In this article we will look at possible clutch failures, as well as methods for eliminating them. After all, sometimes fixing a problem is not as difficult as fixing what went wrong. Below is a table in which each malfunction is associated with the cause and repair option. Clutch diagnostics are performed using problems from the table.

| Cause of failure | Elimination methods |

| The clutch is not fully engaged, as they say slipping. When you press the accelerator pedal, the acceleration of the car is almost zero, although the engine is at high speeds. It feels good when you drive up a hill. In this case, a smell may appear due to overheating of the friction linings. And also the consumption increases. | |

| The flywheel, pressure plate or friction linings of the driven disc may be oily. | All surfaces that are oily should be thoroughly washed with gasoline or another oil cleanser. If there is a very large deposit of oil on the driven disk, then it is better to replace it altogether. After this, you should figure out why they were oily and eliminate oil leaks. |

| It is possible that the friction linings on the driven disk are badly worn or burnt. | The disk needs to be replaced. |

| The clutch drive may be stuck or damaged. | If it is impossible to eliminate jams, it should be replaced. |

| With this breakdown, the clutch is also not fully engaged, but has some other character, so to speak it “drives”. At the same time, gears from 1 to 5 are switched rather poorly, and switching to reverse occurs with noise. But you are sure that the gearbox is in good condition. | |

| The clutch drive may be incorrectly adjusted. | The pedal travel should be adjusted, namely, the pedal travel should be increased. If the plug is deformed, it should be replaced. |

| If the clutch cable gets stuck. | The cable itself should be coated with oil. If nothing has changed, check the cable for damage and fraying. If detected, the cable must be replaced. |

| It is likely that the friction linings are broken, or the rivets are loose, or the end runout is > 0.5 mm (disc warping). | Replace the driven disk |

| The pressure plate or flywheel shows severe and uneven wear. | The flywheel must be replaced. And if the pressure plate is damaged, then the clutch “basket” should be completely replaced. |

| The driven disc hub gets stuck on the splines of the gearbox input shaft. | The surface of the splines should be cleaned from contamination. If there are minor damages, remove them with a file. If the splines are heavily worn, then the disk should be replaced, even with the input shaft. When you assemble, do not forget to lubricate the splines with CV joint-4 grease. |

| The pressure plate is skewed or warped | It is necessary to replace the clutch “basket”. |

| Where the release bearing contacts the diaphragm spring petals, there is a possibility of wear of the latter. | It is necessary to replace the clutch “basket”. |

| The car “jerks” when starting to move. | |

| The clutch drive may stick. | The cable itself should be coated with oil. If nothing has changed, check the cable for damage and fraying. If detected, the cable must be replaced. |

| The driven disk hub on the gearbox input shaft (on the splines) may become stuck. | The surface of the splines should be cleaned from contamination. If there are minor damages, remove them with a file. If the splines are heavily worn, then the disk should be replaced, even with the input shaft. When you assemble, do not forget to lubricate the splines with CV joint-4 grease. |

| The driven disk may be deformed | It should be replaced. |

| In case of severe wear and cracks on the friction linings, or loosening of their fastening. | The driven disk must be replaced. |

| If the elasticity of the spring plates on the driven disk is lost. | The driven disk must be replaced. |

| When the torsional vibration damper springs break or settle, as well as when the windows for the springs wear out. | The driven disk must be replaced. |

| The working surfaces of the flywheel or pressure plate have become scored. | The clutch “basket” should be replaced. |

| The flywheel, pressure plate or friction linings of the driven disc may be oily. | All surfaces that are oily should be thoroughly washed with gasoline or another oil cleanser. If there is a very large deposit of oil on the driven disk, then it is better to replace it altogether. After this, you should figure out why they were oily and eliminate oil leaks. |

| When you engage the clutch, extraneous noises or knocks appear. | |

| When the torsional vibration damper springs break or settle, as well as when the windows for the springs wear out. | The driven disk must be replaced. |

| The driven disk may be deformed | It should be replaced. |

| In case of severe wear and cracks on the friction linings, or loosening of their fastening. | The driven disk must be replaced. |

| When you disengage the clutch there is increased noise. | |

| The clutch release bearing may be worn or damaged. | The bearing must be replaced. |

When do you need to adjust the clutch drive on the “ten”?

