The inability of VAZ engineers to make a normal manual gearbox for the second decade now has forced management to look for other possible solutions to this problem.

Partners in the Renault-Nissan alliance came to the rescue with their Renault mechanics. This box is designed to relieve car owners from noise and howling while driving, which was caused by the old VAZ box.

At the moment, the French gearbox is paired with a 1.6 liter 106 hp engine. 21129 depending on the configuration. The possibility of installing it in tandem with a Nissan 110 hp engine cannot be ruled out. But whether the JH3 can withstand the high torque of the 21179 1.8L engine is a questionable question.

Options

According to the price lists with prices and configurations, the 5-speed manual Renault Arcana JR5 is combined only with the base 1.6 liter engine and front-wheel drive.

The all-wheel drive version of the 1.6 crossover is equipped with a 6-speed manual transmission TL8.

For the top 1.3 liter turbo, the CVT X-Tronic variator is exclusively designed. Some potential buyers see this as a drawback, believing that a version with a 150-horsepower engine and a stick would also be popular.

Inspection and subsequent repair of the synchronizer

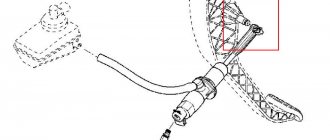

Removing the synchronizer involves removing the gearbox itself. This is hard work and quite dirty, so be prepared with gloves and rags. Since you have to remove the unit, it is worth carrying out cleaning work. Here's how to remove the gearbox synchronizer:

- Remove the gearbox;

- Remove the clutch cable bracket (by unscrewing the bolts and removing the cover);

- Unscrew the fork mounting bolt;

- Move the synchronizer clutch down;

- Unscrew the nuts securing the primary and secondary shafts;

- Lift the gear from the transmission, the fork and remove the synchronizer.

Please note that the algorithm may differ slightly depending on which transmission model is installed in your vehicle. Here it is worth turning to the manuals and looking for information on thematic forums. This kind of work is easiest to do in pairs rather than alone. Once the gearbox has been removed and you have been able to remove the synchronizer, it is worth starting to inspect and service it. Here's what to do:

- Mark the position of the coupling with a marker or chalk relative to the hub, then carefully remove the coupling;

- Wash the removed parts in kerosene;

- Inspect the hub, coupling, splines. There should be no burrs or chips on the parts. Also pay attention to each of the crackers and springs;

- Replace defective parts with new ones. Individual synchronizer components are rarely on sale, but they can be found at disassemblers. Every part should be lubricated with engine oil;

- Assemble the synchronizer, taking into account the position of the mark. If everything matches, then the grooves on its coupling will immediately align with the grooves of the hub. It is better to insert crackers with balls using a screwdriver;

- Install the synchronizer and assemble the gearbox.

As you can see, the work is quite complicated - you need to remember the location of each element of the synchronizer, and to be sure, even mark it with chalk or a marker. Be extremely careful. Since restoring a worn synchronizer requires skill and special tools, we do not recommend trying to troubleshoot it yourself. As for the mechanism that is not too worn out, it only needs to replace individual components, clean and apply lubricant. Otherwise, it does not require specific maintenance. Many craftsmen classify this mechanism as conditionally unrepairable, advising immediate replacement if problems arise with the gearbox.

Mechanics Renault Arcana 1.6 l JR5

As a manual transmission, the Renault Arcana 1.6 with front-wheel drive has a JR5 gearbox with 5 gears, which was developed directly by Renault. In addition to the crossover, it is also installed on many other models of the Nissan, LADA and Renault brands.

Design

This model is a modernized version of its predecessor – JH3. According to the basic principles, they are very similar - a 2-shaft layout and the presence of synchronizers in all gears. The gearbox is combined with the main gear and differential.

However, there are significant differences:

- The clutch is hydraulically driven, whereas the JH3 had a cable clutch. At the same time, with hydraulics, the clutch engages noticeably softer.

- In the JR5, gears are engaged using 2 cables (flexible), unlike its predecessor, which uses a rigid rod. This solution reduced vibrations.

- The mechanics of the Renault Arcana JR5 are able to handle 200 Nm versus 160 Nm for the previous one.

The markings for this transmission are located on the bottom of the crankcase.

The body itself includes 3 elements:

- Gearbox housing;

- Clutch housing;

- Cover (rear) gearbox housing.

As already mentioned, the design uses a hydraulic clutch drive. In this case, the working cylinder and the clutch release bearing are actuated by one unit, which is fixed to the crankcase with 2 bolts.

