Ball joint for VAZ 2114: originals, analogues, articles, prices

| vendor code | Price, rub.) | Art. | Price |

| Original | |||

| 2114-2904192 | from 350 | 2114-2904185 | —/— |

| 21114-2904192-00 | —/— | 21114-2904192-00 | —/— |

| 21114-2904185-01 | —/— | 21114-2904192 | —/— |

| Analogs | |||

| AYWIPARTS AW1320063LR | from 350 – 450 | AS METAL 10LD1500 (VAZ 2114) | —/— |

| FORMPART 1604002 | —/— | LYNXauto C1031LR | —/— |

| LEMFÖRDER 15456 02 | —/— | PATRON PS3101 | —/— |

| BIRTH CX0738 | —/— | FENOX BJ10110E7 | —/— |

| BIRTH CX0099 (VAZ 2114) | —/— | DENCKERMANN D110112 | —/— |

| TRW JBJ156 | —/— | SIDEM 19989 | —/— |

| MOOG LABJ0063 | —/— | BIRTH CX0997 | —/— |

Article number and cost of analogues of original ball joints

The lack of stable quality of original ball joints forces car owners to search for good analogues from third-party manufacturers. At the moment, the market is filled with a lot of alternative spare parts options. The price for non-original supports is comparable to the original. The best brands of balls are presented in the table below.

Table - Recommended alternatives to ball joint 11180-2904192-00.

| Manufacturer | vendor code | Approximate cost, ruble |

| BelMag | BM.0033 | 370-400 |

| Hofer | HF815503 | 300-350 |

| Pilenga | TS-P 3142 | 380-420 |

| Stellox | 52-00840A-SX | 400-430 |

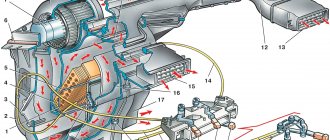

Design features of the VAZ 2114 ball joint

Unlike a number of foreign brands, the ball joint on the VAZ 2114 is mounted independently, without being pressed into the suspension arm. The process of replacing the support is shortened, since there is no need to additionally dismantle the lever with silent blocks.

Considering the method of fixing the ball joint, be extremely careful when overcoming road obstacles and potholes so as not to damage the chamfer of the metal pin. Otherwise, use a grinder to remove damaged threads.

Diagnostics of a ball joint at home (instructions)

It is not difficult to find out the condition of the ball support on a platform or pit. The weight of the vehicle in a compressed state presses on the suspension springs. It is enough to insert the pry bar between the pin and the lever, making several rhythmic movements.

- If play is detected at the finger, then there is a breakdown at the support. It is difficult to see play in the perpendicular plane when the spring is decompressed, especially on massive jeeps, which often accommodate a suspension with many levers.

- When diagnosing on a car lift, you need to press the spring with hydraulics placed under the lever at the bottom and use a crowbar to determine the malfunction of the unit. To identify the state of the ball rod removed from the car, just turn it to the side.

When in this position the apical edge of the finger goes down under its own weight, then the working life of the support is almost exhausted and play will soon arise. It is recommended to replace this support immediately.

Dismountable supports have long ceased to be relevant, even if you received a Moskvich or a VAZ from your relatives, you cannot find spare parts for them to repair the ball joint. It will be easier to install modern units that cannot be disassembled.

The most common causes of failure of VAZ 2114 suspension elements

- failure by the owner of the car to comply with the terms of technical inspection;

- the consequences of saving on high-quality, original spare parts, as a result of which the parts do not maintain the proper service life;

- aggressive driving style of the VAZ 2114. First of all, this is a passenger car, and not a racing car with the appropriate characteristics;

- third-party mechanical damage to the steering knuckle, caliper, hub, support bearing, resulting in deformation of the ball joint;

- violation of installation technology.

Before starting repair work, service station technicians recommend carrying out a comprehensive diagnostic of the vehicle in order to study the general condition, identify breakdowns, and correctly calculate the number of spare parts and consumables. A preliminary inspection will help to accurately identify the location of the breakdown and detect the faulty part.

The process of self-diagnosis is not at all complicated; there is no need for special equipment or tools. A standard set of car keys, a crab-shaped puller, is enough. It is extremely difficult to press out a metal tip without a puller.

