The canister purge valve (CPV) is part of the EVAP system. The EVAP system prevents fuel vapor from escaping from the fuel tank into the atmosphere. It traps gasoline vapors and temporarily stores them in a coal canister - an adsorber.

How to check the adsorber

Many car owners may be interested in the question of how to check the adsorber and its purge valve when the diagnostics showed its malfunction (an absorber error popped up). It is quite possible to make such a diagnosis in a garage, however, for this it will be necessary to dismantle either the entire adsorber or just its valve. And to carry out such a test, you will need metalworking tools, a multifunctional multimeter (to measure the insulation value and the “continuity” of the wires), a pump, and a 12 V power source (or a similar battery).

And now in more detail

How can I check the functionality of this device? An important element in the absorber is the valve. To understand the function, let's look at how the adsorber works. When the car is parked, a large amount of gasoline vapor can accumulate in its tank. Some of the vapor is caught by the recuperator, and the rest settles back into the tank. The part that was caught is sent to the adsorber. When the engine is running, the absorber valve closes and interrupts the access of vapors, now they are sent into the combustion chamber. Why is this necessary? When you start the car, our device prevents vapors from entering the exhaust manifold, thereby reducing the amount of harmful substances in the gas.

What is an adsorber for?

Before moving on to the question of how to check the operation of the adsorber, let us briefly describe the operation of the gasoline vapor recovery system (in English called Evaporative Emission Control - EVAP). This will give a clearer picture of the functions of both the adsorber and its valve. So, as the name implies, the EVAP system is designed to capture gasoline vapors and prevent them from entering the surrounding air unburned. Vapors are formed in the fuel tank when gasoline is heated (most often during long-term parking under the scorching sun in the warm season) or when atmospheric pressure decreases (very rarely).

The task of the fuel vapor recovery system is to return these same vapors to the engine intake manifold and burn them along with the air-fuel mixture. As a rule, such a system is installed on all modern gasoline engines in accordance with the Euro-3 environmental standard (adopted by the European Union in 1999).

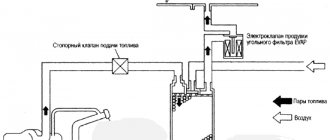

The EVAP system consists of the following elements:

- carbon adsorber;

- adsorber purge solenoid valve;

- connecting pipelines.

There are also additional wiring harnesses leading from the electronic engine control unit (ECU) to the said valve. With their help, this device is controlled. As for the adsorber, it has three external connections:

- with the fuel tank (through this connection, the generated gasoline vapors directly enter the adsorber);

- with an intake manifold (it is used to purge the adsorber);

- with atmospheric air through the fuel filter or a separate valve at its inlet (provides the pressure drop necessary to purge the adsorber).

The adsorber is a kind of barrel (or similar vessel) that is filled with ground coal, in which gasoline vapors actually condense, after which they are sent to the car's power system as a result of purging. Long and proper operation of the adsorber is possible only with its regular and sufficient ventilation. Accordingly, checking the car adsorber is to check its integrity (since the body may rust) and the ability to condense gasoline vapors. Even older adsorbers pass the carbon contained in them through their system, which clogs both the system and their purge valve.

Checking the adsorber valve with a multimeter

The solenoid valve for purge the adsorber directly purges the system from gasoline vapors present in it. This is done by opening it upon command from the ECU, that is, the valve is an actuator. It is located in the pipeline between the adsorber and the intake manifold.

As for checking the adsorber valve, firstly, it is checked that it is not clogged with coal dust or other debris that can get into the fuel system when it is depressurized from the outside, as well as with coal from the adsorber. And secondly, its functionality is checked, that is, the ability to open and close on a command coming from the electronic engine control unit. Moreover, not only the presence of the commands themselves is checked, but also their meaning, which is expressed in the time during which the valve must be open or closed.

