Acquired deficiencies

The crankshaft of the 1.6 engine is quite modern, it is fully counterbalanced, that is, on the extension of each shaft cheek there is a counterweight (eight in total). Imported motors often have only four counterweights. They save.

“Weight loss” is visible everywhere. The thin rod of the connecting rod merges into a smaller lower head. The piston is lightened to the limit. The area where the piston rings are located and two small “tongues” are left, replacing the previous full skirt.

“Weight loss” is visible everywhere. The thin rod of the connecting rod merges into a smaller lower head. The piston is lightened to the limit. The area where the piston rings are located and two small “tongues” are left, replacing the previous full skirt.

A short piston skirt is in the spirit of modern automotive engineering, but this solution does not have the best effect on engine life. Not only is the piston bearing surface small, but also shifting (lateral vibrations) is more possible than with older, tall pistons.

The connecting rods of the current modification of the engine have become noticeably thinner compared to the old ones, with the index 2108. A high-tech break-off connecting rod cover has also appeared, but the width of the connecting rod bearing has been significantly reduced. Yes, the mass of the connecting rod was reduced a little in this way. But this definitely increased the load on the bearing. At the same time, the width of the neck on the shaft remained the same. It would be quite possible to install a connecting rod with a “wide” lower head.

You can clearly see how narrower the lower connecting rod head is than the crankshaft journal.

You can clearly see how narrower the lower connecting rod head is than the crankshaft journal.

Oil

The oil used in this engine is similar to 21126: synthetic, semi-synthetic

5W-30 5W-40 10W-40 15W40

Oil sump volume

This point will be useful for those who are going to change the engine oil. With different transmissions, the volume of oil poured into the engine is also different.

VAZ 21129 + Renault manual transmission (cast crankcase) = 4.4l

VAZ 21129 + robot (stamped crater) = 3.2 l

The engine resource is 200 km. But in practice, you need to monitor the condition of the roller, pump and timing belt, because if individual valve elements jam, they will meet the piston group, and then both will come to an end. In addition, during the impact of these elements, it is not uncommon that the crankshaft bends slightly. You can drive with such a crankshaft, but there will be huge oil consumption.

Timing drive

The latest generation VAZ engine has become “non-plug-in” (that is, if the timing belt breaks, the pistons do not bend the valves), which, on the one hand, pleases, but on the other, brings sadness. For some reason, not a single automaker in the world cares about a “non-plug-in” design. It turns out that VAZ’s timing drive is so unreliable that the manufacturer had to insure itself in this way by providing recesses for the valves on the pistons.

Reliability, weaknesses, maintainability

Reliability

According to the majority of car owners, the VAZ-21127 engine is reliable and, what is especially pleasing, economical to operate. The reliability of the motor is confirmed by many factors.

Firstly, a resource. The manufacturer stated 200 thousand km. But practice shows that in reality it easily reaches 300-350 thousand km and this is not the limit.

The only thing you need to know is that such a mileage is only possible with proper care of the engine. This concept includes timely maintenance, the use of high-quality fuels and lubricants, reducing the time required for regular maintenance, and careful operation of the internal combustion engine.

Secondly, a high safety margin. Despite the fact that during assembly the VAZ-21127 already received factory tuning, the possibility of increasing power remained. But you need to be extremely careful in this matter - additional tuning of the engine significantly reduces its service life.

The pursuit of “extra horsepower” will result in a major overhaul of the entire engine in the near future.

Thirdly, engine reliability is ensured by the presence of imported parts and components (fuel rail, timing belt, tensioner, idler pulley, connecting rod and piston group, etc.).

Piston and connecting rod from Federal Mogul

Fourthly, the reliability of the internal combustion engine has been increased by improving some components and parts in comparison with its predecessor. Thus, the exhaust tract, the ignition system, the use of a metal impeller in the water pump, the replacement of the mass air flow sensor and a number of other innovations have been changed.

Thus, the sufficient reliability of the VAZ-21127 is not a myth, but a reality.

Weak spots

Despite the improvements made to the base model, the VAZ-21127 is not without weaknesses. Among them there are those that appear due to the fault of car owners.

