Over time, every owner of a Lada Kalina car is faced with the need to change ball joints. This operation is quite accessible for independent execution. Read about in what cases it is necessary to change ball joints, and how to replace ball joints on Lada Kalina cars.

Replacing ball joints on Kalina: safety and comfort without extra costs

November 3, 2016

Over time, every owner of a Lada Kalina car is faced with the need to change ball joints. This operation is quite accessible for independent execution. Read about in what cases it is necessary to change ball joints, and how to replace ball joints on Lada Kalina cars.

Signs of faulty ball joints on Lada Kalina

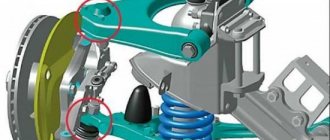

The front suspension of Lada Kalina cars is made according to the MacPherson scheme, in which the upper support is a shock-absorbing strut, the lower is a wishbone connected to the steering knuckle by means of one ball joint. This scheme is quite simple and reliable, however, this assembly contains several moving parts, so it can be difficult to reliably identify a faulty ball joint.

In general, the following signs indicate a malfunction of the ball joint:

- Knock from the front suspension when overcoming uneven roads at low speed;

- Increased effort on the steering wheel when turning;

- Creaking from the front suspension when turning the steering wheel;

- Uneven tire wear;

- Unstable trajectory of the car with a straight steering wheel.

These signs should be treated with caution, as they may indicate problems with the wheel bearing, shock absorber and fastening of suspension parts (levers). To diagnose, you can follow a few simple steps

First, rock the car and listen to the sounds arising in the suspension - although this method helps to localize the cause of extraneous creaks and knocks, it, unfortunately, can provide little information to inexperienced car enthusiasts.

Secondly, you can check the ball for play by shaking the wheel with your hands, grasping it at the top and bottom points. In this case, you need an assistant to depress the brake pedal. There should be no noticeable play when the wheel rocks, although play may again indicate problems with the wheel bearing and suspension parts.

Finally, thirdly, you can check the ball joint for play tactilely. To do this, you need to place your palm directly on the support so as to simultaneously touch its body and finger. When rocking the wheel (which is best left to an assistant), you can clearly feel whether there is play in the ball joint and how big it is.

You should also pay attention to the condition of the protective rubber boot (boot) - you need to periodically inspect it for cracks and tears. Even a small crack will lead to squeezing out the lubricant and getting dirt inside the cover, and, as a result, to intense wear of the ball joint and a sharp reduction in its service life

If a malfunction is suspected or a clear sign of failure is detected, the ball joint must be replaced as soon as possible.

Choosing the right new ball joints

The chassis of Lada Kalina cars of both generations (models 1117, 1118, 1119, 2192 and 2194) is built on a complete base, which is for the most part unified with earlier and later cars of the Volzhsky Automobile Plant.

Major breakdowns

This item is made of durable materials. However, it is under heavy load and therefore becomes unusable over time. The most common breakdowns that occur with ball joints are:

- Mechanical damage in contacting surfaces. As a result of the work, an increased gap is formed between the finger and the body itself, as well as cracks and chips. Because of this, scrolling occurs, and subsequently free movement of parts inside the case. With such a malfunction, further movement is highly not recommended, since controllability deteriorates significantly, which can lead to dire consequences;

- Cuts and tears in the boot. This problem can damage even a fully functional ball joint. The fact is that the boot is necessary to protect against dirt, dust and moisture. If it is torn, then all this will penetrate into the mechanism and, over time, disrupt its operation;

- Lack of lubricants. Because of this, there is not enough friction, so the parts hit each other, creating cracks and chips.

If even one of the above failures is detected, then the ball joint needs to be replaced. First of all, the safety of movement depends on this.

If the boot ruptures, you need to carefully examine the ball itself to understand what condition it is in. If it is good, then you only need to replace the clip, but if not, then you will need to change the entire mechanism.

