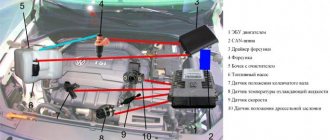

Location of sensors on VAZ 2110 injector (8 valves)

The fuel-injected 8-valve VAZ 2110 has a wide variety of sensors. Each of them has its own important function, the termination of which can lead to certain consequences.

Mass air flow sensor on VAZ 2110

The presence of a large number of electronics provides an abundant number of sensors. We will talk about some of them today:

- Air regulator sensor;

- Fan switch sensor;

- Crankshaft sensor;

- Coolant temperature sensor;

- Speed sensor;

- Phase sensor.

Now let's look at them in more detail.

Symptoms of a problem

Typical signs of a malfunctioning speed sensor on a VAZ 2110 car are as follows:

- unstable operation and incorrect speedometer and odometer readings;

- cessation of stable engine operation at idle;

- errors generated by the computer (P0500 – no sensor signal, P0503 – intermittent sensor signal).

The problems listed above may result from:

- poor contact in the sensor connector due to contamination;

- violation of the integrity of the wiring from the sensor to the ECU;

- mechanical failure of the DS drive (in older VAZ 2110 models).

DPKV

This sensor tells the ECU the current position of the crankshaft. It is inductive, that is, when the above node rotates, it produces certain impulses, the frequency of which allows the computer to make the necessary calculation. If the signal is lost, the power unit stops. That is, its malfunction will not even allow you to get to a car service center. Otherwise, it breaks very rarely.

In this situation, the ECU will show an error code - 0335. However, this does not always mean that it is the DPKV that has become unusable. Sometimes the same combination appears if the mass air flow sensor is not working properly.

How does IAC work?

The functional unit regulates the volume of air supplied to the engine when the throttle valve is closed. This is necessary to ensure automated control of engine speed at idle.

The sensor is also involved in the process of warming up the internal combustion engine to operating temperature in cold weather. IAC operating range is from -40 to +130 degrees.

When the ignition in the car is turned on, the rod on the regulator extends all the way and rests against the calibration point of the throttle pipe. The IAC counts the steps and the valve returns.

When the motor is on, increasing/decreasing steps changes the amount of passing air masses. The required amount of air mass is supplied to the engine, which will ensure normal operation at idle speed.

The IAC on the VAZ-2110 is small in size and consists of three units:

- Stepper motor.

- Springs and rod.

- The needle is cone-shaped.

The device is secured to the throttle body using two threaded screws.

Checking the removed DTOZH

For a more accurate check, it is recommended to remove the device from the vehicle. To do this, you need to let the engine cool, and then drain the coolant from the system.

To remove it, you only need a key “19” (20, 21, 22), with which you can unscrew the sensor and remove it together with the ring.

At the same stage, it is worth assessing the condition of the device itself, its threads, cleaning and lubricating it.

The same operations can be done with respect to the sensor itself. After dismantling is completed, you can proceed directly to work.

Checking with a thermometer

After dismantling, you can check with a thermometer. This option provides the most accurate information, so it is recommended for most cases.

The algorithm of actions is as follows:

- Prepare a vessel and pour water into it.

- Use a boiler to heat water.

- Prepare your multimeter for measurements.

- Immerse the sensor element in the liquid.

- Provide the ability to connect a multimeter to the contacts.

- Place a thermometer in the water to monitor the temperature. It is better to use the electronic version, which provides greater accuracy.

- Heat the water and take measurements for different temperatures, for example, from +5 degrees Celsius and above in steps of “5”.

- Fill out the table containing the resistance parameters in relation to the set temperature.

- Check with the information provided in the vehicle manual.

Of course, inaccuracies may occur during the measurement process. The error depends on several factors: operating conditions and the characteristics of a particular DTOZH. In particular, even in devices of the same model, the resistance parameter may differ.

Without thermometer

If desired, checks can be made without using a water temperature meter.

In this method, you can act according to the principle discussed above, but with minor restrictions.

The general algorithm is:

- Boil the water.

- Install the DTOZh sensitive element into it.

- Measure the resistance at the terminals.

At a temperature of about 100 degrees Celsius, the resistance should be about 177 ohms. But here you need to take into account possible errors.

In particular, at the time of measurements, the temperature may change downward.

The disadvantage of the method is that the test is performed only at one temperature point.

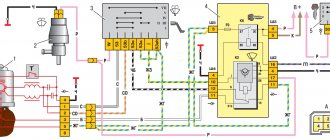

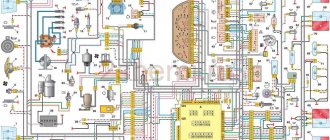

Diagnostics of the VAZ 2110 injector

In this section I will tell you several diagnostic methods. Since there are cases when the “ check engine ” indicator on the dashboard does not light up. And there are no significant deviations in the car. But diagnostics can reveal the problem. So, let's begin.