Step-by-step diagnostic process:

- We take a partner to help, he will press his hands on the wing, simulating the car getting into a pothole. The owner identifies the source by ear from under the bottom;

- if the first method does not bring the desired result, we will use the old, proven old-fashioned method: using a mount we check the condition of the fastenings of the suspension elements, hub, and steering knuckle.

In good condition there should be no third-party sounds, creaks, or grinding sounds. Otherwise, the units must be replaced with new ones.

The manufacturer in the operating instructions indicates a maximum free play of the ball joint pin of 0.8 mm. Without special equipment, it is impossible to check the permissible gap.

In parallel with the diagnosis and replacement of suspension elements, we inspect the steering knuckle, hub, support bearing, and brake caliper. We assess the general condition and decide on the advisability of replacing worn parts.

Since the work is carried out near the shock absorber and spring, we check for the presence of oily streaks and depressurization of the shock absorber cylinder. Finally, we diagnose the support bearing located in the engine compartment.

Replacing a ball joint on a VAZ 2114

After completing the comprehensive diagnostics, we proceed to replacing the ball joint:

- For convenience, we use an inspection hole or a lift. We do not consider a platform or a road overpass due to impracticality;

- We carry out basic safety measures: install wheel chocks, squeeze the parking brake lever, turn on first gear to provide stability;

- unscrew the mounting bolts and remove the wheel;

- Unscrew the two “14” bolts that secure the upper part of the ball joint to the steering knuckle;

- By analogy, unscrew the lower nut securing the pin;

- Next, using a crab-shaped puller, press the finger out of the base. We do this very carefully so as not to damage the thread pitch. We put a wooden spacer for safety;

- lower the edge of the beam down and remove the ball joint from its seat.

We carry out preventive maintenance, troubleshooting, and clean the surface from lubricant residues, metal shavings, and corrosion layers. Apply a thin layer of graphite grease to the eyelet.

If there are no comments on the operation and condition of other parts, we begin assembling the structure again. By analogy, we complete the replacement on the opposite side. Subsequent maintenance after 15,000 km, replacement no earlier than after 35 - 40 thousand km. Do-it-yourself replacement of the ball joint is completed. About how much the service costs at a service station, check directly with the specialists.

Which manufacturer of ball joints is better? There are no fundamental differences, the main thing is that the catalog articles completely coincide with the data in the instruction manual.

Selecting new parts

“What should I replace the old ball joint with?” - a question that arises for many car enthusiasts when such a breakdown occurs. After reading the reviews of VAZ owners of the fourteenth model, we can highlight several reputable brands:

- An original element of the Lada Detail brand . It has an excellent price-quality ratio. It has a large number of positive reviews on the market, but has analogues in similar packaging. To avoid making a mistake when choosing, check the presence of article number 21100-2904192-86 on the package. The price of the product is about 350 rubles per piece.

- BelMag . Also a proven brand in the manufacture of ball joints and more. Most car enthusiasts prefer elements of this brand. There are no analog copies on the market, which is why the risk of purchasing a low-quality item is greatly reduced. The product article number is 1665 , and the price is the same as the original - about 350 rubles per piece.

- Original . It produces parts not only for domestic cars, but also for foreign cars. One of the downsides is the large number of analog copies, so the risk of purchasing a part of poor quality greatly exceeds that of competitors. However, the mechanisms of this brand last much longer than others and this is due to the price of about 400 rubles. The article by which you should look for the product is RG2108-2904192-86 .

Which component you choose is up to you to decide. The mileage from replacement to replacement depends only on your driving style and the quality of the road surface. When operating a car on poor-quality road surfaces, the ball joints fail after 50,000 km. And when driving in urban conditions at a measured pace, ball joints last up to 70,000 km. The ball joint can run longer, but as soon as the boot of the element breaks and dirt begins to get into it, the mechanism fails within a week.

If you contact a car service center with a question about replacing a ball joint, the average cost of work is about 600 rubles, which is almost twice the price of the product itself. This price tag is due to the complexity of the work, since the fasteners are located in such a way that they are constantly subject to corrosion and are difficult to unscrew.

