The beginning of the 90s can hardly be called pleasant for the automobile market, and indeed for the economy of the entire country as a whole. But despite these difficulties, the development of the automobile industry was difficult to stop. As a result of this, engineers managed to develop the VAZ 2111 engine.

The engine had a displacement of 1.5 liters and came off the production line in 1994. This is a completely new engine for the tenth generation of cars. Initially, the engineers were faced with the task of developing it for installation under the hood of the VAZ 2111 station wagon. But it turned out so well that the engine turned out to be in demand for other models of the manufacturer.

Specifications

| Engine capacity, cc | 1499 |

| Maximum power, hp | 72 — 79 |

| Maximum torque, N*m (kg*m) at rpm. | 109 (11) / 3000 115 (12) / 3200 116 (12) / 3000 116 (12) / 3200 118 (12) / 3000 |

| Fuel used | Gasoline AI-95 Gasoline AI-92 |

| Fuel consumption, l/100 km | 7.8 |

| engine's type | In-line, 4-cylinder |

| Add. engine information | distributed fuel injection |

| Maximum power, hp (kW) at rpm | 72 (53) / 5600 76 (56) / 5200 77 (57) / 5200 77 (57) / 5400 78 (57) / 5400 |

| Compression ratio | 9.8 |

| Cylinder diameter, mm | 71 — 82 |

| Piston stroke, mm | 71 — 82 |

| Valve drive | SOHC |

| Number of valves per cylinder | 2 |

Engine tuning

By default, the engine uses the maximum cylinder diameter, so boring them out even more will not be possible or will be too expensive. The following types of tuning are used:

- FNS filter – zero resistance can “revive” the motor;

- throttle 54 – a valve with a larger diameter must be mounted in conjunction with the Federal Tax Service;

- direct-flow exhaust system - spider circuit 4/2/1 and resonator with banks;

- sports camshaft – gas distribution modes change.

Thus, the ICE 2111 is an order of magnitude superior to carburetor modifications, does not bend valves, is economical in operation, so it was produced for a long time and in large quantities to complete the entire line of front-wheel drive cars produced at that time. Thanks to several repair sizes of the piston and cylinder, you can make major repairs on your own.

Source

Peculiarities

1994 brought AvtoVAZ engineers another development of a power unit for installation under the hood of the tenth family. It turned out to be a VAZ 2111 8-valve engine, but a large number of various kinds of problems led to the fact that it was put into production only in 1997. The engine was produced until 2014, and several upgrades were carried out that did not affect the mechanical part.

Structurally, it is an in-line gasoline engine with four cylinders in naturally aspirated design. The working volume of the power unit is 1.5 liters, and its maximum power reaches 78 horsepower, with a peak torque of 116 Nm.

The basis for designing the power unit was the VAZ-2108 engine. If you do not take into account the power system, the power unit is an exact copy of the VAZ-2110 engine. High-strength cast iron was used to make the cylinder block, and liners are not installed in it. The cylinders were machined directly into the body of the block. Manufacturers allowed two repair sizes, so if the cylinders needed to be bored, two overhauls could be made.

The crankshaft was also made from special cast iron, and its design includes five supports. A special feature is the modified shape of the counterweights, which made it possible to dampen torsional vibrations. The connecting rods were made of steel and were forged. A bushing made of a steel-bronze alloy is pressed into the upper head.

The 1.5 VAZ 2111 engine provided for the installation of cast pistons made of aluminum alloy. The piston pin was of a floating type, and therefore provided for fixation using retaining rings. The skirt was designed for the installation of two compression rings and one oil scraper ring.

The cylinder head was made of aluminum, structurally provided for the installation of one camshaft and 8 valves. The design did not include hydraulic compensators, so the thermal gap had to be adjusted manually using washers.

The camshaft was also cast from cast iron, and it provided for the presence of 5 supports. The gas distribution mechanism is driven by a belt, and in the event of a valve break, it does not bend. The VAZ 2111 engine provided an injector as a power supply system. This included electronically controlled multipoint fuel injection.

Many people wonder where the VAZ 2111 engine number is located. The answer is quite simple, since you simply have to remove the air filter housing, since the identification number is located at the end of the cylinder block, directly above the clutch housing and under the thermostat housing.

Typical faults

After many years of operating experience, it was noticed that the 2111 engine is susceptible to the following breakdowns:

| Malfunction | Cause | Elimination |

| ICE “troits”, speed fluctuates | 1) breakdown of the TPS sensor 3) breakdown of the gasket | 1) replacing the damper sensor 2) installation of a new valve 3) replacing the gasket |

| Noises and knocks | 1) valve clearances are off 2) wear of connecting rod bearings or main bearings 3) the service life of the rings and pistons is exhausted | replacement of consumables or major repairs |

| Motor overheating | 1) temperature sensor failure 2) thermostat failure | repair or replacement of components |

The exhaust system of the engine is not fully developed, so the exhaust manifold cracks and its fasteners break. A special feature of the timing belt is the low life of the valve cover gasket.

