Many motorists have encountered the problem that the gearshift lever begins to dangle. What is the reason for this phenomenon? You can immediately determine that the problem lies in the mechanics of the link between the lever and the gearbox. The article will tell you how to fix the problem and tell you about some of the nuances of the process.

Video about how the gearshift lever on a VAZ-2114 can dangle:

The video will tell you how to eliminate a loose gear lever.

Tool for repairing gear knob fastening

In this article we talk about this lever.

Before starting any repair and restoration operations, the motorist needs to collect tools. So, to eliminate the looseness of the gearbox lever you will need: a 13-size wrench and sandpaper.

The gearshift lever is loose: replacing the bushing on a VAZ-2114

Fearing that repairs will take a lot of time and effort, many car enthusiasts postpone it indefinitely or pay huge sums to a car service center. But, in fact, as practice shows, the procedure itself takes little time and almost every car enthusiast can handle it on his own.

So, let's consider the sequence of the process step by step:

- We lift the gearshift knob casing or dismantle it altogether.

We remove the gearshift knob cover.

Unscrew the nut securing the gearbox linkage

Disconnect the rod from the gearshift knob

Worn parts of the gear lever bushing

Video about getting rid of vibration on the gear knob

Recommendations for covering

First of all, you need to remove the handle from the main long gearshift lever. It is the handle that we will tighten. If you wish, you can also replace the cover of the lever itself, which hides the metal pipe in the tunnel. But more on that another time.

The task is to obtain blanks. Here is an option:

- wrap the handle with cling film;

- or just use a plastic bag;

- wrap tape (stationery or masking tape) on top, but most importantly tightly;

- Use a marker to apply future markings on the tape;

- Use a sharp knife to cut the wound tape;

- you will receive something like a blank or papier-mâché;

- remove, level on the table;

- Apply the completed patterns to the purchased material for reupholstery;

- cut according to the pattern, but make leather blanks literally 2-3 mm smaller, otherwise the cover will hang;

- step back 5 mm from the edge of the leather and go through it with a sewing machine (stitch);

- return the pattern to the gearshift knob, treating the reverse side with glue;

- when the glue fixes the handle, you can start sewing together the pieces of leather;

- insert good quality threads into the stitches of the seams and tighten them tightly;

- if leather was used, wet the material after stitching is completed;

- Replace the gear diagram, if there was one.

But there is another option. It is suitable for those who like the old case's shape and seam placement, but the product is simply worn out. To do this, carefully remove the old trim from the gearshift knob.

It will be used as a template for a new case. Cut out blanks from the new material in the shape of the old cover, and sew them together in the same way. The convenience of this option is that you do not need to measure anything, make markings, etc.

IMPORTANT! The cover should be sewn from the wrong side so that the seams are not on the outside. Then the comfort of gripping the gearbox will deteriorate significantly.

I think we can end here. If you have personal experience with gearshift knob trim, be sure to write in the comments, share your secrets and highlight the important points of the procedure.

Thanks to everyone who reads us! Subscribe, ask your questions and invite your friends to join us!

( 1 ratings, average: 5.00 out of 5)

Did you like the article?

Subscribe to updates and receive articles by email!

We guarantee: no spam, only new articles once a week!

Causes of gearshift lever failure

The VAZ 2110 high-speed gearbox is equipped with mechanisms that are designed to withstand heavy loads. The VAZ gear knob copes with its functions perfectly. On the VAZ 2110 – 2112 variants there is a gear shift cushion. This element also has another name: “butterfly”.

It is advisable to understand the reasons why the VAZ 2110 gear shift lever needs to be repaired. As a rule, checking this element is necessary if extraneous noise from the gearbox is noticed.

There are several reasons why a rattling sound began to be noted from the gearbox. In particular, these are:

- defective spare parts;

- spring breakage;

- wear of spare parts related to the engine.

Varieties of backstage

There are many models and designs. Each of them is characterized by its own characteristics. They are usually classified into two main types:

- long stroke;

- short-stroke.

Long-stroke scenes are often called standard. They were used in the production of cars of the domestic VAZ brand (starting from 2109, etc.). Short-stroke rockers are typical for Kalina cars. They are similar in design to long-stroke ones.

Attention! The main difference between long-stroke and short-stroke is size. It is due to this that it is more convenient to change gears to second.

When is it necessary to adjust the gearshift lever?

The need to carry out this procedure arises if the first gear does not engage. Such a manifestation as ringing of the scenes may be the result of a defect in the factory production of this spare part. Also, on a VAZ 2110, adjusting the rocker can help if the speed at the gearbox is difficult to engage.