Changing a ball joint with your own hands is not difficult; the work process does not take more than two hours, unless additional problems arise in the form of rusted fasteners. The repair is carried out without the use of specialized tools and can be carried out anywhere, without having to drive into a hole or overpass. The part itself also has a low price, which allows you to not spend much on repairs.

Replacing a VAZ 2115 ball joint does not present any particular difficulties and you can handle this work yourself, without resorting to the help of service station technicians, while saving a little on the cost of work.

On front-wheel drive cars such as VAZ 2109-2115, the ball has the same shape and mounting design, therefore, the instructions described in the article are suitable for almost any domestic car.

The ball joint is an integral part of the chassis of the machine, which replaced the pivot joints.

Basically, it is a non-dismountable metal structure made of a body and a conical pin, which has a ball shape on one side and a threaded connection on the other.

The ball can withstand quite heavy loads, while keeping the wheels in a vertical position, especially when cornering, that is, it does not allow them to turn out, which is what it is actually intended for.

Although, by its design, a ball joint is considered a durable part, its service life is varied, there can be various factors, such as the ingress of dirt, water and dust through a torn boot, bad roads, or a defective part.

What affects ball wear:

- Lack of lubrication.

- Torn boot.

- Long-term operation (natural wear and tear).

- One of the parts is defective.

Before starting work, you need to prepare the necessary tools and stands for the threshold of the car, so that later you don’t get distracted and don’t spend hours looking for a tool. So, let's go.

Recommendations for suspension maintenance and increasing the service life of mechanisms

- purchase spare parts and components exclusively from certified points of sale, dealers, and official representative offices;

- do not buy parts when their cost is uncharacteristically low, which indicates a fake, not original;

- take a moderate driving style as a rule;

- Operate primarily at medium speeds in the range of 80 – 95 km/h. This will increase the total resource of nodes by 15 - 20%;

- If you do not have personal experience in servicing, use the services of proven service stations and auto repair shops, where they provide a quality guarantee for the work performed.

Take a comprehensive approach to diagnosing and repairing breakdowns, replace all worn-out elements and components. Use handicraft services to a lesser extent. In order to prevent sudden breakdowns, conduct a quick inspection of the VAZ 2114 every day, check the levels of oil, antifreeze, and washer fluid in the washer reservoir.

Do-it-yourself replacement of lower ball joints (for beginners)

Attention, before installing the balls, lubricate them with CV joint or grease under the rubber, which is included when purchasing a pair of balls, otherwise they may soon squeak!

They were changed about a couple of years ago. Then I made the replacement with my brother. I remember we had a terrible time with him. This time I did everything myself. I decided to describe in detail how to do what. We will need: - a wrench - a pipe - heads for 19, 17, 13 - mounting (crowbar) - a jack - a bolt After you have raised the car, put something under the wheels to prevent it from rolling, unscrewed the wheel and placed it under the car, you can start working on the ball ones themselves. First we unscrewed the nut to 19.

If there is a puller, then completely, if there is none, then half.

If there is no puller, then insert a crowbar between the lower lever and the ball, press down and tap with a hammer at the place of the lever where the ball pin is inserted.

After you have been able to tear off the support, unscrew the bolts to 17 (2 pcs).

Then pull the lever down and take out the ball. If you are not too strong, then it would be best to unscrew the stabilizer from the body. But there is a chance that the studs will break off after you start tightening the stub. But with the stabilizer unscrewed, it is easier to pull the lever down and pull out the ball joint.

But, as I progressed, I found another way out of this situation! We simply take and place something solid under the brake disc (bars, bricks, blocks, etc.). I used the boards that cover the hole in the garage. Then we lower the car. As a result, the hub rises and the lower arm will move away from it, and you can easily get the ball joint.

You can also lift the disk with a second jack, but this is dangerous; the jack may come off. Be careful, don't rush! I tore a new boot on the ball.

But installing the ball this way is difficult! It’s still easier to unscrew the stabilizer from the body. It’s easier and you’ll save a lot of time (if you don’t break the stub studs). Reassemble everything in reverse order.

Now a few words about how I steamed with the stub.

I unscrewed it, but it’s not enough to put the power back on. It's about to break! Then we take what can be placed under the brake disc. Again I used boards. We line it up longitudinally under the car (as the engine stands) and use a crowbar to pull the stub mount up and try to get into the studs.

