What is a ball joint

This element is a connecting node. It secures the hub and suspension arms. Ball joints are installed only at the front and allow steering of the front wheels. Without these elements, the wheels would not be so securely fixed, and the car would not behave stable on the road.

Externally, this part looks like a cone with a movable tip. This type is the most successful and took a long time to develop, because previously the supports were of a less successful shape. Initially, they looked like 2 different elements that were connected by welding.

Ball joints on Kalina are usually made of steel for greater strength. The fact is that they are under constant stress. The housing also uses plastic or polymer.

How to determine whether a ball joint is faulty

It is believed that the optimal method of checking the ball joint is to visit a car service center where there is a lift and an appropriate stand. There, specialists will be able to identify faults not only with the ball joint, but also with other elements of the vehicle’s suspension.

However, if the task is only to check the ball, then this can be done in garage conditions using just installation. Well, perhaps it would be desirable for the car to be parked on a pit or overpass. A faulty ball joint can be identified by the main symptom - knocking and free movement of the ball pin when a mount force is applied to it.

Quick check

First of all, you need to “listen” to the ball joint. However, for this it is better to take an assistant, preferably one who knows what sound a broken support makes and generally has some understanding of the elements of a car’s suspension. The verification algorithm is simple - one person rocks the car from side to side (in the direction perpendicular to the movement), and the second listens to the sounds coming from the suspension elements, in particular, from the ball joint.

If such rocking does not produce results, it is worth jacking up the car on the side where you want to check the support. Then, holding down the brake pedal (this is done to eliminate possible bearing play), try to swing the wheel in a direction perpendicular to the movement (that is, away from you and towards you). If there is play and/or “unhealthy” clanging sounds, then there are problems with the ball.

The play of the broken ball will be checked using a pry bar. So, the car needs to be jacked up, and the flat end of the mount placed between the lever and the steering axle. Then, while one person slowly turns the steering wheel, the second person presses on the pry bar. If there is play, it will be clearly felt and even visible to the eye. A similar procedure can also be performed without rotating the steering wheel, especially if the ball joint is already significantly worn.

Choice: original or analogue?

This element is important in the design of the car, so you need to choose it carefully. The choice of spare parts is not small, you can choose exactly the option that suits you best in terms of price and quality.

An original factory-quality ball will cost about 1,000 rubles. Price may vary depending on where you purchase. For the Lada Kalina car, ball joints from the Samara family, as well as the VAZ-2110, are suitable. The catalog number for the spare part is 21100-2904192-82. If the kit includes fasteners, then the number is 21100-2904192-86.

There is an alternative to the original ball one. There are several such options:

| Manufacturer | Catalog number | Cost, rub |

| Weber | SS 2108-4185 | 500 |

| Master-Sport | 1545601/E-PCS-MS | 500 |

| SCT | RM 485 | 500 |

| Denckermann | D110112 | 500 |

| Monroe | L70003 | 550 |

| Ruville | 917210 | 600 |

| Delphi | TC583 | 600 |

| Patron | PS3101 | 600 |

| Pekar | 2108-2904185 | 600 |

| Moog | LA-BJ-0063 | 650 |

| Pilenga | TS-P 3142 | 700 |

| TRW | JBJ 156 | 800 |

| Optimal | G3-199 | 1000 |

Ball joints for Lada Kalina are offered in different quality and cost. An analogue can be purchased cheaper than a factory spare part. Often their quality is equal or even superior. However, it is highly not recommended to purchase the cheapest copy; it is usually of low quality and has a short resource, which is unacceptable for this unit.

Of course, it is best to give preference to a factory-quality ball joint, since they are the ones that are installed by the car manufacturer initially. However, the cost of such a copy is high, so most motorists consider buying analogues.

In this case, you need to choose extremely carefully. You should not buy a ball from an unknown manufacturer, or from dubious places.

