One of the important elements of the ignition system necessary for igniting the working combustible mixture in the internal combustion engine of a car is the ignition module (ignition coil). The VAZ 2110 ignition coil converts low-voltage voltage into high-voltage, which creates a spark on the spark plugs.

It is quite obvious that if a malfunction occurs in the ignition, first of all the spark plugs, wires, caps, and then the ignition coil itself are checked for functionality.

In other words, you need to know how to test module 2110 (ignition coil). Next, we will look in more detail at what it is and how to check the ignition module, what malfunctions occur and how to fix them.

Types of ignition systems VAZ 2107

The evolution of the VAZ 2107 has transformed the ignition system of this car from an unreliable mechanical design into a modern computer-controlled electronic system. Changes occurred in three main stages.

Contact ignition of carburetor engines

The first modifications of the VAZ 2107 were equipped with a contact-type ignition system. This system worked as follows. The voltage from the battery was supplied through the ignition switch to a transformer (coil), where it increased several thousand times, and then to a distributor, which distributed it among the spark plugs. Since voltage was pulsed to the spark plugs, a mechanical breaker located in the distributor housing was used to close and open the circuit. The breaker was subjected to constant mechanical and electrical stress, and it often had to be adjusted by setting the gaps between the contacts. The contact group of the device had a short resource, so it had to be changed every 20–30 thousand kilometers. However, despite the unreliability of the design, cars with this type of ignition can still be found today.

The contact ignition system requires adjustment of the gap between the breaker contacts

Contactless ignition of carburetor engines

Since the beginning of the 90s, a contactless ignition system was installed on carburetor VAZ 2107, where the breaker was replaced with a Hall sensor and an electronic switch. The sensor is located inside the ignition distributor housing. It reacts to the rotation of the crankshaft and sends a corresponding signal to the switching unit. The latter, based on the data received, supplies (interrupts the supply) voltage from the battery to the coil. Then the voltage returns to the distributor, is distributed and goes to the spark plugs.

In the contactless ignition system, the mechanical breaker is replaced by an electronic switch

Contactless ignition of injection engines

The latest VAZ 2107 models are equipped with electronically controlled injection engines. The ignition system in this case does not provide any mechanical devices at all, not even a distributor. In addition, there is no coil or commutator as such. The functions of all these components are performed by one device - the ignition module.

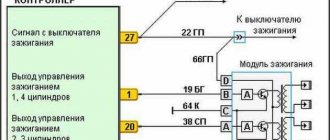

The operation of the module, as well as the operation of the entire engine, is controlled by the controller. The principle of operation of such an ignition system is as follows: the controller supplies voltage to the module. The latter converts the voltage and distributes it among the cylinders.

A little about prices

We have already noted which switch and transistor are used when repairing the ignition module of a dozen. The first costs about 3 dollars, and for the second you will have to pay about 6 dollars.

Some craftsmen use a domestic analogue of the transistor - model KT848A . Of course, it costs less. But its problem is its lower quality and larger size, which somewhat complicates the repair process.

Ignition module

The ignition module is a device designed to convert DC voltage from the on-board network into electronic high-voltage pulses with their subsequent distribution among the cylinders in a certain order.

In the injection VAZ 2107, the ignition module replaced the coil and switch

Design and operating principle

The design of the device includes two two-terminal ignition coils (transformers) and two high-voltage switches. The voltage supply to the primary windings of the transformer is controlled by the controller based on the information received from the sensors.

The operation of the ignition module is controlled by the controller

In the ignition system of an injection engine, voltage distribution is carried out according to the idle spark principle, which provides for the pairwise division of cylinders (1–4 and 2–3). A spark is formed simultaneously in two cylinders - in the cylinder in which the compression stroke is coming to an end (working spark), and in the cylinder where the exhaust stroke begins (idle spark). In the first cylinder, the fuel-air mixture ignites, but in the fourth, where the gases burn out, nothing happens. After turning the crankshaft half a turn (1800), the second pair of cylinders enters the process. Since the controller receives information about the exact position of the crankshaft from a special sensor, problems with sparking and its order do not arise.

