Each owner of a VAZ Six, as a rule, should master certain types of repairs, including adjusting VAZ valves. Considering the level of popularity of cars of the “classic” series, there is absolutely no hope of quickly ousting them from the roads with new products from the automobile industry. We can agree that “old ladies” are not as comfortable and economical, but they have many advantages. The owners of such cars are people with not very large incomes, and they require a minimum of money to repair.

Firstly, Zhiguli spare parts are quite cheap and are presented in a huge assortment in stores. Secondly, the machines have a very simple design and allow the owner to carry out any types of repairs and adjustments himself without visiting a car service center.

Technology requires VAZ valve adjustment

Owners of foreign cars and new domestic cars are completely unfamiliar with many of the procedures that should be carried out with cars designed during the Soviet period. Technology has come a long way. While on classic cars many adjustments have to be made manually, in new cars everything happens automatically.

Adjusting the 2106 valves is required for a very simple reason. During operation, the engine gets extremely hot. As is known from physics, any solid body changes its linear dimensions when heated - they increase. Actually, constant temperature changes lead to changes in the parameters of parts, and some of them require systematic adjustment to factory standards.

First of all, this applies to the timing belt of the car. The gas distribution mechanism of the engine has a very complex design. The main element is a valve that blocks the lumen of the inlet and outlet windows of the block head. The tighter the valve closes, the better. A special lever exerts pressure on the valve stem, if necessary, to open it.

Let us assume that all the parts fit together exactly when cold. As soon as the engine starts, they will begin to heat up and increase in size. The valve stem undergoes the greatest elongation. If there is no required thermal gap after heating, the valve will stop closing the window. This necessarily leads to loss of power and excessive fuel consumption. The designers calculated that there should be a thermal gap of 0.15 mm between the working part of the camshaft and the lever.

The procedure for adjusting the valves of the VAZ 2106

Adjusting valves on a VAZ

Many car enthusiasts are reluctant to adjust the thermal clearances of the gas distribution mechanism. This procedure requires certain skills, endurance, and takes time. Partially, the reluctance to make adjustments is due to ignorance of the algorithm for performing the work and the fear of doing something wrong.

Before you start work, you should prepare. The car must be installed on a level surface, the engine compartment must be well lit.

You will need tools to get the job done.:

- screwdriver;

- wrenches for “10”, “14” and “17”;

- a key to turn the crankshaft;

- dipstick

In order to gain full access to the gas distribution mechanism, remove the cylinder head cover and air filter. To begin the adjustment, you need to rotate the crankshaft until the marks on the pulley and the oil seal cover match. This position will correspond to the compression stroke in the 4th cylinder.

Checking the correctness of the gap adjustment is done as follows:

- a feeler gauge is inserted into the gap between the working part of the camshaft and the valve lever platform;

- when moving, the probe should pass with noticeable difficulty;

- If the dipstick passes too easily or does not pass, it is necessary to adjust the gap.

To regulate the size of the thermal gap, perform the following steps:

- use a wrench set to “14” to hold the head of the adjusting bolt, and use a wrench set to “17” to loosen the lock nut of the bolt;

- by turning the adjusting bolt, the gap size is adjusted;

- the locknut is tightened;

- Using a feeler gauge, the correct adjustment is checked. If necessary, the procedure is repeated.

Each valve must be adjusted at a specific camshaft position. To do this, you must strictly follow the procedure for adjusting the valves of the VAZ 2106. The 6th and 8th valves are adjusted first (counting from the front of the engine).

Next, to adjust the next pair of valves, turn the crankshaft 180º. The 4th and 7th valves are adjusted next, and with each subsequent cranking the following should be checked and adjusted: 1st and 3rd, 5th and 2nd valves. After the cycle is completed, it is necessary to rotate the crankshaft several times and check the clearance adjustments again.

We recommend: Oil leakage from under the crankshaft oil seal: causes and troubleshooting

When to adjust VAZ valves

Unnecessary intervention in the operation of the motor does not always lead to positive results. In order to open the cylinder head cover and begin adjusting the thermal clearances, compelling circumstances are needed. Obvious reasons to check valve settings are: the appearance of a characteristic noise in the valve cover area; a noticeable decrease in engine power and a change in acceleration dynamics; forced overheating of the engine at high speeds. In addition, you need to monitor your mileage. It is recommended to check the correct valve clearance adjustments every 10 thousand kilometers.

The only reason classic VAZ cars are still afloat is that there are a lot of them, they are cheap and easy to repair. These three aspects completely cover all its shortcomings - the archaic design, the increased flowability of some parts, and the obsolete appearance. The VAZ 2106 has a lot of fans that cannot be bought by any Volkswagen or Ford. They love their cars, take care of them and adjust the valves.

