Operating principle

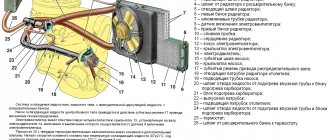

A fan is a device that allows you to increase the efficiency of a cooling radiator. The radiator takes heat from the engine and releases it into the air. This process is accelerated by blowing through the blades of an electric fan.

The coolant flows through a closed, sealed system. Its task is to remove excess heat from overheated engine parts. Hot antifreeze flows into the radiator, is cooled here and returns back. While in the radiator, the coolant passes through a system of thin tubes. The incoming air flow while the car is moving helps to quickly remove excess heat from the engine compartment.

But when the car is stuck in traffic or idling, the air flow stops cooling it. In this case, the cooling system may not cope with its task. An electric radiator fan is designed to create air flow artificially. The temperature for turning on the fan on a VAZ 2114 is 85 degrees Celsius.

Having received a signal that the permissible temperature value has been exceeded, the sensor starts the device’s operating mechanism. An artificial air flow is created that removes heat from the radiator. The mechanism operates until the temperature level drops to an optimal state.

The thermal switch then receives a signal that the normal temperature has been reached and turns off the fan.

The device consists of four plastic blades that are mounted on the EDF shaft. A special controller regulates the automatic operating mode. The thermostat is equipped with a solid filler that is sensitive to temperature changes.

There are main and additional valves. When the temperature reaches 85 degrees Celsius, the main valve opens.

Malfunction

These components do not have a specific service life. They will last a long time if you follow the recommendations for using the vehicle and its systems provided by the manufacturer, follow assembly rules and buy spare parts made from high-quality materials. Spare parts are sensitive to high temperatures; this should be taken into account if the vehicle is used in hot weather conditions. If there are connection problems, then checking the sensor is not difficult - you just need to know where this device is located. It is located on the outlet pipe.

If the question arises of how to check the operation of the ventilation and what breakdowns may occur, then it will be difficult to answer.

Defects

- cracking;

- oxidation of contacts;

- broken cables;

- damage to fasteners;

- contamination of components;

- short circuit;

- microprocessor melting;

- fusion of plastic elements.

Fault indication

- continuous operation of ventilation when the engine is running;

- no fan response after the temperature rises or the air conditioner is activated;

- deterioration in vehicle controllability;

- reduction in the efficiency of the air conditioner.

Causes of failure

- influence of humidity;

- using vehicles on bad roads;

- voltage instability in the electrical network;

- low quality components;

- incorrect installation;

- violation of water tightness;

- frequent overheating.

If the fan turns on, then everything is fine.

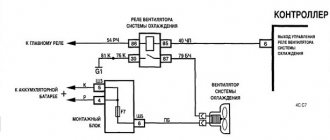

Where is the regulator relay located?

It is located in an additional block.

4 – electric fan relay;

5 – electric fuel pump;

6 – ignition relay.

Relays and fuses may have a different order. Therefore, you need to focus on the color of the wires. The main relay is always located at the bottom. Find the relay that has a thin pink wire with a black stripe coming from it. It comes from the main relay through pin 85. Be careful! Do not confuse this with the red thin wire, which also has a black stripe and extends from the controller. And find a thick white wire with a black stripe (pin 87). This is where the cooling fan relay is located. There is always a fuse next to it. It is an element of the chain.

A little theory

| Characteristic | Explanation |

| Location | The sensor is located in the heater radiator. It is not difficult to determine that this is the one in front of you, since in the radiator it is the only element to which the wires are connected. And if you take a 30 key, then only the sensor has the appropriate fastener size. |

| Response temperature | Sensors may have different temperature limits. But for the VAZ 2114, switching on occurs at 102-105 degrees Celsius, and switching off occurs at 85-87 degrees. When choosing a new meter, focus on the one that has failed, or purchase one with an on and off indicator of 102 and 87 degrees, respectively |

| Operating principle | There is a special contact group inside the sensor. When the coolant in the radiator heats up, this group heats up and expands. When the expansion reaches a certain limit, the contacts close, they transmit a signal to the wiring and the fan turns on |

Cooling fan diagnostics

If signals appear on the dashboard indicating that the permissible temperature level in the cooling system has been exceeded, this may indicate that the fan on the VAZ 2114 is not working. The main symptom of the malfunction is that the mechanism does not start even with a significant increase in temperature. It is urgent to turn off the engine to prevent its elements from overheating.

