Where is

The VAZ 2110 starter is located on the gearbox housing and is mounted on two studs. It is easier to see the starter in detail on 8-valve engines, since there is more free space in the engine compartment with such an engine. In a 16-valve engine, to see the starter, you need to remove the air filter housing.

Instructions for repairing and replacing the device

Replacing a VAZ 2110 starter and repairing it looks like this:

- Disconnect the battery and disconnect the wire plug from the relay. Dismantle the wire itself, which o.

- The starter mechanism should be disconnected from the engine; to do this, unscrew the nuts that secure it.

- If you are making a replacement, then at this stage the device can be dismantled and replaced with a new one. If you decide to repair, then move on.

- On the relay itself, unscrew the nut, and then disconnect the traction element from the screw. The relay is removed; to do this, you also need to unscrew the two clamps.

- Then the anchor is dismantled from the seat; to do this, the element should be slightly lifted up.

- Remove the pins, and then remove the starter cover. The cover is dismantled first with the drive and gear element, and then with the brush assembly and their retainer, which is located next to the commutator.

- Next, the gear is removed from the anchor shaft, and the anchor itself is then removed. Having done this, you can remove the gears from the gearbox. If they show signs of damage or defects, the gears should be replaced.

- The gear component is removed from the cover. Check the quality of the seal and replace it if necessary.

- Using a mandrel, it is necessary to dismantle the restrictive ring; it is located directly on the locking ring, after which the drive and other elements, including supports, levers and washers, are dismantled. Each of the elements, if necessary, must be replaced.

- After dismantling the brushes, you need to check them. If signs of wear are visible, the brushes are replaced. All failed components are replaced, and the starter is reassembled in the reverse order.

Photo gallery “Do-it-yourself device repair”

1. Removing the mechanism cover

2. Removing the gearbox from the housing

3. New and old brushes

Loading...

Starter relay (retractor)

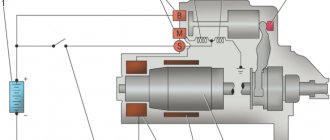

The starter retractor relay is located on the starter itself and serves to move the bendix to the flywheel, and then engage with it. This relay often fails due to poor workmanship. It is quite easy to understand that the solenoid relay has failed; with such a breakdown, the starter will spin at idle, but the engine will not rotate, since the moving part of the drive (bendix) will not engage with the flywheel.

Diagnostics

To check the functionality of the starter removed from the vehicle, use a charged battery. The ground is connected to the body. The positive wire is used to find a breakdown. If the plus is connected to the corresponding contact on the solenoid relay, it will work and extend the bendix, provided that it is working properly. If the relay does not work, then it is recommended to replace it or try to repair the starter yourself. Whether it’s a VAZ or a foreign car, it doesn’t matter - the unit is designed the same on all cars. But sometimes repair is impossible - modern relays are made non-separable. If the positive wire is connected to the contact after the relay, the starter should start. If nothing happens, you need to disassemble the assembly and look for a fault inside it.

Possible starter failures

There can be a large number of starter breakdowns, but most often they are all of the same type. Below are all the most common starter failures.

Brush wear

Starter brushes are a copper-graphite part that conducts electric current. The brushes are in direct contact with the starter armature and rub against its commutator, conducting electric current. During long-term use, brushes become unusable due to friction and must be replaced. This breakdown is not expensive or complicated; you just need to remove the starter and replace the brushes.

Bendix wedge

The Bendix is directly connected to the flywheel and quite often, wear appears inside it or on its gears due to high load, which makes it impossible to start the car from the starter. By design, Bendix is an overrunning clutch that rotates freely in one direction and is locked when rotating in the other direction. This part is sold separately and can be replaced as soon as possible.

Gearbox failure

The VAZ 2110 starter is geared. This modification allows you to reduce the load on the battery and rotate the engine crankshaft much easier and faster due to the additional ratios. Quite often, wear appears on the gears, which can lead to jamming or even breakdown of the entire gearbox.

Winding break

Since large currents flow in the starter, the winding in it is quite powerful and can withstand large currents, but sometimes a large cross-section of wires is not able to preserve the winding and it burns out, rendering the starter unusable. Such a breakdown can be repaired by replacing the rotor.

Solenoid relay

The retractor is an electromagnetic part that is retracted under the action of an electromagnetic force, driving the bendix inward and engaging it with the flywheel. Inside the relay structure there is a regular coil, which quite often burns out and damages the starter.

Almost all starter failures can be repaired by replacing the broken part with a new one.

Node malfunctions

The most common starter breakdowns are divided into several types. These include:

- Damage to the electrical circuit. A sign of such problems is slow rotation or complete absence of it at the crankshaft when starting the internal combustion engine. The reasons for this phenomenon may be a discharge of the battery, rupture of the contacts of the ignition device, unreliable fixation, wear of the wires, or violation of the integrity of the wiring suitable for the relay contact group. If, when starting the internal combustion engine, the armature does not respond and the relay does not operate, then the cause of the failure is most likely due to a break in the solenoid relay wire. In the absence of the described “symptoms”, it is necessary to dismantle, check the plates for short circuits, and the presence of traces of “burning” in the collector system.