Interestingly, in engines equipped with a turbocharger, a vacuum is not created in the intake manifold. Therefore, for the system to operate, it is provided with another two-way valve that operates and directs fuel vapor into the intake manifold (if there is no boost pressure) or to the compressor inlet (if there is boost pressure).

Please note that the canister solenoid valve is controlled by an electronic unit based on a large amount of information from temperature sensors, mass air flow, crankshaft position and others. In fact, the algorithms by which the corresponding programs are built are quite complex. It is important to know that the greater the engine air consumption, the longer the duration of the control pulses from the ECU to the valve and the stronger the canister purge.

Typical air leaks

Of course, each case is individual, but leakage usually occurs in the following places in the engine:

In the case of cars equipped with carburetor engines, finding the choke is much easier. There aren't a lot of electronics or sensors, and extra air usually enters the engine through the brake booster or one of the elements in the carburetor itself.

Air leak in carburetor:

External signs of malfunction

Before checking the adsorber purge valve, as well as the adsorber itself, it will certainly be useful to find out what external signs accompany this fact. There are a number of indirect signs, which, however, can be caused by other reasons. However, when identifying them, it makes sense to also check the operation of the EVAP system, as well as its constituent elements.

- Unstable engine operation at idle speed (the speed “floats” to the point where the car starts and stalls, because it runs on a lean air-fuel mixture).

- A slight increase in fuel consumption, especially when the engine is running “hot”, that is, in a warm state and/or in hot summer weather.

- It is difficult to start a car engine when it is hot; it is usually impossible to start it the first time. And at the same time, the starter and other elements associated with starting are in working condition.

- When the engine operates at low speeds, the loss of power is very noticeable. And at higher speeds there is also a decrease in torque.

In some cases, it is noted that if the normal operation of the gasoline vapor recovery system is disrupted, the smell of fuel may enter the cabin. This is especially true when the front windows are open and/or when the car is parked for a long time in a closed box or garage with poor ventilation. Also, poor operation of the system is caused by depressurization of the fuel system, the appearance of small cracks in fuel lines, plugs, and so on.

Operating principle

So, what does the process of purging the adsorber in a VAZ 2114 look like? When the car is parked, gasoline from the tank evaporates and first enters the separator. There, some of the vapor turns into liquid and flows back. The remaining gaseous fuel, moving along the line, enters a sealed adsorber. Activated carbon absorbs vapors and holds them until the engine starts.

How to check the adsorber

Now let’s move directly to the algorithm for checking the adsorber (its other name is the fuel vapor accumulator). The main task in this case is to determine how sealed its body is and whether it allows fuel vapors to escape into the atmosphere. So, the check must be performed according to the following algorithm:

- Disconnect the negative terminal from the vehicle battery.

- First, disconnect all hoses and contacts going to it from the adsorber, and then remove the fuel vapor accumulator directly. This procedure will look different for different machines, depending on the location of the assembly, as well as the mounting means with which it was secured.

- It is necessary to plug (seal) the two fittings tightly. The first one goes directly to atmospheric air, the second one goes to the solenoid purge valve.

- After this, use a compressor or pump to apply a slight air pressure to the fitting going to the fuel tank. Don't overdo it with pressure! A working adsorber should not leak from the housing, that is, be sealed. If such leaks are detected, then most likely the unit needs to be replaced, since it is not always possible to repair it. In particular, this is especially true if the adsorber is made of plastic.

What is the threat?

Of course, you can continue to travel on roads with such a fault. The car will start to drive, but it will still have floating idle. In addition, if the malfunction of the adsorber is not corrected in time, then at the nearest gas station, when trying to fill the tank with gasoline, the cap can literally “shoot” from the gases that are formed, which are not removed in time. So it would be best to replace the defective part with a new one.

In addition, if the gas tank is poorly ventilated, this can lead to a vacuum. And as a result - deformation and damage to such an important spare part as the fuel pump. And an unventilated adsorber can also cause fuel accumulation in the intake manifold. And this can already affect the stability of the entire engine.

