VAZ starters, despite their reliability, durability and endurance, still fail sooner or later.

The average starter life is usually 5-6 years, which is half the life of the engine. And whether there is a malfunction of the VAZ 21093 starter, or the VAZ 2109 or 21099 starter does not turn, the problem will still have to be solved by diagnosing, repairing, and possibly even replacing this electrical component.

Since the VAZ starter design differs only slightly, we will take into consideration the situation when the VAZ 2109, 21099 starter does not turn.

After turning the key in the ignition, you may find that:

- VAZ 2109,21099 starter does not work after a single click;

- The VAZ 2109, 21099 starter does not work after a whole “trill” of frequent successive clicks;

- The starter response to turning the key is completely absent.

What to do if the starter does not work? Of course, look for the cause of this phenomenon and try to eliminate it.

VAZ 2109, 21099 starter does not work after one click

reasons why the VAZ 2109, 21099 starter does not turn after a single click.

The power bolts on the solenoid relay may have burnt out. This defect leads to the fact that from the supplied 12V, only about 6-7V reaches the starter.

The fork that pushes out the starter bendix may be bent, broken, or otherwise deformed. In this situation, the bendix does not fully fit the flywheel; the cores only partially enter the coil, preventing the contacts from closing.

The teeth on the Bendix sprocket have worn out. Because of this, the solenoid relay cannot transmit voltage to the starter.

Also, the cause of the phenomenon of “one click” of the starter may be either worn-out brushes or armature bushings, or a short circuit in the winding.

VAZ 2109, 21099 starter does not work after frequent clicks

A crackling sound from the starter in response to turning the key in the lock may indicate the need to charge the battery and check whether the terminals on it are oxidized or loose.

Repeated clicks are repeated due to the fact that the retracting winding retracts the core, and the holding winding cannot hold it and lets go. This can continue until the battery runs out completely.

VAZ 2109.21099 starter does not work and there is no response to turning the key

The absence of any response from the starter to turning the key in the lock sometimes indicates a short circuit in the windings (if smoke and a burning smell appears from the starter when you try to start).

If the lack of starter response is not accompanied by “special effects” in the form of smoke and a characteristic odor, you should pay attention to the condition of the additional relay and the contacts of the battery terminals.

The same reaction of the starter is observed when the ring in the starter gearbox is partially destroyed.

If the starter does not respond to turning the key in the lock, you need to take into account that the reason may lie in the key itself. If the check confirms this, it will be enough to just replace the ignition key to fix the problem.

It may also happen that after removing and disassembling the starter, you will not find any damage. Do not rush to replace it with a new one or go to a car service center. Perhaps after you clean the starter, apply new grease and reinstall it, it will come back to life.

After you find and fix the starter malfunction, try not to cause it to break down again in the future, because this lightweight device already has a hard time - the rotation of the massive flywheel and the start of movement of the entire piston group of the engine depend on its serviceability.

Popular causes of malfunction

The most common reasons account for about 95% of all cases when the starter does not turn. That’s why we pay attention to them first.

We recommend: Correct installation of piston rings

The starter does not turn differently in different situations. It is important to take this into account and clearly monitor all associated symptoms. So, even without the help of specialists, you will be able to return the unit to operation and resume normal operation of the ignition system

| Situation | Probable Causes |

| There is one click, after which the starter goes silent. |

|

| Multiple clicks occur in succession |

|

| Clicks are completely absent, as are other signs of starter life. |

|

Bendix

Often, simply disassembling and cleaning the internal components of the starter can eliminate problems with its functionality. Therefore, after removing the device and not finding damaged elements inside it, try to thoroughly clean everything, assemble it and put it back in place. It is likely that the starter will start turning.

When starting the engine, there is no response when turning the key

If a pungent odor appears when starting the starter, we can say that a short circuit has occurred. If there is no such effect, you should check the tightness of the terminals. Make sure the additional relay is working properly. The cause may also be deformation of the ring, which is located in the starter gearbox.