An aluminum-based alloy is used to mold the crankcase of the Renault Arcana mechanics and the clutch housing, while the back cover is stamped from steel. Screws are used to secure the clutch housing to the transmission housing. During the assembly process, the joint between the crankcases is coated with a sealant with gasoline and oil resistant characteristics. The rear cover is secured to the gearbox housing using 3 bolts.

The input shaft is a block of drive gears that is in constant mesh with the driven gears at all forward speeds.

The shape of the gears depends on their type:

- Reverse gear – straight teeth;

- The forward drive is helical.

In this case, the gears of the 1st, 2nd, 3rd and 4th gears of the Renault Arcana mechanics work together with the input shaft, while the 5th speed gear rotates on the shaft (freely). The 5th gear synchronizer is located at the rear end of the input shaft. But the secondary shaft is made hollow inside to supply oil through it under the gears (driven).

On the shaft there are gears (driven) of 1st, 2nd, 3rd and 4th gears with synchronizers. But the V speed gear is on splines on the shaft.

The secondary shaft bearings are different, depending on their location:

- Ball - on the side of the lid.

- Roller – from the clutch housing side. Below it is an oil sump to ensure oil flow into the shaft.

Oil

Despite statements from the manufacturer, which claims that the transmission fluid is filled for its entire service life, its replacement is necessary. It is recommended to do this once every 60,000 km.

Resource

The company claims that the Renault Arcana MT resource is 250,000 km. However, if you properly operate the box and change the oil, it can travel more than 400,000 km.

Problems

As a rule, there are very few problems with manual transmissions. As for the complaints from drivers, they relate to not the most precise operation, vibration at idle and current seals.

Description

The gearbox is new. The gearbox on LADA LARGUS and X-Ray is a 5-speed component of the car, installed in the back of a van with an internal combustion engine. Designed for cars with 16 valve engines. This transmission element integrates and transmits the rotational torque generated by the internal combustion engine to the drive wheels. Its functioning affects the speed and direction of movement of vehicles. Also, the JR5-517 gearbox on a VAZ is a part that provides idle speed.

Specifications

- What cars it is installed on: Renault 8V, VAZ, Lada Largus and their modifications.

- For which engines is it suitable - K4M and K7M, with 16 valves.

- Number of steps – 5.

- The gears are forward and 1 reverse.

- Subordinate numbers (1,2,3,4,5 degrees): 4.928, 3.727, 2.048, 1.321 0.971, 0.738, 3.545.

- Capacity – 2.5 liters.

- Switching the clutch on/off using a working hydraulic cylinder.

- The maximum speed of the 1st stage on an incline and on a straight road is 60-80 km/h.

Design features

VAZ automatic and manual transmissions offered in the catalog of our online store are housings made of rolled aluminum with built-in parts:

- transmission mechanism;

- friction clutch;

- main gear gear.

The gearbox housing houses the primary drive gear assembly and the main gears. Also the secondary shaft with the main gears. For harmonious working interaction of both shafts, synchronization rings are installed on them. In the JR5-517 model, the pressure on the release bearing is transmitted using a hydraulic system, which includes two cylinders - the main and the working one. Speed control is standard - a pair of cables connected to the gear shift lever. Each cable has its own functionality. Let us add that this model has a synchronizer that ensures smooth gear shifting and reduces wear on elements and noise during operation. All speed synchronizers except the fifth one are located on the secondary shaft.

Mechanics Renault Arcana 1.6 l TL8

This is a 6-speed gearbox for the French crossover, which is paired with a 1.6-liter engine and all-wheel drive. Manual transmission6 Renault Arkana TL8 was developed on the basis of the TL4 model and was initially aimed at all-wheel drive vehicles of the Renault-Nissan Alliance.

Design

This is a modern transmission that implements the following principles:

- 2-shaft arrangement;

- Control by 2 flexible cables;

- Synchronizers at all speeds, including reverse;

- Hydraulic clutch drive.

Torque is transmitted to the rear wheels through a driveshaft that is connected through a gearbox. To enable all-wheel drive, a special button is provided in the crossover interior, which closes the electromagnetic clutch.

Oil

As with the previous transmission, oil changes are not provided for by the factory. However, service stations recommend replacing them every 60,000 km.

Resource

As practice shows, the mechanical life of the Renault Arcana 1.6 TL8 is not impressive and is at the 150,000 km mark. However, if you don’t take your crossover off-road and don’t skimp on maintenance, its service life will increase significantly.

Problems

Like the JR5 model, the TL8 manual transmission has no obvious weak points.

As for the most common malfunctions, there is an oil leak through the seals, as well as background noise. In general, the mechanics of Renault Arcana 1.6 - both JR5 and TL8 - perform well. They are quite enough to work in tandem with the 114-horsepower crossover engine.

