In this article we will figure out why a knocking sound is heard when turning the steering wheel in place or while the car is moving. Let's find out the main causes and methods for eliminating them.

Author: Raul_ HF and wheel alignment mechanic; experience - 3 years. Service/repair consultant at Toyota DC; experience - 4 years.

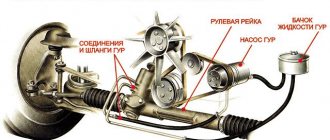

The steering rack is a simple design and fairly reliable unit, which is why today it is used on the vast majority of cars. The wheels turn by moving the rod, which moves the steering rods connected through ball joints to the wheel hubs. The rod has teeth that mesh with the worm gear. The actuator worm mechanism receives rotation from the steering wheel through a system of shafts and cardan joints. Since the entire steering mechanism is subjected to significant stress, parts and components naturally wear out over time. As a result, free play or play is formed in the connections, which can usually manifest itself in the form of knocking noises when driving over uneven surfaces or when turning the steering wheel.

Knocking noise when turning the steering wheel

Thanks to hydraulic or electric power steering, which acts directly on the rod when turning the steering wheel, the main load on transmitting rotation is removed from the steering drive. This significantly extends its service life, however, the component components are also subject to wear and tear over time. A knocking sound when the steering wheel rotates in place is in most cases associated with wear of the crosspieces or splined joints of the steering rack drive shaft.

The crosspieces contain roller bearings. Exhausted rollers cause “biting” of the universal joint. This manifests itself in the form of knocking noises when the steering wheel is turned without the car moving.

The following possible causes are not related to the steering. When turning the steering wheel to the left or right, the CV joint may bite and make a knock if the joint is faulty. For example, damaged by corrosion due to dirt and moisture after driving with a torn boot, or as a result of wear and tear. When you start driving with the wheels turned, knocking noises from the rotation of a faulty drive under load are especially obvious.

Knocks when turning the steering wheel can be caused by a violation of the integrity of the strut spring. For example, a broken coil when turning a wheel touches body elements.

Design characteristics

An important technical characteristic of the Kalina’s front suspension is the presence of shock absorber elements in the strut. In the design of the car, the lower arm and the steering knuckle in a pair are fastened simultaneously with the cross member related to the front suspension, which is carried out using a ball joint. Similarly, due to silent blocks, the brake pads are mated to the suspension.

To adjust the angle of the steering axis, the suspension uses washers that are located in the connection formed by the lever and the brace. The angular contact bearing can be fixed to the wheel drive using a nut. When repairing Kalina's front suspension, it is imperative to take into account the extent to which the process of adjusting components and structural parts is possible.

Lada Kalina hubs are characterized by the presence of fastening nuts, which are interchangeable. They can only have right-hand threads. The presence of a rod, which is a stabilizer, ensures the stability of the transverse, being responsible for it. Its knee, which has rubber hinges, must be secured to the suspension when using silent blocks with racks. Fastening the torsion bar part to the body is ensured by the presence of brackets.

It must be taken into account that the design of the suspension sometimes requires the driver to carry out certain measures that are aimed at strengthening the elements of the strut supports (cups). This allows you to increase your mileage without worrying about suspension chatter.

Improved suspension scheme

Kalina is equipped with SSAZ suspension. At the same time, installation of CC20 or KAYABA models on a car is associated with their best characteristics, while the first guarantees silent operation, which is combined with high reliability.

Knocks when turning the steering wheel while driving

When a wheel hits a sharp bump, the joint, which has lost its rigidity, produces a characteristic knock due to the gap. The problem is resolved by searching for the faulty part, replacing it or repairing it. Knocks when turning the steering wheel while driving on uneven surfaces may indicate probable wear of the following components and elements:

- steering rack mechanism

- steering rods

- steering tips

- rack housing fastenings

- ball joints

- shock absorbers

- anti-roll bar bushings

To restore the power steering rack, special repair kits are provided, which include a set of seals, oil seals and bushings. A high-quality overhaul and correctly adjusted unit will return it to almost its original condition, at an adequate cost for labor and spare parts. Due to the complexity of their design, many electrically driven racks cannot be disassembled or repaired. If an internal fault is diagnosed, this expensive unit is replaced only as an assembly.