If there is a lack of lubrication, it is also necessary to inspect the internal condition of the ball. If its parts are intact, then you just need to add more lubricant. This must be done as quickly as possible, since without lubrication the parts will wear out a lot. When installing a new ball joint, you also need to check for lubrication.

Price list for basic VAZ suspension repair work

Check with our managers by phone. They will be happy to answer all your questions.

The reasons for contacting the service center may be:

- extraneous sounds when the car is moving, such as knocking or grinding;

- vehicle vibration;

- large body roll when cornering;

- uneven wear of wheel tires.

Diagnostics of your car for suspension health will include checking the shock absorbers

tors, springs and struts, ball joints, CV joints, degree of wear of brake pads.

Diagnostics and repair of the VAZ front suspension, as well as repair of the VAZ rear suspension, is carried out at our car service center using special equipment. The car is located on a special stand, which provides unhindered access to all parts of the car. If during diagnostics malfunctions in the operation of the shock absorbers are discovered, they will be replaced, followed by wheel balancing.

Sources

- https://mylada.net/remont/zamena-sharovyx-opor-na-kaline.html

- https://www.zr.ru/content/articles/118912-kalina_neladnaja_lada/

- https://remontvaz.spb.ru/remont-podveski/

Reasons for failure

There are several reasons why a ball joint may fall out. Let's consider the main ones:

Inspecting the ball for wear

To avoid consequences, it is necessary to regularly diagnose and maintain ball joints.

Diagnostic operations

How can you diagnose the condition of ball joints on a Lada Kalina:

It is almost impossible to determine the exact condition of the ball joint, but the above facts indirectly indicate the condition of the supports.

Change ball joints on a viburnum with your own hands

Lada Priora Sedan Snezhka Logbook Replacing the support bearing

Hello. Today we’ll talk about how to replace ball and tie rod ends on a Lada Kalina with your own hands. Why ball and tie rod ends fail and how to diagnose their malfunction is written here

Before starting work, you need to prepare: a set of keys, a universal puller, a jack, WD-40 fluid, as well as new spare parts.

How to replace ball joints on a Lada Kalina - step-by-step instructions

1. Before starting work, apply a few drops of WD-40 to threaded connections that you think may have problems. They will be different for everyone, it all depends on the condition of the car, the roads on which it drives, and the attitude of the owner towards this car...

2. Unscrew the ball joints. There are two TORX bolts that are attached to the hub; for this we take an E12 head.

3. Afterwards, we proceed to the stabilizer strut, it must be unscrewed.

4. Bend down the lever with the ball joint.

5. Using a universal puller, press the ball joint out of the lever. If you don’t have a puller, you can use a crowbar, but in this case there is a high probability of damage to the CV joint boot if the crowbar comes off.

6. When the old ball is removed, take the new ball and attach it to the hub and lever.

7. Jack up the lever, using a jack to place it under the ball. This will compress the spring of the shock absorber strut and screw on the stabilizer bar.

Step-by-step instructions - how to replace tie rod ends on a Lada Kalina

- We unscrew the steering wheel in the direction opposite to replacing the steering tip.

- We remove the locking pin and unscrew the nut securing the tip to the stand.

- Now you need to “release” the tip mounting bolt.

- Using a puller, press the tip out of the stand. Some people use a hammer and simply knock out the tip.

- Next we unscrew the tip, this is done clockwise. If the adjusting sleeve starts to rotate, fix it using a wrench.

6

I draw your attention to the number of turns, it must be counted, this will save you from the need to go to a service station and do a wheel alignment

7. Assembly is performed in reverse order. If the car pulls to the side and the “trick” with counting the turns didn’t work, don’t be lazy and do a wheel alignment.

The result of the work done should be the disappearance of play and knocking, which are an integral part of chassis malfunctions.

That's all for me, thank you all for your attention, I hope everything worked out for you!? Until we meet again, take care of yourself and your car! Text belongs to: VAZ Do-it-yourself repair. Text belongs to: VAZ DIY repair

Text belongs to: VAZ DIY repair

Helpful information:

You can get professional advice when selecting a product by calling (calls within Russia are free).