Transmission oil Suprotek Atomium - a universal soldier in manual transmission

As discussed above, half of the problems with gearbox noise and hum are associated with low-quality transmission oil or insufficient filling. For vehicles with a manual transmission, it is recommended to use Suprotek Atomium transmission oil on a fully synthetic basis. This allows you to achieve stable operating properties throughout the entire service life. The peculiarity of this transmission oil is that it practically does not break down when heated, does not oxidize, does not burn at all and does not evaporate. In addition, the mineral impurities included in the composition absolutely do not enter into chemical reactions with wear products, fuel or other additives.

What's the result?

The design of the gearbox installed on the entire Lada Largus model range, regardless of modifications (JR5 or JH3, etc.), is quite modern and reliable. As a rule, these manual transmissions rarely fail.

If malfunctions and breakdowns of the manual transmission occur (gears fly out or do not shift, noise or crackling noise occurs, etc.), then comprehensive diagnostics should be carried out to identify malfunctions.

Repairs should also not be delayed, since the design of the box is complex; one malfunction can lead to another. It is recommended to immediately contact a service station, where experienced specialists will be able to quickly and efficiently eliminate existing problems.

Gearbox for Lada Vesta: types of manual transmission Lada Vesta, robotic gearbox Lada Vesta. Changing the oil in the Lada Vesta box.

Automatic transmission on the domestic GAZelle Next car: features of automatic transmission, advantages and disadvantages of automatic transmission.

Checking the oil in the Lada Granta gearbox: how to check the oil level in the Lada Granta automatic transmission, checking the oil in the Granta manual transmission. Adding oil, recommendations.

Russian cars with automatic transmission: automatic transmissions on models from the USSR, modern Russian cars with automatic transmission. Popular models, types and types of automatic transmissions.

Lada Vesta with an automatic transmission: what type of automatic transmission is on the Lada Vesta, pros and cons. Prospects for the appearance of an automatic transmission or a CVT on Vesta.

Automatic transmission for Renault Duster: Renault Duster automatic transmission and Duster with a robotic gearbox. Features of these types of automatic transmissions for Duster.

What's the result?

The design of the gearbox installed on the entire Lada Largus model range, regardless of modifications (JR5 or JH3, etc.), is quite modern and reliable. As a rule, these manual transmissions rarely fail.

If malfunctions and breakdowns of the manual transmission occur (gears fly out or do not shift, noise or crackling noise occurs, etc.), then comprehensive diagnostics should be carried out to identify malfunctions.

Repairs should also not be delayed, since the design of the box is complex; one malfunction can lead to another. It is recommended to immediately contact a service station, where experienced specialists will be able to quickly and efficiently eliminate existing problems.

Gearbox for Lada Vesta: types of manual transmission Lada Vesta, robotic gearbox Lada Vesta. Changing the oil in the Lada Vesta box.

Checking the oil in the Lada Granta gearbox: how to check the oil level in the Lada Granta automatic transmission, checking the oil in the Granta manual transmission. Adding oil, recommendations.

Automatic transmission on the domestic GAZelle Next car: features of automatic transmission, advantages and disadvantages of automatic transmission.

Automatic transmission for Renault Duster: Renault Duster automatic transmission and Duster with a robotic gearbox. Features of these types of automatic transmissions for Duster.

Russian cars with automatic transmission: automatic transmissions on models from the USSR, modern Russian cars with automatic transmission. Popular models, types and types of automatic transmissions.

Lada Vesta with an automatic transmission: what type of automatic transmission is on the Lada Vesta, pros and cons. Prospects for the appearance of an automatic transmission or a CVT on Vesta.

Purpose and device

The gearbox is designed for several tasks:

- torque changes,

- speed changes,

- correcting the direction of movement of the car,

- disconnecting the internal combustion engine and transmission and, on the contrary, connecting them (this need is relevant when changing gears, the need to obtain low “creeping” speeds, and short-term stopping of the vehicle),

- locking the torque converter (the function is valuable for reducing the loss of useful energy of the “automatic” when transmitting torque in a situation where the speed of the driven and driving turbines is equalized).

At the same time, some gearboxes are capable of solving all these problems, while others, such as a mechanical one, only do the basics - changing torque and speed. The design of the device depends on the type of gearbox.

The housing of the gearbox with “mechanics” combines shafts (2, 3 or more), a synchronizer, gears, a gear shift lever, wire rings, bearings, and oil seals.

The automatic transmission device (gearbox with “automatic”) is a unit that includes a torque converter, planetary gear, clutches, brake band, control unit (pump + oil sump + valve box).