A knocking noise when turning the steering wheel left or right on the road can be caused by a worn-out shock absorber. The shock absorption efficiency of a worn or leaking suspension damping element is significantly lower than normal, and when receiving load as a result of body roll in turns, on bumps and potholes, such a shock absorber “breaks through.” If MacPherson struts are installed on the front suspension, the bearing of the support cup may also produce a knock when cornering.

The cause of a knocking sound when turning the steering wheel in motion can be wear of the rubber clamps and bushings through which the rack body is attracted to the body or subframe. At the same time, the rack is not rigidly fixed, but “dangles” in its fastenings and knocks when the steering wheel is turned to the right or left, as well as when driving over bumps and holes. The same applies to worn-out SPU bushings, which are not able to tightly hold the stabilizer rod, causing it to move, vibrate and knock due to increased free play.

Features of Kalina's suspension

A detailed inspection of Kalina’s suspension reveals hydraulic shock-absorbing struts, which are attached to the steering knuckle in the lower part, being the basis of the entire structure of the unit. The bolt located in the upper part of the steering knuckle allows you to adjust the camber element.

In the assembly, the upper part passes through a hole that is located in the existing bracket. The body part is equipped with a mudguard, to which the top of the rack is fixed using three nuts. Due to the existing elasticity of this unit, high-frequency vibration is excellently damped. In this case, a characteristic swaying of the Kalina suspension strut occurs during the working stroke.

Kalina's suspension, which is characterized by the presence of conical or coil springs, ensures a particularly smooth ride due to the presence of a stabilizer. This allows you to avoid compromising the lateral stability of the car. This function is also performed by levers that relate to transverse braces. The bearing for turning the strut must allow the wheels to turn.

Knock in the steering wheel on uneven surfaces when driving straight ahead

In cases where knocking is heard on the steering wheel when driving over uneven surfaces, this may indicate wear on the bearings of the steering column shaft located in the cabin. This malfunction causes radial play of the shaft, accompanied by knocking. Axial play of the shaft is also possible due to wear of the locking or sealing rings. In some cases, manufacturers provide the supply of spare parts for inexpensive repair of the dispenser. During the overhaul, related parts, fastening and sealing elements are also replaced, which may still be in working order, but may soon fail and require repeated repair of the unit. On a number of models where disassembly and restoration are not provided, the steering column is replaced as an assembly.

Causes of knocking noise when turning the steering wheel

There are a number of reasons why a knock is heard when turning the steering wheel. To more accurately determine the malfunction, it is necessary to determine three circumstances:

- Sound type. It can be single or repeated, voiceless or voiced (usually metallic), loud or quiet.

- The place from which the sound comes. For example, in the wheel, in the suspension, in the steering wheel.

- Circumstances of occurrence. In particular, when driving, when turning the steering wheel in place, when the steering wheel is turned all the way, when turning left or right.

Based on such data, you can focus on the source of the knocking sound.

| Place of knock | Causes of knocking |

| Knocking in the wheel | Partial failure of the angular velocity joint (the boot is torn, problems with the bearing), noise from tie rods/steering rods, steering rack when driving on rough roads, shock absorber struts (spring knocking), stabilizer struts |

| Rack knock | Damage to the rack shaft, increased play of the bushing and/or shaft bearings, on machines with electric power steering, mechanical damage to the engine shaft and/or worm drive, wear in the steering shaft driveshaft |

| Knocking in the steering wheel | Partial failure of the steering rack, rusting of the rack drive shaft, wear of the worm drive in the EUR and/or mechanical problems with the electric motor |

| Steering wheel position | Causes of knocking |

| When turning the steering wheel all the way (left/right) | When replacing the front control arm, it is possible that the lever hits the subframe when turning. Sometimes craftsmen simply do not fully tighten the fasteners, which cause them to creak when turning. |

| When turning the steering wheel while the car is stationary | Faulty steering rack, universal joint, loose fasteners, tie rods/ends |

| When turning the steering wheel while the car is moving | The same reasons as when the car is stationary, but problems with stabilizer struts and shock absorber struts are added here. |

Below is a list of reasons why knocking occurs when turning in the area of the wheel, suspension and steering wheel, according to the degree of their prevalence.

see also

Steering rack lubricant

- 17 1 21k

Steering rack malfunctions

- 10 2 25k

Why is the steering rack knocking?

