the idle speed of the engine.

The operation of an internal combustion engine requires a carefully balanced mixture of fuel and air - only in this case can stable operation of the engine be ensured with optimal power output. It is with the help of IAC that the air supply to the combustion chambers of the engine is regulated, which helps to achieve the optimal ratio of proportions in the fuel mixture. Since the throttle valve is completely closed at idle, engine operation in this mode is carried out exclusively with the help of the governor, and in the event of a malfunction, it is unstable.

When several electrical consumers are switched on simultaneously (air conditioning plus lights, sound system, cooling fan), a high load occurs on the generator, which is transferred directly to the internal combustion engine. The idle speed sensor helps stabilize the engine as power consumption increases. This is achieved by increasing the air supply to the cylinders. Likewise, high speeds are maintained while the engine warms up.

It should be noted that if the sensor malfunctions, the quality of the air-fuel mixture is seriously impaired, which leads to detonation or the inability to ignite the fuel in the cylinders. This significantly reduces engine power and increases fuel consumption.

As practice has shown, such symptoms are most often observed on injection VAZ cars. Therefore, we will consider the main problems and ways to solve them using the example of a car of this brand.

Signs of IAC malfunction

Unfortunately, the 2110 VAZ DXX is not equipped with a self-diagnosis system, so the “CHECK ENGINE” light signal will not indicate a malfunction. Loss of performance on the VAZ 2110, 2112 is determined by the following main features:

- the engine “stalls”, for no apparent reason, at idle;

- idle speed “floats”;

- when a “cold” VAZ 2110, 2112 engine is started, there is no increased speed at all;

- The engine stalls, namely, after turning off the gear while driving.

Signs of breakdown

Symptoms of IAC malfunction:

- the engine does not idle. At the same time, the idle speed may jump, freeze, and then return to normal;

- engine idling;

- there is no compensation for increased engine load;

- Difficulty starting the engine. If pressing the gas makes starting easier, then this is a sure sign of an IAC malfunction;

- insufficient heating speed is maintained or there is none;

- The car stalls at idle when you let off the gas, when you change gears.

Role in engine operation

To correctly recognize a regulator malfunction, you need to understand how the IAC works. We have already examined in detail the design of the idle air regulator and a brief diagnostic process, so now we will only focus on its role in engine operation.

In the life support system of an internal combustion engine, the idle speed sensor is used to regulate the supply of air passing from the throttle valve (through the bypass channel, the beginning of which is located in front of the throttle valve). When many electricity consumers are switched on simultaneously, the load on the generator and, as a result, on the engine itself increases. To maintain a stable idle speed and battery charge voltage, the IAC opens the passage, allowing more air to enter the internal combustion engine. Similarly, higher speed is achieved when the internal combustion engine warms up.

Breakdowns

Main malfunctions of the idle air regulator:

- power failure, which can be caused by problems with electrical wiring, oxidation of contacts in connectors. If the connection is unreliable, such a malfunction periodically appears, which can complicate the diagnostic process;

- incorrect stroke of the rod due to contamination;

- electric motor failure;

- destruction of the sealing ring;

- barrel wear. The movement of the IAC damper occurs without biting and there should be no slipping of the worm gear. To assess the condition of the rod and worm gear, it is recommended to study the method of disassembling the IAC.

Among the above-mentioned faults, the most common fault is rod contamination. During operation, sludge deposits accumulate in the throttle valve channels. If the throttle valve on your car has not been cleaned for a long time, then, most likely, problems with idle speed are associated with carbon deposits on the regulator rod. To check the IAC it must be removed from the throttle valve. Carburetor cleaner can be used to flush a toilet.

It is recommended to avoid critical contamination of the regulator rod, since increased load on the electric motor can damage the elements of the IAC control system. There have been cases of failure of the resistor of the electronic control unit (ECU) due to overload of the current control channel. Most likely, the increased load was caused by the resistance of mud deposits and carbon deposits to the movement of the rod. The cost of a new resistor is ridiculous, but to quickly identify a fault of this type requires diagnostic equipment and the qualifications of a technician.

Diagnostics

There are three types of idle stabilization systems:

- solenoid (there are only 2 contacts in the connector);

- rotary (3 contacts in the connector);

- step (4 contacts in the connector).

In modern automotive manufacturing, a stepper motor is often used. In the center of such a device there is a ring magnet and 4 windings located at right angles to each other. Applying voltage to certain windings causes the rotor to rotate, which moves a rod (gate) through the worm gear. To determine the working IAC it is necessary to check the condition of the motor windings. To do this, you need to measure the resistance on the first two contacts and on the second two. To measure, you will need basic skills in working with a multimeter and the device itself.

- at pins A, B and C, D there should be a resistance of 40 to 80 Ohms. The absence of resistance will indicate an open circuit (for a VAZ the value is usually 50-53 Ohms);

- There should be infinitely high resistance at terminals A and C, A and D, B and C, B and D, which will indicate that there is no short circuit. This type of failure requires the purchase of a new IAC.

To determine whether power cables are open, you need to “ring” the wiring with a multimeter in resistance measurement mode.

Check engine

Modern injection engine control systems are capable of detecting some malfunctions of the idle speed sensor. As an example, let's consider the recorded deviations indicated in the error mask (list of malfunctions for which the Check engine is turned on) of the VAZ M7.9.7 engine control unit according to EURO III toxicity standards:

- P1509 - IAC control circuit overload;

- P1513 - IAC control circuit, short to ground;

- P1514 - IAC control circuit open or short circuit to +12 V.