It is better to start with the stud that is closer to the rear of the car. We tighten the nut, and the other fastener will be pulled into place.

We unfold the crowbar and tighten the fastening on the other side and again screw on the other stabilizer nut.

I also want to add 1 more method, which is the simplest. To make it easiest to put the stabilizer back, you simply lower the car from the jack with the wheels screwed on. It will fall into place on its own and you can easily screw it on without additional tools.

Look like that's it. If anyone doesn't understand something, ask.

Required tools and materials for DIY replacement

Repairing a ball joint yourself is impossible without the tools listed below.

Table - Tools and materials required to replace the ball joint.

| Name | Note |

| Puller | It is not necessary to replace the ball, but it significantly simplifies the dismantling process |

| Spanner | “at 17”, “at 19” |

| Socket wrench | “at 17”, “at 19” |

| Heads | “at 17”, “at 19” |

| Heavy hammer | Required if there is no puller |

| Grease | ShRB-4, Litol-24 or graphite |

| Balloon wrench | For wheel removal and installation |

| Installation | Can be replaced with any strong rod, piece of pipe or crowbar |

| Metal brush and rags | For cleaning work surfaces |

| Penetrating lubricant | To facilitate the separation of rusted and stuck joints |

Signs of a bad ball joint

- The occurrence of knocking from the wheels when the car is moving (especially for locations with holes and uneven surfaces).

- Can occur at any speed conditions. As a rule, it is observed when crossing ditches, sharp turns and braking. Sometimes it is one-time, and sometimes permanent.

- The appearance of changes in the camber and toe system . Most often, it is not visible to the human eye and is revealed only when the volume of rubber around the edge of the wheels is reduced. For this reason, it often requires contacting car services for diagnostic work.

- The presence of uncontrolled “wobbling ” when moving. If there is play inside the ball joint, the wheel may wobble while driving. For this reason, the car is not able to keep a smooth ride, despite any type of road surface. An increase in speed accompanies an increase in the effect, but it is not always possible to notice it.

- The appearance of a squeaking sound when turning the wheels at the front.

- Uneven wear on front tires. Damage to the structural element in the form of a ball joint causes the steering wheel to lack a strictly vertical position. Due to the resulting angle of inclination, the tread wears unevenly, which can be checked by normal visual inspection.

- When braking, the trajectory changes . Sometimes, almost when the VAZ 2114 car stops moving, along with braking, a slight unplanned turn is made. Along with this, clicking sounds are usually observed, which begin to intensify over time.

Features of individual designs

As mentioned above, this is only the most common version of the ball joint. But there may be, as they say, options.

The same fault detection method is used for all versions.

Video - how a ball joint works when a car is moving:

Important: despite its simplicity and reliability, the ball joint has a limited service life. The worse the quality of the road surface on which the car is driven, the greater the chance that the part will fail ahead of time. Failure of this important component can cause a serious accident. The malfunction should be identified at an early stage of its occurrence.

Necessary tool

- The jack (hydraulic or pneumatic to choose from) is designed to raise the machine to the desired level to simplify the process of checking and further replacing the VAZ 2114 ball joint if necessary.

- A set of wrenches allows you to loosen the tightening on the desired part and unscrew the bolts and nuts.

- A ball joint remover will be needed to remove them.

- Wheel chocks are used to be placed under the rear of the car. Sometimes a brick base is used here to simplify the task.

- Supports under the car to improve interaction with the jack, to ensure safety during the operation. In addition, sometimes a block of wood is also used.

Required tools and materials for replacement

To independently replace the ball joint on a Lada Granta car, you need the tools from the list below.

Table - Tools and materials required to replace the ball joint.

| Name | Note |

| Socket head | Torx E12 |

| Vorotok | Under the end cap |

| Ball joint remover | Makes it easier to remove the ball joint from its seat |

| Balloon wrench | For dismantling and installing wheels |

| open-end wrench | “at 17”, “at 19” |

| Hammer | Required if you do not have a ball joint remover |

| Jack | To lift the car |

| Wheel chock | For fixing the rear axle |

| Penetrating lubricant | To make it easier to unscrew stuck threaded connections |

| Grease | To fill the boots in case the manufacturer has supplied too little lubricant |

| Rags and wire brush | For cleaning fasteners and working surfaces |

Ball joint puller

Methods for checking ball joints yourself

How to check the ball joint on a VAZ 2114 is described below. It is clear that most car owners are thinking about visiting services. But you can carry out a full check of this structural element yourself without unnecessary trips and financial costs.

