Normal VAZ 2106 oil pressure in the system ensures sufficient lubrication of all parts of the engine. If it is low, an insufficient amount of substance reaches the rubbing parts. This leads to accelerated engine wear, increased fuel consumption and incorrect operation of the machine. Due to increased friction between the parts of the power unit, the temperature rises and more by-products are formed that clog the filters.

Low blood pressure cannot be ignored. This will lead to complete breakdown of the motor and the need for major repairs. It's faster, cheaper and safer to fix a problem when it occurs.

A special indicator indicates insufficient oil pressure in a VAZ engine. Sometimes this component breaks, and the car owner learns about the problem by other signs:

- motor overheating;

- low viscosity coefficient;

- clogging of the oil receiver;

- malfunction of the pressure reducing valve;

- increased wear of bearings;

- engine knocks, vibrations;

- the appearance of unpleasant odors.

The best way out of the situation is to contact specialists. They will accurately identify the cause of the problem and fix it. You can try to deal with the problem yourself, but such solutions always carry the risk of creating even greater damage.

When might the warning light come on?

The oil pressure in the engine can drop for various reasons, some of them are insignificant and do not cause harm to the engine, while others, on the contrary, can cause serious damage to the power plant, which can only be eliminated by carrying out a major overhaul.

Therefore, the lighting of a special warning lamp is a serious reason to start looking for the cause.

The oil pressure light can come on in a variety of situations, starting with the fact that it simply does not go out after starting the engine and glowing while driving.

This problem can appear both “hot” and “cold”, at medium loads and at idle, as well as after a planned replacement of the lubricant (especially when switching to a new brand of oil).

When the pressure warning light comes on, this is not a situation where “I’ll just get home and see.” When such a signal appears, measures should be taken immediately.

The first thing to do is to immediately turn off the engine and stop driving. And then look for the cause on the spot or organize delivery of the car to the repair site (by tug, tow truck).

Note that sometimes failures in the sensor occur, so as one of the first measures you should wait 3-5 minutes and start the engine again and let it run in different modes.

If the sensor is “silent”, you can try to continue driving, but it is better not to leave the problem unattended and, if possible, check the components of the lubrication system. If the lamp comes on when the engine is restarted, the car will have to be towed.

How does the oil sensor work and why can it fail?

Now let's consider the situation if you are on the road and the low pressure indicator has triggered.

The very first thing you need to do is stop the vehicle and turn off the engine. As soon as it cools down, you will have to check the lubricant level in the system. There is a special dipstick under the hood for this purpose. It is wiped dry and immersed in its original place. It is quite possible that the level will be below the minimum level. This means that somewhere there is a leak or depressurization of connections. You can set off again only after adding oil to the engine. If the lamp continues to light after starting and does not go out subsequently, it makes sense to think about towing the car to the nearest service station or to a trusted auto mechanic. The matter may turn out to be quite serious, so it is advisable to conduct the examination in a calm environment. Since we have already said that the causes of low pressure may be associated with a faulty sensor, it would be useful to understand the principle of operation of this device. There are certain contacts inside it. Until the ignition is turned on, there is no pressure in the system, so the contacts are closed. When you turn the key and turn on the ignition, but before the starter starts, the warning lamp should be on. If this does not happen, then there may be some kind of malfunction. Maybe the light bulb itself simply burned out, or maybe the contacts were broken or the sensor itself failed. As soon as we start the engine, the contacts open, leading to the light bulb going out.

Main causes of malfunction

Structurally, the lubrication system is quite simple, but its functioning can be affected by other engine elements. Therefore, there are quite a few reasons why the warning light comes on:

- Oil pressure sensor malfunction;

- Damage to the sensor-indicator light circuit;

- Exhaustion of lubricant life or its inadequacy;

- Low oil level;

- Clogged oil filter element, malfunction of its bypass valve;

- Clogged oil intake;

- Oil pump wear;

- Reducing valve jammed;

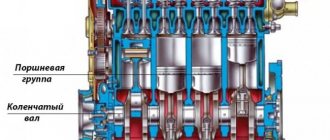

- Critical wear of engine components (crankshaft and timing gear);

- Penetration of other technical liquids into the pan.

Note that these are only the main and general causes of a drop in oil pressure, which are typical for any engine. But there are also reasons that occur only on certain car models.

How to identify and eliminate the causes of low lubricant pressure?

