Tuning and auto gadgets / From Autoclub

- What should a podium look like?

Internal podiumTable: advantages and disadvantages of internal podiums

- Table: advantages and disadvantages of external podiums

- Manufacturing and installation of an internal podium in the door

Gallery: covering the podium with artificial leather

Installing car audio requires a creative approach. Sound quality largely depends on where and how the speakers are placed. For them, podiums are elements of acoustic design. The elements are useful and in some cases necessary. What’s important is that you can make such podiums with your own hands.

Modern fashion for car audio

Today, most modern vehicles come with standard speakers. However, lovers of loud music in cars are often not satisfied with their sound, so they buy larger speakers. In this case, a different kind of problem arises - how to install large-sized equipment in the cabin so that, on the one hand, it does not disturb passengers, and on the other hand, to create truly clear sound?

One of the common ways to solve the problem is to make podiums for speakers. They can not only improve sound quality, but also take the performance of the speaker system to a whole new level.

A DIY acoustic shelf allows you to mount speakers of different sizes and shapes

Modern podiums

Acoustic podiums yourself

Sound organization is a set of measures that includes not only sound insulation or installation of a subwoofer, but also installation in the front doors of the podiums. You don’t have to buy them, although you can find almost any option in stores today. You can make podiums with your own hands if you know the basic nuances of the operation presented in our instructions below. Modern acoustic podiums are not too different from those that came before. Although, this is at first glance, but if you take a closer look, you will see the following:

- Modern podiums are made of high-quality material, which significantly increases their service life. If earlier they were made of plastic, which soon became covered with cracks and delaminated, today podiums are made of more durable material;

Modern acoustic podium

- Acoustically, modern podiums have an excellent and comfortable matte surface that does not leave dirty marks. High-quality plastic or plywood, from which modern podiums are made, is quite difficult to accidentally damage;

- The current podiums are made in such a way that they provide the opportunity to conveniently lay hidden electrical wiring to the speakers;

- Modern podiums are distinguished by a slightly modified configuration, which allows the installation of not one, but several speakers that reproduce different frequencies.

Acoustic podiums for yourself

What are podiums

The acoustic podium is the base for the speaker, thanks to which it is fixed in the desired position. The podium serves as a speaker mount, for example, in a car door or pillar.

Those speakers that are built into the podiums give a completely different sound: richer and deeper, with clearly distinguishable high and low frequencies.

What are speaker shelves used for?

We can say that the podium performs several functions in the car interior:

- the variety of appearance of the podiums helps to hide an unattractive sound system or emphasize the strengths of the interior design;

- expands the acoustic capabilities of the speakers in the cabin;

- podiums can be made from various materials and decorated with leather, wood, velor and other types of finishing fabrics to create a unique interior;

- in complex-shaped podiums it is easy to place non-standard and large-sized speakers, for example, a horn.

What types of podiums are there?

Podiums are divided into only two types: external and internal.

External ones can be considered podiums that are mounted directly in the car interior - for example, on the rear parcel shelf. However, most often, car enthusiasts use internal podiums in car doors to better fix the speaker and improve the character of the sound.

Traditionally, most cars already have standard speakers or holes for them. Usually their sizes depend on the make of the car. Domestic cars typically have speakers with a diameter of 130 mm. Foreign cars can have built-in podiums of larger sizes - 160, 200 and even 250 mm.

Car door speakers are usually round or oval in shape. Depending on the car model, podiums must take this feature into account. In general, the shape of the podium can be absolutely any, since the main purpose of this element is to securely fix the speaker in order to give volume and clarity to the sound.

Round speakers of different sizes can be installed in the doors of any car

New podiums on the Priora in the front doors: differences and features of the products

Before choosing a podium for Priora tweeters, the buyer needs to determine their appropriate size. This applies not only to the purchased speakers, but also to the free space left for a comfortable stay in the cabin. It is unacceptable to install an element that is too bulky, since it will not allow either the driver or the passenger to sit properly in the cabin.

In addition, the podiums should be conveniently attached to the side pads. The newly acquired elements must lie exactly on the surface of the door, without blocking the pocket. And special podiums for Priora, installed in the upper part of the sidewall near the pillar, will allow you to add new notes to the sound. And also achieve surround sound transmission.