How to check the adsorber valve

If after checking it turns out that the adsorber is in more or less working condition, then it makes sense to check its purge solenoid valve. It’s worth mentioning right away that for some machines, due to their design, some actions will differ, some of them will be present or absent, but in general the verification logic will always remain the same. So, to check the adsorber valve, you must perform the following steps:

- Visually check the integrity of the rubber hoses included in the fuel vapor recovery system, in particular those directly approaching the valve. They must be intact and ensure the tightness of the system.

- Disconnect the negative terminal from the battery. This is done to prevent false alarms of the system diagnostics and to enter information about the corresponding errors into the electronic control unit.

- Remove the absorber (usually it is located on the right side of the engine, in the area where the air system elements are installed, in particular the air filter).

- Turn off the electrical power to the valve itself. This is done by removing the electrical connector (the so-called “chip”) from it.

- Disconnect the inlet and outlet air hoses from the valve.

- Using a pump or medical bulb, you must try to blow air into the system through the valve (into the holes for the hoses). It is important to ensure the tightness of the air supply. To do this, you can use clamps or a thick rubber tube.

- If everything is in order with the valve, it will be closed and air will not be blown through. Otherwise, its mechanical part will fail. You can try to restore it, but this is not always possible.

- It is necessary to supply electric current from the power supply or battery using wires to the valve contacts. At the moment the circuit closes, you should hear a characteristic click, which signals that the valve has actuated and opened. If this does not happen, then perhaps instead of a mechanical failure there is an electrical failure, in particular, its electromagnetic coil has burned out.

- With the valve connected to an electric current source, you must try to blow air into it in the manner described above. If it is working properly, and therefore open, then this should work without problems. If it is not possible to pump through air, then the valve has failed.

- Next, you need to reset the power from the valve, and there will be a click again, indicating that the valve has closed. If this happens, it means the valve is working.

You can also check the adsorber valve using a multifunctional multimeter, switched to ohmmeter mode - a device for measuring the insulation resistance value of the electromagnetic winding of the valve. The probes of the device must be placed at the coil terminals (the places where the wires coming from the electronic control unit are connected to it; there are various design solutions), and the insulation resistance between them must be checked. For a normal, serviceable valve, this value should be within approximately 10...30 Ohms or differ slightly from this range.

If the resistance value is small, it means that there is a breakdown of the electromagnetic coil (short interturn circuit). If the resistance value is very large (calculated in kilo- and even mega-ohms), then the electromagnetic coil breaks. In both cases, the coil, and therefore the valve, will be unsuitable for use. If it is sealed into the housing, then the only way out of the situation will be to completely replace the valve with a new one.

Error P0441

Owners of Lada Kalina often note that during the operation of the car, error P0441 appears, indicating that the gasoline vapor purge system is not operating correctly (the air flow differs from the norm). The cause of this malfunction may be:

What should not be immediately considered is the line from the gas tank to the adsorber; here, a breakdown does not in any way affect the readings of the computer or diagnostic scanner. Still, most often Evap-Solenoid fails; this is a characteristic “disease” on Kalina.

If the EVAP valve stops functioning normally, it is not at all necessary that the engine will lose power, the fuel pump will fail, and so on. Mainly due to problems with the control gear, exhaust toxicity increases, and the Check Engine on the dashboard periodically lights up. There are car owners who do not pay attention to the diagnostic warning light, continuing to operate the car, but do not experience any great inconvenience. And most often in such a case, gasoline consumption does not exceed the norm, the engine starts normally, and no serious problems occur in the fuel system.

Source

How to repair the adsorber and valve

It’s worth noting right away that in most cases both the adsorber and the valve cannot be repaired; accordingly, they need to be replaced with similar new components. However, as for the adsorber, in some cases, over time, the foam in its body rots, which is why the carbon contained in it clogs the pipelines and the solenoid valve of the EVAP system.