Low oil pressure in a car engine can significantly shorten its service life. And all due to insufficient mitigation of friction of moving elements. Therefore, at the first signals from the pressure gauge, you must try to eliminate the malfunction.

The most common reasons that lead to unpleasant consequences are:

- engine overheating;

- initially low oil level;

- low lubricant viscosity coefficient;

- clogging of the oil receiver;

- pressure reducing valve malfunction;

- extreme wear of crankshaft bearings.

Diagnostics should begin by checking the temperature in the engine. If it is increased, it means that the lubricant becomes very viscous. As a result, the sensor erroneously registers its low level. Owners of a VAZ 2106 car are well familiar with this problem.

If this is the cause of low pressure, you should pay attention to the following list of possible malfunctions that will need to be eliminated:

- leakage of coolant followed by the formation of an air lock;

- problems with the cooler switch on in the engine or with the fan itself;

- incorrect ignition adjustment;

- radiator clogged;

- increased formation of soot in the combustion chamber.

The latter was especially common in domestically produced cars, for example, in the VAZ 2106 model.

Low oxol levels in the crankcase drainage passages can occur due to severe wear on the piston rings or a leaking radiator. If you have, for example, a VAZ 2106, then the leak can be eliminated by simply replacing the pan gasket. And piston wear can be determined by black smoke coming out of the muffler. Its presence means the need to check the mechanisms on a compression meter and replace them with new ones.

Emergency measures

So, the oil pressure light on the dashboard came on while driving. As already noted, you should immediately stop and turn off the engine. Since while on the road there is no way to accurately determine the cause of the problem, the only diagnostic method is a visual inspection.

After stopping the engine:

- Carefully inspect the power plant for oil leaks - valve cover, pan, oil filter, end surfaces of the engine (near the auxiliary drive pulley and on the gearbox side);

- Check the condition of the circuit to the oil sensor, while monitoring (as far as possible) the integrity of the wire;

- During the time it takes for a visual inspection, the oil will drain into the pan, so we check its level with a dipstick.

Depending on the results of the inspection and level check, we take further actions. If a slight leak is detected, and the dipstick shows the amount of lubricant below o, you can continue moving to the repair site, but first replenish the oil loss and check whether the warning lamp lights up.

To top up, you should use the same lubricant that was filled in (it is not for nothing that it is recommended to always carry oil with you for topping up) or purchase a similar one. During the movement, you should stop periodically and replenish the level.

READ ON THE TOPIC: What oils should be poured into the engine.

We do the same in the case when no leaks are detected, but the level is below normal. We just add lubricant, make sure that the control light does not light up and continue on our way, periodically stopping and checking the dipstick.

If there are no leaks and the oil level is normal, it is possible that the pressure sensor is acting up. Restarting the engine after a short pause (the time it will take to inspect the engine and assess the amount of lubricant) will help verify this.

If the lamp lights up even when you restart it, it is better not to experiment, but to call for help to transport the car to the repair site.

It is strictly forbidden to operate the machine if the dipstick shows a level higher than normal or if there is a foamy whitish coating on it - emulsion (you can additionally check for the presence of emulsion on the oil filler cap).

This indicates that other technical fluids, such as antifreeze or fuel, are leaking into the pan. An excessive level of oil (liquid mixture) in the pan has a strong negative effect, as does its lack.

The problem is diagnosed by the non-characteristic color of engine oil and smoke from the exhaust pipe.

These are all the measures that can be taken in an emergency situation - when the lamp lights up while driving and there is no necessary equipment and tools for a more detailed search for the cause.

Important points

- all the recommendations mentioned above are valid for almost the entire family of classic VAZ cars - from VAZ 2105 to VAZ 2110;

- Completely draining the oil from VAZ engines, which was discussed above, is practically impossible. This is hampered by the very design of these motors, which has many holes, cavities, and channels. The old oil remains in all this. This problem can be partially solved by placing the machine on an inclined surface (or jacking up one or two wheels) to facilitate the flow of oil to the drain hole. But even such measures will not lead to complete cleaning of the engine from the so-called waste, so that for the next 20 thousand km the car will run on a mixture of new oil and waste;

- if to check the indicator in the car you need to install another, known-to-be-good sensor, but the required model is not at hand, then you should remember that the oil pressure sensor from the VAZ 2106 can be installed on other classic models of this family, in particular, on the VAZ 2107 and VAZ 2109. But it will not be possible to install sensors from these models on the VAZ 2106.