The external design of the podiums also plays an important role. For example, in a car with a classic black and gray finish, you can buy podiums on a Priora in regular black or dark gray. But silver linings will look no less attractive, giving the interior a more modern look.

A car with a brown or beige finish should be complemented with podiums in a coffee or pleasant brown shade.

Small additions should not only be of high quality and convenient. The elements must look stylish in the car where they are installed. That is why only stylish podiums on Priora with tweeters can complement the interior and create really good sound from the media system. And during operation they will not cause any discomfort or noise.

How to make universal podiums for speakers

In most cases, you can do without investing in the purchase of factory podiums and make the element yourself. It's not as difficult as it might seem at first glance.

To successfully make a podium you will need the following materials:

- plywood 6–8 mm thick;

- degreaser;

- cardboard;

- polyurethane foam;

- putty;

- glue;

- epoxy adhesive;

- nylon tights;

- dye;

- fabric or leather for covering.

In order to put your idea into practice without any difficulties, it is best to prepare the necessary tools in advance:

- scissors;

- hacksaw/jigsaw;

- pencil;

- stationery knife/blade;

- sandpaper;

- putty knife.

Almost all the tools and materials for making podiums are available on the farm of an experienced craftsman

Why do you need a podium?

VAZ-2110 interior tuning with your own hands. Description, instructions

Many motorists who install speakers in standard places are unaware of how much the sound quality suffers. The car has several places for installing speakers: in the front door trims, on the luggage compartment shelves, inside the dashboard.

However, these places are not suitable. The point is that speakers work well when they are mounted firmly. In this case, the membranes operate at full amplitude. That is why the speakers of home acoustic systems are made of solid materials. In cars, the plastic is soft and thin enough to keep the speaker completely immobile. In addition, the movement of the car creates vibration in the casings, and the speakers are subject to additional shaking. Acoustic podiums are designed to minimize unwanted vibration.

Another reason for installing podiums is to extend the speakers into the open space of the cabin. If they are level with the door trim, then the sound partially goes under the trim.

Dimensions and shape of the acoustic podium

The technology described below involves the manufacture of podiums for speakers located in the front or rear doors of the car. Most often, there is one speaker with a diameter of 13 centimeters in the door. However, regardless of its size, the podium manufacturing technology will be the same:

- First you need to figure out what kind of podium shape is suitable for the interior of your car.

- It is necessary to measure both the dimensions of the existing speaker and the dimensions of its protective mesh.

- The diameter of the speaker ring will correspond to the diameter of the seat for it in the podium. And the outer diameter of the ring will be equal to the diameter of the protective mesh.

- Once you have approved the form, you need to draw it on a piece of cardboard.

- The resulting template must be carefully cut with scissors.

- Next, we apply the template to a piece of plywood and trace it with a pencil.

- For two doors we will need two plywood blanks that can be cut with a hacksaw or jigsaw.

- It is necessary to cut out the hole in the podium as accurately as possible, since if the proportions are violated, the speaker in the pocket will not be securely fixed.

Photo: correct procedure for making a shelf in a car door

It is recommended to carefully calculate all the parameters of the speaker in order to cut out a ring with the required dimensions

The hole must exactly follow the shape of the podium

Giving the podium volume and the desired shape is an important stage of the procedure

In order to give the plywood podium an attractive appearance, polyurethane foam is usually used. It is applied to the surface of the plywood. Then you need to do the following:

- when the foam has completely hardened, you need to work on the shape using a stationery knife or blade - you can give the workpiece absolutely any shape;

- After initial processing, you will need to apply one or two layers of putty to the product. After it has dried, you will need to give the podium the smoothest and most embossed shape possible by treating it with fine-grained sandpaper;

- the resulting product can be painted in any color, and it is advisable to paint in three layers for deep color saturation;

- As another design option, reupholstery is also allowed - that is, the use of elastic fabrics that can be attached using adhesives to decorate the podiums. You can cover the podium blanks with almost any type of fabric or artificial leather, but you should take into account the practicality of the material and its durability.

Upholstery with artificial leather is one of the most labor-intensive stages in design.

Video: how to make a podium in a car door with your own hands

The process of creating podiums - from coming up with the shape to cutting the foam and polishing the workpiece - turns into a real art for creative people. Every car enthusiast can feel like a sculptor creating a masterpiece!

