Carburetor VAZ 2105

What is a carburetor and what are its functions? Today, carburetor modifications of vehicles are considered to be “outdated”, since they have been replaced by more “tenacious” injection ones.

However, in our country, carburetor versions of cars will be popular for a long time, since most AvtoVAZ cars are designed specifically on the basis of carburetor engines. Including the VAZ 2105 model, popularly called the “five”.

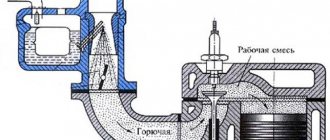

So, the carburetor is the most important mechanism in a car engine. Its main purpose is to prepare the fuel-air mixture and supply it to the engine cylinders. Simply put, a carburetor is needed to ensure that the engine receives fuel in the doses necessary for operation.

The air filter was removed for demonstration; the carburetor is located directly below the filter housing.

Carburetor design

The engines of the VAZ 2105 car are equipped with carburetors of type 2105–1107010. This number must be indicated on a black plate, which is attached to the cover of the carburetor itself.

The device has two chambers so that the processes of formation of the fuel-air mixture and its supply to the cylinders occur quickly and correctly. In fact, structurally, the carburetor has a huge number of small parts interconnected, but technically the device is not considered complex.

The cast body combines many small parts, each of which performs its own function

In order for the engine to operate in different modes (warm-up, idling, medium load and high speed), the carburetor consists of three main parts:

- The upper one consists of the device cover and fittings for fuel supply.

- The middle one is the carburetor body itself, which houses two internal combustion chambers and diffusers.

- Lower - includes the float chamber and throttle valves.

In the proper operation of the VAZ 2105 carburetor, small parts such as gaskets, springs or jets play a huge role. It is these parts that most often fail, which affects the operation of the engine.

Parts of the carburetor body 2107–1107010: 1 — rod of the pneumatic drive of the second throttle valve; 2 — pneumatic drive housing; 3 - diaphragm; 4 — pneumatic drive cover; 5 — fuel jet of the transition system of the second chamber; 6 — fuel nozzle body; 7 — small diffuser of the second chamber; 8 — accelerator pump nozzle; 9 — screw valve of the accelerator pump; 10 — main air jet of the second chamber; 11 — emulsion tube of the second chamber; 12 — main air jet of the first chamber; 13 — emulsion tube of the first chamber; 14 — main fuel jet of the second chamber; 15 — main fuel jet of the first chamber; 16 — accelerator pump adjusting screw; 17 — fuel jet of the idle system; 18 — fuel nozzle body; 19 — return spring of the accelerator pump; 20 — accelerator pump diaphragm; 21 — accelerator pump cover; 22 — small diffuser of the first chamber; 23 — lever return spring; 24 — three-arm air damper control lever; 25 — connection rod with the throttle valve; 26 — throttle valve return spring bracket

The essence of the operation of the carburetor unit on the VAZ 2105 comes down to the following processes:

- A strictly limited amount of gasoline enters the float chamber through a special valve.

- Fuel is directed through the jets to chamber No. 1.

- Here, gasoline is crushed into tiny pieces and mixed with parts of air.

- If the maximum amount of fuel is required (for example, during acceleration), then chamber No. 2 begins to work in the same way.

- After the fuel-air mixture is formed, the accelerator pump directs the fuel to the diffusers and then directly to the cylinders.

Expert advice

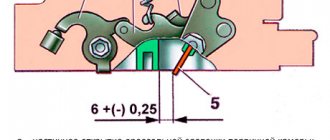

After completing the procedure for adjusting the VAZ-2105 carburetor device, experienced auto mechanics recommend paying attention to the following critical points:

- Valve location - is in the retracted position, with the idle speed jet touching the seat in the carburetor body.

- Lubricating the rubber seal with special motor oil.

- The location of the air damper intended for cold passage is in a vertical plane, while the suction handle is lowered.

- The condition of the solenoid valve - the presence of damage and malfunctions is checked as follows:

- turn on the ignition;

- remove and put the connector on the valve;

- listen to the sounds coming from the solenoid valve.

If clicks are heard during the inspection process, the part is in full working order.

How to breathe life into old Zhiguli Zhiguli “five” were produced from 1980 to 1995. and enjoyed deserved popularity. The main power unit that was installed on cars of this model was a four-cylinder, four-stroke internal combustion engine with a displacement of 1.29 liters, 1.45 liters and 1.57 liters. To create a combustible mixture for the engine, domestically produced Ozone carburetors were used, as well as their modifications. We will look at adjusting the VAZ 2105 carburetor with our own hands in this article.

So, first, let's talk about the device itself, designed for mixing air and fuel in a certain proportion, supplying the resulting mixture into the engine cylinders and ensuring stable operation of the engine in various modes. This is a fairly accurate and complex unit. Therefore, the precise performance of its functions depends on strict maintenance of the parameters established during its production and configuration.

What carburetors are installed on the VAZ 2105

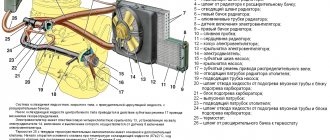

All carburetor installations equipped with the VAZ 2105 are focused, first of all, on minimizing fuel consumption. Of course, AvtoVAZ engineers throughout the history of the “five” experimented with the equipment of the car in order to identify the most effective mechanisms.

Over the years, various modifications of carburetors were installed on the VAZ 2105. All of them had both their advantages and disadvantages, which the drivers themselves often had to identify while driving.

Modification of DAAZ

The Dimitrovgrad Automobile Unit Plant (DAAZ) has launched the production of carburetor units under license from Weber. The main quality of DAAZ products is ease of operation and repair. The production of all parts necessary for repair and replacement was established, so if necessary, the driver could easily buy the necessary components and independently carry out the work of adjusting the carburetor.

DAAZ carburetors provided the car with increased speed characteristics, since the new nozzle system made it possible to react as quickly as possible to an increase in speed and supply the required amount of fuel to the engine.

A significant drawback of the Dimitrovgrad Automotive Unit Plant carburetor can be considered fuel consumption. In the combined cycle, the device required at least 10–14 liters of fuel per 100 kilometers.

There are no cons. The DAAZ 2105 carburetor is an excellent thing. The machine does not leak or overflow, the consumption is normal... Thanks to the manufacturer for such an excellent product. We will use your services and recommend you to friends.

Gosha 5410

https://otzovik.com/review_2963738.html

The first VAZ 2105 cars were equipped with DAAZ carburetors

Modification "Ozone"

The Ozone carburetor is considered a modified version of the device that was assembled at DAAZ under license from Weber. "Ozone" is a more advanced version of the old "DAAZ". This carburetor has higher environmental friendliness, and also significantly reduces fuel consumption per 100 kilometers.

However, not everything is so good in the Ozone design. After numerous complaints from VAZ 2105 drivers, the designers identified a major drawback of this type of carburetor. The device is equipped with two chambers, but a pneumatic valve takes part in the operation of the second chamber. It was because of this that drivers had problems, since even with the slightest contamination the valve began to work incorrectly.

I have an Ozone 2105 with a mechanical drive for the shutter of the second chamber, the calibrations are standard. I tried installing jets of increased diameter - it seemed to me that the flow rate increased noticeably, but the dynamics were not much