Location of the ignition module VAZ 2107

The ignition module is located on the front side of the cylinder block above the oil filter. It is secured to a specially designed metal bracket using four screws. It can be identified by the high-voltage wires coming out of the housing.

The ignition module is located on the front of the cylinder block above the oil filter

Factory designations and characteristics

VAZ 2107 ignition modules have catalog number 2111–3705010. As an alternative, consider products numbered 2112–3705010, 55.3705, 042.3705, 46.01. 3705, 21.12370–5010. They all have approximately the same characteristics, but when purchasing a module you should pay attention to the engine size for which it is intended.

Table: technical characteristics of the ignition module 2111–3705010

| Name | Index |

| Length, mm | 110 |

| Width, mm | 117 |

| Height, mm | 70 |

| Weight, g | 1320 |

| Rated voltage, V | 12 |

| Primary winding current, A | 6,4 |

| Secondary winding voltage, V | 28000 |

| Duration of spark discharge, ms (not less) | 1,5 |

| Spark discharge energy, MJ (not less) | 50 |

| Operating temperature range, 0С | from -40 to + 130 |

| Approximate price, rub. (depending on manufacturer) | 600–1000 |

Purpose and characteristics

Coil 2111-3705010 is intended for:

- formation of high-voltage pulses;

- distribution of signals between the spark plugs in accordance with the firing order of the cylinders.

Main technical parameters of the unit:

- operating voltage – 12 V;

- current in the primary circuit – 6.4 A;

- voltage in the secondary circuit – 28 kV;

- spark duration – at least 1.5 ms;

- discharge energy – 50 MJ.

Read, it may be useful: Removing the steering column switch VAZ 07

Diagnostics of malfunctions of the ignition module of injection VAZ 2107

The ignition of the injection VAZ 2107 is completely electronic and is considered quite reliable. However, problems can arise with it too. The module plays an important role in this.

Signs of a malfunctioning ignition module

Symptoms of a faulty module include:

- the Check engine warning light on the dashboard lights up;

- floating idle speed;

- engine tripping;

- dips and jerks during acceleration;

- change in sound and color of exhaust;

- increased fuel consumption.

However, these signs can also appear in case of other malfunctions - for example, in case of problems with the fuel system, as well as in case of failure of some sensors (oxygen, mass air flow, detonation, crankshaft position, etc.). If the engine starts to operate incorrectly, the electronic controller puts it into emergency mode, using all available resources. Therefore, when the engine operation changes, fuel consumption increases.

In such cases, you should first of all pay attention to the controller, read information from it and decipher the error code that has occurred. To do this, you will need a special electronic tester, available at almost any service station. If the ignition module fails, error codes in engine operation may be as follows:

- P 3000 - no sparking in the cylinders (for each cylinder the code may look like P 3001, P 3002, P 3003, P 3004);

- P 0351 - break in the winding or windings of the coil responsible for cylinders 1–4;

- P 0352 - a break in the winding or windings of the coil responsible for 2–3 cylinders.

At the same time, the controller can produce similar errors in the event of a malfunction (break, breakdown) of high-voltage wires and spark plugs. Therefore, before diagnosing the module, you should check the high voltage wires and spark plugs.

Main malfunctions of the ignition module

The main malfunctions of the VAZ 2107 ignition module include:

- a break or short to ground in the wiring coming from the controller;

- lack of contact in the connector;

- short circuit of the device windings to ground;

- break in the module windings.

Checking the ignition module

To diagnose the VAZ 2107 injection module, you will need a multimeter. The verification algorithm is as follows:

- Raise the hood, remove the air filter, find the module.

- We disconnect the block of the wiring harness coming from the controller from the module.

- We set the multimeter to measure voltage in the range 0–20 V.

- Without starting the engine, turn on the ignition.

- We connect the negative (usually black) probe of the multimeter to ground, and the positive one to the middle contact on the harness block. The device must display the voltage of the on-board network (at least 12 V). If there is no voltage or it is less than 12 V, the wiring or the controller itself is faulty.

- If the multimeter shows a voltage of at least 12 V, turn off the ignition.