Engine tripping. Most often, this problem occurs due to clogged fuel injectors or faulty spark plugs. In the first case, it is enough to flush the fuel system; in the second, you will have to change the spark plugs.

When the engine fails, the main share of the blame lies with the car owner, since untimely maintenance and refueling with low-quality gasoline are what cause this malfunction. Timely replacement of spark plugs (after 15-20 thousand kilometers of a car) also eliminates this problem in the internal combustion engine.

The next weak point is the possibility of engine overheating. The author of this phenomenon is a faulty thermostat. Its timely replacement prevents overheating of the motor. In this case, all elements of the cooling system must be clean and in working condition, the coolant level is normal, and there are no leaks in the system.

Electrical malfunctions. Here, first of all, doubts about the performance are caused by the ECU, ignition coils and sensors. The true cause of failures can only be identified by diagnosing the engine at a specialized service station.

Timing belt Engines manufactured before July 2022 are of particular concern. Their problem was that the valves were bent when the timing belt broke. The manufacturer stated its resource is 180-200 thousand km, but you should not delude yourself with this.

The fact is that the belt can wear out, but the deflection pulley does not. At about 80 thousand km, the car jams. As a result, the drive belt breaks.

The condition of the timing belt must be monitored

Engines manufactured after this date do not have the problem of bent valves. This is facilitated by specially designed pistons.

Car owners often notice extraneous knocking noises in the engine. As a rule, this noise is created by hydraulic compensators. But knocking can also be caused by an extremely worn SHPG, or, less commonly, by burnt-out valves. In any case, when knocking occurs, the engine requires professional diagnostics.

Malfunctions detected and corrected in a timely manner postpone repairs for a long time.

Competitive or not?

Technical characteristics of the VAZ 1.6 engine

| Engine model | 11186 | 21126 | 21127 |

| Valve mechanism | 8 valves | 16 valves | |

| Cylinder diameter × piston stroke, mm | 82,0 × 75,6 | ||

| Working volume, cm3 | 1596 | ||

| Rated power, hp at engine crankshaft speed, min-1 | 87 5100 | 98 5600 | 106 5800 |

| Maximum torque, N∙m at engine speed, min-1 | 140 3800 | 145 4000 | 148 4200 |

The performance of the domestic engine with a displacement of 1.6 liters is very far from modern ones. Judge for yourself: most foreign engines with a displacement of 1.6 liters have a power of more than 120 hp. And this indicates that the design of the VAZ engine is outdated. Even the controlled length of the intake pipe used on the 106-horsepower version of the engine will not replace variable valve timing systems.

But on foreign cars it is also implemented on the exhaust camshaft (in addition to the intake). In general, if we recall the famous Honda engines of the nineties, they produced about 160 hp due to valve control and high speeds. or more with a working volume of 1.6 liters. And these were naturally aspirated engines for mass-produced cars.

The alliance partner Renault has a similar line of power units. Having similar technical characteristics, French engines, however, are more advanced from a design point of view. And in terms of reliability, they outperform VAZ engines.

The alliance partner Renault has a similar line of power units. Having similar technical characteristics, French engines, however, are more advanced from a design point of view. And in terms of reliability, they outperform VAZ engines.

Design features of the Lada 21127 16 valve engine

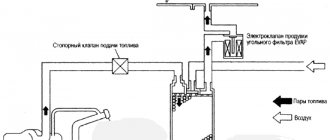

The donor for the new power unit was the already well-known VAZ 21126 engine. The main difference from its predecessor is the use of a modern intake system with flaps. Let us briefly describe the principle of its operation. Air enters the cylinders in different ways: at high speeds it is directed along a long path, and at low speeds it is directed through a resonance chamber. Thus, the completeness of fuel combustion increases: i.e. power increases - consumption decreases.

Another difference is the abandonment of the mass air flow sensor in favor of DBP+DTV. Installing a combination of absolute pressure and air temperature sensors instead of the mass air flow sensor saved owners from the common problem of floating idle speed.

Otherwise, this is a typical VAZ injection 16-valve unit, which is based on a cast iron cylinder block. As on most modern Togliatti models, there is a lightweight Federal Mogul ShPG, and the Gates timing belt is equipped with an automatic tensioner.