The ball joint is one of the most important components of the front suspension of front-wheel drive cars, including the Lada Kalina. The main purpose of the ball joint is to be the connecting link between the steering wheel hub and the suspension arms. That is, during vertical movement, the hub rotates, but the horizontal position of the wheel remains unchanged. The condition of the ball joint should be carefully monitored. Otherwise, there is a high probability of serious consequences, especially if the breakdown occurs while driving. If the ball joint fails, the wheel will turn outward and the car is guaranteed to fall onto the wing. If you imagine such a situation at high speed, there is a high probability that its development will lead to a serious accident.

Video review on replacing ball joints on Grant

For those who are too lazy to understand photo reports, everything can be shown clearly and easily using the example of a video review, which was taken from open sources.

This concludes this repair report.

Before starting work, you need to prepare: a set of keys, a universal puller, a jack, WD-40 fluid, as well as new spare parts.

1. Before starting work, apply a few drops of WD-40 to threaded connections that you think may have problems. They will be different for everyone, it all depends on the condition of the car, the roads on which it drives, and the attitude of the owner towards this car...

2. Unscrew the ball joints. There are two TORX bolts that are attached to the hub; for this we take an E12 head.

5. Using a universal puller, press the ball joint out of the lever. If you don’t have a puller, you can use a crowbar, but in this case there is a high probability of damage to the CV joint boot if the crowbar comes off.

- We unscrew the steering wheel in the direction opposite to replacing the steering tip.

- We remove the locking pin and unscrew the nut securing the tip to the stand.

- Now you need to “release” the tip mounting bolt.

- Using a puller, press the tip out of the stand. Some people use a hammer and simply knock out the tip.

- Next we unscrew the tip, this is done clockwise. If the adjusting sleeve starts to rotate, fix it using a wrench.

6

I draw your attention to the number of turns, it must be counted, this will save you from the need to go to a service station and do a wheel alignment

Text belongs to: VAZ DIY repair

In the design of a car, the ball joint plays a very important role, since it bears all the load that the vehicle experiences

Also an important function is the level of inclination of the wheels. On the Lada Kalina, the factory ball joint is not very reliable, so many car enthusiasts replace the standard part with an analogue

Video on replacing a ball joint

The video material talks about replacing the ball joint of the Lada Kalina and the features of the process.

Which brands can you trust?

If you decide to buy a ball joint, we recommend paying attention to the products of the PILENGA brand (Italy). The Italian company is one of the largest suppliers of spare parts for European and American car factories, the entire range meets EU quality standards

Another reputable European brand is DELPHI. The company occupies a leading position in the production of mechanisms for the braking system and steering. It supplies spare parts for 25 automakers. The products of the HANSE brand (Czech Republic) also deserve attention.

For owners of Japanese cars, we can recommend ball joints 555 - a well-known brand manufactured by Sankei Industry (Japan). The brand's products are used on the assembly lines of Nissan, Toyota, Honda, and are also supplied to the secondary market. At the same time, there are a large number of low-grade counterfeits of 555 brand spare parts, so before you buy, you need to make sure of the authenticity of the part (this, in particular, is evidenced by the manufacturer’s proprietary hologram).

* Please check the applicability of parts specifically for your car with our managers by phone (calls within Russia are free).

| Manufacturer | Detail number | Part name | Applicability* |

| 555 | SB4942 | Spherical bearing | NISSAN X-Trail T31 |

| 555 | SB3841 | Spherical bearing | TOYOTA Land Cruiser Prado II (J120) |

| 555 | SB3842 | Spherical bearing | RENAULT LOGAN |

| Pilenga | TSP3140 | Spherical bearing | FORD FOCUS 2, C-MAX, VOLVO C30, S40, V50 |

| Pilenga | TSP3175 | Spherical bearing | WV POLO SEDAN, RAPID, FABIA |

| Pilenga | TSP3185 | Spherical bearing | Daewoo NEXIA, LANOS |

| Delphi | TC687 | Spherical bearing | Opel Astra G |

| Delphi | TA1897 | Spherical bearing | Ford Fiesta |

| Hanse | HB010205 | Spherical bearing | VAZ 2108 |

| Hanse | HB892207 | Spherical bearing | MITSUBISHI COLT I, LANCER II |

How to replace, for example, the lower ball joint in a Honda Civic is shown in the video below. Well, IXORA managers will help you choose original ball joints. Our store offers a wide range of high-quality spare parts for car suspension.