So, the car owner will have to solve the problem of the burning oil pressure indicator on VAZ cars by the method of elimination. Logic dictates that first you should check the most obvious options that do not require serious intervention in the design of the machine: check the oil, check the sensor itself, assess the condition of the oil filter. Well, if a solution has not been found, you can proceed to inspecting the electrical wiring and removing the oil pump.

Consequences of ignoring the problem

Stopping the engine when the pressure lamp lights up is a mandatory measure. Ignoring the signal can result in very serious problems:

- As a result of “oil starvation”, the contacting surfaces of components and mechanisms will begin to work “dry”, which will lead to their intense wear and high heating. If you take a crankshaft, the main and connecting rod bearings will begin to melt and “wrap” around the journals, which will lead to jamming of the crankshaft;

- Lack of lubrication will lead to intense wear of the camshaft “bed”;

- Wear products - small metal shavings - will spread through the channels of the lubrication system, which can lead to their clogging. Also, chips can cause jamming of the pressure relief valve and damage to the oil pump gears.

Elimination of such malfunctions is only possible through a major overhaul of the power plant.

The concept of compression, its measurements

There is no such characteristic among the technical data specified in the vehicle’s operating manual. There is a slightly different concept - compression ratio. There is no direct relationship between these two parameters; they are united by only one thing - in both cases we are talking about pressure.

- The compression ratio is a calculated constant value; it has no dimensional units. For the VAZ 2106 engine and its modifications it is 8.5. This figure is the result of dividing the total working volume of the cylinder by the volume of the combustion chamber. In simple words, the air-fuel mixture entering the cylinder space is compressed 8.5 times by the upward moving piston.

- Compression is a variable value; its value depends on the technical condition in which the engine is located. This parameter shows what pressure occurs in each individual cylinder when the crankshaft rotates using the starter. It is measured with a pressure gauge, which is screwed in instead of a spark plug, the unit of measurement is 1 kgf/cm2 or 1 Bar, which is almost the same thing (1 kgf/cm2 is equal to 0.98 Bar).

Compression is measured to determine the degree of wear of the cylinder-piston group. Its values were obtained experimentally, in practice. The measurement is performed as follows: all 4 spark plugs are unscrewed, and in their place, a pressure gauge with a check valve is screwed into each cylinder one by one, and by rotating the starter, the maximum pressure that can be pumped by each piston is determined. In the VAZ 2106 engine, the ideal figure is 13 kgf/cm2, but this is a rare case; such pressure is found on new, only run-in engines.

Looking for a fault

Until the cause of the oil pressure light coming on is eliminated, it is better not to operate the car. To solve the problem, you can contact a service center, or identify and fix the problem yourself, saving on service station services. Much depends on the make of the car.

If there are no visible causes of the problem - there are no leaks, and the level is normal, we carry out diagnostics.

Self-testing is carried out “from simple to complex.” The main working element of the system is the lubricant. Therefore, we check it first.

If the lubricant is not changed on time (every 8-10 thousand km), perhaps the oil has exhausted its resource and has become very liquid, which is why the oil pump is not able to pump it in the required quantity, creating the necessary pressure.

In cases where the lubricant has been changed relatively recently, make sure that the tolerance and specification of the engine oil that was filled in matches the car’s engine.

Next, we move on to the next stage of testing - measuring the pressure in the system.

Machine diagnostic procedure

There is a known homemade method that will help you find out if there are problems with blood pressure:

- Start the engine and warm up the car well (drive 5-6 km).

- Depress the brake and clutch at the same time.

- Engage the gear and gradually release the clutch (hold the brake).

- If the tachometer shows below 500 rpm and the lamp does not light up, the pressure is normal.

If there is a problem, you can look for the breakdown yourself. Then at the service center you will spend less time on diagnostics, pointing out to the mechanic the most likely cause of the malfunction. The check is carried out according to the following algorithm:

- Open the hood of the car and check for oil leaks. If they are, there is a leak in the system.

- Inspect the oil filter. If there are smudges, try tightening the part clockwise. Perhaps the problem will go away.

- Inspect the crankcase (located on the bottom) for leaks. If they are identified, you must urgently contact the service center, having first provided “first aid” - plug the gap using dry welding, fabric or a special rubber gasket.

You should start checking after the car has warmed up and stopped for ten minutes.

What pressure should be in the system?