Often, visible or invisible damage to the key itself is the cause of failure to start the engine. Even if no damage is found, there is no need to rush to buy another one. It should be thoroughly cleaned and lubricated thoroughly. Perhaps after this it will continue to operate as normal.

After the repair has been carried out, do not put too much load on this small unit. After all, in fact, it begins the process of rotation of the massive flywheel and the operation of a group of engine pistons.

You should also know that the main task of the starter is to set the crankshaft of the car in motion until the spark catches the engine.

How to fix starter malfunctions with your own hands

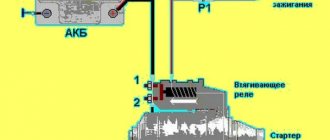

The electrical component of the starter consists of the following structural elements:

- winding;

- brush assembly;

- solenoid relay.

When checking the solenoid relay, skip the starter operation, bypassing its switching. The relay has 3 terminals at once, one of which is the control terminal. The remaining 2 large terminals, located at the input to the battery and at the output of the starter, are closed using a screwdriver or wrench. Closing for a short period of time is enough, the main thing is that the tool you are using does not touch the metal body directly under the hood.

Observe the changes in the starter during the process of closing the terminals - if the device rotates, perhaps with a clearly audible crackling sound, then the fault is caused by the solenoid relay.

Remember that starting the engine in this way is prohibited, because the main gear of the device does not engage.

Most likely, the contact planes on the inner plane simply burned out, and therefore a dielectric layer of metal oxides formed on top. To burn the contacts, there is no need to make great efforts; just one start of the VAZ-2109 engine is enough.

There are 2 ways to repair the VAZ-2109 solenoid relay:

- Dismantle the device and disassemble it into components, clean the contacts.

- If it is financially possible, it is better to replace the relay completely. Practice shows that if a relay fails, the contacts will have to be cleaned more and more often to restore its operation. If you want the repaired relay to last a long time, give preference to this option for repairing the starter if the device does not spin or click.

Candles

Unscrew the spark plug, place it against ground and crank the starter. If there is a spark, then there is probably a problem in the fuel system. We will tell you about it later.

It is necessary to do otherwise when the unscrewed spark plug works properly, but it turns out to be wet. Here you should check the timing belt. The latter sometimes jumps off, which disrupts the correct gas distribution and, accordingly, the VAZ engine does not want to start.

If you see that the spark plugs are filled with fuel, then perhaps this very circumstance is preventing you from starting the engine. Dry them with a burner or on a gas stove burner. When they turn out to be wet again during the next attempt, you will have to find out why this happened.

If there is no spark, the cause is sought further. It often lies in problems:

- crankshaft pulley or sensor that controls its position (DCPV);

- computer.

In most cases, the VAZ model 2109 injector does not want to start precisely because of the failure of the DPKV. Failure of other sensors does not prevent the engine from starting, it will simply not work correctly.

Individual situations

If the VAZ 21099 injector stops starting, you can try to close the contacts of the mechanism in a straight line.

But sometimes there are emergency situations when the device stops functioning, let’s consider a few of them:

- The injection engine does not start in cold weather, but all devices work normally, the battery is charged. If there is no click, you should first diagnose the safety components, electrical circuit, and also the solenoid relay. If the device clicks, the relay must be replaced.

- The starter turns all day, there is a spark, but in the evening the engine stops starting. Before checking the starter, it is necessary to fully charge the battery, and then clean the contacts on both the battery and the mechanism itself. If these steps did not help solve the problem, you need to check the battery itself more carefully - try closing the contacts with a wire, which may cause a spark to melt. If this does not help, try applying a positive charge from the battery directly to the relay. If there are no changes, the unit will have to be replaced.

- If the car was operated normally all day, but after parking for five minutes it stopped starting, you can try to close the mechanism. You need to directly close two bolts on the relay; if this helps, but later the problem reappears, then disassemble the unit completely. Most likely, the problem lies directly in the erasing of the brushes. In this case, they will need to be changed.