Typical breakdowns, causes, elimination

Since the 21127 motor uses a lightweight ShPG, as a result of a sudden belt break, the piston is 100% guaranteed to bend the valve. In addition, there are “diseases” characteristic of this motor:

| Power reduction | 1) burnt valves 2) clogged air filter 3)fuel system malfunction 5) wear of camshaft cams | 1)replacement of valves 2) cleaning or replacing consumables 5) installation of a new camshaft |

| The internal combustion engine runs after the ignition is turned off | 1) carbon deposits inside the combustion chambers and on the valves 2) Problems with the ignition switch | 1)washing with a cleaning agent 2)replacing the ignition switch |

| Emergency pressure lamp comes on | 1) wear of the oil pump or main bearings 3) low oil level | 1) replacing parts 3) adding lubricant to the level |

In principle, no special complaints were noticed with the ICE 21127; this power drive is considered reliable and economical to operate.

Features of 21129 engine/differences

The main feature of the 129 engine is the “innovative” for AvtoVAZ installation of an intake receiver with variable chamber geometry and volume. Due to the damper, the volume of the intake chamber changes depending on the speed. As practice shows, the damper is activated at 3500 engine speeds.

In addition, the engineers managed to get rid of the mass air flow sensor - mass air flow sensor. Along with him, his ailments went away, which tormented the owner of the 21126 engine: unstable idling, sometimes exorbitant consumption, high cost. Instead of mass air flow sensors, engineers installed a connection from DBP and DTV sensors (atmospheric pressure and air temperature sensors). This is where the differences from the 126 engine end. Speaking in fact, the intake system with variable geometry is as old as the world and has been installed by global manufacturers almost since the 80s.

Differences 21129 from 21126 (mounted layout, transition from mass air flow sensor to DBP+DTV, presence of an intake receiver with variable geometry.

Differences between 21129 and 21127 (Different layout, different firmware)

Engine tuning 21129

Tuning the 21129 engine is no different from the 126 engine.

Easy tuning : Euro-2 or Euro-2 firmware + installation of 4-2-1 exhaust

Medium tuning : Exhaust 4-2-1 + Shafts + firmware (preferably flashed online)

Deep : includes modification of the head, replacement of valves, pushers, etc. All technical characteristics of Vesta.

Guys, with which engine is it better to take 126 or 127 (106 hp)? About the Priora 1.8 with an engine of 128 (124 hp) the reviews are bad, that they bring it to the service in tow, the timing roller gets stuck.. In general, let's discuss which engine with is it better to take?)

Engine VAZ 21127 1.6 l

The VAZ 21127 engine emerged in 2013 from the 21126 engine, completely retaining its design. Changes have been made to the design of the intake manifold - in the unit combined with the receiver, which was already used in the previous version, the developers installed dampers to regulate air flows.

This, in turn, required the abandonment of the DMVR sensor; instead, DTV and DBP (air temperature and absolute pressure, respectively) are used. In other words, the designers have produced budget tuning, which is usually used by owners to independently increase engine power.

Which cars are equipped with ICE 21127?

Immediately after development, engine 21127 is recommended to be installed on cars manufactured by AvtoVAZ:

- Lada Granta - since 2013, Lux and Norma configurations;

- Lada Kalina-2 - since 2013, only with a manual transmission, mainly on sedans and hatchbacks;

- Lada Priora - since 2013, Luxury equipment.

In principle, the engine’s sufficiently high performance characteristics made it possible to install it on the Lada Largus, Vesta and X-Ray. However, by the time of their serial production, the ICE 21127 had been upgraded to the next version 21129 with a control unit that complies with Euro-5 standards, so the plant management limited itself to the indicated modifications, leaving the volumes the same.

Specifications

power 21129 (127) – 106 hp. (21126 – 98hp)

Torque 21129 (127) – 150 N.m (21126 – 145 N.m.) at 4000 rpm.

Mixed fuel consumption is 7-10 liters per 100 km. More details about fuel consumption

Recommended fuel – AI 95

Motor weight – 115 kg.

The table above shows the torque and power graph of the 1.6L 21129 engine and its comparison with the 21179 1.8L engine.