Made of plywood and treated with polyurethane foam, this podium is no different from the factory one

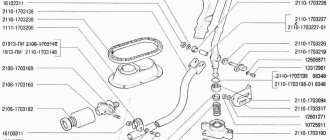

Guide to making and installing podiums in doors on a VAZ 2110

- Initially, you need to remove the entire door trim. In the future, determine the future location where the new podium will be installed.

- Subsequently, you need to prepare the place for subsequent installation. As a result of determining and final selection of the location for future installation, it is imperative to paste the inner surface of the door with a material that absorbs vibrations.

- The next step is to draw the shape of the podium; in this case, you should definitely take into account the above recommendations (tips). First of all, you need to take cardboard and cut out a tentative template from it. Subsequently, you need to attach it to the place and immediately determine the attachment point.

- After this, the prepared template must be attached to the plywood. Or to any other material that was subsequently chosen for manufacturing.

- Now, after tracing the test piece, the final part is cut out using the final material. And finally, you need to drill the necessary holes in it with an electric drill for further installation of fasteners.

- Then you need to apply the prepared workpiece one more time, but at the same time you need to drill holes in the car door directly in the metal for further fastening.

- The next step is to treat the plywood blank in several layers with any protective compound or varnish of your choice and finally wait until the blank dries completely.

- Then, using stainless steel bolts, you need to attach the podium on the VAZ 2110 to the car door with locknuts and washers.

- Then you should connect the desired acoustic dynamic speakers and only then secure them.

- After this, you need to try on the position of the car door trim panel.

- If this happens and the card partially blocks the diffuser, if necessary, then it is worth marking a larger hole for any speaker.

- Finally, make the existing holes larger according to the pre-applied markings. And then put the trim panel back in place. If ultimately required, the standard speaker grille can be easily modified. To do this, you need to take glue and acoustic fabric, cover it with a standard grille and then insert the speaker into the panel. Then you should completely assemble the vehicle door for the VAZ 2110. And immediately check how much better the sound of the outgoing music has become.

Making a podium in machine racks

The option of placing shelves in racks is more complicated due to the fact that they will need to be dismantled. However, it is quite possible for a neat car enthusiast to independently manufacture podiums on racks.

So, the work consists of performing the following steps:

- Dismantling the racks.

- The position of the speakers and their height on the stand should be carefully calculated so that they do not obstruct the driver’s view.

- In the right place you will need to screw the speaker cup with self-tapping screws.

- After this, you can use nylon to give the stand the desired shape.

- Next, the product is treated with epoxy glue to give it greater strength.

- To make the stand look smooth and even, you can lightly sand its surface with sandpaper, and then apply epoxy glue again.

- Then a layer of putty is applied, and after it dries, the final sanding of the stand is carried out.

Further, at the request of the car enthusiast, you can either paint the rack or reupholster it.

Video: how to make your own shelf in racks for tweeters and tweeters

Why install speakers on podiums in the doors of a VAZ 2110

Content

The simplest explanation for why a podium is needed on a VAZ 2110 is, at first glance, quite easy to understand; using them, you can move the speaker out of its usual seat. But this is not the main reason out of several that still exist.

In order for any car speaker to sound great, you definitely need to calculate everything correctly, starting first with the acoustic design and ending with a rigid base. When the internal acoustics are turned on, they begin to experience heavy loads. If in this case it is not drowned out, they begin to flow onto the trim panel and other elements made of thin material. And how correctly the sound distortion occurs. The podiums serve precisely to dampen vibrations.

Algorithm for making a podium for a car ceiling

The podium on the ceiling of the car is characterized by large dimensions, since the largest speakers are usually located in this place.

Despite this, any car owner can make a podium on the ceiling - you just need to very carefully install the structure:

- It will be necessary to dismantle the headliner so as not to damage it during operation.

- The shape and appearance of the podium are selected based on the size of the speaker.

- Usually plywood and polyurethane foam are also used.

Obviously, the procedure for manufacturing ceiling podiums is similar to the similar process in the production of door podiums.

It is noteworthy that these schemes for the manufacture and further design of podiums are suitable for any type of speakers - both round and oval. Regardless of the available speaker dimensions (13, 16, 20 and 25, as well as oval 6*9), the podium will fulfill its main purpose - to improve the sound quality of the acoustics in the cabin and securely fix the speaker in the desired position.