You also need to inspect the spare part before purchasing. Its surface should be perfectly smooth without welds. If the item is dirty gray in color, then it is better to refrain from purchasing it, since it most likely has undergone heat treatment.

If, even after completing these steps, questions still remain, then it is best to contact the store managers who will help you decide.

The role of support in the suspension and the consequences of failure

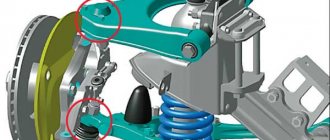

The part is a ball pin with a thread at the end, enclosed inside a metal housing. So that it can rotate, a sleeve made of hard plastic (usually fluoroplastic) is installed between the ball and the body. The pin is screwed with a nut to the steering knuckle of the wheel hub, and the part itself is bolted to the suspension arm. To prevent dirt from getting inside the hinge, it is protected on the open side with a rubber or silicone boot.

Note: in some car models, the ball joints are integral with the levers and are also replaced together.

The task of the element is to provide a hinged attachment of the hub to the lever so that it can rotate . That is, the support bears the load from the weight of the car, impacts from the wheel and the impact of friction when turning. Now it becomes clear what the risk of malfunctioning this important part is. First of all, the plastic sleeve wears out, causing the ball to begin to dangle inside the body. If measures are not taken, then on a strong bump the ball pin will pop out of the body, and the wheel will come off along with the hub.

Despite the fact that after separation the ball hub is held on a stand or on a second lever, the wheel becomes uncontrollable. The consequences are unpredictable and depend on the speed of movement at the time of the breakdown. That is why it is important to monitor the condition of these elements and respond in a timely manner to extraneous sounds coming from the chassis. If the first signs of a malfunction of the ball joint appear, it is advisable to check it and clarify the diagnosis in order to replace it with a new one in time.

Major breakdowns

This item is made of durable materials. However, it is under heavy load and therefore becomes unusable over time. The most common breakdowns that occur with ball joints are:

- Mechanical damage in contacting surfaces. As a result of the work, an increased gap is formed between the finger and the body itself, as well as cracks and chips. Because of this, scrolling occurs, and subsequently free movement of parts inside the case. With such a malfunction, further movement is highly not recommended, since controllability deteriorates significantly, which can lead to dire consequences;

- Cuts and tears in the boot. This problem can damage even a fully functional ball joint. The fact is that the boot is necessary to protect against dirt, dust and moisture. If it is torn, then all this will penetrate into the mechanism and, over time, disrupt its operation;

- Lack of lubricants. Because of this, there is not enough friction, so the parts hit each other, creating cracks and chips.

If even one of the above failures is detected, then the ball joint needs to be replaced. First of all, the safety of movement depends on this.

If the boot ruptures, you need to carefully examine the ball itself to understand what condition it is in. If it is good, then you only need to replace the clip, but if not, then you will need to change the entire mechanism.

If there is a lack of lubrication, it is also necessary to inspect the internal condition of the ball. If its parts are intact, then you just need to add more lubricant. This must be done as quickly as possible, since without lubrication the parts will wear out a lot. When installing a new ball joint, you also need to check for lubrication.

Reasons for failure

There are several reasons why a ball joint may fall out. Let's consider the main ones:

- Wear. The most common malfunction that occurs on cars.

Inspecting the ball for wear

- Insufficient lubrication in the boot leads to the fact that the finger begins to creak and may eventually simply break.

- The penetration of dirt and water into the ball contributes to the development of corrosion, which can affect the operation of the vehicle. At best, a wedge and the inability to turn the wheels; at worst, the car will fall onto the asphalt.

To avoid consequences, it is necessary to regularly diagnose and maintain ball joints.

Diagnostic operations

How can you diagnose the condition of ball joints on a Lada Kalina:

- The first thing you need to pay attention to is the condition of the boot. If it has cracks or is torn, then it must be removed and the ball should be inspected.

- We hang the wheel a little and swing it up and down with our hands. If there is play, then it’s time to replace the ball.