Thus, each of these reasons leads to the appearance of play in the gearshift knob on the VAZ 2110. Taking this into account, this mechanism is subject to mandatory diagnostics. Timely detection of faults will allow the motorist to avoid problems with the gearbox.

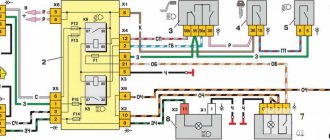

Features of the device and structure of the transmission mechanism

The fourteenth model is equipped with a five-speed gearbox similar to the unit installed on the G8, with the exception of the main pair.

According to consumer reviews, the lack of quality of the fourteenth gearbox includes the selection of gear ratios: a very short first speed and a long second. This drawback leads to a loss of vehicle dynamics when switching from first to second gear during acceleration.

The gearbox housing, rear cover and clutch housing are the main parts of the gearbox design structure.

Internal device groups:

Main couple

The drive shaft functionality reduces the speed transmitted from the engine to the crankshaft. The transmission coefficient is 3.7. Thus, the main pair of the “fourteenth” is capable of reducing the indicated speed by approximately 4 times. The length of the gears can be changed by controlling the main pair mechanism. What affects acceleration and the maximum possible speed limit of the vehicle.

Differential with gear ratios

The differential gear ratios of the stock VAZ 2114 gearbox include: 3.636 (first speed number); 1.95 (second speed number); 1.357 (third speed number); 0.941 (fourth speed number); 0.784 (fifth speed number) and 3.53 (reverse speed number).

Having an idea of the structural features of the gearbox mechanism, it is necessary to begin preparing tools, materials and tools that will be useful during the removal and disassembly of the box.

Restoring the functionality of the VAZ 2110 gear shift lever

How to remove rattling gear lever on a VAZ 2110? It seems possible to eliminate this manifestation yourself. If the problem lies in the spring, there is no need to disassemble the box or take other complex actions. In some cases, the problem can be eliminated by purchasing a repair kit for the rocker, including bushings, washers, etc.

The main purpose of the bushing is to hold the lever in a certain position. This element experiences heavy loads. Given this, it may burst over time. The result of this is excessively free movement of the lever. The bushing must be replaced.

When installing the spring, it is recommended to wrap the handle with a tourniquet to ensure a tight fit.

To install new plastic or rubber washers from tools, you need a set of keys, files, and a screwdriver. You also need a plastic cover, from which a washer is cut out using scissors.

- Removing the casing from the gearshift lever.

- The nuts and screw are unscrewed.

- The bushing, washer and bolt are removed.

- The washer is cut to fit the sleeve.

- All dismantled elements are installed back.

WE ELIMINATE VIBRATION

Now you need to carefully inspect the bushing externally, after all, it is precisely because of it that the gearbox lever 2115 rattles. If there is any external damage that is too obvious and signs of wear, then you may have to look for a new part so that you do not have to repeat these manipulations in the future . Now let’s figure out what operations need to be carried out in order to understand how to adjust the rocker on a VAZ 2114:

- We remove the outer plastic braid of the bushing to free its iron body.

- Now we need to see if there are any signs of friction on it. Their presence will indicate that the size is incorrect. They will be especially pronounced if the sleeve is slightly longer than necessary. If this is confirmed, then these extra millimeters are the reasons why the VAZ 2115 gearbox lever rattles. In this case, you need to try on how much excess is in the hole and simply grind it off with a file, usually there are only 1-2 millimeters there.

- Now you need to select some kind of gasket according to the shape of the part, or simply wrap it with electrical tape so that it fits into place more tightly and then does not move.

So it became clear how to eliminate the rattling of the VAZ 2114 gearbox lever and why this generally happens. After our simple manipulations, the vibration should completely disappear, now the lever will always be in a calm state.

The described methods do not require any special knowledge and can be performed by an ordinary person in his garage with a minimum set of suitable tools.

Gear shift knob, or what is the design of the system?

A feature of all manual gearboxes is the need to manually operate the lever. We can assume that it is precisely this that performs the most important function in determining the speed limit of your movement. This means that without it, driving a vehicle becomes simply impossible. The principle of operation of the lever is quite simple: by tilting it in the longitudinal and transverse directions, you set it to a position that corresponds to a certain speed.

The gear shift lever handle is connected to the synchronizer via a fork, the position of which transmits information about the number of the selected speed. The synchronizer sets the gears of the gearbox so that the generated engine power allows the car to move at a given speed. When the position of the lever corresponds to neutral gear, it is held in place by springs. The gear shift pattern is often depicted on the head of the lever.

