To begin with, it should be noted that on cars such as the VAZ-2107, the manufacturer can install starters of various types. Essentially, they perform the same function, but may differ slightly from each other in terms of design. Also note that the starter is a special mechanism that generates direct current, while creating the torque necessary for the crankshaft to start rotating.

Starter components

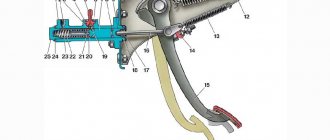

To repair a part of any device, you need to understand what it consists of. So, for example, the design of the starter is as follows:

- anchor;

- frame;

- drive unit;

- relay. Connection to it is made using contact bolts, which are considered structural elements. Each of them consists of parts that are fairly easy to replace if necessary.

Remember that it is quite easy to repair the starter on a VAZ-2107 with your own hands. To do this, you need to know what exactly it consists of, as well as what it is intended for.

Cleaning nickels from carbon deposits on the solenoid relay

All this is best done on a removed part, which you can read about here. After this, you need to use a deep socket and a wrench to unscrew the three nuts securing the cover to the body, as is clearly shown in the photo below:

When all the nuts are unscrewed, you need to press on all the bolts from the same side and pull them out from the back:

Now carefully fold back the relay cover, but not all the way, as the wire will get in the way:

Pay attention to the central copper plate: it will definitely need to be cleaned of plaque and carbon deposits, if any. Also, you need to unscrew the nickels themselves (two in total) by unscrewing the two nuts on the outside of the cover:

And then you can take them out from there with your hands, from the back side:

Also clean them thoroughly with fine sandpaper until shiny:

After completing this simple procedure, you can put everything back in place in the reverse order. If the problem was precisely the burnt nickels, then it will definitely disappear!

troubleshooting

In order to correctly determine where to start, you should think about what could be the reason that the starter does not work:

- If, after you turn the key in the ignition, the engine stubbornly refuses to start, you should check the light bulbs located on the instrument panel. If they burn weakly or go out completely, most likely the reason lies in a non-functioning battery. Or it may simply be discharged. We pick up a tester and check the battery capacity and voltage;

- if the battery is fully operational, you need to check what position the speed switch is in and move it to the “P” position;

- The next thing to figure out is whether the power from the ignition switch is getting directly to the starter.

There are two ways to do the last step.

Method 1. A wire made of copper with a cross-section of 2.5 mm is inserted into the open connector. One end goes to the starter and the other to the battery terminal. Thanks to this method, it is possible to simulate ignition.

Method 2: This verification method will require two people. One of them will turn the key in the ignition switch, while the second will touch the tip of the wire that comes from the unloading relay with a control probe. If the warning light comes on during this procedure, this indicates that there are no problems in the ignition switch, as well as in the relay.

Purpose of the starter and its location

The “ten” has a small, but quite powerful 4-band electric motor, which is responsible for the primary rotation of the crankshaft. Without the participation of an electric motor, it is impossible to ensure the required crankshaft rotation speed. We replace this unit, since for a gasoline engine with an average cylinder capacity, 3 kW of energy is enough to start.

The starter supplies energy from the battery; it is a DC motor. Receiving voltage from the battery, the motor power is increased by four brushes. They are the main elements in any car starter. If necessary, the brushes can be replaced. If the starter meters are faulty, they can be purchased separately and replaced. But to do this, in any case, you will first need to remove the starter.

Starter repair

As you know, VAZ-2107 cars are equipped with both injectors and carburetors. In this regard, the sequence of actions and the repair work on the starter itself may differ slightly from each other. However, no matter what your car is, it is quite possible to solve this problem yourself.

First of all, it is necessary to dismantle the starter. To do this, the car is installed above the inspection hole or raised on a lift. But first you should disconnect the negative terminal from the battery. Next, the procedure depends on what is installed on your car: carburetor or injector.

Reasons why the starter does not work

If the solenoid relay operates but does not turn, the cause may be a burnt-out commutator. It will need to be cleaned. Another option is that the brushes are worn out and will require replacement.

If the armature turns, but the flywheel does not, then the reason may be in the clutch: slipping, rupture of the ring, or slipping along the axis of the lever. Replacing the clutch and engagement lever will help.

A strange sound that a gear starter makes when the armature rotates is a weak fastening, a skewed fastening, damaged flywheel drive gear teeth, worn bushings at the bearing.