Photo: step-by-step production of a plywood shelf

The procedure requires caution, as it is easy to damage the interior trim.

It is necessary to accurately calculate the dimensions of the podium based on the size of the speaker

The workpiece must be treated with polyurethane foam, sanded and painted

What should the podiums be like for the VAZ 2110?

As a result, it was found out by people over time that podiums are intended not only to improve the appearance, namely the midrange. After all, the sound quality of speakers of various sizes depends on it.

To achieve a more effective result and subsequently dampen unwanted vibrations, the podiums on the VAZ 2110 must be quite heavy despite their small dimensions.

In order to make the podium heavier, it is best to make it from a special material. But motorists most often opt for cheaper material such as plywood. It is very easy to process it at home with your own hands.

As you know, plywood itself is a fairly light material and, in order to increase its weight, the podium for the VAZ 2110 needs to be made as large as possible. But at the same time, you should definitely take into account all the features of the vehicle inside the cabin.

In the process of determining the right size, you need to focus on the quality of the outgoing sound of the outgoing music, but you should make sure that additional elements do not interfere with the operation of the main devices. For example, you can take a newly installed speaker; it should not interfere with the subsequent use of the door handle. Acoustic podiums on the VAZ 2110 must be attached to a metal base, but not to the door trim.

Why is this necessary:

- First of all, a weak mounting base does not provide complete vibration absorption.

- Secondly, it simply cannot withstand a heavy podium with a speaker.

Main stages of the procedure

The process of installing and fixing any podium in any part of the car is as follows:

- Take a ready-made podium with a speaker built into it.

- The podium is screwed on the inside of the casing with self-tapping screws.

- However, to achieve truly clear sound, you will need to experiment with the installation - some screws will be tightened all the way, and some will not. That is, you need to give the podium such a position so that the speaker can reveal its sound to the maximum.

- It is recommended to soundproof the doors and ceiling (in this case you can achieve even clearer sound).

- After completing all the work, reassemble the ceiling, racks or doors (depending on where exactly the podium was mounted).

To enjoy clear and powerful sound in your car, there is no need to overpay for expensive speakers and factory-made podium elements. Most car enthusiasts are able to assemble a podium for the speakers in the car on their own from available means.

Didn't find the information you are looking for? on our forum.

Lada 2110 #HateHolic › Logbook › Making podiums. First experience (horn + casings)

I decided to put off the Priora salon for now until it warms up, or until I can properly heat the garage. Yes, and it was necessary to first try on something that was not a pity. My old skins were bought on Avito, and over time they became very worn out. I put up with this disgrace for a very long time, but finally the opportunity arose to fix it.

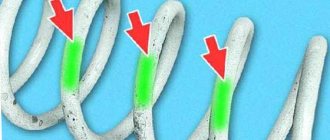

I started the process from the corners. In fact, I started it back in January - I set up the rings, drilled holes at the points of contact with the resin (as advised) and everything calmed down because there was no place to work with the resin.

As a result, only in August I got down to business, but broke down. The furniture stapler did not penetrate the plastic, so I had to go to my friends and use a pneumatic stapler. One corner pulled perfectly, but the second fell apart and had to be re-glued.

I put it in two layers of glass mat and coated it a little with resin on the inside.

Then I sanded it with a petal attachment on an angle grinder, and a little by hand. And I’ve finished the work for now, I’m waiting for a salary to putty it all.

Then I started working on the door cards, peeled off the foam in layers, cleaned it, adjusted the rings, then again, and again - everything was fine.

I'm tired of displaying them. I tightened the board so that all the speakers were placed in the same plane. I screwed it on with self-tapping screws and substituted plywood scraps to ensure rigidity. Then I drilled holes along the planned contour.

Next, I stretched the lycra and started nailing it with a stapler - it’s absolutely terrible, the casing simply broke in several places, I had to screw a piece of tin on the bend to give it shape, otherwise it wouldn’t have worked (in the end I removed it and it turned out as if it had happened).

Finally I started applying resin and glass mat. In the end, I made a mistake when, having applied only one layer of resin and letting it dry, I began to cut off the back of the skin; it apparently had not completely dried and sagged a little. Lumps appeared (I did the second skin differently - I applied a layer of glass mat on the front side, then cut off the back wall and put two layers on the inside. The same with the first.