Robotic gearboxes can be based on either mechanical solutions with an electric or hydraulic clutch and gear control system, or automatic gearboxes equipped with an electro-hydraulic clutch drive.

Let's look at the clutch, gears, shafts and synchronizers in more detail.

Clutch

Designed to transmit torque from the flywheel of the internal combustion engine crankshaft to the input shaft of the gearbox.

It is thanks to the presence of the clutch that the engine can be carefully disconnected from the transmission for a short period of time, and the transmission can be protected from overloads.

The standard clutch on most manual transmission vehicles includes the flywheel, pressure plate, driven plate, throwout bearing, drive, fork, and clutch switch.

One engine is connected to the wheels, the other to the internal combustion engine. The moment the driver releases the pedal, the discs are pressed against each other and begin to rotate together.

It is the classic clutch as such that is most often talked about when using a manual transmission, and when driving with an internal combustion engine on an automatic transmission they talk about a combined solution of the clutch and torque converter. Its immediate function is similar to that of a clutch. But the driver does not need to perform any routine actions and press the clutch manually. The checkpoint itself will do everything for him.

As for robotic solutions such as DSG (with mechatronics), they have two clutches. The presence of two clutches is valuable for increasing the power of the vehicle, while minimizing slippage and optimizing fuel consumption.

Indeed, physically, at the moment of switching, the engine speed when using two clutches can remain at the same level.

In the picture below you see the “behavior” of the clutch in the DSG robotic gearbox at the moment after switching to second gear.

Gears and shafts

Gears and shafts are the main “controllers” of torque. It is the gears and shafts that help change the gear ratio. Integral elements of all manual transmissions and some automatic transmissions (for example, Honda).

The design of a manual transmission is most often designed so that the shaft axes are in a parallel plane. Gears are mounted on top.

The primary or drive shaft (pedal shaft) is connected to the flywheel through the clutch basket. The lugs help advance the second clutch disc and direct torque to the intermediate shaft through the gear.

The end of the secondary shaft is adjacent to the bearing on the drive shaft. Since there is no fixed connection, the shafts are independent and there is no obstacle to them rotating in different directions. There are no obstacles to varying speeds.

The design of an automatic transmission involves a planetary gearbox instead of gears and shafts. Gears and shafts always rotate as a single unit. But structurally it can be either different parts or a non-separable unit.

Synchronizers

Synchronizers are an integral element of a gearbox with gears - except for solutions with sliding gears. Physically, the work of synchronizers is due to the force of friction.

The function of synchronizers is to equalize the rotation speed of gears and shafts, thereby creating all the conditions for smooth gear shifting. Thanks to synchronizers, the gearbox wears out less and makes less noise.

Synchronizers are actively present in manual transmissions and robotic gearboxes. For cars with planetary automatic transmissions, an alternative to synchronizers is friction control elements. Synchronizers consist of a clutch, locking rings, a retaining ring, a spring, and gears.

How does a standard synchronizer work?

- The clutch is fed towards the gear.

- The clutch locking ring absorbs the force.

- The tooth surfaces begin to interact.

- The locking one acquires the position “on the stop”.

- The teeth of the coupling are opposite the teeth of the locking ring.

- The clutch engages with the ring gear.

- The clutch and gear are blocked.

It would seem that there are quite a lot of steps, but all this happens in a fraction of seconds - at the moment the driver engages the gear.

Operating principle of manual gearboxes

Transmissions with “mechanics” use various combinations of gears during operation.

The operating principle of a manual transmission is based on creating connections between the primary and secondary shafts. Thanks to the use of gears with different numbers of teeth, the transmission adapts to the conditions on the road and the driver's goals.

As the speed of rotation of the output shaft of a manual transmission increases relative to the speed of rotation of the input shaft, the amount of torque from the internal combustion engine to the wheelbase decreases.

When the speed of rotation of the output shaft of the manual transmission decreases in relation to the speed of rotation of the input shaft, the amount of torque from the engine to the drive wheels, on the contrary, increases.

Gearboxes vary in the number of stages. Each stage has its own gear ratio. It represents the ratio of the number of teeth of the driven gear to the number of teeth of the drive gear.

A low gear has the highest gear ratio, and a high gear, on the contrary, has the smallest gear ratio. The lower the gear ratios, the faster the vehicle can accelerate.

When gear ratios and vehicle speed change, the clutch is used to momentarily disengage the transmission.

Depending on the design of the gearbox, it can be two-shaft or three-shaft. Both the device and the operating process of the units are somewhat different.