General symptoms

Symptoms are manifested by seven signs, which include:

- When you shift gears, a crunching sound appears;

- the sound of knocking in the box;

- oil leak;

- there is no speed fixation;

- tight lever movement during switching;

- The control room is buzzing;

- noise in the gearbox.

Each of the listed symptoms has its own etymology and an exact picture of its manifestation, which objectively characterizes the root cause of the malfunction.

Crunch in the gearbox

This type of repair requires disassembling the gearbox structure.

The main reasons, a sign of which is a crunching noise during gear shifting:

- faulty gearbox synchronizer (definitely requires replacement of the synchronizer);

- malfunction of the clutch basket (during operation of the vehicle, the “petals” may fly off). The violation is eliminated by replacing the part, and a new clutch disc is also installed;

- Damage to the clutch cable is classified as an indirect cause of gearbox malfunction, but if the cable breaks, the vehicle cannot move;

- factory defect of the gearbox shaft.

Knocking at the checkpoint

The sounds of gearbox tapping are ambiguous due to their multiplicity. Therefore, the picture of the malfunction is accurately established by diagnosing the vehicle.

The box starts knocking if:

- The oil level is not set correctly. An indirect indicator is the amount of oil being poured;

- the distance between the brakes and clutch packs is either too small or, conversely, too large;

- sagging appeared in one of the valves in the box;

- The solenoid has failed.

Oil leakage

If there is an oil leak, the repair task is facilitated by the ability to determine the location of the leak, but most often in practice this is impossible to determine.

Faults that cause oil leakage are the following:

- the seals are worn out;

- the shafts are worn out;

- there was a malfunction in the gearbox input shaft play;

- parts are depressurized: formation of cracks, microholes, etc.;

- The speedometer drive shaft seal is worn out.

Speeds are flying out

This kind of phenomenon occurs during gear shifting. The main reason for the appearance of such a malfunction is wear of the teeth on the gears and coupling. A factor contributing to the development of weakening speed control is a violation of the rules of gear shifting technique, which occurs when the speed limit is not observed. Replacing the gears of the specified parts eliminates the described problem.

The handle is tight

Factors under the influence of which the movement of the handle is difficult are damage to the locking teeth of the lever itself, wear of the jet thrust, and violation of the integrity of the gearbox drive parts.

The box is humming

This sound appears mainly during neutral transmission. The main reason is the low quality of lubricants. Therefore, the first action that must be performed when this type of technical problem occurs is to check and, if necessary, add oil. If the box continues to hum, then it is necessary to perform diagnostics, since the bearing on the input shaft may be worn out.

Noise in the CP

The box begins to make noise when the oil level is insufficient. This situation can be resolved by adding oil. If the noise does not stop, then it is caused by wear of the seals and mechanisms. This can be eliminated by installing new parts to replace worn ones.

Upon completion of the process of identifying the malfunction, its cause and source, as well as the factors influencing the occurrence of malfunction of the gearbox, it is necessary to become familiar with its structure and the structural features of the mechanism.

How can the gear shift lever be positioned?

The location of the gearbox levers can be either floor-mounted or steering column mounted. And despite the fact that the latter is considered more convenient to use, nevertheless, in most cases, car manufacturers prefer the first option. This is due to some disadvantages of the steering column arrangement, including: low speed and clarity, the likelihood of incomplete gear engagement, the rods wear out much faster, sometimes they can jam, as well as “knocking out” the gear.

But in both cases, the design of the gear shift lever remains the same. The only differences can be in length, and if previously it could reach even 30 cm, today manufacturers strive to make it as small as possible, eliminating too much travel of the gear lever. Therefore, with a floor arrangement, nothing will change significantly in the design, but there will be noticeably fewer breakdowns.

Material selection

The choice of material for covering is a serious and responsible matter: the driver will touch it during operation for several years. Therefore, the material should be pleasant to the touch, comfortable, wear-resistant, and breathable. The choice largely depends on the financial capabilities of the car owner and his tastes. People have different tastes: some like bright colors, others want to use almost snakeskin. Many people strive to stand out with interior decoration, to show individuality and originality.

The gear shift knob is made from different materials. Reupholstering the gear knob with leather is the best option in terms of price and quality ratio. The most popular is genuine automotive leather. It has qualities that are in many ways superior to furniture and haberdashery leather: more moisture-resistant, wear-resistant and strong. Analogs can withstand operating conditions (temperature changes, frequent contact) for no more than 2 months, automotive leather will last 5-7 years.