Everything took a very long time to dry, it was cold in the garage, I had to turn the heater on them while I was in the garage. All this took me probably two weeks, while everything dried, new layers were applied. There was also not enough time to work. But in the end everything dried out, and I began to remove the whole thing with a petal nozzle and sandpaper.

It turned out well, but there are some problems. There's still a lot of puttying and sanding involved, but that's for another time. You also need to make a separate volume for the middle, the resin just ran out

The speakers are: -Ural Armada D200 from about 100Hz -Alphard Machete MM-60 from about 200Hz -Alphard HLS-20 from 6kHz (temporarily not connected) Having installed the 20's, I simply went crazy with the volume, very unexpectedly. Impressive lows appeared. Of course, this is all a dishman budget, but it’s enough for now. Result: About 3 liters of polyester resin were spent

300r/kg. Glass mat approximately 2 kg. Lycra small piece (about 1*1)

Source

Podiums for sensors

Podium for Subaru GDB sensors 00-07 60mm SPD-00001523

Podium for Subaru GRB sensors, 4 sensors 60 mm SPD-00002264

podium for sensors Subaru Forester SG 60mm shagreen SPD-00002990

Podium for sensors Subaru GDB 00-07 52mm SPD-00001765

podium for sensor on left pillar 60mm triple el-pod60-3-ST-L

podium for 60mm triple sensor el-pod60-3

podium for sensor on the right pillar 60mm triple el-pod60-3-ST-R Out of stock

podium for sensor on left pillar 60mm double el-pod60-2-ST-L

Source

Functionality of podiums

There are technical and decorative podiums. Technical podiums are designed to mask structures and communications; such podiums are also called functional. Interiors are decorated with the help of decorative podiums; their second name is designer podiums. Podiums are usually installed either in large residential premises or in small apartments. For the interiors of small apartments, podiums help create additional usable space; drawers are built into them, which can replace outdated mezzanines. Besides. with the help of a small elevation of the floor, they delimit the hallway and the living room. kitchen and dining room.

On the podiums there is a recreation area, children's play corners, libraries, home theaters, a work area, and a dining room. Modern interior styles, thanks to podiums, make rooms more functional and harmonious. Sometimes podiums are used to decorate furniture. For example, you can decorate a sleeping area, a dressing room or a wardrobe in an original way. Installation of the podium can take place on the basis of a frame or according to the monolith principle. It is easier to make a podium with your own hands on the basis of a frame structure, which is then sheathed with basic and decorative materials, floorboards, laminate, and covered with textile floor coverings. Monolithic podiums are installed in rooms with a large load on the floors.

What to consider when planning a podium

- The height of the podium varies from 15 to 50 cm, depending on its purpose and your requirements for it. When equipping a sleeping place, a greater height will be required than when arranging storage space.

- If the apartment is small with low ceilings, then a high podium will further reduce the space. You will have to be content with a low design or abandon it altogether.

- The podium needs to be placed in a suitable place that is not a passageway, otherwise it will interfere with household members’ ability to comfortably move around the apartment.

- It is necessary to visually highlight the podium in the space of the room so that it does not merge with the tone of the main floor, otherwise you can easily trip over it.

- If the podium is high, then you need to make several comfortable steps with an anti-slip coating. The optimal height of the steps is 10 – 15 cm.

- If the podium will be placed in a children's room, then all sharp corners need to be rounded and can even be sheathed with soft material.

Making acoustic podiums for the VAZ 2110 with your own hands

If it is not yet clear from the title of the article, this guide will describe almost the most creative work to improve the systems of a VAZ car. In particular, many car owners complain about the VAZ branded acoustic system. The sound is weak, unsaturated with some extraneous grinding and hissing. To change the situation you need to install new speakers in the doors. And for this you need to either buy full-fledged podiums for speakers in the store or do tuning of the VAZ 2110 with your own hands.

The chances that you will be completely satisfied with the acoustic podiums presented in the store are minimal. In addition, such systems are quite expensive. If you are interested in installing acoustics on a VAZ 2110, then you are clearly not an indifferent person and will be able to patiently and creatively complete the steps described below for making an acoustic podium.

First, a list of necessary materials and tools:

- polyurethane foam in cylinders (1-2 cylinders depending on the planned size of the podium);

- binder – epoxy or polyester resin;

- Chipboard or plywood;

- putty for fiberglass – 500 g;

- a set of sandpaper with different grits;

- putty knife;

- self-tapping screws;

- jigsaw;

- construction stapler.