Car enthusiasts who already know how to adjust the clutch on a VAZ 2110 can promptly diagnose the condition of the unit. They are helped in this by having experience and knowledge; they do not need any consultations at a car service center. For example, no one will argue that replacing a clutch cable requires subsequent adjustments. Before you take a ruler to measure pedal travel, you need to pay attention to the behavior of the car:

- Jerks and impacts, as well as noise when turning on the speeds, indicate the need to adjust the drive.

- The start of the vehicle movement immediately after releasing the pedal indicates a lack of free play.

- In the case when the car does not move even with the clutch pedal fully released, the free play exceeds the norm.

How to check pedal travel?

Clear signs of trouble require a performance check of the clutch control pedal. The procedure is simple, does not require special skills and is described in detail in the instruction manual. So, before adjusting the clutch on a VAZ 2110, we perform the following steps:

- Place a ruler perpendicular to the outer edge of the pedal, resting it on the floor.

- Determine the distance from the floor to the outside of the pedal.

- The acceptable distance is considered to be 120-160 mm ; if the readings are outside the norms, adjustment of the drive is required.

Causes

Russian-made cars are often susceptible to such “diseases”.

This may be due to the poor-quality mechanism of the device. One way or another, the owner of a VAZ 2110, faced with the fact that the clutch pedal has failed or is moving, needs to somehow solve the problem. First, let's look at the reasons for slipping:

- One of the clutch elements is oily. Here we can talk about a flywheel, a pressure or driven pulley, or friction linings. In this case, it will be necessary to clean the oily elements of the system with acetone or gasoline, and then wipe everything dry. In addition, the driven shaft may need to be replaced. And, of course, it is necessary to eliminate the cause of the oiling.

- Increased wear or burning of the friction components of the driven shaft. It will be necessary to completely change the clutch.

- The clutch drive itself is stuck or mechanically damaged. In any case, you need to eliminate the jam or change the drive.

- If the pedal falls, this may indicate that its travel is not adjusted.

Loading …

Traditional method: how to adjust the clutch on a VAZ 2110 without visiting a car service center?

Over the past few years, auto parts manufacturers have respected domestic car owners. By paying a little more, they have the opportunity to buy and install an imported clutch as a kit. But installing a new basket, disc and release bearing is only half the battle. It is necessary to correctly configure the drive of the transmission mechanism, for which it is enough to repeat a few simple transitions:

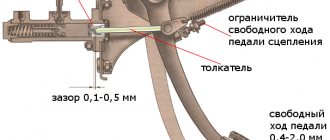

- Open the hood of the car (the engine is turned off) and find the junction of the cable and the clutch release fork.

- Using two open-end wrenches “13”, unscrew lock nut 1 (see photo), and use nut 2 to adjust the free play of the control pedal within 120-130 mm. The pedal stroke increases when nut 2 is unscrewed, and when it is tightened, it decreases.

- Press and release the pedal 3-5 times, then check the pedal stroke size with a ruler.

- If necessary, repeat the adjustment and then tighten the locknut.

The given procedure for setting up a backlash-free drive is overly simplified and is designed for car enthusiasts who do not have as their goal an in-depth knowledge of the car’s design.

Why does the clutch fail?

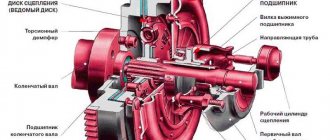

The clutch disc is a consumable item and sooner or later still needs to be replaced. It is impossible to repair a worn disk. The fact is that when it comes into contact with the flywheel, it begins to grind down for a while and only then the parts interlock with each other. Thus, the thickness of the clutch decreases and eventually the disc loses its function.

You can also “grind off” the clutch in a quick way. Many drivers, when starting to move, press the gas too hard and at the same moment quickly release the clutch pedal. At these moments, clutch wear increases significantly and then it will need to be replaced quite soon. Rapid disc wear is also achieved by driving quickly in low gears. At that moment, when the speed is high and the gear is selected too low, the clutch does not have time to transmit the required torque to the intermediate shaft and begins to slip. Thus, it receives additional “unnecessary” friction and wears out quickly.

Reasoning about alternative regulation

Before adjusting the clutch on a VAZ 2110 in the traditional way, let’s think about how justified it is, and whether there is any point in using an alternative option. According to reviews from many owners of “ten” cars, and not only them, the clutch control pedal is quite high from the floor. The inconvenience that most drivers get used to is actually quite significant.