- 59 2 107k

How to eliminate steering rack knocking

- 43 1 64k

How to disassemble the steering rack

- 36 0 57k

A knocking sound when turning the steering wheel indicates problems with the vehicle's steering system. The causes of knocking may be malfunctions of the constant velocity joint (CV joint), ball joint, wear of the steering tip and/or support bearing, stabilizer link and other malfunctions. In any case, when a knock is heard when turning the steering wheel, it is necessary to carry out diagnostics as quickly as possible, since malfunctions of the steering system not only worsen over time, but can also lead to emergency situations when the car is moving, even an accident.

Constant-velocity joint

With the wheels turned completely to one side, the CV joint will most often creak (it may even give impacts to the steering wheel). When turning the car to the left, the right outer CV joint will crunch/knock, and when turning to the right, the left one will, accordingly. Inner CV joints usually creak when driving at high speed on uneven roads, so they have nothing to do with knocking when turning. So if you hear a knocking sound when turning or sharply accelerating your car, the outer joint most likely needs to be replaced. However, first you can remove it and inspect it - if there is no wear or it is small, then CV joint lubrication will help.

Tie rods and tie rods

Due to natural wear and tear, the lugs and rods may, over time, become loose and squeak and make knocking noises when turning the machine. To diagnose, you need to jack up the car on the side where the annoying sound is coming from and first remove the wheel. Next, you need to shake the rods and tips and check for any play in them. It often happens that the boot on the tip breaks, which means dirt and moisture gets inside. This causes a corresponding knock.

There are cases when, for example, when performing a wheel alignment operation, a car enthusiast or master forgets to tighten the fastening nut between the steering rod and the steering tip. Accordingly, when you turn the steering wheel, both in motion and at a standstill, a loud metallic knock will be heard. You can determine more precisely if you shake the front wheel left and right with your hands, it will dangle and make similar sounds.

Steering rack

Steering rack malfunctions are one of the most common causes of knocking noise when turning wheels. Moreover, this can happen both while moving and when turning the steering wheel in place. There are several reasons why a car's steering rack may knock:

- Loose steering fasteners.

- The plastic support sleeve has failed (considerably worn out, play has appeared).

- The occurrence of play in the rack shaft bearings.

- Increased gap between the teeth of the steering rack (this leads to both play and a dull knock when the steering wheel rotates in place).

- The anti-friction gasket wears out, causing the clamping “cracker” to vibrate, knocking directly on the rack body.

How to replace the lower cross

To repair, you need to unscrew the protective cover, which will interfere with access to the cross. To remove it you need to unscrew three bolts. Before unscrewing the column, it is blocked. This will make it possible to keep the audio signal loop intact. Just as in the case of the bushing, you need to make notes here with a marker.

So, here it is - the cross. Now you need to disassemble it - you can use a vice and carefully cut it. You can install a new one, but first you need to prepare the seats - they are thoroughly cleaned and lubricated.

It is also better to prepare the installation sites on the crosspiece - before installing it, remove the covers and treat all places with lubricant. After pressing, check and lubricate the crosspiece again - this will protect it from moisture.

Steering cardan

If, when turning the steering wheel, you hear a knocking sound from the steering column, then the steering wheel shaft driveshaft is most likely to blame. Very often UAZ owners face this problem. A malfunction occurs due to an increase in the gap in the spline joint. On VAZs, a knocking sound from the steering column occurs due to a broken universal joint. It can be heard both while driving and when turning the steering wheel back and forth in place.

Many owners of domestic front-wheel drive VAZs - “Kalinas”, “Priors”, “Grants” - are faced with the fact that over time the crosspiece in the driveshaft begins to creak. Its diagnosis is carried out according to the procedure described above. If play and creaking are detected, the car owner can choose one of two options. The first is to buy a new cardan, the second is to try to repair the installed one.

Moreover, they are repaired not because of the high price, but because of a large number of defective new cardan shafts. In particular, we are talking about the fact that the cardan can “bite”. This is caused by the fact that its half with splines moves with jamming, and jerks are already felt in the new part. Accordingly, when purchasing a new crosspiece, you need to make sure that it moves freely in all directions. It often happens that in a fork with splines, the bearings are initially skewed due to misalignment of the holes. Therefore, it is up to the car owner to decide whether to buy a new cardan or not.

Another way out of the situation is to replace the existing needle bearings in the cardan crosspiece with caprolactane bushings. This option is supported by the fact that many taxi drivers who own VAZs, due to the fact that they have to turn the steering wheel a lot, do exactly this.