The work on independently manufacturing an acoustic podium for the VAZ 2110 takes place in several stages

- The very first step is modeling the shape and size of the future podium. You need to proceed from the size of the speakers that you plan to install. First, draw a pattern on the cardboard, then transfer its shape to the chipboard. Using a jigsaw, cut out the desired shape.

- Place the cut ring on the base and determine the desired angle of inclination of the speaker. To do this, insert a thick sheet of cardboard or other material rolled into a tube inside the ring. At this stage, it is important to make sure that the future acoustic VAZ 2110 podium and speakers will not interfere with closing the door or opening the glove compartment.

- The next task is to create volume and shape. This is done using polyurethane foam. Following the instructions on the can, start creating volume.

- Pour the foam without sparing, the main thing is to fill out the desired form, you also need to fix the ring in the desired position. Leave the workpiece until the foam hardens.

- After the foam has dried, you can proceed directly to shaping the shape of the podium. Nothing complicated here. Using a sharp utility knife, cut off any rough edges and excess volume. Be careful not to cut off too much.

- When the general outlines are already clear, smooth out small unevenness on the workpiece using fiberglass putty. Apply a thin layer of putty to the foam and leave everything to dry.

- The workpiece is almost ready, it already has volume and density. Now you need to smooth out all the minor irregularities. For sanding, sandpaper of various grain sizes is used (depending on the size of the unevenness). Sand the homemade product until you get a flat and smooth surface.

- When you are satisfied with the result, proceed to puttying.

- Mix up the putty and apply it in an even layer to the surface of the product. After drying, smooth out any uneven areas again. Be careful not to damage the almost finished form.

- Finish sand the acoustic podium using fine-grained sandpaper. In order not to do extra work, decide that perhaps you will not cover the product with paint, but cover it with leather. Then minor irregularities can be left behind. The skin will hide them all.

- Next, before painting, be sure to prime the surface.

- You can also approach painting creatively - you can not just apply a layer of paint, but create some kind of texture. The applied anti-gravel coating looks pretty good. The top can be coated with matte paint. And everything will become very nice.

With a certain level of skill, you can make such an acoustic VAZ 2110 podium that everyone will envy you and even ask where you bought such beauty. Now mount and connect the new speakers - you are guaranteed to be delighted with the results.

Types of podiums

According to their design, all podiums are divided into:

- monolithic;

- frame.

Monolithic podiums

made of concrete. They are mainly used as a platform for installing a bathtub or shower. This option is more suitable for a private house, where the concrete foundation transfers the load directly to the ground.

For apartment buildings, even with concrete floors, this option is extremely undesirable, since it creates an unacceptable load on the floor.

It is clear that the only “filling” of such a design can only be the communications inherent in the bathroom. And even then it is not recommended to bury them in concrete.

Frame podium

assembled from wooden frame bars and sheathed with chipboard, plywood, OSB or rough board, which is then subjected to external finishing. All sheet materials are laid in 2 layers in order to increase the load-bearing capacity of the site.

To construct the frame, you can also use metal structures, which are subsequently also sheathed with sheet material.

Such designs allow you to safely experiment with both the exterior decoration of the podium and its “filling”.

Installation of the podium

- First you need to dismantle the old flooring in the place where the podium will be located. This is not a prerequisite, but if you want to place heavy furniture on the site, then dismantling the old floor will somewhat reduce the load on the floor.

- The next stage is the installation of the frame for the future podium. The frame logs are installed at right angles and fixed with ordinary nails or self-tapping screws. The installation step of the logs is approximately 40 cm. In order to ensure better sound insulation, good soundproofing material should be placed under the logs (most often, mineral wool or soundproofing tape made of rubber is used).

- The structures are secured using anchors or dowels. The frame can only be attached to the walls if they are permanent. They do not attach to the partitions.

- If you decide to illuminate the podium, then it is necessary to carry out all electrical communications before covering it. The cable power must correspond to the total power of the lighting fixtures.

- It is necessary to leave small seams between adjacent sheets of vertical cladding of the podium to ensure deformations that will inevitably arise during operation of the site. Gaps can be sealed with sealant.