Why is valve adjustment necessary?

People will soon lose the habit of adjusting valves, just as they have forgotten how to hunt mammoths. Good or bad, but in any case, someday the last four-cylinder engine in the world with the numbers “2106” poured onto the cylinder block will knock.

But until this happens, we will have to service them and put them in order, and adjusting the VAZ 2106 valves, the video process of which you can watch on the page, will remain relevant.

Valve adjustment is carried out for a very simple reason - solids expand when heated, and the gaps between them decrease. And the gas distribution mechanism of the VAZ 2106 is designed in such a way that it requires a certain thermal gap between the valve pusher lever and the camshaft journal. When developing the six engine, it was determined that this gap should be 0.15 mm. With such a gap, when the timing parts heat up, the valves close tightly and ensure the normal supply of the combustible mixture to the combustion chamber and the timely removal of exhaust gases.

When to adjust valves

There are no specific regulations for adjusting the valves of VAZ engines. But they need to be adjusted in cases of violation of the integrity of the gas distribution mechanism - replacing the camshaft, replacing valve seals and other work that involves removing the camshaft.

The valves are adjusted as necessary, when this is indicated by a characteristic sound from under the valve cover. If the valves have lost the required clearance, the car is unstable because the valve timing is off. Excessive fuel consumption and loss of power may also occur.

Preparing for adjustment

The adjustment process itself is very simple, you need to know some patterns and order of operation of the cylinders, and be able to do just a little. You will also need a feeler gauge to check the gap when adjusting. You will also need:

- open-end wrench 14;

- carob at 17;

- the dipstick itself;

- key or “crooked starter” to turn the crankshaft.

It is advisable to carry out the work in good lighting and on a level area. Before we begin the adjustment, we will provide ourselves with access to the timing belt by first removing the air filter and the gas distribution mechanism cover.

Adjustment technology

To begin the adjustment, you need to align the marks on the crankshaft pulley and the front cover of the cylinder block. Now the piston of cylinder 4 is located at TDC on the compression stroke. We also check the mark on the wire timing gear. It falsely coincides with the tide on the camshaft housing. That is, now you can check those valves that are in a free state and are completely closed. These are the 6th and 8th valves.

Then we take the prepared dipstick and insert it into the gap between the rocker and the camshaft cam. The probe should pass with barely perceptible tension.

If it passes freely, the gap is large. If it doesn’t go through at all, the gap is insufficient.

If necessary, we adjust the gap with an adjusting bolt, tearing off the lock nut with a 17mm wrench, and adjust the position of the bolt relative to the rocker with the bolt itself. We ensure that the probe passes with a slight interference fit. Holding the adjusting bolt in the desired position, lock it with a lock nut. All adjustments. The remaining valves are adjusted in the same way, but in a certain order.

The procedure for adjusting timing valves VAZ 2106

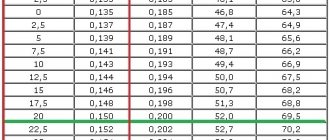

Each of the valves is adjusted in a strict sequence that must be strictly followed. There is nothing complicated about this, and for clarity, we have summarized the methodology in a table:

Is valve adjustment necessary?

Internal combustion engines use intake and exhaust valves. The intake valve is responsible for supplying the fuel-air mixture to the cylinder, and the exhaust valve is responsible for removing exhaust gases.

For proper operation of the VAZ 2107 engine, there must be a gap of 0.15 mm between the rocker and the valve stem. If this distance is greater, a characteristic “knock of valves” will appear. If the distance is less or there is none at all, the valve will not close completely, which can lead to “burnout of the plates.”

In addition, an incorrectly set thermal gap leads to a decrease in engine efficiency.

The VAZ 2103 engine is a transitional version of the third generation engine

By analogy with previous modifications of the internal combustion engine line, the VAZ 2103 engine retained the overhead camshaft position. The engine power has been increased, the attachment is rotated by a belt, the chain remains only on the timing sprocket.

Technical characteristics of the engine 2103

In the third ICE 2103, the manufacturer AvtoVAZ returned the original cylinder diameter of 76 mm and increased the volume of the combustion chamber, so the technical characteristics of the engine are as follows:

class B – 76.01 – 76.02 mm

Probe for adjusting valves VAZ 2107

The distance between the rocker and the rod on a cold engine should be exactly 0.15 mm. To check and adjust, you can use either a set of universal probes or a more convenient special probe.