- The unit does not turn at all, but the car can be started from the pushrod. If the problem is not with the starter, then check the fuse box and ignition switch. But before this, you should check the wiring - the reason may lie in the oxidation of the contacts.

We recommend: How to replace the steering column switch?

Solution

- First you need to put your “nine” in neutral gear, and also turn on the parking brake.

- After this, the hood opens, you need to find the red cable on the retractor.

- Using a thick screwdriver, you need to short-circuit the terminals on this component. When a short circuit occurs, sparks may fly in different directions - there is no need to worry, this is a normal situation.

- Then you need to try to start the engine. If you notice that the starter starts to work normally when screwing in, then the problem is not with it. If the device does not turn, then most likely it will need to be changed.

- If the mechanism is working properly, the red wire from the solenoid relay must be removed, and voltage from the battery must be applied to this terminal. If there is a pop, the relay will be fully operational. If there was no clap, then most likely the reason lies precisely in the relay.

- Check the contacts on the starter, it happens that due to oxidation it stops turning.

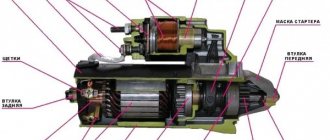

Device

- retaining ring

- restrictor ring

- overrunning clutch drive

- lever axis

- front cover

- drive lever

- armature relay

- traction relay

- back cover

- protective cover

- lock washer

- pinch bolt

- shim

- brush spring

- brush

- frame

- anchor

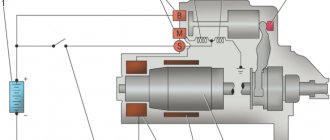

Brushes and winding

Inside the starter housing there are 4 steel cores (shoes) with a winding that is connected into a circuit.

Healthy! Some cars do not use cores with windings, but magnets, which is much more convenient.

The current to the winding comes from the central input, and the output is output to two copper-graphite positive brushes that go to the commutator. Also connected to it are negative brushes that come from the starter mass. All brushes are constantly pressed using small springs. But, since graphite is not the most durable material, these elements tend to wear out quite quickly. When brush wear reaches a critical level, the solenoid relay stops receiving current.

In the event of such a breakdown, the starter will not make any extraneous sounds. To repair, you will need to disassemble it and evaluate the condition of the brushes. If everything is in order with them, then we look at the windings. If they burn out, the layer of varnish that is applied to them will also burn out. Also, instead of copper color, the windings will be black. An unpleasant burning smell also indicates a problem. In this case, the best thing would be to replace the entire assembly, although you can get by with new windings.

Rare situations

They happen noticeably less frequently than those we described above. But under no circumstances should we exclude them.

After reviewing the situations below, compare them with the behavior of your starter and a car that has stopped turning or clicks but does not turn.

- With an injection engine at a frosty temperature of about -20 degrees Celsius, all devices function. This indicates that the battery is fully charged. At the same time, for some reason the starter refuses to turn. Your actions:

- If there are no clicks when you try to start the engine, check the condition of the fuse, wiring and solenoid relay;

- If there is a clicking noise, the most likely source of the problem is the solenoid relay. It must be replaced.

- The engine started normally throughout the day, but in the evening it suddenly stopped working normally. When you turn the key in the ignition switch, there is only a click, but the starter does not turn. When you try to start the engine several times in a row, several clicks are heard. Your actions: Charge the battery;

- Crimp, strip and tighten the contacts on the starter and battery;

- If the first two points do not produce results, check the battery itself. To do this, the wire closes its contacts. If the battery is working properly, a spark will appear that melts the wire;

- Connect the plus from the battery directly to the solenoid relay. If the starter is silent, replace the starter.

car battery

- During the day the car started without problems. But after being idle for several minutes, attempts to start the car fail. When you turn the key, the relay is activated, but the starter stubbornly refuses to turn. By closing the two bolts of the solenoid relay, everything started. We reached our destination, stopped, and turned off the engine. When I try to start again, the same situation occurs. Just locking the bolts no longer works. Your actions:

- Disassemble the starter housing;

- Check the condition of the brushes. There is a high probability that they have been completely erased. Hence this effect;

- Replace the brushes with new ones. This is cheaper than completely replacing the unit.