- The podium area is covered with slab material in 2 layers. To give the structure additional rigidity, the slabs are laid staggered. If they are large, it is better to cut them into smaller parts.

- The last stage is decorating the surface of the podium. For this, you can use any floor covering: carpet, linoleum, laminate, solid board, parquet.

It should be taken into account that the total load on the floor is usually 400 - 800 kg/sq. m. Therefore, you need to at least approximately determine the weight of the podium and all the objects that will be placed on it (and under it). The power of the structure frame depends on this calculation:

- If the load does not exceed 150 kg/sq. m, then a log section of 50*50 mm is sufficient.

- If the load exceeds 300 kg/sq. m, it is better to use timber with a cross section of 70*70 mm.

The simple design of the podium allows you to design and install it yourself. But we must remember that its arrangement is a redevelopment and requires approval.

DIY speaker podiums

Speakers of this size are usually located in the front of the cabin. The basis of the structure is 10 mm plywood. It’s good if there is impregnated material. Such plywood will not delaminate, and the podium will last a long time. First, installation rings of the appropriate diameter and a base are cut out of multi-layer plywood using a jigsaw. Two rings form a hollow cylinder, which will be the seat for the loudspeaker. The rings and the base are not connected coaxially, but so that the speaker system diffuser is directed in the required direction. This is achieved by shifting the vertical guides to the desired angle.

The guides are cut out of the same plywood and fixed with self-tapping screws. To make the connection more durable, a little epoxy resin is added to the connection point. Then the hollow structure must be filled with polyurethane foam. Thick paper rolled into a tube is placed at the speaker installation location. After the polyurethane foam has completely dried, the paper is removed, and the structure is processed with a sharp knife and sandpaper to give it the desired shape. Leatherette is used as a decorative covering. Its color is chosen taking into account the design of the car's interior. The artificial leather covering is glued with glue 88. This work should be done very carefully, since secondary gluing leads to a deterioration in the appearance of the structure. A loudspeaker of this diameter has low power, so no special fastening is required to secure the podium to the installation site.

DIY podiums for speakers

16 cm loudspeakers can be included in an acoustic system design consisting of two active elements. Podiums for such acoustics are usually installed on the doors of the car. To make podiums for 16 cm speakers with your own hands, you will need multilayer plywood, fiberglass, polyurethane foam and epoxy resin. The technology itself is quite simple, but it will require time to dry the layers of fabric after impregnation with epoxy resin. First, all the elements of the future acoustic system are cut out of multilayer plywood. These are the base, rings for installing speakers and vertical connections. The structure is then assembled into a single whole. Wooden blocks or metal fastening profiles can be used as vertical elements.

Next, the entire structure is filled with polyurethane foam, with the exception of places for installing loudspeakers. Then everything unnecessary is removed from the podium, and its surface is treated with fine sandpaper. For strength, a thin layer of epoxy resin with a hardener is applied to the surface and rubbed into the pores of the mounting foam. This procedure can be repeated several times. The finished podium is finally sanded over a layer of resin. The finished product is finished using artificial leather.

You can make podiums for speakers in doors yourself using another technology. After the frame for installing the speakers is made, the entire structure is covered with thin fabric, which is impregnated with polyester varnish or resin. After complete drying, a thin layer of epoxy resin and fiberglass is applied to the workpiece.

There should be at least three layers of fiberglass with epoxy resin. After the future podium has completely dried, a layer of fiberglass putty is applied to the structure. All excess is cut off, and the surface is brought to condition using coarse and fine sandpaper. To finish the finished product, you can use leatherette or several layers of enamel, which is matched to the tone of the interior trim. Using this technology, you can make podiums for speakers with your own hands for one, two or three speakers.

Final work

As noted above, the correct setting of the orientation of the speakers is considered a very important point, which will subsequently affect the creation of the podium frame. This includes focusing the beeper correctly, as well as listening to it. How correctly the speaker is adjusted, the music perception will be as comfortable as possible.

To accurately carry out the entire debugging process, you should start by setting the speaker, which is located near the driver, to the passenger’s left ear. Accordingly, the passenger speaker is tuned to the driver's right ear. Thus, a control point is reached in the cabin, where the sound waves intersect. This means that the music will evenly create a “load” on everyone sitting in the car.