The engine should not be operated with a faulty electric cooling fan. This may damage the cylinder head.

If the cooling fan on a VAZ 2114 does not work, the following malfunctions may be the cause of the breakdown:

- The fan switch sensor on a VAZ 2114 has failed.

- Lack of contact at the sensor connector.

- The wiring has broken.

- Electric fan relay faulty.

- The fuse has blown.

- Damage to the device's electric motor drive.

Unplug the device. Connect it to the battery terminal. Maintaining polarity. If a direct connection to an energy source starts the electric motor, then the drive is working. There may be problems with the wiring, the fuse, or the temperature sensor.

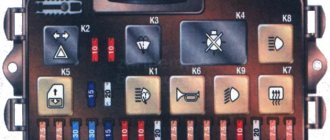

Now it’s time to diagnose the fuse. You don't even have to open the plastic box to do this. If the relay malfunctions, the horn stops working at the same time as the fan. Therefore, if you notice the loss of the sound signal, it means that the fuse has definitely blown. You can find it in the engine compartment in a small plastic box. We release the cover, pressed by two latches, take out the burnt fuse with tweezers and replace it with a new one.

But diagnosing a relay is quite difficult. Especially for those who are exclusively “you” with auto electrics. To check functionality, the easiest way is to find a working relay and temporarily install it. If, after installing a new device, the fan begins to work properly, then it is time to replace the old one.

To diagnose the temperature sensor that supplies a signal to the radiator, you need to disconnect the connector from the sensor and start the ignition. The emergency mode will start, in which the electric fan will start blowing. If the fan starts late when the connector is disconnected, the sensor is most likely faulty. Replacing it will take no more than five minutes. You just need to unscrew two bolts using a Phillips screwdriver and install a new device in its place.

Even if a malfunction has occurred in the VAZ 2114 fan itself, this does not mean that it is time to change it. Sometimes you can simply replace a damaged bearing or brushes. But if the electric motor is faulty, it is much easier to purchase a new mechanism.

Causes of malfunction on the VAZ-2114

- Fan motor malfunction . The problem is resolved by replacing it with a working one;

Replacing the fan motor

Changing the fan relay

Checking for an open circuit

Changing the coolant temperature sensor

Video about replacing the fan switch sensor

How to make a replacement

If you are convinced that the cause of the malfunction lies in the fan motor, then the easiest way to carry out repairs is to completely replace the device. In this case, there is no point in spending money on a new casing. It will be cheaper to just buy a new electric motor.

Necessary tool

No special tool is needed. The work is carried out simply using 8 and 10 socket wrenches and a Phillips screwdriver.

Step-by-step algorithm of work

You can replace the cooling fan motor without removing the radiator.

- Disconnect the connector and device wiring harness from the casing.

- Unscrew the mounting bolts using a 10mm wrench.

- Unscrew the lower fastening nut.

- Using a 10 mm socket wrench, unscrew the mounting nut from the radiator.

- Using a size 8 socket wrench, unscrew the two pressure plate nuts.

- Remove the plate.

- Remove the electric fan along with the casing.

- Let's start dismantling the electric motor. Using a 10 mm wrench, unscrew the three mounting nuts and remove the engine along with the blades.

- Using a screwdriver, pry up the lock washer.

- And take it off.

- Remove the impeller.

- Put the impeller on the new motor. Make sure that the shaft pin fits into the impeller groove.

- Reassemble in reverse order.

Replacing the VAZ 2115 stove fan

So, a replacement was still needed. There's nothing wrong with that - today you can choose from a variety of alternatives, in a wide range of price ranges. You will have the opportunity to save money, but remember that the main thing when choosing parts for your car is not to go cheap. In general, the average cost of an optimal fan ranges between one and a half thousand rubles.

Removing a faulty fan is not difficult - you only need to have a regular set of tools with you. In the VAZ-2115, the heater unit is located under the hood, directly under the windshield. The procedure is as follows:

- disconnect the terminal (“minus”) from the battery and the power wire (“plus”) directly from the motor itself;

- remove the protective cover of the fan casing, secured with two screws;

- disconnect the ground (the nut located at the bottom connecting to the heater);

- open the casing and unscrew the screws securing the fan and air intake grilles;

- We move the fan towards ourselves a little, removing it from the mount, then turn it 90 degrees and remove it.

How to replace a temperature sensor

Before starting work, you need to partially drain the coolant from the cylinder block.

- Remove the wire.