- The presence of a squeak, as well as heavy turning of the steering wheel, can also be signs that the ball joints are in critical condition.

- Instability in control, namely departure from the trajectory of movement to the left or right, with the steering wheel in a level position, indicates that the ball joint has failed.

It is almost impossible to determine the exact condition of the ball joint, but the above facts indirectly indicate the condition of the supports.

Replacing the ball joint

Initially, you will need to install the car in a comfortable position, secure it with the handbrake, and also jack up the wheel. The next steps are:

- You need to unscrew the support pin nut on the lever. To do this you will need a 19 key;

- Using a puller, you need to press out the finger. This is done very carefully so as not to damage the boot;

- Now, using a 17 key, you need to unscrew both bolts that secure the part to the fist;

- Move the lever and also remove the ball joint at the same time.

The faulty part has been removed, and a new one can now be installed. This is done in the same way as removal, but in reverse order. Before doing this, it is recommended to make sure that the new spare part is free of defects so that its surface is perfectly smooth.

It also happens that the fastening bolts become stuck due to the fact that they have not been touched for a long time. In this case, trying to unscrew them will be a pointless exercise. They need to be soaked in WD-40 and left in this state for a day. After this period has passed, the bolts will unscrew without much effort. To prevent such problems from arising in the future, it is recommended to lubricate the mounting bolts before installation.

Not every motorist has a ball joint remover, and it is not profitable to buy one, because it will be needed very rarely. There is a way out of this situation. You need to unscrew the nut a little so that it remains on the pin, and then use a crowbar to slightly press the lever from top to bottom and hit the lever with a hammer. After several strokes the desired result will be achieved.

Change ball joints on a viburnum with your own hands

Lada Priora Sedan Snezhka Logbook Replacing the support bearing

Hello. Today we’ll talk about how to replace ball and tie rod ends on a Lada Kalina with your own hands. Why ball and tie rod ends fail and how to diagnose their malfunction is written here

Before starting work, you need to prepare: a set of keys, a universal puller, a jack, WD-40 fluid, as well as new spare parts.

How to replace ball joints on a Lada Kalina - step-by-step instructions

1. Before starting work, apply a few drops of WD-40 to threaded connections that you think may have problems. They will be different for everyone, it all depends on the condition of the car, the roads on which it drives, and the attitude of the owner towards this car...

2. Unscrew the ball joints. There are two TORX bolts that are attached to the hub; for this we take an E12 head.

3. Afterwards, we proceed to the stabilizer strut, it must be unscrewed.

4. Bend down the lever with the ball joint.

5. Using a universal puller, press the ball joint out of the lever. If you don’t have a puller, you can use a crowbar, but in this case there is a high probability of damage to the CV joint boot if the crowbar comes off.

6. When the old ball is removed, take the new ball and attach it to the hub and lever.

7. Jack up the lever, using a jack to place it under the ball. This will compress the spring of the shock absorber strut and screw on the stabilizer bar.

Step-by-step instructions - how to replace tie rod ends on a Lada Kalina

- We unscrew the steering wheel in the direction opposite to replacing the steering tip.

- We remove the locking pin and unscrew the nut securing the tip to the stand.

- Now you need to “release” the tip mounting bolt.

- Using a puller, press the tip out of the stand. Some people use a hammer and simply knock out the tip.

- Next we unscrew the tip, this is done clockwise. If the adjusting sleeve starts to rotate, fix it using a wrench.

6

I draw your attention to the number of turns, it must be counted, this will save you from the need to go to a service station and do a wheel alignment

7. Assembly is performed in reverse order. If the car pulls to the side and the “trick” with counting the turns didn’t work, don’t be lazy and do a wheel alignment.

The result of the work done should be the disappearance of play and knocking, which are an integral part of chassis malfunctions.

