April 20, 2017 Lada.Online 185 946 65

If, while operating a LADA car, you notice that during load (when the air conditioner is running, the heating is on, etc.) in a traffic jam, the engine begins to operate unstably (troits, pulls poorly, etc.), perhaps the reason lies in the ventilation system crankcase The article proposes to solve the problem by installing a PCV valve from a foreign car.

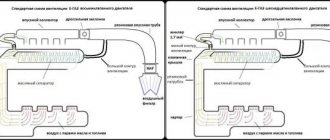

Diagram of the standard crankcase ventilation system

The crankcase ventilation system of VAZ engines consists of two circuits that operate at different load modes and speeds:

- The small ventilation circuit is connected to the valve cover and the intake manifold (behind the throttle body). This connection diagram provides intensive crankcase ventilation due to the vacuum that occurs in the intake manifold when the throttle is closed. To avoid an effect such as hyperventilation, the cross-section of the small circuit is limited by a jet in the cable throttle body with a diameter of 1.7 millimeters. This circuit operates in the region of 800-1500 rpm.

- A large ventilation circuit is connected to the valve cover and the air pipe (in the pre-throttle space). This scheme provides intensive crankcase ventilation at high speeds. The cross section of the large contour is 16-18 millimeters

Examples demonstrating the shortcomings of the standard crankcase ventilation system:

- A car is going down a hill with the gear in gear. In this mode, the engine operates at higher speeds with a reduced load. A high vacuum is created in the crankcase, and a large ventilation circuit is connected, in which there are no control valves. Since both circuits are connected to one volume of the oil trap, a strong vacuum in the crankcase will draw a fresh portion of air bypassing the throttle. The mass air flow sensor will show increased air flow, and the ECU will try to close the throttle. Having realized that this is not possible (it is already closed), the lean mixture will be corrected by increasing the fuel supply (fuel consumption will increase). As a result, the entire internal volume of the engine will work as a parallel receiver of very significant volume, connected to the intake, bypassing the throttle. It is this volume that will interfere with the formation of a high-quality mixture.

- A car in a traffic jam drives under tension with additional consumers (for example, the air conditioner is on). The compressor clutch is connected, the load increases abruptly. The engine does not have enough air, it begins to pull it from the crankcase, bypassing the throttle. But the ECU is also aware of the clutch engagement and also supplies more air by opening the throttle. The vacuum drops sharply, the vacuum brake booster (VBR) does not have enough strength to hold the car. Leap forward. The ECU sees an increase in oxygen and closes the throttle. A sharp increase in vacuum, VUT seizes. The car jerks, the transmission hits. And so on ad infinitum.

As a result, in both cases, when the engine is running, speed jumps occur and the engine choke under the load. Jerking and vibration are possible on manual transmissions, automatic transmissions and automatic transmissions. To eliminate these shortcomings, it is proposed to modify the design according to one of the presented schemes.

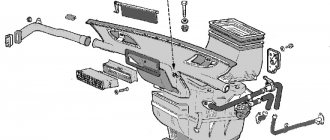

How heating and ventilation work

There is supply and exhaust ventilation in the interior of the VAZ 2110. The windshield trim has holes through which air either spontaneously (when the car is moving) or forcibly - with the help of a heater fan - enters the passenger compartment. The supplied air exits through the provided slots - at the ends of the doors, between the upholstery, and door panels.

But you don’t need to think that the VAZ 2110 is all covered with cracks, and the air simply doesn’t stay in it.

In fact, all of the holes mentioned are equipped with valves that work “for release” and prevent (at least hypothetically) the spontaneous entry of air from the outside.

However, you can make high-quality tuning of the heating system, then the car will be truly comfortable.

Heating is done as follows:

- The air passes through the heater radiator, while warming up. The heating temperature is controlled by a relay;

- Next, the warm air is distributed through the air ducts;

- Special deflectors direct the main flow of hot air to the windshield and to the center of the cabin. The flaps can be used to block/open the flow to the side windows;

- There are two more flaps - for heating the front window and also for the feet of the driver and passengers. For this purpose, deflectors are provided for the front seats: one pair is at knee level, the other is almost on the floor. For rear passengers, there are air ducts under the front seats plus a pad on the floor tunnel;

- There are special handles to control air flows;

- The fuse located in the mounting block protects the entire electrical heating system from blowing. Operating principle of the heater

If desired, you can carry out tuning, adjust the flow of heat to different parts of the VAZ 2110 interior, thereby improving comfort.