Without removing the wheel

To quickly check the ball joints on a VAZ 2114, it is not necessary to remove the wheel about which you have doubts and questions about a potential malfunction. But it is worth stocking up on a small amount of time and it is advisable to invite one more person, since together you can perform the diagnosis with a greater degree of accuracy.

A quick check comes down to listening to the ball joint of the VAZ 2114. To do this, you need to swing the car in directions perpendicular to the main one for the car. At the same time, you should listen carefully to the sounds that arise from the ball joint and suspension.

With the wheel removed and on a jack

For a more accurate and detailed check of the VAZ 2114 ball joints, you will need to remove one of the wheels using a hydraulic or pneumatic jack. But as mentioned above, in order to increase safety (especially in cases with subsequent installation), it is necessary to think about stronger and more stable supports.

Thus, if uncertainty arises when performing the quick check from the previous point, it is worth using a jack. To do this, you need to lift the VAZ 2114 from the side where you want to check the condition of the ball joint. The wheel is rocked in the same way: in directions perpendicular to the movement. Using this approach, play in the bearing system can be confirmed or eliminated.

Using the same principle, after checking the VAZ 2114 ball joint, you can dismantle and install a new part. But in this case, you must first select and purchase it.

Is it possible to drive with a broken ball joint?

Many car enthusiasts who are faced with a similar problem for the first time are interested in the question: if the ball joint is knocking, is it possible to drive with such a breakdown? The answer depends on the degree of wear and damage of the specified unit. If the knocking noise from the ball joint while driving has just appeared and the car is not yet “driving” on the road, it does not knock when turning, that is, there are only early signs, then you can still drive such a car. However, make sure that the driving speed is not high, and also try to avoid potholes and uneven surfaces. And, of course, you still need to think about the upcoming renovation. After all, the sooner it is done, the cheaper it will be, firstly, and secondly, the car can be operated safely!

If the breakdown of the ball joint has already reached such an extent that the car “fidgets” on the road and the knock of the ball joint while driving is clearly audible, then it is better to refuse to operate such a car until repairs are carried out. As a last resort, you can drive it at low speed and following the rules of safe driving to a car service center or garage, where you will have to replace it (usually the ball joint cannot be repaired and is only replaced with a new one).

Source

Signs of a faulty ball joint VAZ 2114

If, while driving over bumps or small irregularities, you hear a knocking sound in the front suspension of a VAZ 2109, 2114, then this is a reason to start looking for a fault! There are two ways to check the ball joint of a VAZ 2109 - 2114 for a malfunction.

The first method does not require an inspection hole, but a jack is required. We hang the front wheel on a jack and sharply pull it toward and away from us. If the ball joint is faulty, it will make a sound and the wheel will have play.

If you have a garage with an inspection hole or overpass, then inspect the ball joint boots for damage. If the boot is torn, this is a sign of wear on the ball joint of the VAZ 2114 and it is better to replace such a ball joint even if it does not knock yet. Place a crowbar or pry bar between the ball and lever. Place one end on the lever and the other on the bolt or ball housing and try to move them apart. For convenience, you can turn the steering wheel towards the wheel being tested. If there is play, the ball must be replaced.

Many people wonder: can a ball joint fly out on a VAZ 2109? Answer: Yes! Maybe! Therefore, if there are signs of a malfunction of this part, do not delay repairs. Moreover, it is not difficult. Next, I will tell you how to replace the VAZ 2109 - 2114 ball joint with your own hands.

replacement and diagnostics of Remzon VAZ

In this article we will talk about how to repair the suspension on a VAZ 2114 car, and more specifically, about replacing ball joints.