Rotting of foam rubber occurs for banal reasons - from old age, constant temperature changes, exposure to moisture. You can try to replace the foam separator of the adsorber. However, this cannot be done with all units; some of them are non-separable.

If the adsorber body is rusted or rotten (usually also due to old age, temperature changes, constant exposure to moisture), then you can try to restore it, but it is better not to tempt fate and replace it with a new one.

Checking the valve using a homemade tester

Similar reasoning is valid for the solenoid valve of the gasoline vapor recovery system. Most of these units are non-separable. That is, the electromagnetic coil is sealed into its body, and if it fails (insulation breakdown or winding break), it will not be possible to replace it with a new one.

This is exactly the situation with the return spring. If it has weakened over time, you can try to replace it with a new one, but this is not always possible. But despite this, it is still better to perform a detailed diagnosis of the adsorber and its valve in order to avoid expensive purchases and repairs.

Some car owners do not want to pay attention to the repair and restoration of the gasoline vapor recovery system, and simply “turn off” it. However, this approach is not rational. Firstly, this really affects the environment, and this is especially noticeable in large cities, which are not known for their clean environment anyway. Secondly, if the EVAP system does not work correctly or does not function at all, then under pressure gasoline vapors will periodically escape from under the gas tank cap. And this will happen as often as the temperature in the gas tank increases. This situation is dangerous for several reasons.

Firstly, the tightness of the tank cap is broken, the seal of which is broken over time, and the car owner will probably have to periodically buy a new cap. Secondly, gasoline vapors not only have an unpleasant odor, but are also harmful to the human body. And this is dangerous provided that the car is parked in an enclosed area with poor ventilation. And thirdly, fuel vapors are simply explosive, and if they come out of the gas tank while there is a source of open fire next to the car, a fire hazard will arise with very dire consequences. Therefore, there is no need to “turn off” the fuel vapor recovery system; instead, it is better to keep it in working order and monitor the adsorber and its valve.

Conclusion

Checking the adsorber, as well as its electromagnetic purge valve, is not very difficult even for novice car owners. The main thing is to know where these components are located in a particular car, as well as how they are connected. As practice shows, if one or the other unit fails, they cannot be repaired, so they need to be replaced with new ones.

As for the opinion that the fuel vapor recovery system needs to be turned off, it can be attributed to misconceptions. The EVAP system must work normally and ensure not only environmental friendliness, but also safe operation of the vehicle in various conditions.

Source

How to make a smoke generator to check air leaks with your own hands

In principle, the matter is not tricky. All you need to do is have a pack of cigarettes, a sealed food container, a couple of hoses on hand, and your homemade smoke generator is ready. This device can even be used for professional car diagnostics.

We cut two holes in the container and hermetically insert two hoses into them. We connect a car compressor or any other to one of the bottoms. And insert a cigarette into another hose from inside the container and connect it to the intake manifold receiver. Close the sealed lid. The smoke from the smoke generator will indicate intake leaks on the car.

Thus, at home you can determine air leaks with your own hands.

Such a device for car diagnostics will also cost money. You need to buy a container, hoses, clamps, and a compressor for inflating tires. All this will cost a pretty penny and using this method of searching for air leaks is a last resort.

If possible, to check it, you should go to specialists who have a professional device. By paying about 300 rubles, you will find out where there is no leak on your car and fix it right away.

Malfunctions in the fuel vapor recovery system Lada Kalina

Since the solenoid valve itself is not a complex device, it has few malfunctions as such - it may not open or close when necessary, or may freeze in a certain position. But the culprit of the breakdown may not only be Evap-Solenoid; the gasoline vapor recovery system does not work correctly for other reasons:

- connecting pipes are pinched or clogged;

- normal vacuum is not created in the system;

- due to an open circuit, there is no voltage on the valve;

- the carbon filter is completely clogged (which is rare);

- The control unit malfunctions.