Selection of ball joints for Lada Kalina

Its front suspension is not much different from previous VAZ models, for example, Priora, Samara, etc. The chassis of different generations of Kalina itself does not stand out fundamentally. On the first generation and on Lada Kalina cars of 2 different modifications, ball joints with catalog number 21100-2904192-82 are installed, and for supports with a set of fasteners, catalog number 21100-2904192-86.

The modern auto parts market offers customers different types of supports. The first are original (welded from several parts), and the second are stamped and reinforced. Structurally, all these hinges are arranged identically. The only differences are in the manufacturing technology and quality of the steel used, as well as its thickness. This determines the strength of the products, their durability and, of course, cost. In terms of size and principle of operation, they are no different from each other. From this we can conclude that the question of choice is not fundamental and depends on the personal preferences of the car owner.

Experienced car enthusiasts, as well as auto mechanics, recommend using exclusively original components. Only by choosing the original, you can be guaranteed to obtain the declared quality, reliability and long service life. However, as practice shows, original spare parts are sometimes much more expensive than analogues, so most car enthusiasts prefer to use the second option.

When choosing analogues, you need to approach the issue carefully and responsibly. You should not choose very cheap spare parts from an unknown manufacturer, and you should also not take components from markets, unknown points, or simply from your hands. Before purchasing, you should carefully inspect the components. There should be no visible welds on them; the surface should be gray, which indicates heat treatment of the part.

The components must have an emblem and a quality mark. As a rule, fakes do not have this.

Indirectly, quality is indicated by holograms on the case or packaging of components, as well as an additional set of fasteners. The cost of a ball joint for Kalina usually does not exceed 500 rubles. It's inexpensive, but it's worth considering that purchasing units for tuning can be significantly more expensive. For example, those from Pasker are valued tens of times higher.

How to choose the right one

Professionals say that it is better to give preference to original spare parts, since only they can guarantee impeccable quality, reliability and durability. But this option is expensive, which is why a significant part of motorists pay attention to analogues of original spare parts.

But here you need to be very careful: do not trust unknown manufacturing companies and do not buy components from unverified points on the market.

Before buying a product, it is necessary to conduct a thorough visual inspection: there should be no traces of welding on the body. Also, the parts should not undergo heat treatment, as can be seen from the dirty gray color of the surface.

But that’s not all: manufacturers of fakes sell products with a perfectly smooth surface, but! There is no emblem or quality mark here.

Quality can be determined by the hologram on the case and packaging in steel or red shades, with a mandatory set of fasteners.

The optimal price for VAZ supports is 500 rubles. True, not so expensive, but if you want to purchase tuning parts, then the price will be two zeros more - in the region of 20,000 to 48,000 rubles, from Pasker.

Changing the ball joint on a Lada Kalina: photos and video

In the design of a car, the ball joint plays a very important role, since it bears all the load that the vehicle experiences

Also an important function is the level of inclination of the wheels. On the Lada Kalina, the factory ball joint is not very reliable, so many car enthusiasts replace the standard part with an analogue

to replace the ball joint

The material talks about replacing the ball joint of the Lada Kalina and the features of the process.

Ball joint replacement process

When you have decided on a spare part, you can carry out the replacement operation. So, let's look at the step-by-step process of changing the ball joint on Kalina:

- We dismantle the wheel.

- We clean the ball joint and all surfaces that connect to it.

- Unscrew the fastening of the ball joints.