- Using a 21 wrench, unscrew the temperature sensor.

- Take it off.

- Install the new one in reverse order.

Sensor check

First, we advise you to check the sensor that you think is faulty. Even if it turns out that it doesn't really work, at least you'll have peace of mind.

Plus, be sure to check the new sensor before installing it. This will make sure it works. Today there are quite a lot of fakes on the market, so there is always a chance to purchase a low-quality fan sensor.

Searched object

To check you will need a certain set of tools and materials, which includes:

- Capacity;

- Water;

- Coolant;

- Thermometer;

- Multimeter.

Let's start checking.

- Pour water or regular coolant into the prepared container.

- Lower the sensor into it with the threaded part.

- Connect the multimeter terminal to the regulator contacts. The measuring device must be in resistance measurement mode. Although if the multimeter has a dialing function, then choose it.

- Place a thermometer into the liquid.

- Heat the water.

- When the liquid temperature reaches the regulator response temperature (92 degrees Celsius), the contacts should close and the multimeter will start beeping.

- If this does not happen, the sensor really does not work and needs a replacement.

If you purchased a regulator that is not working, be sure to go to the store and ask for a replacement or refund. But only if you have a receipt. It is better to purchase spare parts in specialized, good stores. There is less risk of getting caught by a fake.

Conclusions: what exactly should be done if the fan does not work (action algorithm)

First, check whether the “plus” is connected to one of the terminals in the connector. Then connect the connector from ground to check the serviceability of the electric motor. In some cases, you can observe this:

- Both fuse F5 and the additional fuse are working;

- The fan relay operates as expected;

- The DTOZh sensor is working;

- The motor can only be turned on by applying a potential of “0 Volt”.

There will be only one conclusion: the ground contact has come loose, which ends the entire power line. This means you will need to contact an auto electrician. All other faults can be overcome by yourself.

Element F5 may burn out as a result of the horn closing. But then “+12” is not called up on the connector, which should immediately alert you.

Tips for motorists

The release date of the first trial batches of the VAZ-2115 car is considered to be 1997, and until the year two thousand they were equipped with carburetor engines from the VAZ-21083, and in the 2000 they began installing injection engines. On carburetor “tags”, troubleshooting that caused the fan to refuse to turn on was not so difficult, since the fan electric motor was activated by a temperature sensor through a relay. It is their serviceability that should have been checked when searching for a fan failure.

Problems with turning on the engine cooling system fan on VAZ-2115 passenger cars began after installing an injection engine on it. They were due to the fact that initially, the electronic control unit (ECU) was programmed to turn on the fan when the coolant temperature was more than one hundred degrees (102-105). This resulted in a fault that was difficult to find.

The point was that if the expansion tank cap was not sealed, the temperature of the coolant could not rise above one hundred degrees, as a result of which the fan did not turn on even if its entire electrical circuit was in good working order. After all, the electronic unit, in order to turn on the fan, waited for the coolant temperature to exceed 102 degrees.

After engines that met EURO-3 environmental standards began to be installed on the VAZ-2115, the firmware of the electronic control unit was changed and the coolant temperature at which the fan was supposed to turn on became 95-97 degrees Celsius, which greatly facilitated troubleshooting in the electrical circuit for turning on the fan.

In order to find the reason for the failure, you need to press the sound signal button. Thus, you will check the serviceability of fuse F5 (20 A), which protects both of these electrical circuits. If the fuse is intact, then open the hood and, with the engine running, remove the two-pin plug from the temperature sensor located in the thermostat housing. If the fan starts working, it means the ECU turns on the fan motor through a relay. In this case, the temperature sensor will have to be replaced.

If the fan does not turn on, you will have to check the serviceability of its electric motor by supplying voltage to it directly from the battery. But before you do this, you need to carefully inspect the contacts of the fan motor connector, since they are the most common cause of failure.

Cooling fan malfunctions

In addition to a stuck thermostat and a torn V-belt, a faulty cooling fan can be the cause of too high a coolant temperature, but only during prolonged idling. But a faulty fan doesn't have to mean the end of your trip:

- After the engine has cooled down, you can drive to the nearest workshop at medium speed and at a relatively fast pace. In this case, it is necessary to monitor the temperature indicator and control light.

- Idling and driving slowly can be fatal to the engine. In this case, practically no cooling air passes through the radiator. If you absolutely must drive further at low speed, then it is better to immediately start looking for the causes of the malfunction and, if necessary, “bypass” the thermal switch.