Perforated leather

Leather for cars has a special polymer coating that protects it from mechanical damage. In addition, thanks to the polymer layer, car leather is resistant to ultraviolet rays, chemical exposure from alcohol, gasoline, oil, endures frequent stretching longer, and the paint is highly resistant to abrasion.

An alternative to genuine leather are artificial materials: eco-leather and artificial leather. For the production of eco-leather, polyurethane is used; its composition contains 70% of the substance. Leatherette is made from polyvinyl chloride (PVC). The use of polyurethane allows eco-leather to “breathe”, which distinguishes it from artificial leather. The cost of artificial materials is much lower than natural leather, so eco-leather is gaining popularity.

The covering material can be faux suede such as Alcantara. It is a material with a rough surface, pleasant to the touch. The roughness prevents the hand from slipping. The Alcantara-covered handle looks very aesthetically pleasing. In winter, when touching the material, a feeling of warmth is created, and in summer, on the contrary, suede gives the effect of coolness.

It is possible to reupholster with rubber material with an adhesive backing. They are easy to finish and are inexpensive.

Perforated leather is most convenient, as it is softer and more elastic than smooth leather. True, the pores should be small so that dirt does not clog. Smooth leather is more resistant to wear. The thickness of the material should be from 1.2 to 1.4 mm. The color can be any - it must match the overall color scheme of the interior. The classic option is black.

Shift lever squeak and other problems

From all of the above, it is clear that this part is one of the most important in the entire gearbox, and if it fails, then driving such a vehicle becomes life-threatening. The most common reasons why such an emergency can occur are either mechanical damage or the consequences of incorrect operation. Here are a few breakdowns that you can easily detect on your own.

You should know that the gear shift knob should move freely, without jamming . If difficulties arise in performing this action, most likely the spherical washer or ball joint has failed. They need to be replaced urgently. The creaking of the gear shift lever also indicates a malfunction. If spontaneous shutdown occurs, then you should definitely check the spring; it is quite possible that it simply jumped off.

Price issue

Short walker

Actions on your own, you only have to purchase the necessary parts and ordinary consumables. If you contact a car service, the minimum cost of the service will be 800-1000 rubles. That is, the savings are obvious.

The curtain itself costs about 400 rubles. From here it becomes clear why we did not advise buying a repair kit, but rather completely replacing the part. There will be no savings as such, but the difference as a result of the repair will be significant.

How to repair a gear shift lever?

In any case, no matter what happens, repairing the gear shift lever involves replacing failed parts, and without completely removing it it will be impossible to do this. For this purpose, the plastic protective plate is dismantled and the hinge cage is released. After which it is necessary to move the jet rod to the side and remove the entire lever. But in order to free up access to all the plastic bushings and axles, it is necessary to remove the cover for the gear shift lever.

Check how the axle moves. If it is loose, then you need to change all the bushings, and do not forget to lubricate the new spare parts with special lubricant before installing them.

To replace the spring, it must be pulled out, and for this you need to dismantle the retaining ring and the hinge with the lever. If you cannot do without replacing the ball joint, you should carefully push the spherical washer apart with your fingers and remove the worn part. At the same time, when installing a new one, lubricate it.

The thrusts change as follows. There is a clamp at the bottom of the car; you should loosen it. Next you need to disconnect it from the hinges and, by unscrewing the fastening nut, you can freely pull out the rod. Installation of the new one is carried out in the reverse order. Thus, having replaced all damaged elements with new ones, you can drive safely. At the same time, do not forget that periodically it is necessary to adjust the gear shift lever.

Let's get started

The most common factor influencing the “inadequate” behavior of the gearshift lever in the VAZ 2114 is the first reason described above. Therefore, this is where we should start solving the problem. To do this, you will need the following tools: electrical tape, sandpaper (grinder), ruler, 13mm wrench and lubricant.

Actions are performed in the following order:

- Remove the handle cover.

- Unscrew the nut and remove the handle and rod.

- We take out the bushing.

- We remove the plastic bushings and clean the metal bushings from dirt.

- We measure 2-3mm from the edges with a ruler, draw a line, glue electrical tape under the line for convenience, cut off the excess with a grinder (you can use sandpaper, but this will be a serious test).

- We put everything in place, lubricate it if necessary, don’t forget to tighten the nut, and put on the casing.

- Enjoying the silence.

There is a second way. It's a little more complicated. Washers are cut out of the plastic cover, or special rubber (plastic) nuts are purchased. You need to screw them on both sides of the drawstring, then you may not have to grind it down (although usually you still have to). The method is designed to reduce rattling by dampening vibration with rubber or plastic.