The ball mount is marked with an arrow. - The stabilizer link also needs to be unscrewed for easy replacement.

We unscrew the stabilizer mount for easy replacement of the Kalina ball joint - We bend the lever down.

- We take a special puller for balls and press it out of the lever seat.

- Installation is carried out in reverse order. Using a jack, raise the lever and tighten the stabilizer mount Installed a new ball joint on Kalina

Peculiarities

Consequences of untimely replacement of the ball joint

Harsh operating conditions, poor road surfaces, loads and passengers place a lot of stress and responsibility on the ball joint. Therefore, the condition of this node must be monitored regularly.

The entire load does not go to the ball joint itself, but to a small ball, which can fall out if worn out and worn out. If you remember, not so long ago you could see a Lada car on the road with a fallen ball joint.

Reasons for failure

There are several reasons why a ball joint may fall out. Let's consider the main ones:

- Wear. The most common malfunction that occurs on cars.

- Insufficient lubrication in the boot leads to the fact that the finger begins to creak and may eventually simply break.

- The penetration of dirt and water into the ball contributes to the development of corrosion, which can affect the operation of the vehicle. At best, a wedge and the inability to turn the wheels; at worst, the car will fall onto the asphalt.

To avoid consequences, it is necessary to regularly diagnose and maintain ball joints.

Diagnostic operations

How can you diagnose the condition of ball joints on a Lada Kalina:

The first thing you need to pay attention to is the condition of the boot. If it has cracks or is torn, then it must be removed and the ball should be inspected. We hang the wheel a little and swing it up and down with our hands.

If there is play, then it’s time to replace the ball. The presence of a squeak, as well as heavy turning of the steering wheel, can also be signs that the ball joints are in critical condition. Instability in control, namely departure from the trajectory of movement to the left or right, with the steering wheel in a level position, indicates that the ball joint has failed.

It is almost impossible to determine the exact condition of the ball joint, but the above facts indirectly indicate the condition of the supports.

Ball selection, articles

The choice of ball joints for the Lada Kalina should be treated carefully, since it determines what loads the car can withstand:

Original

If you believe the spare parts catalog, then the original catalog number of the Lada Kalina ball joint is 2108-2904185. The average cost is 1000 rubles per piece.

Original Kalina ball joint produced by AvtoVAZ

Analogs

Belmag ball joint is an excellent option for replacing original spare parts

Let's consider possible options for replacing the original spare part:

| Weber | SS 2108-4185 | 500 |

| Master-sport | 1545601/E-PCS-MS | 500 |

| SCT | RM 485 | 500 |

| Denckermann | D110112 | 500 |

| Monroe | L70003 | 550 |

| Ruville | 917210 | 600 |

| Delphi | TC583 | 600 |

| Patron | PS3101 | 600 |

| Pekar | 2108-2904185 | 600 |

| Moog | LA-BJ-0063 | 650 |

| Pilenga | TS-P 3142 | 700 |

| TRW | JBJ 156 | 800 |

| Optimal | G3-199 | 1000 |

As you can see from the table, you can buy an analogue cheaper than the original. But don’t go to extremes and buy the cheapest.

TRW ball joint recommended for installation on Kalina

conclusions

The process of replacing ball joints on the Lada Kalina is quite simple and easy

But, it is worth paying attention to the choice of part, since it depends on its quality how long and the quality it will hold the suspension

How to choose the right one

Professionals say that it is better to give preference to original spare parts, since only they can guarantee impeccable quality, reliability and durability. But this option is expensive, which is why a significant part of motorists pay attention to analogues of original spare parts.

But here you need to be very careful: do not trust unknown manufacturing companies and do not buy components from unverified points on the market.

Before buying a product, it is necessary to conduct a thorough visual inspection: there should be no traces of welding on the body. Also, the parts should not undergo heat treatment, as can be seen from the dirty gray color of the surface.

But that’s not all: manufacturers of fakes sell products with a perfectly smooth surface, but! There is no emblem or quality mark here.