Schemes for upgrading the crankcase ventilation system

Schemes for modifying the crankcase ventilation system, as well as a description, are provided by IgorRV.

For LADA cars with manual transmission and AMT (“robot”), scheme No. 1 “Crankcase ventilation scheme with PCV valve for E-GAS and cable throttle” is suitable:

It is necessary to install a PCV valve (article 94580183, price about 400 rubles) from a foreign car into the small crankcase ventilation circuit. When connecting the PCV valve to a small circuit on an E-GAS, use a new hose (petrol-oil-resistant 8 mm without fabric reinforcement). On a cable choke, connect to the receiver, not to the choke.

As a result, the valve will shut off the circuits in transient modes, which will allow:

- Accept the load without jerking or dropping engine speed (for example, when the compressor is running, heated windows, seats, etc.).

- Reduce vibration load at idle

- Increase traction from the bottom (noted by owners of automatic transmission with VAZ-21126 engine, manual transmission with VAZ-21227, 21126 and 11186 and AMT with VAZ-21127).

- Get a sharper response to the gas pedal and faster shifts (on AMT). Perhaps due to the fact that the valve does not allow the engine to slow down, maintaining a more optimal switching algorithm.

- Reduce oil consumption through ventilation.

The valve replacement period is 40,000 km.

For LADA cars with automatic transmission (Jatco) and AMT (“robot”), scheme No. 2 is suitable:

Description of scheme No. 2: The pressure reducing valve is connected in series to a large ventilation circle. Thus, it regulates the flow of crankcase gases at high speeds and during transient processes. This allows:

- Exercise full control over the flow of crankcase gases between the small and large circuits.

- Improve engine operating mode.

- Reduce vibration load.

- Reduce oil release into ventilation.

For LADA cars with automatic transmission (Jatco) and AMT (“robot”), scheme No. 3 is suitable:

Description of scheme No. 3: To improve the operation of the braking system and facilitate the process of holding the car on the brakes in mode “D”, an “Ejection Pump” was used. Due to the flow of crankcase gases from the small circuit, the vacuum in the tube leading to the vacuum booster increases. This happens at low speeds, which is very helpful when driving in traffic jams. Keeping your foot on the brake all the time is not very easy, but this pump makes the task easier.

- Getting rid of vibrations, failures, transmission shocks.

- The engine begins to operate more calmly and softly.

- The force on the brake pedal becomes less.

- The air conditioner turns on almost imperceptibly.

Required:

- ejection pump (article 10793 VIKA, price 546 rubles);

- pressure reducing valve (article 1117701500 JP GROUP, 422 rubles);

- PCV valve (article 94580183 GENERAL MOTORS, 400 rubles);

- clamps (about 10 pieces, 600 rubles);

- thin, petrol-resistant 8 mm hose 50 cm (100 rubles);

- standard ventilation pipe.

Installing the PCV valve on Granta

:

Installing the PCV valve on Vesta:

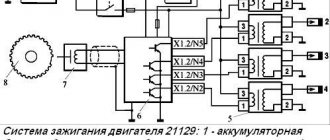

By the way, there are other ways to modify the crankcase ventilation system. Are you ready for such modernizations? Let us remind you that modification of the ignition system (installation of capacitor ignition coils in the harness) is also common among owners of LADA cars.

Keywords: lada xray engine | Lada Vesta engine | Lada Largus engine | Lada Granta engine | Lada Kalina engine | Lada Priora engine | Niva engine | universal article

0 0 0 0 0 0

Share on social networks:

Disadvantages of the heater in the VAZ-2110

The main disadvantages, as a result of which car owners are forced to improve and modernize the heating unit:

- Weak air flow to the side mirrors and driver's feet. This problem often occurs during normal operation of the heating unit.

- Often consumers encounter a leak on a radiator device. The unit is equipped with a special tap, which wears out over time and begins to leak coolant. The faucet requires repair, but often the problem can only be solved by replacing the radiator assembly.