Advantages

Manufacturers managed to make the 8-valve VAZ 2111 engine quite popular, since its design had a fairly large number of different solutions that entailed advantages. The main positive qualities of the power unit are the following:

- Great dynamics. Since the engine has fairly good maximum power and torque, it had no problems accelerating passenger cars with normal performance.

- Reliability. The VAZ 2111 engine block is made of high-strength materials, so its service life can only be envied. With proper operation and appropriate maintenance, you can manage to drive about 350 thousand kilometers on it without the need for major repairs.

- Injection power system. Thanks to this solution, the designers were able to achieve maximum fuel economy during operation of the power unit, regardless of which particular driving cycle it is currently used in.

- Two repair sizes. Even if it was necessary to overhaul the power unit with a boring, this could be done twice. Manufacturers have provided for this due to the fact that liners are not installed in the block, and the cylinders are machined directly into it.

- Minimum amount of vibrations. The developers have put a lot of effort into achieving maximum balance for the entire structure. Thanks to this, when driving a car with such an engine, vibrations are practically not felt under the hood.

Cylinder head

The cylinder head of the 2111 injection engine is the same as that installed on the 21083 model, there is only one difference - the head mounting bolts are longer.

The camshaft is similar to 2110. Its landing dimensions are the same as the shaft from 2108, but the profile of the cams is slightly different, which is why the lift of the valves has increased: intake - 9.6 mm, exhaust - 9.3 mm (on 2108, both were raised by 9 mm). In addition, the angles of inclination of the cams relative to the groove into which the cylinder head drive belt pulley key is installed were changed.

Thanks to the changes made, the manufacturer was able to improve the performance of the 2111 engine.

As for the timing drive, it is structurally the same as on 21083. The belt (19 mm wide) has 111 teeth with an involute profile.

Problems

But despite a fairly large number of advantages, the VAZ 2111 8-valve engine with an injector was not without typical problems that entailed a fairly large number of breakdowns. The main ones noted by car enthusiasts are the following:

- The cooling system of the VAZ 2111 engine included the installation of low-quality components, which often led to its overheating. Typically, the most common culprit is a broken thermostat or fan. A little less often, the circuit may simply depressurize.

- Power unit owners are constantly faced with leaks and fogging. But this is not scary at all, because although there are many of them, they are very small. This results in the oil level not decreasing at all.

- While the engine is running, you may notice that its speed fluctuates. If this happens while idling, then you should pay attention to the sensors. First you need to check the mass air flow sensor, and only then pay attention to the IAC and TPS.

- The VAZ 2111 engine often stalls, and this usually occurs due to a malfunction in the ignition system. But if nothing is found there, then you should prepare for serious repairs, since the cause may be burnout of one or more valves.

- There may be noise under the hood during operation. Most often this occurs due to the fact that the thermal clearances of the valves are incorrectly adjusted. But if this does not help, then you should go to the service. A loud knock can come from the pistons or bearings, both connecting rod and main bearings.

What cars was it used in?

The 2111 engine was installed on the following models of front-wheel drive VAZ cars:

- 2108 – three-door hatchback;

- 21083 – three-door hatchback;

- 2109 – five-door hatchback;

- 21093 – five-door hatchback;

- 21099 – sedan;

- 2113 – three-door hatchback;

- 2114 – five-door hatchback;

- 2115 – sedan;

- 2110 – sedan;

- 2111 – five-door station wagon;

- 2112 – five-door hatchback.

The engine was installed on the “eights” and “nines” after 1987, respectively.

Maintenance

If you do not want to face the need for premature repair of the VAZ 2111 engine, then you should pay attention to its proper maintenance. The timing belt needs to be replaced after 100 thousand kilometers, but there is no need to worry too much about this, since if it breaks, the valve does not bend.

The VAZ 2111 engine practically does not consume oil, but it must be replaced after traveling 10 thousand kilometers along with the filter. The motor can be filled with 15W40, 5W40, 10W40 and 5W40. In total, it contains 3.5 liters of oil, but for replacement you need to take 3.2 liters.

Since the design does not provide for hydraulic compensators, the thermal clearance in the valves must be adjusted after every 20 thousand kilometers. Otherwise, you may encounter quite a lot of problems.

Pros and cons

The above description of the parameters exceeds the characteristics of the entire line of internal combustion engines existing at that time, produced by AvtoVAZ. However, “inherited” from the 21083 and 2110 engines, the 2111 engine received disadvantages:

- breakage of studs in the muffler-exhaust manifold mounting;

- breakdown of the fuel submersible pump;

- leaking valve cover gasket;

- low resource of cooling system elements;

- periodic adjustment of valves.

The advantages are low oil and fuel consumption, possible boosting with your own hands, but only by modifying existing units.

Modifications

The VAZ-2111-75 engine differed from the main engine in the operation of the power system. The need to increase environmental standards for exhaust gas emissions for the Euro 5 standard forced the installation of a phased fuel injection system. The engine oil pump also received changes, since its cover was now made of aluminum, and there was a hole on it for installing the crankshaft position sensor.