It is worth especially noting once again that the gap of 0.15 mm is set on a cold engine. If work is carried out “hot”, then it is necessary to take into account the coefficient of thermal expansion and set gaps of 0.20 mm.

We will also need two open-end wrenches - 13 - for the head of the adjusting bolt - 17 - for the locknut

Setting valve clearances using an indicator

The procedure for adjusting the indicator when using the indicator generally does not differ from the sequence of actions when adjusting using a probe, but a different tool is used. To adjust the valve mechanism in this case, you will need a rack (bar) and the indicator itself; the device is sold as a set in specialized auto stores. If you really want to, you can make a bar for installing the indicator yourself; finding the necessary drawing on the Internet is not a problem.

When setting the gaps using an indicator, a more precise setting is obtained, since the feeler gauge is not able to catch all the irregularities of the camshaft cams and wear on the rockers. The procedure for the RK using a special device is as follows:

- just as when adjusting with a feeler gauge, set the gear to neutral, open the hood, remove the valve cover;

- we combine the camshaft marks to adjust the 8th and 6th valves;

- We attach the indicator strip to the studs on the left side of the camshaft bed;

- if we adjust the sixth valve, we fix the indicator on top of the corresponding (6th) rocker using a holder;

- Using a key or hand, we raise and lower the rocker, and note on the indicator how many divisions the arrow deviates.

Here it makes sense to refer to the table, which provides data on indicator settings, since when adjusting with a probe, TK is measured in millimeters, and with an indicator - in divisions. For example, for a standard value of 0.15 mm the indicator value is 52, which means that the arrow with the required gap deviates by fifty-two divisions. If the TK is greater than the norm, it needs to be reduced; let’s look at how this happens:

- Let’s say, instead of the required 52, the indicator showed the value 72 (“extra” 20 divisions);

- set the arrow to “zero”, loosen the lock nut, use a 13mm wrench to turn the adjusting bolt towards decreasing the gap, watch the indicator;

- when you turn the key, the indicator needle begins to deviate counterclockwise, it is necessary that it “passes” 20 divisions (since 72-52 = 20);

- Having achieved the desired reading on the dial gauge, holding it with a key of 13, use the “seventeenth” key to tighten the lock nut;

- Having adjusted both valves (8 and 6) in this way, turn the shaft and adjust the cl. No. 4 and 7, then we then repeat all the operations that were described earlier for a carburetor internal combustion engine.

After the adjustment, install the valve cover, start the engine, see how it works, listen for any extraneous sounds.

Valve adjustment marks 2107

Before starting the adjustment, it is necessary to set the TDC (top dead center) of the gas distribution mechanism (GRM). To do this, you need to turn the crankshaft and align the point (hollow) on the sprocket with the protrusion on the body. In this position, you can begin adjusting valves 6 and 8.

You can rotate the crankshaft in the following way. Put the gearbox at 5 speed. Using a jack, lift one of the front wheels and turn it until the marks are in the position corresponding to TDC. In the same way, you can rotate the crankshaft to adjust subsequent pairs of valves.

Preparatory work

So, the engine is cooled down, and the car itself is placed on a flat surface and immobilized. You can start working:

- Remove the carburetor air filter cover and remove the filter;

- We unscrew the filter mounting bolts and remove it, having first disconnected the pipes going to it;

- We remove the cable for manual control of the air damper (choke) and disconnect the throttle linkage;

- Unscrew the bolts securing the valve cover and dismantle it;

- Check the chain tension (it must be normal, otherwise you will have to adjust the tension first);

- Remove the distributor cap.

Now you need to set the TDC of the piston in the 4th cylinder and the marks on the knees will help with this. camshaft drive shaft and cover. shaft, as well as on the camshaft gear and its cover.

To do this, you can use a key of appropriate size, which you need to rotate the knees. shaft for the drive pulley bolt. Or use one of the drive wheels. To do this, you need to hang it with a jack, engage 4th gear and slowly turn the raised wheel. In this case, the transmission will ensure rotation of the crankshaft. But with the second method, you will need an assistant, since it will be difficult to check the coincidence of the marks.

We recommend: How to install heated mirrors with your own hands?

The procedure for adjusting the valves of the VAZ 2107

So, our crankshaft is set to the TDC position according to the marks (see above). Now insert the feeler gauge between the camshaft lobe and the valve arm (rocker). It is very important that the probe fits into the gap “with interference.” If the dipstick dangles or does not fit in, it is necessary to make an adjustment.

1) Loosen the lock nut (17). 2) Turn the adjusting bolt (key 13). 3) Tighten the counter nut. 4) Check the gap again with a feeler gauge (it should fit “with interference”) 5) If the gap is too large or too narrow, loosen the lock nut again, turn the adjusting bolt and tighten it.