If you plan to install component acoustics in the car, then the speakers are aimed at the rear view mirror, which is located in the cabin. As a guide, you can take an imaginary point located 10 cm in front of the passenger's head. This setting is especially important for fans of “heavy” music.

The design of the speakers implies the presence of a piston. Sound waves are generated by the movement of a diffuser, which compresses the air. When the waves exit the speaker, a vibration of a certain strength is formed. If the podium is not tightly fixed to the door, it will begin to vibrate.

Firstly, this will significantly affect the quality of the sound produced, and secondly, it can lead to deformation of the product itself. In addition, the metal on the door bends quite easily. The podium acts as a reliable speaker holder: the more rigidly it is fixed, the less vibration and deformation will be caused by loud listening to music.

Everyone chooses the shape of the podiums and the design approach to their production. But in any case, they must have appropriate rigidity. Therefore, when making a product with your own hands, you should use a durable frame. There is no need to rely on polyurethane foam, as it does not provide adequate rigidity.

To create truly high-quality music sound, you should remember that each car interior will “sound” differently. This depends on many features, for example, each surface has its own absorbing properties. Ideal sound is achieved by selecting the right audio equipment. Moreover, even an ordinary antenna requires proper configuration.

We do it ourselves

If you try, the homemade podium will not be much different from the factory one. But the price will be much less. Plus an additional reason for pride.

To complete the work you will need a set consisting of:

- plywood (take a thickness of about 6-8 mm);

- PVA;

- epoxy;

- cardboard;

- degreaser;

- nylon tights;

- polyurethane foam;

- paints;

- putties;

- leather or fabric (will be tight);

- scissors;

- pencil;

- hacksaw or jigsaw;

- sandpaper;

- spatula;

- stationery knife.

I will say right away that in this case we are considering the option of making a homemade speaker podium, which will later be installed with your own hands in the front or rear doors of the car. Often a speaker with a diameter of 13 cm is used here. But no one bothers to make a design for the rear shelf.

But size is not key. The entire preparation procedure looks like this:

- think over the shape of the podium;

- take measurements of the speaker and its special protective mesh;

- the diameter of the ring here will be exactly equal to the diameter of the corresponding landing socket or place on the future podium;

- the external diameter of the existing ring we need, in turn, corresponds to the diameter of the tread (protective) mesh;

- a sketch is drawn on cardboard;

- the template is cut out;

- applied to plywood;

- outlined and cut out;

- a perfectly even hole is cut for the podium.

Do everything as accurately as possible so that no problems arise later.

If you are done with this, proceed to the next step.

Manufacturing process

You have already made the preparation. But it’s too early to relax. There is still a lot of work ahead.

- A layer of polyurethane foam is applied to the surface of the workpiece;

- The foam hardens, and the required shape is given with a blade or sharp knife;

- Next, apply 1-2 layers of putty;

- When it dries, make the product smooth using sandpaper;

- The product is painted in a suitable color;

- It is better to apply the paint in 3 layers;

- An alternative to painting is upholstery with fabric or leather;

- The banner is secured with glue.

The installation process finishes it all off. The most optimal method of fastening is installation using self-tapping screws on the inside of the existing door trim. This will preserve the sound quality, ensure reliable fixation, and at the same time definitely will not spoil the appearance of the interior and the podium structure in particular.

Do not forget to additionally use soundproofing materials. They are used to make noise on doors. This is not necessary, but it is useful and effective.

I think you have figured out how to make podiums in the doors. They can also be installed in rear shelves and racks.

DIY podiums for speakers under 20

The speakers with a diameter of 20 cm are large in size and have decent power. Such speaker systems are usually installed on the trunk shelf. In order to make podiums for 20 speakers with your own hands, you need to use thick plywood. First, a base is cut out of it according to the size of the seat. The thickness of the material should be as thick as possible, since high-power speakers and the mounting board can resonate at high power. Rings for acoustics and vertical posts are cut out of the same plywood to provide the necessary tilt.

The loudspeaker mounting areas are covered with thin nylon fabric and impregnated with varnish. The top part is cut out and removed. A layer of epoxy resin and fiberglass is applied to the hardened surface. After applying 3-4 layers and completely drying, the surface is cleaned and sanded. You can cover the finished shelf with any decorative material, upholstery fabric or artificial leather. Some car owners install speaker systems on the ceiling of the car interior. It is not difficult to make podiums for ceiling installation according to the described schemes.