Almost every owner of a domestic VAZ has encountered the problem of high idle speed. That is, when starting the engine, the speed is increased as expected, but when warming up, it does not fall below 1500 or 1000 revolutions, which is not normal. There may be several reasons for this - including a malfunctioning TPS and idle air control.

To fix the problem, you should diagnose the main components and components that affect the increase in speed.

Why might there be high idle speed?

One of the main reasons may be the failure of the IAC, which is responsible for adjusting the engine speed at idle. If the sensor malfunctions, the speed can “float”, rise and fall spontaneously. If the sensor completely fails, the car may simply stall at idle.

Also, increased speeds can be caused by a malfunction of the throttle position sensor (TPS). Over time, moisture gets under the sensor, which leads to the formation of oxide and rust on the regulator rod. To check this, you need to unscrew the sensor and carefully inspect it and the rod. If rust is found on them, they should be treated with penetrating lubricant or WD 40.

As a rule, the problem of increased speed on the VAZ 2110-12 lies precisely in these two sensors. Therefore, first of all, you need to pay attention to them.

Problems with carburetor cars

So, let's start with common carburetor problems. Often the engine speed does not drop due to problems with the throttle valve. For example, when the driver steps on the gas, the throttle must be opened wider to allow more air to enter the cylinders to burn fuel. After the gas pedal is released, the throttle closes and the speed decreases.

If the damper does not close completely, an over-enriched mixture enters the cylinders, and the speed is increased. The cause may be severe contamination of the throttle assembly or damage to the valve itself (deformation). First you need to clean the damper; carburetor cleaning liquid is suitable as a cleaner.

Where are the IAC and TPS sensors located?

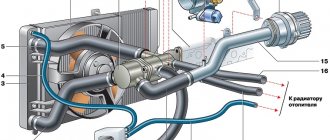

So, first, let's check the IAC sensor. It is located on the throttle assembly below the TPS sensor. Dismantling it is very simple - remove the block from the sensor and use a Phillips screwdriver to unscrew the two bolts securing it. Then we pull out the sensor or perform diagnostics on it, read about this below.

The throttle position sensor is located above the IAC and is also secured with two bolts. It unscrews quite easily; there is no need to remove either the pipe or the throttle itself. Disconnect the block, unscrew the two bolts and pull out the sensor.

To make sure that the problem with high speed is really in one of these sensors, and maybe in each other at once, you should diagnose them.

Let's sum it up

As you can see, in order to accurately determine why the engine speed is not reset, in many cases in-depth diagnostics may be necessary. For carburetor engines, cleaning and adjustment of the carburetor itself is often necessary, while the injector will require computer diagnostics.

If the problem is not on the surface (the throttle cable has become sour, after washing or dry cleaning, the carpet in the cabin is not installed correctly, which presses the gas pedal, etc.), then it is better to take the car to a service center.

The most complex situation is when the design of the power system involves the presence of a large number of sensors and actuators. In this case, even the use of diagnostic equipment does not always allow you to quickly and accurately determine the problem.

If diagnostics are difficult, it is optimal to deliver the car to a service that specializes in repairing a specific brand of car. As a rule, these are official dealer service stations; it is less common to find third-party organizations.

Finally, we note that timely detection of a problem allows you to save the life of the internal combustion engine and other components and assemblies. In other words, high idle speeds, floating speeds and jumps indicate that there are problems with the air/fuel supply or with mixture formation. Ignoring such problems negatively affects the engine and its service life.

Didn't find the information you are looking for? on our forum.

Diagnostics of the IAC sensor VAZ 2110

There are several ways to check the idle speed control. To check we need a multimeter. First, let's describe the simplest way:

IAC check method 1

- Disconnect the block and unscrew the sensor

- Turn on the ignition

- We connect the block to the removed sensor, the needle in it should extend. If this does not happen, then the sensor is faulty.

IAC check method 2

- Disconnect the negative terminal of the battery

- Using a multimeter, we measure the resistance of the external and internal windings of the IAC, while the parameters of contacts A and B, and C and D should be 40-80 Ohms.