2-shaft gearbox: device and principle of operation

Twin-shaft solutions are very popular on front-wheel drive cars. The design includes the following elements:

- crankcase – load-bearing element, housing. All other parts of the device are attached to it. It also protects the unit from external influences, and a person from rotating parts, and also serves as a storage facility for oil.

- shafts – primary and secondary,

- gears (in blocks), part is attached to the drive shaft, part to the driven shaft,

- spline (connects PV and clutch),

- synchronizers.

Important!

The main gear and differential are also located inside the crankcase, but the gear shift mechanism is located outside it.

The shift lever is in the neutral position: the gears rotate, the torque from the internal combustion engine is not transmitted to the wheels.

The lever is moved - the synchronizer clutch also changes position. The angular velocities of the corresponding shaft and gear are equalized. Torque is transmitted from the primary shaft to the secondary shaft. Torque is transmitted from the internal combustion engine to the drive wheels with a given gear ratio.

The picture shows the reverse gear separately. For him, the gearbox has a reverse gear. The idler gear is used to correct the direction. It is mounted on a separate axle.

VAZ 21809 - modern manual transmission Lada Largus

In 2022, a station wagon with a 16-valve internal combustion engine VAZ 21129 received a domestic gearbox 21809. This is a modern 5-speed manual transmission with a cable drive control, but without a hydraulic clutch, equipped with reliable multi-cone synchronizers in first and second gears.

Due to the relative novelty of this manual transmission, comprehensive breakdown statistics have not yet been collected. On the forums you can find complaints about transmission noise in a certain speed range, difficult shifts due to premature wear of synchronizers and oil leaks. Owners also note extraneous noises and knocking in the gearbox at idle engine speeds.

Spare parts, maintenance

Products from the Dustershop77 range that may be of interest to you:

| Name | Manufacturer | Price | Availability | Add to cart |

| BR-001-GARD-URDP | Mud flaps enlarged (widened) Duster-GARD front | Duster-Guard | 1300 / 1100 rub. Discount: 1000 rub. | >10 |

| DC495 | Discount card (Dusterclubs.ru, Dustershop77.ru) | 700 / 500 rub. Discount: 500 rub. | >10 | |

| DC218 | Air deflector “Warm feet” for Duster, Logan, Sandero, Largus | 500 / 300 rub. Discount: 250 rub. | >10 | |

| patriot-001-1 | Gearbox coupling and gas tank protection (steel) | Patriot | 5400 / 4500 rub. Discount: 4000 rub. | >10 |

| 005-008502 | Trunk sill protection | Russian Artel | 1500 / 1100 rub. Discount: 900 rub. | >10 |

| NRD-009102 | Frill under the windshield (RA) | Russian Artel | 1800 / 1700 rub. Discount: 1600 rub. | 5 |

| DC654 | Frill with fastening without 3M tape (Duster/Terrano) (ArtForm) | ArtForm (Yuago) | 3500 / 2500 rub. Discount: 1900 rub. | >10 |

| R12711 | Wind deflectors (window deflectors) COBRA/Autoplex | COBRA/Autoplex | 2000 / 1600 rub. Discount: 1500 rub. | >10 |

| RA0052 | Door sill trims (front+rear) RA | Russian Artel | 2500 / 1600 rub. Discount: 1400 rub. | >10 |

| def-001 | Hood deflector Vip-Tuning | VIP-Tuning | 2000 / 1500 rub. Discount: 1100 rub. | >10 |

Boxes Lada Largus

- Auto

- Lada

- Largus

- checkpoint

During its production, three different gearboxes were installed on the Lada Largus:

| 5-speed Renault JH3 | classic mechanics with lever control drive |

| 5-speed Renault JR5 | classic mechanics with cable drive control |

| 5-speed manual transmission VAZ 21809 | AvtoVAZ transmission replaced foreign manual transmission |

What gearboxes are installed on the Lada-Largus

In general, all internal combustion engines (ICEs) have the same drawback - insufficient adaptability to vehicle operating modes. The internal combustion engine is capable of developing power and torque in a small crankshaft speed range. Moreover, with a decrease in the number of revolutions, the developed power decreases.

During operation, the car moves at different speeds and requires varying torque. For example, when starting from a stop, the speed of the car is low, but the traction force must be large. On the contrary, when moving on a good road, the car develops high speed without requiring much traction force.

In order to ensure a change in the magnitude and direction (reverse movement) of the torque at constant power of the power unit within a wider range, a gearbox is used. In addition, with the help of a gearbox, the engine and drive wheels are disconnected for an unlimited time and, unlike the clutch, without the participation of the vehicle driver.