Quality can be determined by the hologram on the case and packaging in steel or red shades, with a mandatory set of fasteners.

The optimal price for VAZ supports is 500 rubles. True, not so expensive, but if you want to purchase tuning parts, then the price will be two zeros more - in the region of 20,000 to 48,000 rubles, from Pasker.

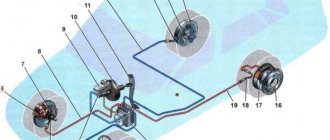

Procedure for replacing ball joints

Before performing work, you should put the car on the parking brake, jack it up and remove the wheel.

Dismantling the ball joint is carried out as follows:

- Using a 19mm wrench, unscrew the nut securing the support pin to the lever

- Using a puller, press the pin out of the lever.

- Using a 17 mm wrench or a TORX E12 socket, unscrew the two bolts securing the ball to the steering knuckle

- Using a pry bar, press the lever down and remove the ball joint.

The nut and bolts can be pre-treated with WD-40 or similar, but in most cases the fasteners can be removed without special preparation.

If you don’t have a ball joint remover on hand, you can proceed as follows:

- Partially unscrew the nut, leaving it on the finger;

- Use a pry bar to apply force to the lever from top to bottom;

- Press out the finger with confident hammer blows on the lever.

The ball joint can now be inspected and tested for proper performance. The support must be clamped in a vice and the finger must be checked by hand for play in the axial and radial directions. Normally, a play of up to 0.7 mm is allowed; if there is even slight movement of the finger, the entire support must be replaced. If there is no play, the support is suitable for further use.

Often, the ball joint is in normal condition, but its rubber protective cover (boot) is torn and deformed - in this case, you can install a new cover. To do this, the boot is dismantled, the hinge is cleaned of old grease, the new cover is filled to half the volume with grease, and installed on the support.

The boot of the new ball joint must also be filled with lubricant. By forgetting to do this, you dramatically reduce the life of the entire part.

The new ball joint is mounted in the reverse order. Moreover, there are two possible ways:

- First install the support on the steering knuckle, then move the lever and screw the nut onto the pin;

- First, install the support on the lever, then bring this entire structure to the steering knuckle and fasten the support with two bolts.

The second method is less convenient in that it is quite difficult to bring the support to the steering knuckle so that the mounting holes of both parts coincide, so it is better to resort to the first method.

During installation, it is recommended to use a torque wrench, the nuts securing the support to the steering knuckle are screwed with a force of 50-63 Nm, the nut on the pin is screwed with a force of 80-96 Nm.

A car with a new ball joint can be operated in normal mode; after about 100 km, it is recommended to check the fastening of the support and, if necessary, tighten the bolts and nut with the force specified above. The part does not require any further maintenance.

It's hard to find a child who doesn't like active play outside, and every child has dreamed of one thing since childhood - a bicycle. Choosing children's bicycles is a responsible task, the solution of which determines the joy and health of the child. Types, features and selection of a children's bicycle is the topic of this article.

The warm season, especially spring and summer, is the season for cycling, nature walks and family holidays. But the bike will be comfortable and bring pleasure only if it is chosen correctly. Read the article about the choice and features of buying a bicycle for adults (men and women).

Swedish Husqvarna tools are known all over the world and are a symbol of true quality and reliability. Among other things, chainsaws are also produced under this brand - read all about Husqvarna saws, their current model range, features and characteristics, as well as the issue of choice in this article.

Heaters and pre-heaters from the German company Eberspächer are world-famous devices that increase the comfort and safety of winter operation of equipment. Read the article about the products of this brand, their types and main characteristics, as well as the selection of heaters and preheaters.

Many adults do not like winter, considering it a cold, depressing time of year. However, children have a completely different opinion. For them, winter is an opportunity to roll around in the snow, ride the slides, i.e. have fun. And one of the best helpers for children in their non-boring pastime is, for example, all kinds of sleds. The range of children's sleds on the market is very extensive. Let's look at some types of them.

conclusions

The process of replacing ball joints on the Lada Kalina is quite simple and easy. But, it is worth paying attention to the choice of part, since how long and how well it will hold the suspension depends on its quality.