- If the instrument scale is zero, it is necessary to replace the IAC with a serviceable one, and if the required parameters are obtained, we check the resistance values in pairs B and C, A and D.

- The multimeter should detect an open circuit

- With such indicators, the IAC is serviceable, and if they are absent, the regulator must be replaced.

IAC test method 3

- Disconnect the block from the sensor

- Using a voltmeter, we check the voltage - the “minus” goes to the engine, and the “plus” to the terminals of the same block of wires A and D.

- The ignition is turned on, and the received data is analyzed - the voltage should be within twelve volts, if less, then most likely there are problems with the battery charge. If there is no voltage, then you will have to check both the electronic control unit and the entire circuit.

- Then we continue the inspection with the ignition on, and analyze terminals A:B, C:D one by one - the optimal resistance will be about fifty-three ohms; During normal operation of the IAC, the resistance will be infinitely high.

Ways to eliminate the “sore”

How to fix the problem? For this we only need a screwdriver. Let's begin the procedure.

- By disconnecting the terminal block and also unscrewing two screws, we dismantle the assembly.

- We notice that traces of rust inside interfere with the movement of the wheel that regulates the position of the damper.

- We fill the insides of the defective device with a penetrating anti-rust aerosol.

- Use a development screwdriver to turn the wheel.

- We reassemble in reverse order.

Check to see if the engine idle speed is now high. The problem should go away.

Now let's look at another case. Let's say we have high idle speed in a VAZ 2114. This is what we do when faced with this situation.

When clarifying the circumstances of the problem under investigation, we always initially check the operation of the idle speed sensor. This device consists of a needle built inside an electromagnetic coil. The needle either moves inside the coil, moving away from the hole in the throttle pipe, or moves out, closing this hole, thereby stopping the supply of air for combustion of the mixture.

Also read about adjusting engine idle speed and repairing a Tavria car muffler with your own hands. This element is located at the throttle valve, opposite the gas pedal cable. To diagnose it, we pull out the terminal block from it, start the car, after which we see that we still have high engine speeds that have not changed at idle. Then we remove this defective unit, then clean it or replace it. For work we take:

- Unscrew the two screws. We take out the broken node.

- We connect the wiring to it. Turn on the ignition. If the needle of the device moves slightly inside the coil to the touch, then it is working.

- If the needle does not react when an electric current is applied, wash the device with a toothbrush using gasoline.

- We do the assembly in reverse order.

When you cannot restore the functionality of this unit with your own hands, it is better to purchase a new one. Moreover, the cost of spare parts is low.

Other fixes

This node can be diagnosed as follows. It is necessary to disconnect the terminal block from our mass flow regulator, and then start the engine, after which it is necessary to drive the crankshaft speed above 2000 rpm.

In this case, the emergency mode is automatically launched, portions of the mixture are now calculated only by the position of the damper. If the sensations show that the car with the disconnected sensor has become more dynamic than with the connected one, then the malfunction of this unit is obvious. To replace it, take the following tools:

- Phillips screwdriver;

- flat screwdriver.

- After turning off the engine, disconnect the wires from the mass air flow sensor.

- Loosen the clamp and remove the hose on the inlet pipe.

- We dismantle the defective device by unscrewing two bolts.

- We are replacing the device.

- We do the assembly, moving backwards point by point.

This is how this cause of high revs is eliminated.

For some reason it didn't help

Now let's look at another situation. The car owner changed, for example, the idle speed sensor, and the crankshaft speed became high, or remained high as before.

The reasons for this unpleasant phenomenon may be as follows.

- Most likely, the car enthusiast made the replacement just like that, at random, maybe it would stop turning too quickly. The real state of affairs suggests that the fault needs to be looked for elsewhere.

- If this sensor is not a completely new model, it has an adjusting bolt, it may need to be tightened in order to adjust the problem unit. Modern idle air valves do not require any additional adjustment when installed. However, for example, if the Priora has high idle speeds, then you can look for the adjusting screw on this car.

