The installation of a camshaft in the cylinder head of passenger cars led to a reduction in the metal consumption of the engine design, since the need for rods and rocker arms disappeared. But it was necessary to provide a camshaft drive. Initially, a chain was used for this, but over time it was replaced by a belt, although it did not completely replace the chain.

Timing drive diagram of a VAZ 2105 car

For the first time, a belt drive in VAZ cars was used on the VAZ-2105 model. But the engine with such a drive was experimental, so it was not installed on all cars; some models were sold with an engine from the VAZ-2101 and 2103, which had a timing chain drive.

How does the gas distribution mechanism work?

On the VAZ-2105, a belt drive for a gas distribution mechanism was used for the first time. It became experimental, which is why you can still find cars equipped with a chain drive. They received their engines from VAZ-2103 and VAZ-2101.

The advantage of cars equipped with a belt drive is that they are easy to maintain - you can replace a worn part with your own hands, without visiting a service station. The disadvantage is that the belt needs to be changed more often than the chain. The main signs of wear are protruding threads, discoloration, and tears.

The chain wears out over a longer period of time and is less likely to break. It is double-row, but this does not protect against possible stretching during long-term use. The disadvantage of chain drive engines is that this timing element is located inside the engine due to the need for constant lubrication. Repairs need to be done at the moment when the engine begins to run noisier.

DEVICE AND FEATURES OF THE TIMING BELT DRIVE OF THE VAZ 2107 CAR

Production of the 8-valve 1.3-liter VAZ power unit with a belt instead of a timing chain began in 1979. Initially, the VAZ 2105 internal combustion engine was produced with the index 21011 and was intended for the Zhiguli model of the same name, but was later installed on other Tolyatti cars - the VAZ 2107 sedan and the VAZ 2104 station wagon. The decision to install a belt drive instead of a timing chain drive was caused by the increased noise of the latter. The engine, which was not the quietest, began to make even more noise as the mechanism parts wore out. The modernization made the power unit more modern, but in return it required increased attention to the condition of individual structural elements.

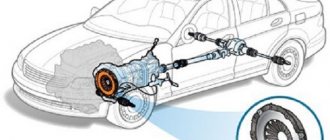

The functions that were previously performed by the chain were assigned to a belt drive. Thanks to it, it is set in motion:

Transverse teeth on the timing drive parts prevent slipping of the rubber structural element and ensure synchronous operation of the crank and gas distribution mechanisms. At the same time, during operation the belt stretches, so to prevent it from jumping on the pulley teeth, the drive was equipped with an automatic tension unit.

INTERCHANGEABILITY OF VAZ TIMING BELTS

The prototype of the VAZ “belt” engine was the OHC power unit, which was installed on the FORD Pinto passenger car. Its timing mechanism drove a fiberglass-reinforced timing belt that had 122 teeth. Due to the fact that the VAZ 2105 belt has exactly the same number of teeth and similar dimensions, some owners of the domestic “classic” had an alternative to Russian-made belts. Of course, only a few had such an opportunity - in times of total shortages, one had to be content with less reliable products. Initially, only belts from BRT were installed on the engine, but a little later, more durable belts from Gates, which is the world leader in this market segment, began to be supplied to the conveyors of the Volzhsky plant.

Today, the owner of a VAZ 2107 has a huge selection of spare parts, including for the timing belt drive. When purchasing, you must keep in mind that the VAZ 2105 power unit is suitable for timing belts with catalog number 2105–1006040 (in another spelling 21051006040). It has already been said above that rubber products produced by Gates and Bosch are considered to be some of the best. The products of global industry giants such as Contitech, Kraft, Hanse, GoodYear and Wego are no less high-quality. The cheaper offers of domestic Luzar cause the most criticism, despite the fact that they are not represented in the retail network as widely as the market leaders.

On my own behalf, I can add that owners of “sevens” can use a standard timing belt from FORD cars. Belts from OHC engines of Pinto, Capri, Scorpio, Sierra and Taunus cars of 1984 and later are suitable for the “five” engine. Please note that until 1984, the 122-tooth belt was installed exclusively on power units with a volume of 1800 cm3 and 2000 cm3. The drive element of the weaker 1.3 and 1.6 cc power units was shorter and had 119 teeth.

TENSION MECHANISM

In order for the timing belt of the VAZ 2107 to be constantly tensioned, a simple (one might even say primitive), but at the same time extremely effective and reliable design is used. Its basis is a shaped metal plate (hereinafter referred to as the tensioner lever), on which a smooth roller with a pressed-in rolling bearing is mounted. The plate base has a hole and a slot for movably attaching the lever to the cylinder block. The pressure on the belt is carried out thanks to a powerful steel spring, which at one end is connected to a bracket on the rotating plate, and at the other is rigidly attached to a bolt screwed into the cylinder block.

During operation, both the surface where the roller contacts the rubber belt and the bearing wear out. For this reason, when replacing the timing belt, be sure to check the condition of the tensioner unit. If the roller is in good condition, then the bearing is washed, after which a fresh portion of lubricant is added. At the slightest suspicion, the rotating structural element should be replaced. By the way, some drivers prefer to install a new roller at the same time as replacing the belt, without waiting until its bearing fails. It must be said that today the cost of this part ranges from 400 to 600 rubles, so their actions can be considered quite appropriate.

What do you need for repairs?

Before repairing, you must prepare the necessary tools. If your car has a modern VAZ-2105 engine, then to repair the gas distribution mechanism you will need to have sets of ring and open-end wrenches (with numbers 10, 13, 17, 30), a socket wrench for 17. Purchase new components in advance - a tension roller and a belt.