We repair the starter on a car with an injection engine

We remove the mudguards, both main and additional. This action is impossible if you do not have a socket wrench size 8. Using it, you need to unscrew 4 screws that are located on the main panel, or rather, on its side and front fastenings, as well as 2 bolts located on the additional one. There is also a lower screw, but it has a different diameter. To remove it you will need a 10 mm socket wrench.- Now, using a long 13mm socket wrench, unscrew the bolts that secure the clutch housing and starter. After this, unscrew the bolts with which the starter is attached directly to the bracket and the inlet pipe extension.

- We remove the stretch marks of the intake pipeline and very carefully, using the same wrench, unscrew the exhaust manifold nut, and then remove the shield.

- We disconnect the wire that we have left from the battery terminal and remove the tip located on the contact rod.

- The traction relay output must be freed from wire 50, and then the starter itself must be removed. Now it can be disassembled. Before doing this, try to thoroughly clean the part to remove any dirt stuck to it.

Once the starter is in your hands, the procedure is as follows (by the way, it is absolutely identical for any type of engine of the above car):

- check the solenoid relay. After connecting the 50th relay output to the “plus” terminal of the battery, we connect the starter housing directly to the “minus” terminal. This way, it will become clear whether the problem is in the relay itself or is it in something else. If it is in working condition, then a distinct click will be heard during this action;

- To check the integrity of the windings, you need to get rid of the starter cover and disconnect the brush assembly. Using an ohmmeter, check whether there is a short to the starter housing;

- if the results of our test showed that the relay still works, we take out the anchor. To do this, unscrew the bolts securing the starter casing, remove the lock washer, as well as the gaskets. Then unscrew the two nuts and completely remove the back cover. Thus, the starter winding housing is freed from the studs;

- unscrew the nut of the eccentric rotation axis and remove it from the body, disconnecting the armature.

At this point, the process of disassembling the starter can be considered complete. The anchor, by the way, cannot be repaired, but it can easily be replaced with a new one. Reassembling the starter is carried out in the reverse order.

Diagnostics of VAZ 2107 starter faults

The VAZ 2107 starter can fail for various reasons.

The starter hums, but the engine does not start

The reasons for the situation when the starter hums, but the engine does not start, may be the following points.

- Over time, the teeth of the starter gear stop engaging (or do not engage well) with the flywheel. This usually occurs when the wrong engine lubricant is used. If you pour thick oil into the engine in winter, the starter will have difficulty cranking the crankshaft.

- The gear that meshes with the flywheel may be misaligned. As a result, the teeth engage with the flywheel ring with only one edge. This is usually due to a failure of the Bendix damper system. Externally, this manifests itself in the form of a characteristic hum or grinding noise and results in broken flywheel or drive teeth.

- There have been disturbances in the power supply system to the starter (brushes are worn out, terminals are oxidized, etc.). Insufficient voltage does not allow the starter to accelerate the flywheel to the required speed. At the same time, the starter rotates unstably, a hum and buzzing appears.

- The pusher fork, which brings the starter teeth to the flywheel crown and removes them after the engine starts, has failed. If this fork is warped, the relay may operate but the drive gear will not engage. As a result, the starter hums, but the engine does not start.

The starter clicks but does not turn over

Sometimes the VAZ 2107 starter clicks, but does not spin. This may happen for the following reasons.

- There are problems with the power supply (the battery is discharged, the battery terminals are loose or the ground is disconnected). The battery should be recharged, the terminals should be tightened, demining should be carried out, etc.

- The fastening of the solenoid relay to the starter housing is loose. This usually happens when driving on bad roads or as a result of over-tightening the mounting bolts, which simply break while driving.

- A short circuit occurred in the traction relay and the contacts burned out.

- The positive cable going to the starter has burned out. It is also possible that this cable may become loose. In the latter case, it is enough to tighten the fastening nut.

- As a result of wear on the bushings, the starter armature became jammed. In such a situation, replacement of the bushings is necessary (removal and disassembly of the starter will be required). A short circuit or break in the armature windings can also lead to a similar result.

- Bendix is deformed. Most often, its teeth are damaged.

Bendix of the VAZ 2107 starter fails quite often

Video: VAZ 2107 starter clicks, but does not turn

Crackling sound when starting the starter

Sometimes when you turn the ignition key, a cracking and grinding sound is heard from the starter. This may occur as a result of the following faults.

- The nuts securing the starter to the body have become loose. Rotation of the starter causes strong vibration.

- The starter gears are worn. When starting, the overrunning clutch (Bendix) begins to make a cracking noise.