The driver gets tired during the trip, he wants to change gears less and less, each time lifting a heavy boot. This affects not only the speed of movement, but also the condition of the transmission. Experienced drivers assure: when the clutch pedal is released, it should be positioned so that it can be depressed without lifting the heel from the floor. It’s not without reason that on UAZs and Gazelles, where adjustment is impossible, experienced drivers place a piece of board under the mat.

The classic adjustment order indicates data that ensures the clutch disengages with a large margin. As a result, by fully depressing the pedal, the driver forces the bearing to bend the diaphragm spring much more than is technically necessary. As a result, it loses its characteristic properties, and at critical moments it simply breaks. And it doesn’t matter that you chose a branded clutch kit - everything is subject to the laws of physics.

Method for alternative clutch drive tuning

Experienced car enthusiasts prefer to make adjustments individually for each set of coupling parts. The event does not require an assistant or special equipment:

- Start the engine, depress the clutch and engage reverse gear. On almost all VAZ models it does not have a synchronizer, so the disks are completely disconnected.

- Slowly release the pedal and simultaneously engage and disengage reverse gear.

- The moment the speed is switched on is manifested by vibration on the shift knob. If the setting was made according to the official factory instructions, then the start of activation will correspond to a distance of the pedal from the floor of 75-100 mm.

- Set the cable length so that the “grasping” moment corresponds to 20 mm from the floor to the top edge of the pedal.

After we adjusted the clutch on a VAZ 2110 in this way, the clutch pedal in the initial position is much lower than the brake pedal. This allows you to instantly switch the toe of the boot without raising your foot to the handlebars. Early activation greatly simplifies the process of driving a car; gears are engaged smoothly and without jerking.

Clutch diseases

VAZ 2110 clutch malfunction and disc replacement

Let's start with the fact that the VAZ 2110 clutch is always associated with a certain list of problems known to specialists. What clutch malfunctions exist are presented below:

- The car's clutch slips and does not engage fully. As a result, it may be impossible or very difficult to change gears, especially first and reverse.

- When you press the clutch pedal sharply, the engine begins to gain speed, but the car does not accelerate. This situation is especially dangerous when overtaking, when the driver, not knowing about the faulty clutch, tries to overtake the vehicle in front.

What is a clutch malfunction?

- The clutch does not disengage completely, and a characteristic crunching sound is heard when changing gears.

- When starting there are jerks.

- While driving, the car rattles, knocks or makes noise, and when the clutch is engaged, the sounds only intensify.

Eventually

In conclusion, it should be noted that there are some “homemade” ones who specifically move the release bearing away from the basket, explaining their actions by the fact that in this way they will be able to extend its service life. However, they will have to be disappointed - the bearing is unlikely to become more durable, but the petals of the diaphragm spring will gradually be milled by the untwisted bearing race. And, please note, we are not discussing the discomfort from increased pedal travel, which can result in much greater expenses than purchasing clutch elements.

Clutch slipping in a car, first of all, affects the deterioration of traction and also negatively affects the dynamics. There are several reasons why the clutch may start to slip; in this article you will learn in detail about each of them, as well as how to eliminate such a nuisance as clutch slipping.

Causes of slipping and ways to eliminate them

Not in all cases you will necessarily have to buy a completely new clutch. Once, out of inexperience, I changed a unit, which turned out to be almost completely serviceable. In reality, it was just necessary to change one inexpensive component. But sometimes you have to learn from your mistakes.

From everything I have learned, I realized that determining the cause of clutch slipping plays a key role here. Your further actions directly depend on this.

- The clutches are worn out. Your actions depend on the degree of wear. When the distance between the working elements used is less than 0.2 mm, you can simply adjust the free play of the pedal. In case of severe wear, the driven disk and linings are replaced;

- Oil appeared on the linings. Oil on the friction linings may appear due to certain problems in the flywheel drainage or an excessive amount of lubricant in the box. The oil should be removed and the surface dried. Kerosene works well. After cleaning, go through with fine sandpaper;

- Damage to the integrity of the rubber components of the hydraulic drive. When they swell, the clutch very often begins to slip. Here you will have to remove both cylinders (worker and main), wash them with alcohol, replace the rubber elements and clean the expansion holes. Don't forget to bleed the clutch and the brakes themselves;

- Loss of elasticity of pressure springs. This problem occurs on old cars that have been in use for over 10 years. Elasticity decreases gradually, which causes the required level of pressure on the driven disk to drop. As a result, the clutch slips. The check is carried out by removing the clutch disc. If elasticity has decreased, they will have to be replaced.