- Worn starter brushes. The presence of such problems may be indicated by difficulty starting the car, but not always. The reason for this phenomenon may be “hidden” in a battery failure. Complete wear of the brushes leads to the spring “resting” against the brush holder (contact is ensured only due to its mass). This can be easily checked by changing the position of the starter. The reason for premature wear is the misalignment of the brushes during the operation of the starter.

- Broken traction relay. This is indicated by a failure of the internal combustion engine, since it will not be possible to start the engine without a working relay. The “symptoms” of a malfunction of this starter element include its rapid rotation, even after starting the internal combustion engine, idling movement (without contact with the flywheel of the engine, which does not start), and a click after turning the key in the ignition device. It may not exist if there is a break in the coil, the armature is jammed, or there is no power for some reason.

- Lack of starter rotation with a characteristic “buzzing” sound. This phenomenon indicates the occurrence of a short circuit in the electrical circuit, in which power is supplied to the brushes of the electric motor. However, it is in working condition. In such a situation, the holding coil often does not work and the bendix does not move. Its gear cannot engage the flywheel gear, and the electric motor runs in idle mode. The reason may be that the force of the retracting element “enters” the bendix through a lever made of plastic (has the shape of a grip). If the movement resistance of the bendix is high, then the plastic elements break down. As a result, it is not moved to the working position and the starter rotates, but does not transmit torque to the flywheel. Another reason for the failure of the rotor can be severe wear of the teeth, which are located on the rotor shaft of the electric motor. Do not forget that complete destruction of the mentioned teeth can also cause failure. This type of malfunction is related to the breakdown of the motor and is not related to the functioning of the drive. The presence of such a breakdown is indicated by the activation of all starter mechanisms, that is, the rotation of the electric motor and the transition of the bendix to the working position. It can be locked by turning the key in the ignition.

Many car enthusiasts complain that the battery discharges quickly and cannot activate the starter. You can read about the reasons for battery discharge here:

The main malfunctions of the unit include: the appearance of oxide on the wires and terminals, failure of the traction relay and traction winding, wear of the brushes, breakage of the armature

The listed faults can cause more serious problems if they are not corrected in time. Ignoring problems will most likely lead to vehicle failure at the most inopportune moment. The best solution is to contact a specialized service station when the first signs of the listed problems appear.

The following material will help you figure out why the starter does not turn in a VAZ 2110 car:

The starter doesn't turn over

There are many reasons why the starter does not work, but first of all you need to check the most common reasons why the engine will not start.

Checking contacts on the battery

Often the reason when the starter does not turn is due to loose terminals on the battery or their oxidation. It is enough just to clean the oxidized terminals from chemical reactions and tighten them with a force that will ensure reliable contact.

Battery discharge

Quite often, especially in winter, after a period of inactivity, the car’s battery may discharge, and thickened oil during parking will not allow the weak battery to rotate the crankshaft with the starter. You can check the battery with a regular multimeter; in winter its voltage should not be less than 12V, in summer not less than 11V. This voltage is not an indicator of the battery charge; at such values it is better to charge the battery.

Egnition lock

In some cases, the contact part of the ignition switch may fail. This is due to aging or poor quality parts. In this case, when turning the key, the contacts will not close to turn on the starter.

Winding break

If the winding on the stator or rotor of the starter breaks, the magnetic field that rotates the armature will not appear and the starter armature will not move.

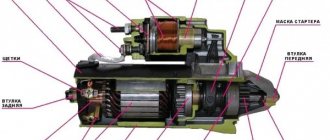

Other main components of the starter include:

- Drive shaft.

- Gear with inner ring.

- Microrelay anchor.

- Winding.

- Brush holder.

- Magnet.

- Shaft support and liner drive.

- Armature core and other parts.

They produce two types of starters: simple and geared. Experienced specialists advise using a gear option, because such a starter consumes less current and helps start the shaft even with minimal battery charge. As for a gearless starter, it directly sends forward motion to the gears, which increases current consumption. Devices of this type have certain advantages over a starter with a gearbox. They are simple in design and can be easily repaired.

Replacing the VAZ 2110 starter

To remove the starter, you need to prepare a tool that will be needed during the work process.

Required tool:

- Ratchet;

- Extension;

- Head 13mm;

- Open-end wrench 10mm;

- Open-end wrench 13mm;

Step-by-step instruction

- Disconnect the negative terminal from the battery

- We dismantle the air filter box together with the mass air flow sensor

- Unscrew the wires from the starter

- Unscrew the nuts securing the starter to the gearbox

- Removing the starter

DIY starter repair

Maintenance or repair of the starter must be carried out in accordance with certain algorithms, compliance with which requires certain experience and knowledge, as well as the use of the necessary tools. Troubleshooting always begins with disassembling the starter, after which diagnostics are carried out, and if problems are detected, repairs are carried out.

Tools and Supplies

To troubleshoot, you need to prepare the following tools:

- Socket heads for 13 and 15.

- Extension.

- Handle equipped with a ratchet.

- Ohmmeter.

- A special analyzer equipped with a light bulb.

- Phillips and flathead screwdrivers.