- Due to the lack or absence of lubrication, the bendix began to move along the shaft with difficulty. The assembly should be lubricated with any engine oil.

- Flywheel teeth damaged as a result of wear no longer engage with the starter gear.

- The timing drive pulley has come loose. In this case, a crackling noise is heard when the engine starts and disappears after warming up.

Starter won't start

If the starter does not respond at all to turning the ignition key, the following situations are possible:

- The starter is faulty.

- The starter relay has failed.

- The starter power supply circuit is faulty.

- The starter fuse has blown.

- The ignition switch is faulty.

It happened once to start the engine in winter, when the starter flatly refused to rotate through the ignition switch. I stopped the car at the lake where I went fishing. When I was putting it back together, the starting device was inactive. There's no one around. I did this: I found the control relay, removed the wire from it connecting the system to the ignition switch. Next, I took a long 40 cm screwdriver (I found one in my bag) and closed two starter bolts and one retractor bolt. The starter started working - it turned out that sometimes this happens with these devices due to cold and dirt. It is necessary to apply current directly to make the electric motor work.

Review: Gear starter StartVolt VAZ-2101 - A powerful replacement for the standard classic starter.

View from the side of the box:

Another side surface of the package:

The next side shows the starter power, its starting speed, and the minimum temperature of its efficiency:

Starter power 1550W. significantly exceeds the power of the standard Zhiguli starter, which has a power of 1300W. The starter kit comes with a passport with a warranty card, but it all consists of advertising parts for the electrical equipment of the car manufactured by the StartVolt company. The photo shows a receipt pasted by the seller with the cost of this starter:

The starter itself in the box is carefully placed in a foam shock-absorbing cell:

At the rear end of the starter you can see its power terminals and copper parts:

The starter itself is manufactured in China under license and under the control of a Russian company, it is compact and its weight is small, about 3 kg:

The working part of the starter is somewhat smaller than the similar part of a standard starter; the gear feed mechanism and the starter fastening itself are, of course, standard:

View of the starter itself from the other side:

I would like to note the fact that the 13 wrench nut on the upper terminal at the top right in the photo (the lower nut on the copper bolt) was loosely tightened, and we managed to tighten it well. When tightening this nut, the force may cause the black cage of the round insulator of the solenoid relay to turn slightly, from where the copper bolts come out. To prevent this from happening, you need to tighten the nut carefully, without excessive lateral forces, and hold the cage itself with your hands. If the clip still turns a little, you need to carefully return it to its place with your hands and force. In the working position, this clip is fixed with an internal lock, and you can feel this fixation with your hand. In the following photo you can evaluate the comparative dimensions of the new and old standard Zhiguli starter:

The difference, as they say, is visible to the naked eye. After installing the new starter, the car's engine was started. To be honest, I was delighted when the starter was working. The speed of the crankshaft at startup is such that it seems that the spark plugs have been pulled out of the engine, and cylinder compression has ceased to interfere with the operation of the starter. The startup sound has also changed dramatically. I also liked the fact that when the starter is turned on, the voltage drop in the on-board electrical network is relatively small. So far, the operation of this starter on the car brings true satisfaction. All that remains is to wait for the winter cold and check the confidence of starting the engine in the cold. I think such a starter will be able to do it.

This is interesting: How to disassemble a spark plug

Mechanism repair and installation

After removing the starter from the car, we disassemble it and inspect the components. Particular attention is paid to the condition of the bendix and sliding bearing bushings; the housing must be disassembled for inspection. Carefully remove the brushes from their sockets and clean the commutator of dirt. We assemble the device and check its functionality using the battery.

Installation of the VAZ 2107 engine starting mechanism is carried out in the reverse order of removal. If during testing it is revealed that the starter cannot be restored, it is replaced with a new one. If an injector is installed on the car, after connecting the battery, it will take some time to create the necessary pressure in the gas line. The engine should be started only after the pump has stopped running.

Dismantling the unit

To perform this operation, you need a set of wrenches and a portable lamp to illuminate the work area. The procedure for dismantling the starter is as follows:

- Disconnect the battery.

- On the solenoid relay, unscrew the nut on the contact pin and remove the wire connecting it to the battery.

- Turn off the control circuit.

- Using a key set to “13”, unscrew the three bolts securing the starter to the cylinder block.

- Carefully remove the device from its seat and, unfolding it, remove it from the engine compartment.

When dismantling the device, be careful not to damage nearby wiring.