- The starter doesn't turn over. When you try to close it, only noise arises, like when a drill is working. The engine shows no signs of life. But it was possible to start it from the pushrod without any problems. Your actions:

- Make sure your starter is working properly;

- If everything is fine with it, go to the mounting block and check the fuses;

- Also examine the condition of the ignition switch. It is possible that the problem is with him;

- Do not forget to check the wiring for breaks and short circuits;

- Check the status of the contacts. It’s not uncommon that minus does not reach the starter relay only for the banal reason of oxidation or burnt wire.

We recommend: Everything about replacing the cylinder head gasket on a VAZ 2112 car

Having understood the reasons for the failure of the starter, you can bring the device back to life on your own. Don't rush to throw away your old starter and buy a new one. The practice of VAZ 2109 owners shows that partial repairs, and sometimes even simple cleaning of the device, make it possible to restore the functionality of one of the main elements of the ignition system for a long time.

The starter relay clicks, but it doesn't turn over.

If, when you turn the ignition key, clicks are heard from the starter relay, but the unit itself does not spin, then the problem may be associated with a malfunction of the control cable that powers the relay, or with a problem in the performance of the relay itself.

In such a situation, the car can be started if you short-circuit the “plus” from the battery to the positive control terminal from the ignition switch (the smallest wire of the three is connected to it). If, with such a connection, the starter starts to spin, then the malfunction is definitely not related to the battery, and the problem should be looked for in the relay, ignition switch or wiring.

Solenoid relay diagnostics

If the starter does not turn when the engine starts, but clicks are heard, the first step is to diagnose the relay itself. It connects to the battery and ignition switch via 2 cables. One of them (thick section) comes from the positive terminal of the battery, and the second (thin section) goes from the positive control terminal of the ignition switch. The relay also has a third terminal (thick section), which connects it to the starter motor.

To diagnose a possible malfunction in the solenoid relay, you need to use a jumper to connect two terminals to which thick wires are suitable. To connect them to each other, you can use a regular screwdriver, wrench or other available tools. Grasp the insulated surface of such a tool and use it to connect the two large terminals (it is important that the “jumper” does not touch any other metal parts under the hood).

If the result of shorting the terminals is the rotation of the starter, then the problem is related to the contact pads in the relay, which could be burned due to the high current supply. In such a situation, it is necessary to replace the relay, since the procedure for cleaning the contacts will take a lot of time, but due to the lack of an alloy of non-ferrous metals on them, which is applied at the factory, they will not work for long.

Diagnostics of wiring and contacts

If the starter clicks but does not turn, poor contacts or wiring problems may be to blame. Most often, a malfunction occurs along the path of current transmission from the positive terminal of the battery to the solenoid relay. The starter requires about 200 Amps to start, but if there are problems in the wiring and contacts, much less current can reach it. This leads to the fact that it is possible to power the solenoid relay (which requires 10 Amps), but there is not enough current to spin up the starter itself.

How to charge the battery in a VAZ-2109

If the starter malfunction is due to lack of battery charge, start charging the device. To properly charge the battery, carry out the procedure in a ventilated room. It is not necessary to remove the unit from the car; the process can take place directly in the VAZ-2109. When charging the battery, follow these requirements:

- Disconnect all electrical cables.

- Immediately before charging, carefully clean the terminals from adhering dirt and dust, paying special attention to oxidized areas.

- It is advisable to completely discharge the battery before charging - to do this, turn on all electrically powered devices.