Also, when decrypting, the error code may appear as “IAC Problem.” In this case, you should not immediately buy a new regulator, as the problem may lie in the power cables.

You can read error codes through the diagnostic connector using a special scanner. The code can be easily found on the Internet. In most cases, thorough cleaning will help delay replacement. The most accurate and fastest way to identify a faulty idle air control valve is to monitor its operation in real time. This will require an oscilloscope and diagnostic skills. It will not be possible to apply voltage to the sensor terminals to observe the movement of the rod. The IAC is controlled by pulse width modulation (PWM). There are special devices on sale for quickly checking the MAC of VAZ cars. But their cost is too high if we talk about the frequency of use when repairing a personal car. You can find testers made by you on amateur radio forums.

If there is instability at idle, car owners are first advised to check the condition of the idle speed sensor. Instability of the DXX or XX regulator is manifested in the following:

- While driving, the car stops when changing gears;

- Turnover drops sharply or starts to rise again.

If you find any of these problems, the IAC will likely need to be replaced. But first, let's try to figure out what kind of device this is.

How to remove IAC

If signs of malfunction characteristic of the IAC are detected, then it will need to be removed (first for inspection). On the VAZ 2110, this sensor, which is small in size (easily fits in the palm of your hand), is located in a seat on the throttle body (can be seen in the photo).

Removing the idle air control

If necessary, its dismantling is quite easy - it is secured with only two screws. In extremely rare cases, it is necessary to remove the entire VAZ 2110 throttle assembly.

Dismantling is carried out in the following sequence:

- The VAZ 2110 is placed on the handbrake;

- The negative terminal of the battery is disconnected;

- The wiring harness connected to the IAC is disconnected;

- Be sure to clean the connection between the sensor and the throttle body to prevent dirt and rust from getting into the hole;

- Unscrew the fastening screws holding the idle speed sensor of the VAZ 2110.

Appearance and location

DHX is responsible for adjusting the idle speed. Hence another name: idle air control. Externally, the device is a miniature electric motor, at the end of which there is a small cone-shaped needle.

Where is it? The IAC is attached to the throttle body with two screws or simple paint. Next to the DHX is the throttle position sensor. Therefore, there should be no problems finding the sensor.

How to check the sensor?

If you have a tester, checking is easy:

- Set the VAZ 2110 to the handbrake;

- Disconnect the IAC connector to check;

- Check the voltage of the VAZ 2110, 2112 sensor circuit, while connecting the “minus” to the engine, the “plus” to the removed block, namely to terminals A: D (marked on the block, you can see the diagrams);

- The ignition is turned on and the readings given by the idle speed regulator are checked, which should be about 12 V. The value will be less - most likely the battery is discharged. When there is no voltage, it is necessary to check the entire circuit, and then the electronic control unit. There are no malfunctions, which means the circuit is working - the IAC installed on VAZ 2112 engines and other modifications are checked;

- The tester terminals are connected to the block, the circuit is as follows - first to terminals A: B, then to C: D. The resistance should be within 53 Ohms;

- Next, pairs A: C, B: D are checked - in this case, the resistance on a working product will be infinitely large.

When, as a result of these checks, the sensor reveals a discrepancy in the readings, it should be replaced. Also, the inoperative state of these VAZ 2110, 2112 engine sensors, in the unscrewed position, can be checked by attaching a block to them, then you need to turn on the ignition.

When the power is connected to the working product, the rod with the needle will change position. No changes will occur on a broken sensor. If a breakdown of the idle air regulator is detected, of course, it must be repaired. But there is no need to rush to a car service center - you can do the repairs yourself, saving money and time. But first, in general, it is worth cleaning the IACs; often after this they return to “life”.

Sensor diagnostics

You can check the idle air valve yourself. Its faults can be divided into two parts: mechanical and electrical. There are several verification methods.

Visual inspection

First you need to conduct a visual inspection. In this way, you can detect body defects, needle wear, and carbon deposits. If deposits form, you can clean them with carburetor cleaner. It is also recommended to clean the entire throttle body as it is in a similar condition.

Using diagnostic programs

The operation of the IAC can be checked using a diagnostic adapter and special programs. For example, you can use the simplest ELM327 adapter and the OpenDiagMobile program. In the program menu you need to select the desired position of the XX regulator and watch the operation of the valve. It is better to set it at least 20 steps more than the current position.

Wiring check

For this we need a multimeter. With the engine off, remove the connector from the sensor. We set the measurement limit on the measuring device to 0-20 V DC voltage. We measure the voltage at the connector. Normally it should be 12V.

Checking the regulator resistance

To do this, we will need to measure the resistance between terminals A, B, and C and D after disconnecting the sensor terminal. We move the multimeter to the position of measuring resistance at the limit of 0-200 Ohms (Ω).

The normal value is within 50-55 Ohms. The resistance between A and C, B and D must be infinity.

Checking with throttle assembly

There is another way to diagnose IAC. To do this, you will need to remove the throttle assembly from the studs along with the sensor.

By connecting the valve connector and turning the ignition on/off, you can observe the operation of the IAC live. See how the needle works, if it is rubbing somewhere, check the evenness of the stroke, hear suspicious sounds.