You don’t need to choose a cheap belt, then it will last a long time and fit perfectly. It is not necessary to change the tension roller along with the belt, but most car enthusiasts do complex repairs. This is necessary so as not to disassemble the mechanism several times.

Required Tool

Next, let's look at how to replace the chain and belt on the 2105. First, you need to understand the tools and accessories required to perform this operation; there are not many of them.

To replace the chain drive you will need:

- Open-end and spanner wrenches (10, 13, 17);

- Crankshaft pulley nut wrench (36);

- Flat screwdriver;

- Hammer;

- New chain;

And to replace the belt you will need even fewer tools:

- Open-end and spanner wrenches (10, 13, 30);

- Socket wrench (17);

- New belt;

- Chain replacement

Having all this, you can start working. First, let's look at the chain replacement sequence. To do this, it is better to place the car on an overpass or inspection hole, and put wheel chocks under the wheels.

How to replace a belt yourself

Installing this component is easy if you follow the detailed instructions:

- Gain access to the timing mechanism by first removing the alternator belt.

- Start by disconnecting the battery terminals, and then remove the battery completely. Use a 17 mm socket wrench to loosen the generator mount and lift this unit. This is necessary to relieve the belt tension.

- At this stage, use a 10 mm wrench to unscrew the fastenings of the upper part of the composite protective casing. There is no need to dismantle 2 more parts yet.

- We combine the marks on the shafts – camshaft and crankshaft. The mark on the timing pulley looks like a thin stripe. In other versions of the VAZ, a similar mark is made in the form of dots.

- The mark on the camshaft should align with the mark on the belt pulley.

- Check that the crankshaft mark is on the longest line.

- The correct setting of the shafts can be checked by the distributor slider; ideally it is in position 1 or 4 of the cylinder. If you made a mistake, get the ignition back to normal. To do this, just move the third pulley of the oil pump and distributor. There are no marks on these nodes, so you need to be extremely careful.

- Now you need to remove the remaining parts of the timing belt guard.

- To loosen the tension roller, use a 13mm wrench. Do not remove this unit completely, but turn the head to 30mm so that the belt loosens.

- Gently slide the belt out from under the hood.

- Now you only need to replace this component with a new one. Use a roller to adjust its tension. The optimal tension force is that at which you can grasp the belt over a long section with two fingers and turn it 90 degrees.

- Check the placement of the marks, they should still match.

- Tighten the 13 pulley completely with a wrench. Then reassemble the mechanism.

Also check out

- Replacing power steering fluid in a VAZ 2115 without going to a service station

- How to install a rear view camera on a VAZ 2112 with your own hands

- How to replace brake fluid on a VAZ 2110 yourself

- Align the marks on the camshaft and crankshaft. The mark on the camshaft pulley on the VAZ 2105 looks like a thin strip, and not a dot, as on the VAZ 2101 or VAZ 2106. The mark on the crankshaft should correspond to the longest mark on the camshaft.

Replacing the timing belt on a VAZ 2105 with your own hands

- The mark on the camshaft should also match the mark on the timing belt pulley.

Replacing the timing belt on a VAZ 2105 with your own hands

- The distributor slider should be in position 1 or 4 of the cylinder. If errors occur, it is possible to quickly return the ignition to normal by turning the third drive pulley of the oil pump and distributor.

- Remove the second and third halves.

- To make the timing belt tension less, you need to loosen the roller fastening with a key to “13”, and turn the roller from right to left with the head to “30”.

Replacing the timing belt on a VAZ 2105 with your own hands

- After reducing the tension, move the timing belt to the side and try to remove it from under the hood.

- Install a new belt, tension it using the tension roller.

Replacing the timing belt on a VAZ 2105 with your own hands

Correct tension of the VAZ 2105 timing belt in the video:

- It is important that the existing marks match. If this does not happen the first time, you need to repeat the entire algorithm from the beginning until the desired result is obtained.

- Fully tighten the roller with the key set to “13”.

- Check the position of the distributor slider.

After this, you can start the engine to make sure it is working properly. If no defects are found, you can reassemble in the reverse order, while not forgetting about the tension of the alternator belt.

What is the difference between replacing a chain?

If your car has a chain version of the timing mechanism, then before repair you need to prepare more tools. Additionally, take to

a 36mm hatch for the crankshaft pulley nut, a hammer and a flat-head screwdriver.

The chain drive is more difficult to access. Disassemble the mechanism and replace the chain according to the instructions:

- At the initial stage you need to remove the valve cover, otherwise you will not get to the camshaft sprocket.

- While controlling the crankshaft using the pulley mounting bolt, carefully turn it until the mark on the camshaft drive gear aligns with the mark on its housing. The latter was made using the casting method. The long mark located on the crankshaft pulley should match the marking on the timing cover. Once all the marks are set correctly, proceed to the next step of work. If this does not happen, continue to rotate the crankshaft.

- Unscrew the crankshaft bolt. Before doing this, engage 4th gear and install the handbrake. Do not immediately unscrew it completely. First, tear off the bolt and check whether the marks match. If they are in the required places, then you can continue to unscrew it.

- After unscrewing the bolt, remove the pulley.

- Remove the timing chain cover by removing all bolts and nuts.

- The easiest way to loosen the chain tension is to remove the chain tensioner along with the shoe. You can do it differently - recess the spring-loaded rod into the body, and then fix it.

- Now all you have to do is remove the bolts securing the sprockets of the auxiliary and camshafts. First you need to press out the lock washers using a flat-head screwdriver.

- Remove the chain along with the shaft sprockets, being careful not to turn them.

- Replace the chain and reassemble.

This job is a little more complicated than replacing a regular belt, but if you are well prepared for it, no problems will arise.