Computer diagnostics

Computer diagnostics are carried out in two ways. First, contact a service station. Where specialists see the full characteristics and errors through a computer. They will point out the problematic part and usually send you to change it. But as I said earlier , this does not always help. Since the specialist sees only the electrical sensor from which there is no signal. But the problem may also be in the wiring, and you go to auto parts and spend money.

Main causes of failure

Although the fuel sensor is not a consumable item, it also does not last forever. This device has a certain service life, which depends on:

- from the manufacturer;

- fuel quality;

- operating conditions and maintenance of the vehicle.

The reasons for sensor failure include the following:

- oxidation of contacts on the slider, lever element;

- wear of resistive tracks. Then the slider can be moved;

- sometimes, in order to correct the instrument panel readings, it is enough to bend the slider;

- resistor failure;

- broken wires. In this case, it may happen that the main two wires are connected securely, and the one that goes to ground may come off and, as a rule, is not visible.

On a note! If the wires are disconnected at the connection point, this is easily detected. If a break occurs on the wire connecting the FLS to the indicator on the dashboard, then such a breakdown will not immediately make itself known. In this case, its condition is checked with a multimeter.

It is worth remembering that repairing the fuel level sensor in a VAZ 2110 is not always able to extend the life of the device. Often it will have to be replaced anyway.

Coolant temperature indicator

Antifreeze or coolant is used to cool the engine. To ensure proper operation of the power unit, the coolant also has its own controller. In its functionality, this regulator is vaguely reminiscent of the choke that is equipped with 8- and 16-valve carburetor engines of the “ten” and other vehicles. The sensor itself is designed to monitor the temperature of the consumable.

Installing a new antifreeze sensor

In fact, this device also provides fuel regulation. If the power unit is running cold and has not yet warmed up, it will receive more gasoline for normal operation. Readings about the coolant temperature are displayed on the control panel in the vehicle interior. In accordance with these indicators, the driver will always be able to find out about the overheating of the unit by the way the sensor arrow on the dashboard begins to move into the red zone.

The antifreeze temperature sensor periodically fails; it is characterized by the following malfunctions:

- Loss of electrical contact inside the controller, resulting in its inoperability.

- The device is installed in such a way that it may be exposed to moving elements, particularly the accelerator pedal cable. It would be even more correct to say that the cable does not act on the sensor itself, but on its wires, which in fact can lose insulation as a result of long-term use.

- Often the regulator breaks down if the ventilation device starts to function on an engine that is not warmed up.

- If the motor is overheated, it may be difficult to start.

- If the fuel temperature controller fails, it can lead to increased gas mileage. If you encounter one of these problems, then to ensure normal operation of the car engine, you need to replace the controller. Detailed replacement instructions are presented in the video below (author - REPAIR VAZ 2110, 2111, 2112).

Idle speed sensor for VAZ-2110

Idle speed regulator.

First, let's decide on the catalog number and price of the unit. An idle speed sensor with the original catalog number 2112-1148300 . Its price for 2022 is about 500-550 rubles, depending on the greed of the seller.

By the way, exactly the same regulator is installed on all Priora and Kalina, Tavria, Nanos and Sens.

Be careful not to confuse the sensor we need from below.

How does it work and how does it not work?

The sensor, or idle air control, is designed to dose air into the intake manifold while the throttle valve is closed.

Idle speed sensor disassembled.

The device is not too complicated. It consists of a stepper electric motor, a calibrated spring-loaded cone and a rod. Installed in the intake manifold after the throttle valve . It is this regulator that is responsible for the smooth and smooth operation of the engine at idle speed.

Sensor on the throttle assembly.

Simply put, the idle air control sensor is a simple valve or actuator that controls the air supply when the throttle is closed, according to commands from the electronic engine control unit. When starting the engine in cold weather, the ECU opens the idle speed control slightly and supplies more fuel to the combustion chamber, increasing the speed to speed up the engine warm-up.

Once the engine warms up to operating temperature, the stepper motor moves the conical valve stem forward and reduces the amount of air consumed, thereby reducing the speed. This is how the sensor works.

Signs of sensor malfunction

But it does not work in cases where:

- the engine does not hold idle, the speed fluctuates;

- the engine stalls at idle and when driving in neutral with the throttle closed;

- a cold engine does not start without an open throttle, that is, until we press the gas pedal, the engine will not start;

- low and unstable idle when the engine warms up.

In this case, the Check Engine lamp will not light up . If it lights up, then we look for the cause in the throttle position sensor. In the case where the symptoms are present, but the lamp does not light, the cause should be sought in our sensor. Therefore, now we will check its functionality.

Most often, the sensor fails due to contamination or age; on many VAZ 2110 cars, the sensor has not been changed from the factory, which, of course, seriously affects its operation and the operation of the entire car as a whole.