- The central air duct of the system includes two parts that are not sealed together. From the radiator device, this blower must supply a heat flow to the feet of the passengers sitting in the rear. If we take into account all the bends, then this is at least 2.5 meters. Of course, the heat flow does not reach the rear passengers.

Symptoms of a heater malfunction

The main signs by which you can identify problems with the heating unit:

- The temperature mode of the heater is not regulated. The problem usually lies in the control unit or in the operation of the heater dampers.

- The sensor located on the ceiling does not function. It is designed to determine the temperature inside the car.

- The heating unit does not function; only cold air flow is supplied to the vehicle interior.

- The side windows of the car or the feet of the driver and passengers are blown with hot air ineffectively.

- The volume of refrigerant in the cooling system decreases. The problem can manifest itself covertly or overtly. In the latter case, a leak can be noticed from the lines of the heating system or radiator device.

- The heating unit functions, but is very noisy.

The channel In Sandro's garage spoke in detail about replacing the electric motor of the heating unit on the "ten".

Modifying the stove, simple techniques

Modernizing the VAZ 2110-2112 stove is a thorough and multifaceted process. If you don’t have the time or opportunity to fully remodel the stove system, but you need a positive result in the shortest possible time and with minimal effort, because winter is almost upon us, you can try to listen to the following advice.

1. The easiest way to increase the air flow of the heater for heating the feet of the front seats in the cabin is by blocking the heater ducts for the rear ones. Any tool at your disposal will do

Thus, you sacrifice the comfort of your passengers, but is this really important if, for example, you prefer to drive alone; 2. A similar result can be achieved by blocking the air channels of the central deflector oven by cutting a suitable plug from a sheet of aluminum

Obviously, in this case, the heat flow directed to the side windows and other furnace ducts in the car increases.

Stove damper tens

- 3. Often, standard VAZ 2110 door seals are not enough for reliable sound and heat insulation. Simply gluing additional insulating tape around the perimeter (for example, from K-Flex) can significantly improve the comfort inside the VAZ interior with minimal time and money investments;

- 4. Replacing the 5-hole thermostat with a more modern 6-hole thermostat, which controls the engine cooling and heating system in VAZ cars. These thermostats are completely interchangeable, so there should be no problems. A 6-hole thermostat is technologically more advanced, and therefore the heating of the stove radiator in a car will be more efficient. Such pleasure costs about 350 rubles.

Stove tap repair

VAZ heater valve

The heater tap (see photo above) is designed to regulate the flow of coolant through the heater radiator. On VAZ 2113, 2114, 2115 models the same heater faucet is installed. The main failures of the stove tap are oxidation, jamming, leakage, which results in a puddle of coolant appearing under your feet.

Why is the faucet leaking?

- With the onset of spring, we close the heater tap and move the regulator to the extreme position.

- From spring to autumn, we don’t use it, so the faucet turns sour.

- In winter, we open the tap again, turn on the stove, and as a result the tap flows.

- In this case, it must be replaced.

- In addition to replacing the faucet itself, it is recommended to replace the cabin filter in the fall because... it becomes clogged with leaves and the air flow weakens.

Which faucet to choose

In the spare parts store you can see three heater taps:

- The body of a ceramic faucet is ordinary plastic, but the locking mechanism consists of two ceramic plates.

- Factory cost from 80 to 100 rubles. The operating principle of which is based on a rubber membrane. As practice shows, it is not reliable, subject to acidification and is installed only if there is nothing better at hand.

- Let's move on - ball valve. Its operating principle is based on a ball with holes instead of a membrane, as in the second version. This specimen is subject to oxidation, but is much more reliable than a factory faucet.

- The ceramic faucet is the most reliable of all of the above; we recommend installing it to avoid unnecessary problems.

- The only drawback is the reduced throughput of the ceramic faucet, which reduces heat transfer. It turns out: the most reliable faucet is a ceramic one, but the heating weakens when using it.

Where is the stove valve located?

The heater valve is located under the console (in the center). Remove the side panel near the passenger's feet. Two pipes lead to it. To change the heater tap you do not need to drain the antifreeze or remove the dashboard. But in this case, you have to lie head down and do some of the work by touch.. To change the heater tap you will need:

https://youtube.com/watch?v=jzYwcI9TPzw

How to replace a stove faucet

We carry out the work on a cold engine:

- Completely remove the instrument panel.