The sensor serves only to determine the pressure drop, but it does not indicate the exact indicator of this parameter. Therefore, a conventional 10 bar dial pressure gauge is used for measurement.

For measurements, you can use any device, adapting it to the engine or using a pressure gauge specially designed for this.

To use a conventional pressure gauge, you will have to improve it a little so that it can be connected to the motor. To do this, you will need the pressure gauge itself, a piece of thick-walled rubber tube, clamps and a threaded fitting for the hole for installing the pressure sensor.

We connect all this into one structure, and securely clamp the joints of the tube with the pressure gauge and fitting with clamps.

With a special pressure gauge for measuring oil pressure on engines, such a procedure is not required, since it is already equipped with a fitting and adapters for connecting to the engine.

Measurement is performed using the following technology:

- Disconnect the wire and unscrew the pressure sensor;

- We screw the pressure gauge into the sensor seat and tighten it well (but do not overdo it, since the thread in the hole is aluminum and breaks easily);

- We briefly start the engine (a short period of engine operation will not cause any damage);

- We look at the device readings.

If the pressure gauge shows pressure above 1 Bar, the lubrication system is functioning normally and the cause should be sought in the sensor or wiring.

The thermostat is the boss

Not a very pleasant breakdown, especially if it happens on the road. And if the engine is boiling due to a faulty thermostat, then there is only one way out - to change this element of the system. True, at first you can slightly “reanimate” him; for this you need to apply several sharp blows to his body with something heavy.

But such a “rough” solution may not always help. There will be much more trouble if liquid leaks out of the tank. The thermostat allows the system to switch the circulation of liquid between two circles - large and small. These circles differ in that in the first one a radiator is connected to the cooling process. And if it does not connect, then the liquid boils.

On VAZ 2107 cars, and indeed on all cars of this manufacturer, the thermostat fails in such a way that the antifreeze continues to circulate in a small circle. And even if you turn on the radiator fan with the button, this will not save the situation.

The car still drives poorly, the antifreeze boils, and you won’t be able to immediately understand why this is happening. And the answer is very simple - to increase the life of the thermostat, do not pour running water into the system. Use any antifreeze, in particular antifreeze. The water leaves a large amount of scale, which interferes with the movement of the thermostat element.

Checking the lubrication system components

If replacing the sensor and ringing the wiring did not bring any results, and the lamp still works, you should look for the cause further.

The next steps are:

- REPLACE THE OIL FILTER. This element is equipped with a bypass valve and if this valve does not work, then after starting the engine the system needs time to pump oil (this problem manifests itself in the form of a constantly burning light after starting). Another problem associated with the filter is its severe clogging, which is why it creates a strong obstacle to the movement of oil, preventing it from rising to the cylinder head where the sensor is installed;

- REMOVE THE PAN AND INSPECTION THE OIL PICKUP. Over time, the intake mesh becomes clogged with various deposits (this is especially true with frequent changes of oil brands and the use of additives). Due to deposits, it is difficult for the pump to “pull” the required amount of working fluid from the pan, so the pressure will be insufficient;

- CHECKING THE OIL PUMP. Backlash and wear marks on the gears will indicate severe wear. Due to the gaps, the unit is simply not able to pump oil and a loss of pressure occurs;

- WE ASSESS THE CONDITION OF THE REDUCTION VALVE. This element is designed to relieve pressure when a certain value is exceeded. But if the valve gets stuck in the open position, it will leak oil, preventing the pump from pumping up the required pressure.

These indicate the causes of pressure drop associated with the lubrication system.

Radiator fan

As you understand, the engine operates in a variety of modes. Sometimes he pulls the car along the highway at high speed, and sometimes through a traffic jam. And in the latter case, the speed is lower than that of pedestrians.

What's the difference? And the fact is that the radiator on a VAZ 2107 car is blown in these two modes with different amounts of air. In the first case, the flow is enough to maintain the temperature balance, but in the second it is not enough

And it doesn’t matter whether it’s an injector or a carburetor, the radiator must be blown normally

You have to create an artificial flow using an electric fan. In earlier VAZ 2107 cars (and indeed in the “classic” series) impellers were used that were mounted on the axis of the liquid pump. With the help of these mechanisms, the radiator is subjected to airflow. An electric fan may not perform its functions for the following reasons:

- The impeller has been destroyed.

- The sensor responsible for turning on the fan has failed.

- The motor winding burned out.

- Destruction of electrical wiring (breakage, contact failure, oxidation).