- Observe the movements of the ammeter needle; it should approach the zero mark.

- Monitor the temperature of the electrolyte - it will increase during charging. For example, the temperature of the electrolyte has increased to 40 degrees, then the current should be halved. If within 2 hours the density of the electrolyte and the battery voltage in the VAZ-2109 remain unchanged, it means that the battery is fully charged.

Typically, 10-12 hours are enough to charge the battery. Please note that in the summer the electrolyte in the VAZ-2109 heats up at an accelerated pace, so the car owner’s task is to regularly check the density and level of the material.

Repair

In some cases (namely, when a collapsible type relay is installed on the starter), you can try to repair it. To do this, you need to remove the starter and dismantle the relay in the same way as mentioned above. After this, carefully halve the device by unscrewing the end mounting nuts.

The old core (which most often causes the relay to jam) will need to be removed, replacing it with a new one, after which all that remains is to assemble the relay and mount it on the starter.

The cost of such a repair (with replacement of the core alone) will be much less than replacing the entire relay. True, when separating one half from the other, as well as assembling the relay back, you should be very careful, since if you act carelessly, either the core or its return spring may fly out and get lost.

Common causes of failure

Identification of starter components

If on a VAZ 2109 the injector or carburetor stops starting the engine, and the starter does not click, this may be due to various malfunctions.

In general, it should be noted that there can be several options for a malfunction of the starter unit:

- When you turn the key, the device operates once, that is, only one click is heard.

- When I try to start, there are several clicks, but the engine does not start.

- The starter on the VAZ 2109 carburetor does not work completely - there are no clicks.

If the injector does not start, and the starter unit makes only one click, the cause of the problem may be:

- power screws on the solenoid relay, these elements could burn out, as a result of which the voltage supplied to the mechanism will be less than 12 volts;

- a fork designed to push out the bendix, this component could wear out, break or become deformed, as a result the bendix cannot reach the flywheel normally;

- if the car does not start with the key, the teeth on the bendix may have worn off, as a result of which there will be no current from the relay to the starter device;

- wear of brushes or bushings of the so-called anchor;

- winding short circuit.

Starter unit "nine"

If the device clicks several times, but does not turn the engine and, accordingly, the VAZ 2109 does not start, then there may be several reasons:

- the battery is dead;

- oxidation of the terminals occurred, as a result of which they became loose;

- The holding winding of the system cannot properly fix the core.

You can turn the key as much as you like, but if the mechanism does not show any signs of life and the engine does not start, then the cause of the malfunction may be as follows:

- short circuit of the winding, if this is the case, then you will hear a burning smell in the car interior, and smoke may even appear;

- collapsed as a ring located in the gearbox;

- very rarely the problem is the key.

If you have dismantled the mechanism and found no damage, try cleaning it and reinstalling it. It is quite possible that after this the VAZ 2109 starter will start working normally (the author of the video is the Avtoelektika HF channel).

see also

Comments 59

the problem was in the ECU. I changed it to January and everything is ok

Guys. And I have such garbage. I turn on the ignition, the pump pumps up and everything is as it should be. I start it up. The engine runs for a couple of minutes and the pump relay starts clicking. Well, and accordingly, the pump also works in time with the clicking of the relay. The engine seems to be throttling. What kind of garbage can anyone knows

Have you tried changing the relay? Measure the voltage on the relay during such garbage. Will the voltage fluctuate or is it constant 12 volts?

So yes. And if it jumps, then where to dig next?