The most common causes of failure of the mass air flow sensor:

- Filter contamination;

- Aging factor;

- Mechanical damage;

- Damage to the power supply circuit;

- Oily thread contamination;

Let's briefly consider each of the reasons and how to extend the service life of the mass air flow sensor.

Filter dirty

In order for the mass air flow sensor to last much longer, change the air filter in a timely manner, since a dirty filter can damage the sensor by preventing its filament from cooling, and dust deposits may also appear on the sensor.

Aging

On older cars, the sensor loses its properties; the thread changes the resistance from its nominal parameters, which leads to incorrect determination of the amount of air and, consequently, incorrect operation of the internal combustion engine.

Mechanical damage

Quite often, when repairing a car, the sensor is subjected to mechanical stress, which can damage it.

Crankshaft regulator

Depending on the type of car, on a 16- and 8-valve engine, the location of all controllers may be different. However, all of these devices combine into one functioning system, and the crankshaft adjuster is no exception. Thanks to this controller, the electronic engine management system of the “tens” can independently determine at what point to supply gasoline and a spark through the spark plugs in order to ignite the combustible mixture. In fact, the design of the device is a magnet, as well as a coil of thin wire.

The crankshaft sensor has certain advantages:

- As practice shows, at “tens” this regulator can work for quite a long time. Its service life does not decrease even as a result of using the vehicle’s power unit under increased loads.

- The crankshaft adjuster works in conjunction with the crankshaft pulley.

- If the device fails, the engine may not be able to start. Or, if the regulator breaks down, the speed parameters will be reduced to 3.5 thousand per minute.

This controller is installed on the oil pump, actually at the very top of the shaft teeth. Or rather, one millimeter from the cloves. You can learn more about how to replace this controller yourself from the video below (the author of the video is the channel In Sandro’s Garage).

What is a mass air flow sensor and where is it located in the VAZ 2110

Mass air flow sensor is one of the devices involved in controlling an injection engine. The abbreviation stands for: mass air flow sensor. It is entrusted with the task of measuring the volume of air directed into the power unit. The mass air flow sensor works in conjunction with two other sensors: atmospheric pressure and air temperature.

In its modern version, the mass air flow sensor is a hot-wire flow meter. The working element is a thin platinum wire to which voltage is applied. The more air passes through the sensor, the more the wire cools. Therefore, to maintain a constant temperature, it is necessary to increase the voltage, by the value of which the ECU judges the volume of air entering the engine.

The mass air flow sensor notifies the electronic control unit about the amount of air directed into the engine

The serviceability of the device affects the optimal operation of the naturally aspirated engine. The mass air flow sensor is a small device. It is mounted on the air filter housing of the VAZ 2110. From the device there is a pipe to the throttle valve.

The MAF sensor is located on the air filter housing

Renault Logan

On Renault Logan you can use many types of DTOZH, for example, MEAT & DORIA 82187, JP GROUP 1293102400, Vernet WS2602 and others.

Originals:

- 12-RENAULT-7700101968 (triangle contacts) - installed on 8 valve engines until 2012.

- 12-RENAULT-226307034R – after 2012 (contacts in a row).

All of them are suitable for K4M and K7M motors, their locations vary.

So on the K4M (8 valves), the temperature meter is installed in the water distributor housing (in the cylinder block). He is alone, transmits information to the instrument panel and works in conjunction with the ECU.

On the K7M engine at the rear end of the cylinder head.

On the body of the block there are markings for the three terminals “A”, “B1” and “B2”. The operating voltage is measured, as in the case above, with the ignition on between terminal “B1” and ground. The norm is from 4.8 to 5.2 V.

If voltage is not supplied to the block, disconnect the wiring harness from the ECU and use a tester to check the wiring for an open circuit. We take measurements between “B1” and pin “13” of the ECU.

If the circuit is working, then the control unit has failed.

We switch the tester to the “Resistance measurement” mode and check for an open circuit in the “ground” circuit of the sensor between terminal “B2” and the body of the machine (engine).

Readings of less than 1 ohm indicate a healthy circuit. If the device shows infinity, then there is a break between terminals “73” of the ECU and “B2” of the block.

Next, if you don’t want to remove the coolant temperature sensor from the engine, use a tester to measure the resistance readings on a warm and cold engine between the sensor terminals “B1” and “B2”.

Normative data are shown in Table 4.

| Temperature, 0C | Resistance, Ohm |

| 120 | 105 |

| 110 | 135 |

| 90 | 240 (+/ — 30) |

| 80 | 335 (+/ — 35) |

| 50 | 810 |

| 25 | 2050 |

| 20 | 3500 (+/ — 500) |

| 4 | 7500 (+/ — 500) |

To further check the device, you can use one of the methods discussed above.

For greater reliability, it is advisable to dismantle the device; use a 21 head.