- Failure of a relay, fuse, button (if these elements are present in the design).

The last point applies mostly to VAZ 2107 cars, in which the fan switching circuit has been modified by installing a button in the passenger compartment. With its help, the driver can forcefully start the fan.

If it doesn’t start even from the button, you need to find out the reasons. To do this, connect the wires from the fan to the battery terminals. If it doesn’t work, the motor winding is damaged.

Please note: for better airflow, use a diffuser! This is a small plastic element that will force more air to flow to the radiator. And if there are no breakdowns in the fan, then be sure to install a diffuser, the radiator will thank you

Components affecting the operation of the lubrication system

But as already noted, other components and mechanisms can affect the functioning of this system.

Such mechanisms primarily include the KShM. If the engine has worked a significant life without major repairs, then wear of the elements of this mechanism will negatively affect the operation of the lubrication system as a whole.

Due to the large gaps between the crankshaft bearings and journals, there is a strong loss of oil pressure, which is why the lamp comes on. In this case, the problem can only be solved by a major overhaul.

The lubricant itself can aggravate the problem of component wear. The exhaustion of the resource or the mismatch of the oil brand can cause it to become very liquid after heating, which is why the pump cannot create pressure. You should pay attention to the condition of the oil if the lamp constantly comes on after the engine warms up.

Filling with thicker oil allows you to delay the overhaul or eliminate the “hot” signal, but this measure is temporary - eventually the engine will have to be repaired.

Knock sensor

To reduce detonation in the engine, DD is used. It is necessary for more accurate setting of the ignition timing by adjusting the ignition timing.

Symptoms of a problem

- If it breaks down, the ECU will not be able to adjust the ignition angle, which will negatively affect power;

- The sound of the engine changes, the knocking of fingers appears under load;

- In the event of a breakdown, the engine malfunction indicator will light up on the instrument panel;

It fails extremely rarely, but if it shows too distorted data after engine repair, it is possible that the repair was done incorrectly.

Third-party liquids in the pan

As for the increased oil level, it is not necessary to check the lubrication system, since the reason for the lamp to operate is the ingress of technical fluids into the pan. And here it is necessary to establish where they are leaking from and eliminate the damage.

If instead of oil an emulsion of asphalt or another color is found, this is an antifreeze leak. Coolant usually ends up in the sump due to a damaged head gasket, which will have to be replaced to fix the problem.

But if there is no emulsion, but the level is higher than normal, and the oil itself is very liquid, fuel penetrates into the pan. The main reasons for this phenomenon are:

- Occurrence of rings;

- Misfires;

- CPG wear.

As a result of such malfunctions, the fuel supplied to the combustion chambers does not burn, but flows down the cylinder walls into the sump.

More - no less

Many people mistakenly think that the maximum mark on the dipstick is just a warning mark, and that filling a little more won’t cause anything terrible.

If you overfill the oil, excess pressure is created in the oil lines, which helps squeeze out the oil through all possible gaskets, pipes, but most often the oil seals.

Plus, a paradox appears - the more oil, the worse it lubricates and leads to accelerated wear of parts. But the fact is that if there is an excess of oil, it begins to foam intensely and it loses its lubricating properties. And this already leads to a major overhaul of the engine, which will cost a tidy sum.

Another factor is winter.

The season of operation of the car can also affect the lubrication system. In winter, in severe frosts, the oil can harden so much that the first time after starting the engine the pump is not able to pump it in the required quantity. Preheating the pan before starting the engine can eliminate this problem.

Another reason for the pressure lamp to light up after starting the engine in winter is condensation. Due to temperature changes, moisture accumulates inside the engine, which then settles and freezes on internal surfaces, including the oil intake screen and oil channels. In this case, letting the car sit in a heated place will help - after the engine heats up, the condensate will melt and drain into the pan.

Note that the above describes the general causes of a drop in engine oil pressure, which are typical for any car - VAZ-2109, 2101, Priora, Niva, 2110, 2114, etc.

Oil quality

Quite often in VAZ 2106 models, problems with pressure arise due to the use of insufficiently high-quality chemistry. For this reason, experts recommend choosing products only from proven and responsible manufacturers of motor lubricants. In particular, for VAZ 2106 cars, experts advise using oil of the 0W, 5W series in winter and 20W, 30W in the warm season. When using such products, you don’t have to rack your brains about where the oil “disappeared.”