Then I don’t know then) look at the contacts then. But he shouldn't jump. It's either there or it's not there

Damn, I removed the terminal while it was back to normal. Now I don’t know where to look

People! Tell me about these relays! I had a similar situation the other day, I couldn’t start the car, I checked it with a light bulb, there was voltage coming from the fuse, but the relay didn’t turn on, I replaced the relay, it didn’t help! I look at the cross wires on the relay (as I understand it from the brain) and there is no voltage on them when I turn on the ignition, it turned out that this is only a consequence! There are three relays and three circuit breakers, one for the fan, the other for the fuel pump, and the third for powering the brain? It was the third fuse that blew, I replaced it, installed the same one, it started and it immediately blew! I set it to 10A because 15 had run out, and I really wanted to get home, so it started up and drove another 15 km, and only when I arrived at the gate did it burn out again! What could be shorting there and how to solve it? Until this moment, I replaced the radiator with the stove, the heat is terribly hot, maybe it caused the wires to melt? Only then would it constantly burn out, as I assume, please help! Anyone who has had this problem, please respond!

you have it somewhere. Look further at the wire and look for a short to ground.

I have already found what the problem is, all that remains is to find where it shorts, in short, everything can be treated with electrical tape!)

If the starter of your car turns normally, but the car does not start, the first thing you need to do is check that the fuel pump is turned on. On domestic cars, its operation can be heard from the passenger compartment; when the ignition is turned on, a characteristic buzzing sound comes from under the rear seat or trunk. If the fuel pump does not work, you need to check the integrity of the fuses and the activation of the main relay of the engine management system and the fuel pump relay. On the VAZ-2107, VAZ-2108, VAZ-2109 and their modifications, relays and fuses are located on the shelf under the glove compartment or under it. On VAZ-2110 and similar ones, you should look in the heater console on the passenger side by unscrewing the fastening screws and removing the side cover. On GAZ cars they are located under the hood on the front wall of the cabin, closer to the passenger side.

Dismantling and replacement

If one or another equipment fails, you must first check the condition of the fuse responsible for it.

In practice, removing and removing an unusable fuse or relay is not difficult. To do this you need:

- Raise the hood and disconnect the minus from the battery. Since you are working with the fuse box responsible for electrical equipment, the car should not be energized at this moment;

- Find the mounting block. It is located in the engine compartment opposite the driver's seat directly under the windshield. The top of the block is covered with a plastic cover. To remove it, simply press the latches on the sides;

- Remove the cover and look at the back side. There is an electrical diagram showing the location of one or another fuse or relay. Just find the element that is responsible for the failed equipment according to the tables above;

- Remove the fuse. All mounting blocks are equipped with special pliers. Manually removing fuses is not recommended. The relays are removed by gently rocking up and down;

- Replace the failed component.

Fuse failure is determined by the melted filament. These are fusible elements that melt and make contacts, preventing equipment from being damaged by excessive voltage.

That's it, all that remains is to replace the fuse block element, close the cover, replace the battery terminal and check the functionality of the equipment.

Loading …

Flywheel teeth

The flywheel wears out over time. The fastest thing to deteriorate is the crown that clings to the starter. Improper handling of the ignition key causes its teeth to grind down. This also happens due to constant loads.

In this state, the starter gear or overrunning clutch rotates idle, without clinging to the flywheel.

The flywheel teeth can be tested without dismantling the starter. Here's what to do:

- set the third or fourth speed;

- push the car half a meter forward - with the efforts of several people;

- try to restart the engine.

If the car starts, the crown will have to be replaced. This confirms the wear of any tooth. It is also possible that the teeth have worn off all over the circle, but this rarely happens.

Wear of flywheel ring teeth

Low compression

Finally, if the starter turns but does not start, the engine may be the cause. This occurs due to low compression, which usually occurs in the morning or in cold weather. The pressure is insufficient to compress the fuel mixture, so the internal combustion engine does not start. In addition, the crankshaft rotates with resistance, which also complicates starting.

Weak compression also occurs for the following reasons:

- There are burrs on the cylinders;

- there is a problem with the piston rings;

- block gasket burnt out;

- cylinder head cracked;

- Timing valves are leaking.

It is noteworthy that in some cases adding a small amount of oil will help increase compression. It is desirable that it be a synthetic composition.

In some situations, a special type of additive is used (more on this below).