Tools:

- Straight box spanner 17 mm

- Straight box spanner 19 mm

- Tubular socket wrench 17 mm

- Mounting blade

- Large hammer

- Jack

Parts and consumables:

- Spherical bearing

- Grease ShRB-4, 6 grams

- Rags

Note:

The operation is performed when replacing a ball joint or its protective cover. The car must be installed on an inspection ditch or overpass.

1. We hang the wheel and remove it.

2. Using a 19mm wrench or socket, do not completely unscrew the nut securing the ball joint pin to the lever.

3. Using a mounting spatula, we create tension and strike the lever with a hammer until the pin is pressed out. Completely unscrew the nut securing the ball joint pin to the lever.

4. Using a 17mm spanner, unscrew the two bolts securing the ball joint to the steering knuckle.

5. Pressing the lever down with a mounting blade, remove the ball joint.

6. Remove the protective cover.

7. A working ball joint should have no play in its pin. Any dirt trapped under the ball joint cover must be removed. Before installing a new protective cover, put approximately 6 g of ShRB-4 lubricant or other grease into it.

8. We replace the faulty support with a new one and install it in the reverse order.

The article is missing:

- Photo of the instrument

- Photos of parts and consumables

- High-quality photos of repairs

How to replace a ball joint

You will need: keys 17, 19, TORX E12...

...And a ball joint remover.

Note

The work is shown using the example of a ball joint for the left strut. The right pillar support is replaced in the same way.

1. Brake the car using the parking brake, install wheel chocks under the rear wheels. Use a jack to lift the front of the machine and place it on a secure support. Remove the front wheel.

2. Unscrew the nut to secure the ball joint to the lever.

3. Press the pin for the ball joint out of the lever itself using a ball joint puller.

4. Remove 2 bolts to secure the ball joint to the steering knuckle.

5. Using a mounting shovel, press the lever down and remove the ball joint.

6. Holding the support in a vice, check the radial and axial movements (play) of the ball pin in the support. The flame should not move due to manual effort. If there is movement of the ball pin in the support that is noticeable by hand, the ball joint should be replaced.

7. If the protection cover is torn, you need to remove the top dirty layer of lubricant (if it is noticeable that dirt has managed to penetrate inside the support, it must be replaced) and apply new lubricant.

8. Install the spacer sleeve until it stops.

9. Place grease in the new protective cover (half its volume)

10. Before installing the dirt-proof cover, apply sealant to the surface of the support

11. Install the ball joint in the reverse order.

During the installation process, do not damage the protective cover for the ball joint. A damaged cover must be replaced.

12. After approximately 100 km, check the tightness of all threaded connections. If necessary, tighten them up at appropriate moments.

To check the condition of the suspension ball joint, remove the wheel and measure the distance “A” between the lower arm 29 and the brake disc 9.

If this distance changes by more than 0.8 mm when the suspension is rocked, replace the ball joint.

Characteristics of the ball joint on the Lada Kalina

This unit holds the wheel in a certain position, while at the same time allowing the hub to rotate and maintain horizontal stability. The ball joint is called because of the ball-shaped tip. Structurally, it is a cone-shaped unit.

The Lada Kalina uses a modern collapsible element, although the first VAZ models had stamped assemblies from several parts, and then cast structures. The ball joint installed on a Lada Kalina car, regardless of modification and generation, has a standard device that includes several main components:

- frame;

- a part in the form of a cone (another name is “finger”);

- rubber protective boot (prevents dirt and dust from entering).

The main elements are made of high quality steel. This is due to the fact that during operation the working parts are constantly exposed to load, friction and, as a result, high temperatures. The only exception is the hollow part of the body, which is covered with polymer materials. Plastic is mainly used for these purposes.

The main advantage of the Kalina ball joint is the extreme simplicity and efficiency of the design, which allows the contacting parts to move freely at equal angles.