We repeat the above steps until we achieve the correct gap of 0.15 mm.

About choosing styli

Uneven knocking noises in the area of the upper part of the valve cover indicate increased clearances. According to the instructions for setting the VAZ-2106 valves, they can be adjusted. The gaps are changed using special feeler gauges for classic VAZ models. These probes are wide. The standard set of feeler gauges is narrow and cannot cover the entire width of the gap in the operating area of the pressure levers and camshaft cams. This will not allow you to accurately determine whether the gap is correct. On the case in which the dipstick is sold, there is a diagram for adjusting the valves in the form of a convenient table.

Adjusting valves on a VAZ 2107 by micrometer

Instead of a feeler gauge, a micrometer mounted on a special rail is used to adjust the valve clearance. With its help you can control the amount of free play of the rockers. A gap of 0.15 millimeters corresponds to a rocker free play of 0.52 millimeters.

The rack has special nuts that allow it to be screwed onto the camshaft mounting studs. This allows it to be installed sequentially over each pair of valves. It is necessary to tighten the rack fastening nuts well so that it does not swing during measurements. After this, you need to fix the micrometer (indicator) on the rail so that it rests against the edge of the rocker that presses the adjustable valve.

To check the clearance, you need to lift the rocker cam with a special grip or finger and check the amount of free play using the arrow of the device. If it is not equal to 0.52 mm, then it should be set in the same way as when adjusting using a feeler gauge.

This adjustment method is more accurate and reliable. The feeler gauge, passing between the rocker and the camshaft, ignores the possible gap that appears as a result of wear on the parts.

The micrometer determines the actual amount of free play of the rocker; in addition, it is easier and more reliable to navigate by the indicator readings than by the free movement of the feeler gauge. This allows you to adjust the clearances in the valve mechanism as accurately as possible.

If the motor is worn out

For a VAZ-2107 or other classic with a slightly worn engine, everything will go like clockwork, but a car with high mileage and a worn out engine may upset you. The knocking of the valves will become even louder after adjustment. Why did this happen? When the engine is running, the parts of the valve mechanism are worn in to each other, changing their original shape.

Rockers and adjusting bolts require replacement at high mileage

So the supporting surfaces of the adjusting bolts change from spherical to oval. By turning such a bolt during adjustment, you break their mutual fit, forcing you to break in again. The gap you just set will quickly “float away” and start all over again... What is the way out? The rockers and adjustment bolts need to be replaced. The camshaft itself can most likely still work; it needs to be changed if the cams are severely worn. To see how it all looks, watch this video. The author very clearly shows the correct way to configure the valve mechanism.

Features of adjustment 2107 injector

- Firstly, there is no slider on the injection model, so the rotation angle can only be set along the camshaft (the same as for the carburetor model)

- Secondly, there is no need to remove the air filter housing to gain access to the cylinder head cover (unlike the carburetor model)

- Thirdly, to turn the crankshaft on an injection model, you won’t be able to use a 38mm wrench. You can jack up the rear wheel, put the gearbox in high gear and change the crankshaft angle by turning the rear wheel.

Features of setting valve clearances on the VAZ “Classic” injector

VAZ classic engines with a fuel injection system were produced both with hydraulic pushers and with a mechanical drive. The adjustment scheme for the VAZ-2107 injector is absolutely no different from the standard valve adjustment on a carburetor engine, there are only some design differences (a different air filter housing, no carburetor, a changed crankshaft pulley (with teeth for reading pulses)).

All valve train parts

1 - valve; 2 - retaining ring; 3 - guide sleeve; 4 — oil deflector cap; 5 — support washer of the outer spring; 6 — support washer of the internal spring; 7 — internal spring; 8 — outer spring; 9 — spring plate; 10 - crackers; 11 — valve drive lever; 12 — lever spring; 13 — adjusting bolt; 14 — lock nut of the adjusting bolt; 15 — bushing of the adjusting bolt; 16 — locking plate of the lever spring.

With your own hands or a service station

Having become familiar with how the VAZ-2105 valves are adjusted, the driver can calmly make a decision.

If he does not have time or does not want to rely on his limited experience, then the above recommendations and advice, which seem overwhelming, will allow him to turn to the service station with a pure soul and not be afraid that the money is wasted. On the other hand, there is nothing fundamentally difficult about the replacement, so the driver can easily cope with the above instructions on his own. All you need for a good repair is determination and attentiveness and, of course, preventive maintenance of the entire car system. The main thing is to remember that a working car means safety for both the driver and other road users.