Replacing the VAZ 2107 clutch with your own hands

It is recommended to perform this procedure on an inspection hole and overpass. First of all, it is necessary to immobilize the car using anti-recoil devices. Using the gearbox for this is not allowed, as it will need to be removed.

First, remove the negative terminal of the battery and drain the brake fluid from the clutch reservoir. After this, you need to remove the starter from the engine and disassemble the gearshift lever inside the car. To do this, the upper handle is twisted.

Now you need to go under the car. Unscrew the driveshaft mount to the gearbox splines. First, it is necessary to mark the position of the disconnected elements, since there is a risk of incorrectly assembling the units in the future, which is why vibration and humming then appear. The terminals for turning on the reverse lamp are disconnected from the gearbox, and the speedometer drive cable is disconnected. Next, unscrew the two nuts securing the clutch cylinder and move the latter to the other side. Remove the nuts securing the gearbox to the bottom of the car.

The last step is to unscrew the nuts that secure the transmission to the engine. In this case, you will need the help of a partner who will hold and insure the heavy unit from falling. To make it easier to dismantle the gearbox and tear it off its mounts, it is recommended to set the shift lever to the position that corresponds to third gear to make work easier.

To avoid unnecessary replacements in the future, we recommend replacing the following list of parts in advance: the engine flywheel crown, the release bearing, the drive disk (and driven) and the bolts that secure the basket. Many experienced craftsmen replace the basket with the disk with a new assembly.

What to do if the clutch slips?

Many drivers change consumables too late. The same applies to the car's transmission. In this article we will look at a fairly common problem for many car enthusiasts and tell you what to do if the clutch slips? But before considering the problem, let’s figure out what kind of part it is, what it is intended for and how do the symptoms of its failure manifest themselves?

What actions should be taken if the clutch slips?

First, let's try to extend the life of the disk. To do this, you can adjust the pedal stroke, and accordingly change the position of the disk relative to the flywheel. For this purpose, a special adjustment device is provided in the car interior or under the hood. By tightening the corresponding nuts, we can raise the pedal, thereby pressing the clutch disc harder against the flywheel. This method is recommended only for those who have not yet worn out the friction linings on the working part of the part. Therefore, it is not recommended to use it in all cases.

Let's get started

So, we drive the car into the pit and block the rear wheels by holding the parking brake lever. We reset the box itself to “neutral”. Next, we tear off the wheel bolts and raise the front left part of the car. After removing the wheel, you will need to unscrew the bolts securing the lower ball joint. You should also remove the mass air flow sensor and the clamp securing its pipe. We also take out the air filter. Next, remove the clutch cable from the fork. To do this, loosen the two nuts that attach the cable to the bracket on the transmission. After this, remove the negative terminal from the battery and unscrew the starter mounting bolt. Nearby, unscrew the gearbox mounting bolt using a 19 mm wrench with an extension. Remove the upper starter mount and remove the chip from the speed sensor. We also unscrew the speedometer cable, which is installed in the box.

After this, paired with a lever, we remove the longitudinal stretcher. We unscrew the third bolt securing the gearbox. It is located in the CV joint area. We unscrew the bolts securing the reaction rods and take them out. Next, loosen the nut that is located on the gearbox control rod clamp. We also extract the traction outwards. Next, install a stop under the engine.

Next, unscrew the rear engine mount nuts. Then carefully remove the gearbox from the engine and lower it to the floor. The element will hang on the axle shaft. Now we have access to the clutch. We take out the basket along with the disk and perform troubleshooting.

Incomplete inclusion

A characteristic symptom is that the transmission is difficult to engage or does not engage at all. May be accompanied by a strong crunch even with the pedal fully depressed. There are several reasons for this failure:

- Deformation or damage to the driven disk.

- Worn clutch fork.

- Incorrectly adjusted cable drive.

- Worn diaphragm springs on the clutch disc.

- Insufficient pedal travel.

- Lack of lubrication in the bearing guide sleeve.

- Different adjustment of pressure plate levers.