This option implies the complexity of repair work. As for dismantling, they usually use 13mm wrenches and a flat-head screwdriver.

On the Internet you can find many conflicting reviews about various cardan shafts and bushings. For VAZ “Kalina”, “Priora”, “Granta” cars, crosspieces of the “CC20” and “TAYA” brands are often installed, or a more expensive option is Japanese spare parts Toyo and GMB.

Replacing the bushing: step-by-step instructions

The process of replacing the bushing is not very complicated. First of all, the car must be driven into the garage, since repairs will take some time. So let's get started. We remove the steering column panel - this is very simple, we need to unscrew all the bolts and remove it from the latches. As a rule, it is held on by three bolts. After this, we remove part of the air vent - which does not interfere with washing - there will be a lot of dust in it.

After our workplace has been prepared, we unscrew everything that prevents us from removing the steering column. When this work has been done, we use a marker to mark the position of the column that we will need to establish during its final collection. So, the column is removed - we do it carefully, since it weighs a lot. In the photo below we will see the place without the column, as well as the column itself and its bushing in an approximate version.

Next, we need to put something soft on the floor, for example, foam rubber and a rag on top of it. Next, on the prepared surface, with the steering wheel down, we place the steering column itself. You won't be able to pull the bushing out by hand. Therefore, we screw several screws into it - they will serve as a support for us to further pull it out. When the self-tapping screws are not fully screwed in, cover the steering wheel with a rag and rest your feet on it, and with your hands, using pliers, pull the sleeve by the self-tapping screws. After some effort, it will come out of its place. In the photo you will see that the bushing is no longer there.

Next, we need to clean the shaft from old grease and dirt. After cleaning, treat it with new lubricant and install the new part in its place.

As a rule, after replacing it, the knocking disappears, but if the crosspiece is in order. If it was broken or worn out, it also needs to be replaced. Now it's time to replace the cross.

Shock absorber struts and/or support bearings

If the cause of the knocking lies in the shock absorbers or support bearings, then there will be knocking not only when turning the steering wheel to the right/left, but also when driving in a straight line. However, during sharp turns, especially at high speed, such a knock will be more pronounced, since additional loads will be applied to the shock absorbers and bearings.

In the latter case, the cause of the knock may be a broken shock absorber spring. This usually happens at its edges (top or bottom). Accordingly, when driving on uneven roads, as well as when the car rolls in turns, the driver may hear a metallic clanging sound. When turning left - right spring, when turning right - left spring.

You can check the shock absorbers and bearings by examining them for play. To do this, you need to dismantle the wheel and shake/twist the shock absorbers and bearings. In rare cases, the knocking noise may be caused by a loose fastening nut.

Front stabilizer

If the stabilizer link partially fails, a dull knock is heard when the wheels turn while moving. Moreover, the wheels begin to knock if they are turned to one side or the other at approximately 50...60%. However, a faulty strut itself can creak not only when turning, but also when the car is moving on an uneven road. Often the car also “fidgets” on the road, that is, it is necessary to constantly control (twist) the steering wheel. Additional signs - the car body rolls too much when entering a turn and sways when braking.

Subframe (atypical situations)

Sometimes atypical situations that are quite difficult to diagnose lead to knocking when turning. For example, there is a known case when, while the car was moving, a small stone hit the subframe and got stuck there. When you turn the steering wheel in one direction or the other, a natural displacement of the steering gear elements occurs, and they seem to run over this stone. When the elements were restored to their original position, they jumped off the stone, making a characteristic sound. The problem was solved by removing the stone.

When repairing suspension elements, for example, when replacing the front arm, the latter may touch the subframe when turning the wheel. Naturally, this is accompanied by a blow and a grinding sound. To get rid of it, it was enough to lift the subframe using a pry bar.

Preparing for diagnosis

You need to start by trying to determine the location and nature of the sound. A clear and loud knock in the steering wheel is generated by the impacts of metal on metal, while a muffled knock is generated by metal on plastic. Check the tire pressure: their difference can also cause noise.

Before inspection, you need to clean the front suspension, the easiest way is with a powerful jet of water. After it dries, you can put the car on a pit or viewing platform. There you need to wipe the parts dry with a rag and, if necessary, clean off dried dirt or rust with a brush. Among other things, this way you will save yourself from sand falling from above.

When preparing to diagnose the suspension, you should pay attention to the tightening of the threads, rubber cushions and boots.