These are the elements that fail most often, despite the fact that they are practically eternal. Judging by the instructions for use. But the service life of ball joints is affected by the driver’s driving style, the quality of the road surface, and most importantly, the initial quality of the product. Unfortunately, more and more often you can find low-quality products on the market, refurbished ones, which will last very little. There is an opinion that restored ball joints can work for quite a long time. But is there any point in restoring such a simple and fairly cheap mechanism?

The cost of a ball joint for a VAZ 2114 car, as well as for most front-wheel drive models, is no more than 500 rubles. Moreover, for such a price you will get a very high quality product. But let’s get closer to the topic of the article, namely, repairing a car’s suspension.

Diagnosis of ball joint malfunction

Identifying the breakdown is quite simple; to do this, you just need to sit in the front seat of the car. If a peculiar crunch appears from the suspension, we can talk about a malfunction of the VAZ 2114 ball joint. You don’t even need to try to look for any other reasons, the malfunction is in this particular joint. Moreover, a peculiar crunch can be observed when the car is moving slowly. During acceleration it usually disappears, but this depends on the degree of wear of the mechanism.

And the second diagnostic method is to pull the car wheel in a vertical plane with your hands. If there is a breakdown, you will definitely hear a crunch. A similar phenomenon occurs when using a mount. It must be installed between the suspension arm and the wheel hub. If you move the mount sharply, you can still hear the same nasty sound.

To be sure, you can even drive the car onto a viewing hole or overpass. Grasp the suspension arms and pull them down several times. A good knock, as they say, will come out. And if you put your palm on the body of the VAZ 2114 ball joint, you can feel a slight vibration from the inside.

Preparation for replacement and tools

To carry out the repair you will need the following tools:

- Ball joint remover. The price of such a tool is about 350-400 rubles. I advise you to purchase it, as it will definitely be useful to you in the future.

- Standard set of wrenches and screwdrivers.

- Litol type lubricant.

- Jack and reliable supports.

- Wheel chocks, which are placed under the rear wheels to prevent the car from rolling away.

That's all, now you need to prepare the car for repair. To do this, you need to install wheel chocks, loosen the wheel bolts, lift the side being repaired using a jack and install it on a support. Wooden blocks can be used as support, but it is not advisable to use materials such as bricks, cinder blocks, and the like. They are fragile and the car can simply fall during repairs. If necessary, treat all threaded connections with a penetrating lubricant such as WD-40.

Carrying out replacement

Now the crucial moment has come, it is necessary to remove the old ball joint of the VAZ 2114 and install a new one in its place. First, using a 19mm wrench, unscrew the nut that secures the ball joint pin to the front wheel hub. After this, you need to install the puller so that the small ball on its bolt is clearly in the middle of the hinge pin.

Carefully screw in this bolt until the pin comes off the wheel hub. After this, you need to use a key “17” to unscrew the bolts that secure the joint cage to the suspension arm of the VAZ 2114. That’s all, the dismantling is complete. Now all that remains is to install a new hinge, which it is advisable to pre-lubricate with Litol. To be honest, I also used CV joint type lubricant for this purpose.

I haven’t noticed much of a difference; the ball joints have been working without problems for three years now

Please note that when installing a new joint, you may have to install several blocks of wood under the arm and lower the body so that the ball pin fits into the hole in the hub. But this job can be done with a good pry bar.

The repair is complete, good luck on the roads and fewer breakdowns!

How to replace a ball joint on a VAZ 2114

To replace the ball joint of a VAZ 2109, 2114, place the car on a jack and remove the wheel. Now unscrew one nut securing the ball joint to the lever and two bolts securing the ball joint to the hub.

If you have a ball joint remover

If you have a puller, place it as shown in the photo and remove the ball.

Article number and cost of ball joint analogues

Many car owners prefer non-original ball joints. This is due to the fact that, at a comparable price, products from third-party manufacturers are often of higher quality compared to original supports. The brands that have proven themselves best among car owners are presented in the table below.

Table - Good analogues of the VAZ 2109 ball joint.

| Manufacturer | vendor code | Approximate cost, ruble |

| TRW | JBJ156 | 420-460 |

| Delphi | TC583 | 310-360 |

| Sidem | 19989 | 410-440 |

| Lemforder | 1545602 | 435-460 |

| ABS | 220119 | 550-700 |