Looking at the structure of the ball in more detail, it can be noted that it is actually a steel finger, which on one side ends with a tip in the form of a small ball. The tip rests on a plastic (or polyurethane) gasket. The bushing and ball end are located in the body and are rolled to prevent flyout. The body is additionally galvanized against corrosion. It is fixed to the upper or lower control arm and the threaded part is secured with a knuckle nut. Thanks to this, the fist is not fixed too tightly, which allows it to rotate along with the wheel hub, and the vertical position is maintained when the vehicle’s suspension is operating.

The ball joint is a fairly reliable and durable unit if you follow the operating rules. The long service life of the ball joint is possible thanks to the lubricant located in the part of the housing where it comes into contact with the working part. Insufficient lubrication, its leakage and moisture entering the internal cavity can cause premature failure of the entire assembly. To protect the working parts, a special boot made of rubber that is resistant to aggressive environments is used.

In order for the ball joint to last as long as possible, every car enthusiast should check the condition of the suspension from time to time, paying special attention to the rubber boots. There should be no cracks or other visible damage on their surface. If there are defects, it is recommended to check the condition of the entire assembly for wear.

If there are defects, it is recommended to check the condition of the entire assembly for wear.

Malfunctions

Despite the fact that the support parts of the Lada Kalina are made of durable steel, the unit, which experiences the most powerful loads, fails from time to time, because it is the suspension that experiences the vibrations that come from driving on a bad, bumpy road, and the suspension also absorbs a significant part of the weight of the machine, which leads to wear of parts.

Replacing a ball joint on a VAZ 2110 2112, Kalina, Granta, Priora, 2108 2109, 2114 2115

Video instructions for replacing balls

for VAZ 2110-2112,

Kalina

and Granta, Priora and other front-wheel drive...

Replacing the ball joint of a vase and how to determine wear

The Auto_Repair channel will help you troubleshoot your car with your own hands...

- Most often, the contacting surfaces in the supports wear out, which are in constant friction. Mechanical damage and overheating lead to deformation: the formation of a gap from the pin to the body, chips, cracks. For this reason, parts malfunction, rotate, even hang out in the body, and as a result, have the most negative impact on the operation of the suspension. And since the stability of the car depends on the suspension, we can say for sure: faults in the ball joints lead to loss of controllability, and, therefore, to an accident.

- In addition to deformation of the contacting surfaces, damage also occurs in the boot; rupture of the boot also has a bad effect on the operation of the entire system, because in this case, all the dirt, dust and water that falls on the suspension while driving gets inside, which causes corrosion processes and rapid wear. components.

- Lack of lubrication also leads to the formation of mechanical deformations. Therefore, you must always monitor the lubrication level in all systems, without losing sight of the suspension.

Design

First of all, you need to know the differences between upper and lower ball joints. The first are cast-in-place structures that work in compression - they are subjected to light loads, which results in a long service life. Lower ball joints are most often created on the basis of sintered metal bearings, which allows them to withstand shock and tension. Most experts strongly do not recommend saving on lower ball joints, since they often fail with very serious consequences.

Lower ball joint

To understand how to choose a ball joint, you also need to know about the fundamental differences between the designs of these units. The most common production method is the sunset production method - it allows you to obtain very high strength at a relatively low manufacturing cost. However, it cannot withstand very large shock loads - therefore, if you frequently drive with a heavy load on a bad road, it is worth regularly checking the condition of such front suspension components.

About a third of ball joints produced in China, Russia, Turkey and Poland use a stamped-welded design. It allows you to get by with minimal costs and significantly reduces the weight of the part, but has rather low strength. It is recommended to install such ball joints only on small cars with minimal loads on the chassis, and even in this case they should be replaced every 25–30 thousand kilometers.

The best option used by American and Western European manufacturers is solid forged ball joints. They are very strong and can withstand loads of more than 5 tons without breaking. Despite their high cost, they are popular due to their long service life.