The VAZ-2111-80 engine could be found under the hood of export models starting from 2108, 2109 and 21099. The difference was that a knock sensor was installed on the engine, for which holes had to be made in the cylinder block. The same was done to install the ignition module and generator. In addition, manufacturers changed the profile of the camshaft cams, thereby achieving a change in valve lift height. Changes were also made to the power system, since in order to comply with Euro 2 standards it was necessary to make pair-parallel fuel injection.

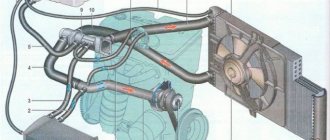

Location under the hood of the car

The 2111 engine, together with the gearbox and clutch mechanism, forms a single power unit, which is mounted on three rubber-metal supports in the engine compartment of the car.

To the right (if you look in the direction of movement of the car) from the cylinder block there is a set of drives: a crankshaft, a camshaft, and a pump for pumping antifreeze through the cooling system. The drives are made in the form of toothed pulleys connected by one belt. A generator is installed on the same side, which is also connected to the crankshaft pulley via a poly-V-belt.

A thermostat with a temperature sensor is mounted on the left side of the cylinder block.

Timing device VAZ 2110 injector 8 valves

Many people are concerned about the question of whether the valves on the injection engine of the VAZ 2110 bend. No, they don’t. The 8-valve injector does not suffer from this defect. But this does not mean that you should not monitor the timing belt. Because loosening and subsequent jumping of the belt by a certain number of teeth will lead to inevitable problems. It is worth paying special attention if engine oil gets on the belt; an oiled belt will not last long. Below is a detailed image of the timing diagram of the 8-valve injection engine “tens”. See the photo below.

When replacing the timing belt on a VAZ-2110, it is necessary to clearly align the marks on the camshaft and crankshaft pulleys; without this, the engine will not operate normally. Another important point is that when the tension roller moves to its original state, the marks shift as the belt tension changes. Therefore, carefully check whether the timing marks are clearly aligned before putting on the cover covering the timing belt.

How to remove and install a new VAZ-2111 engine

Despite the upgraded engine characteristics of the VAZ-2111, the device may fail over time. It makes sense to contact a service station or try to fix the problem yourself. In this case, it will not be possible to do without an assistant; you will also need an inspection hole and a winch.

Step-by-step instructions for replacing the device in a domestic car look like this:

- Remove the hood. To avoid confusion, mark with a marker where the washers should be located in the future.

- Relieve fuel system pressure by running the starter for 15 seconds. The chip with the wires coming from the fuel pump remains disconnected.

- After removing the battery, set aside the engine cover, which is made of plastic.

- Unscrew the air filter housing.

- Remove the throttle drive cable from the VAZ-2111 device by prying the spring with a screwdriver.

- Turn the block with wires away from the TPS, the block with wires from the IAC, and the hose from the module responsible for its intake.

- After disconnecting the block with wires from the ignition module, you will also have to remove the following components:

- block with wires coming from the DPRV;

- with wires from DCPV;

- from the valve that blows through the adsorber;

- block with wires from the oil fill indicator in the oil pan;

- with wires from the cooling fluid temperature sensor;

- do not forget about the temperature sensor;

- remove the wire block from the knock meter;

- pull out the ground wires and the minus wire tip from the mechanism.

Now remove the generator, drain the oil and antifreeze, set aside the cooling system hoses from the thermostat, the gearbox, and finally access to the engine is free.

Engine 2111 continued the series of power plants produced by VAZ, replacing models 21083 and 2110 on the assembly line. This engine is considered the first fully modified domestic injection engine.

Crank mechanism of engine 2111

The cylinder block is made of cast iron, similar to model 21083. The factory diameter of the cylinder is 82 mm; when boring, it can increase by 0.4 or 0.8 mm. Cylinders are divided into classes. Depending on the diameter, models A, 5, C, 2, E are distinguished. Wear is allowed - no more than 0.15 mm.

Five main bearings with caps are attached to the bottom of the block. The middle support has slots for support half-rings. They are designed to prevent the crankshaft from deflecting from its axis. The crankshaft play should not exceed 0.26 mm. If the indicator is exceeded, the half rings are replaced.

Bearing shells (main and connecting rod) are thin-walled from steel-aluminum alloy. The crankshaft is made of high-strength cast iron. There are 5 main and 4 connecting rod journals on the shaft. Eight counterweights are cast on the shaft.

At the front end of the crankshaft there is a camshaft drive pulley. The generator drive pulley is attached to it using a pin. In the space between the parts of the pulley there is an elastic element that softens the vibrations of the crankshaft. There are only 60 teeth on the pulley, 2 of which are missing to determine the top dead center (TDC) of the piston.

The other end of the shaft is attached to the flywheel. The flywheel is also cast iron. It is installed in such a way that the conical hole located next to it stands exactly opposite the connecting rod journal of the fourth cylinder. This is necessary to set TDC when assembling the VAZ 2111 engine.