- Without connecting the connector with wires, disconnect the high-voltage conductors from the ignition module.

- Switch the multimeter to resistance measurement mode with a measurement limit of 20 kOhm.

- To check the device for an open circuit in its primary windings, we measure the resistance between contacts 1a and 1b (the outermost ones in the connector). If the resistance of the device tends to infinity, there is indeed an open circuit in the circuit.

- We check the module for breaks in the secondary windings. To do this, we measure the resistance between the high-voltage terminals of the first and fourth cylinders, then between the terminals of the second and third cylinders. In operating condition, the module resistance should be about 5–6 KOhm. If it tends to infinity, the circuit is broken and the module is faulty.

Video: checking the ignition module of the VAZ 2107

Work order

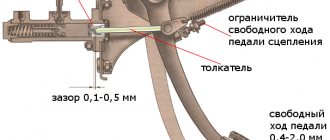

Before starting work, it is necessary to set information in the control unit. Sensors will help do this.

In order to set the ignition on a VAZ 2110 8 valve injector, you must have some skills related to car repair:

- Find the gas distribution mechanism and release it from the case.

- There should be a distance not exceeding 0.5 - 0.7 mm between the sensor and the crankshaft toothed disk. This is necessary so that the pulse from the sensor can pass without uninterrupted formation of sparks.

- The crankshaft pulley should remain in place. How can I check this? The marks located on the flywheel will help with this. They must match the marks on the gearbox housing. To do this, you need to turn the crankshaft.

- It is necessary to ensure that the mark located on the oil pump is aligned with the boss of the cylinder block.

- There must be a coincidence between the mark on the camshaft drive wheel and the timing belt cover.

- Pistons 1 and 4 of cylinders, provided that all points are aligned, will be in the upper position. The distance between the teeth should coincide with the boss on the cylinder block. The tooth located at the 20th place will coincide with the crankshaft sensor.

- The sensor will send a signal to the internal combustion engine control system. It will mean that the piston of the first cylinder is in the upper position in a compressed state.

Replacing the ignition module of a VAZ 2107

In case of malfunction, it is better to replace the ignition module with a new one. Repair is possible only if the breakdown is not a break or short circuit of the windings, but a visible violation of any connection. Since all the conductors in the module are aluminum, you will need special solder and flux, as well as certain knowledge from the field of electrical engineering. However, no one can guarantee that the device will work flawlessly. Therefore, it is better to buy a new product that costs about a thousand rubles and be sure that the problem with the ignition module has been solved.

Even an inexperienced car enthusiast can replace the module independently. The only tools you will need is a 5mm hex wrench. The work is performed in the following order:

- Open the hood and disconnect the negative terminal from the battery.

- Remove the air filter housing, find the ignition module and disconnect the high voltage wires and the wiring harness block from it.

- Use a 5mm hex to unscrew the four screws securing the module to its bracket and remove the faulty module.

- We install the new module and secure it with screws. We connect the high-voltage wires and the wire block.

- We connect the terminal to the battery and start the engine. We look at the instrument panel and listen to the sound of the engine. If the Check engine light goes out and the engine runs stably, everything is done correctly.

How to evaluate the work already done

Accurate diagnosis is carried out using a computer. However, it is also possible to independently assess how correctly the circuits are functioning.

- With the ignition off, check the contacts.

- Find out the voltage inside the module at terminals C and B.

- Check the high voltage wire. To do this, you need to take a candle and place it in the cap. In this case, it should be attached to the cylinder block. If the internal combustion engine is turned on using the starter, a spark will appear. The check is done for all wires. If a spark does not appear, then you need to check or even replace the entire ignition system.

- If the engine continues to operate incorrectly, the power system will need to be checked.

For the carburetor model VAZ 2110, marks are also set in order to regulate the ignition system.

If the ignition of the VAZ 2110 8-valve injector occurs early or, conversely, late, then the ergonomics of the entire engine deteriorates. Power also decreases. The engine is exposed to high temperatures and excessive loads. Among other things, detonation may occur. All this can lead to the VAZ 2110 losing ignition.