That's all for me, thank you all for your attention, I hope everything worked out for you!? Until we meet again, take care of yourself and your car! Text belongs to: VAZ DIY repair

Text belongs to: VAZ DIY repair

Lada Kalina Station Wagon 2008, 81 l. With. - spare parts

Lada Kalina, 2012

Lada Kalina, 2012

Comments 30

which ball joints did you choose and how were they diagnosed, thank you

So far I’ve been driving the Samarazapchast ball joints, they rattle at low speeds on uneven surfaces. I’ll probably install a Lemferder - the reviews about them are more positive.

I installed cedar, the lemferder had to be ordered, the price was the same, I bought the ones that were in the store

factory ones passed 62tk removed in excellent condition. replaced it with a bzak factory.

I installed lemforder balls on my last Kalinka, they performed excellently)

Try to remember where they were made? Nowadays only China makes it, but before it was made in Germany.

Yes, I didn’t look too closely) there were all sorts of German words on the box) I didn’t even buy them myself) they were in the store from the craftsmen) they said they were good) they didn’t deceive me)

Try to remember where they were made? Nowadays only China makes it, but before it was made in Germany.

So why is China confusing?

Same garbage, enough for 20,000 miles! I installed it, I don’t remember which ones. All front-wheel drive vehicles had at least 100,000 miles on them before. Although I sold two viburnums for 65,000.

what they put on the conveyor belt is not at all what they sell and they walk normally

At my last viburnum, there were conveyor belts. Result: 20,000 km and the bells have become like bells. I'm surprised myself.

So, just like me, I was unlucky.

I drove the car 35t after purchase, I haven’t changed the ball joints yet. Mileage is only 123t. The mechanic I sometimes get serviced by says it’s still relatives.

Relatives go for a long time, if you're lucky. But I was unlucky - the mileage is 127, and the ball joints have already been changed 5 times.

I had no luck with the tie rod ends; I changed them twice in 35 tons of mileage.

Kedr, Belmag run fine. If imported, then lymphedore so that the catalog number ends in 01, they are fine if other numbers are better not to take and TRW is good

They also advised me to use lymphders, they say there are no problems with them.

Kedr, Belmag run fine. If imported, then lymphedore so that the catalog number ends in 01, they are fine if other numbers are better not to take and TRW is good

I just looked through the catalogs and didn’t find a limper with 01 at the end, only 02 is there

I don’t have them since 01, now I installed them in 02 that summer, now they say they need to change them (I also don’t know what to install... apparently a consumable)

Hello!

Somehow, almost immediately after purchasing Kalina 2, my left (driver’s) ball joint creaked. Replaced NOT under warranty

.

We installed a ball joint from AvtoVAZ. At almost 60,000 km, the right ball joint began to knock (especially after a long period of inactivity). Self-diagnosis revealed play in the right (passenger) ball joint. After choosing for a long time, I decided to install TRACK ball joints of the “TRS” 2108 series on the Lada Kalina 2 (2194)

.

From the manufacturer of TRS series ball joints:

“The TRS series ball joints are intended for those who are interested in motorsports, for professional racers, as well as for those whose car is used in professional activities. The developed new design of the liner has greater rigidity and has grooves for lubrication and removal of wear products, which significantly increases the service life of the product.

The use of a solid forged body eliminates the possibility of its deformation and the appearance of fatigue cracks, unlike a body made of thin-sheet stamped parts. The ball joint is assembled by plastically deforming the upper part of the housing. As a result, high values of force to pull the ball pin out of the body are achieved (2.5 times higher than the standard), and high safety during operation is ensured. The original design of the liner is more rigid (compared to serial products); it is equipped with grooves for lubrication and removal of wear products. Lubricating molybdenum disulfide on the ball pin sphere also helps reduce wear on the assembly. The sealing rings of the protective cover ensure complete sealing of the unit. The material of the protective cover made of polyurethane provides strength 3-4 times higher than that of rubber, while fully maintaining elasticity. Operable at temperatures from -65°C to +110°C. The housing coating protects the product from corrosion during operation. The actual mileage reaches 100,000 km.