- It is possible that the new spare part was defective.

- The new spare part was installed incorrectly.

Diagnostics of TPS VAZ 2110

To diagnose the sensor we need a voltmeter.

- It is necessary to turn on the ignition and check the voltage between the slider contact and the minus with a voltmeter. The voltmeter should read no more than 0.7 V.

- Now you need to turn the plastic sector, thereby completely opening the damper, then measure the voltage again. The device must show at least 4 V.

- Turn off the ignition and disconnect the connector from the sensor. We check the resistance between the slider contact and some terminal.

- Slowly, turning the sector, monitor the voltmeter readings. Make sure that the needle moves smoothly and slowly; if you notice jumps, the throttle position sensor is faulty and must be replaced.

Symptoms of TPS malfunction

- Deterioration of vehicle dynamics

- Floating idle speed

- Jerking during acceleration

- High idle speed, car does not slow down

- The engine may stall at idle

If one or more of these symptoms are detected, the sensor should be checked and diagnosed in the manner described above.

Reasons for floating speed on fuel-injected cars

Now let's move on to the injector. Please note that on many injection cars, after cleaning the throttle valve, the assembly also needs to be additionally “trained”. As for problems, the injection system itself is more complex, that is, there are more reasons for high speeds compared to the carburetor.

Coolant sensor - coolant

As a rule, problems with speed can be caused by problems with both mechanical elements and electronic components. In the list of main malfunctions, experts highlight malfunctions of the coolant temperature sensor, which is installed in the cooling system.

In simple words, if the specified sensor gives an incorrect signal, the ECU considers that the engine is cold and activates the warm-up mode. In this case, the control unit raises the speed so that the power unit operates stably and reaches operating temperature faster.

Idle air control - IAC

Also, problems with speed can begin due to problems and malfunctions in the operation of the IAC (idle air regulator). It also happens that the throttle cable gets stuck and becomes wedged. The spring that closes the throttle valve may also become stretched or damaged.

Air leak

Special attention should be paid to gaskets, since air leaks can lead to disruption of mixture formation. This means that you need to separately inspect manifold gaskets, injector seals, etc.

Which TPS sensor to choose for replacement

For stable and long-term operation of the sensor, we advise you not to buy too cheap analogues of questionable quality. The factory installed throttle position sensor was GM 2112-1148200 .

- DPDZ /2110/ GM 2112-1148200 price from 300 rub.

- DPDZ /2110/ PEKAR 2112-1148200 price from 200 rub.

- TPDZ /2110/ StartVOLT VS-TP 0110 price from 200 rub.

- TPDZ /2110/ HOFER HF 750260 price from 150 rub.

- DPDZ /2110/ CJSC Account Mash 2112-1148200-05 price from 400 rub.

- DPDZ /2110/ JSC RIKOR ELECTRONICS 2112-1148200 price from 300 rub.

Replacing the Throttle Position Sensor on a VAZ 2110

Using a Phillips screwdriver, unscrew the two sensor mounting bolts, disconnect the block and remove the sensor.

If traces of rust or oxidation are found on the rod, which regulates the speed, it is necessary to clean it with penetrating lubricant.

Next, a new sensor is installed, the block is connected and the idle speed is checked.

Which IAC sensor to choose for replacement?

2112.1148300-04 was installed on cars 2110-12 . If for some reason you cannot buy a factory one, you can install an analogue sensor from other manufacturers.

- РХХ /2110-12/ engineer. (2112.1148300-04) factory (KZTA, Kaluga) price from 600 rub.

- РХХ /2110-12/ engineer. FENOX SIP10100O7 price from 300 rub.

- РХХ /2110-12/ engineer. HOFER HF 750381 price from 250 rub.

- РХХ /2110-12/ engineer. MANOVER MR-2112-1148 price from 350 rub.

- РХХ /2110-12/ engineer. StartVOLT VSM 0112 price from 450 rub.