- Place a rag under the passenger's feet and the faucet to absorb spilled coolant.

- Open the hood, remove the heater hose clamps, then remove the pipes from the tap itself, drain the antifreeze into a prepared empty container.

- We move to the salon. Using a Phillips screwdriver, unscrew the clamps securing the heater pipes to the faucet and remove them. We place a container for coolant under the pipes

- We take out the lever rod bracket and pull it out of the hole.

We take out the rod bracket, pull it out of the hole in the lever

- Let's move under the hood again. Using a 10mm wrench, unscrew the fastenings of the faucet to the shield.

- We return to the salon and take out the faucet.

We insert the new tap in the reverse order of removal:

- Installing the new faucet in place

- We secure it from the engine compartment using two nuts (pre-lubricated with a product that protects them from corrosion)

- From inside, open the tap completely and tighten the bracket.

- Then we put on the pipes from the passenger compartment and secure them from the engine compartment.

- Pour in coolant

- We start the engine and warm it up. We check the pipe clamps, tighten them if necessary, and turn on the heating.

If you don't fully understand something, be sure to watch our video.

How to modify and modernize the stove with your own hands?

There are many options for tuning and improving the operation of the heating unit, which you can do yourself. To implement each task, you will have to completely or partially disassemble the heating unit.

Before remaking the heating unit of the VAZ 2110, it is necessary to seal the main air duct as much as possible.

Improved side ventilation

There are two ways to improve side ventilation:

- lay the corrugation, which will be aimed at blowing the glass of the side windows;

- modification of the VAZ 2110 stove may involve sealing all the cracks that lead to loss of air flow.

First option

Modification of crankcase ventilation can be done in several ways. For example, on the M50 you can install an oil separator unit from the M52 model. However. This manipulation does not solve the problem of having a container for draining liquid, external aesthetics and the need to place a water seal.

One of the current solutions to the problem under consideration would be the installation of a HEPA filter, which contains wire and filament components that make it possible to adjust as accurately as possible the amount of gases released. The inside of the oil separator is filled with copper wire wool. In the standard version, the packing should protrude slightly beyond the base of the lid. The corrugated inlet and throttle assembly are thoroughly wiped. After performing the manipulations, the element is checked by mechanical purging for changes in air flow.

Alternative options

The next version of the improvement involves installing a hose with a small diameter into the crankcase ventilation circuit of the EPK valve of the “Cascade” model. In idle mode, the valve for standard exhaust gas outlet should be opened. Considering the fact that when installing the system in question, the supply of harmful impurities through the throttle valve stops due to the circuit opening. This is very important in the case of a transition of the engine operating mode from idle to light loads, when a lean air-fuel mixture is categorically unacceptable. Ventilation is carried out through the entire line, including the carburetor unit.

After further replacing the durite with a hose from the vacuum ignition advance device, it is reasonable to increase the diameter of the main jet of the first combustion chamber or simply reduce the input fuel flow to 4.5 mm. The scheme under consideration was tested on a model of the domestic VAZ 2101. At the same time, the following positive aspects became noticeable:

- The pedal drop during acceleration has disappeared;

- The engine's operation became smooth;

- There are no intermittent oscillations at idle.

Using the recommendations of specialists and folk craftsmen, it is possible to independently correct a number of malfunctions and shortcomings of a personal vehicle. Modification of the crankcase ventilation is appropriate for some vehicle equipment, regardless of the year of manufacture and country of manufacture. This problem is most pressing for domestic cars with carburetor engines.

How can you upgrade your VAZ-2110 stove yourself?

Owners of the “ten” often encounter various kinds of problems in the design of this car. They can touch, in principle, any unit, including the stove. At the same time, when it’s winter outside, of course, no one wants to freeze while traveling. So we have to finish what the designers started, modernizing the stove in order to make it work more efficiently. Considering the harsh Russian climate, such improvements can safely be called a necessity, and not a whim of car enthusiasts.

Generally speaking, the design solution of the VAZ-2110 stove can be described as quite successful. But in order for this unit to work normally, it also requires high-quality assembly and the absence of effects in the components. At the same time, both the first and second are long-standing problems of the domestic automobile industry. So motorists have to fix factory defects on their own.