What does P0335 mean?

The crankshaft sensor (CSS) tells the engine control unit (ECU) where the crankshaft is at any given time. Many vehicles use this information to determine when the spark plugs should fire and to deliver the correct amount of fuel.

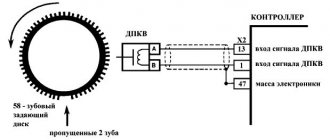

The crankshaft position sensor is stationary. It works in conjunction with a ring gear attached to the crankshaft. The movement of the toothed ring in front of the sensor creates a voltage signal that is sent to the ECU.

If the controller does not detect voltage pulses from the DPKV, fault code P0335 is activated. This could be due to a faulty sensor, but it could also be a problem with the ring gear, wiring or connector.

The OBD2 code P0335 refers specifically to the sensor on bank 1, also called sensor A. Bank 1 is the side of the engine that contains cylinder 1. You may see it in combination with other codes related to the crankshaft position sensor, especially P0336-P0339.

Some vehicles use the crankshaft position sensor only to detect misfires. In this case, it is a less serious code that is unlikely to cause symptoms while driving.

If the DPKV controls the timing of the spark plugs, the occurrence of trouble code P0335 will activate the vehicle's limp mode. This makes it especially important to find the cause of the problem as soon as possible.

Verification methods

The symptoms described above may be signs of a malfunction of more than just the crankshaft sensor. Such symptoms also apply to spark plugs, displaced marks in the timing belt assembly, high-voltage wires, and ignition coil. Here it is important to know how to test the controller.

Checking the DPKV will help make sure that the fault is in it, and not in a skipped timing belt or a dirty engine throttle valve.

There are several diagnostic methods. Since most DPKVs are inductive, we will consider testing just such a controller on the shaft.

wrench

If the engine does not start and there are no measuring instruments or service stations nearby, you can check the position sensor with a wrench. For this method it is good to have a second person as an assistant:

- Open the hood and unscrew the sensor fixing bolt.

- Take the DPKV out and clean it of dirt.

- Turn on the ignition.

- Remove the cushion on the second row of seats so that you can better hear the operation of the fuel pump in the tank.

- Without removing the contact chip, apply a wrench to the end of the sensor.

- The second person should at this moment hear the fuel pump turning on.

This key test triggers the induction coil and simulates the passage of a pulley. If the fuel pump turns on every time a metal object is applied, then the controller responds to the position of the shaft. If the pump is not heard, then the symptom will definitely indicate a breakdown.

Oscilloscope

Checking the crankshaft sensor with an oscilloscope is done in two ways and gives a more accurate idea of the controller's response to the position of the shaft. In the first case, the action occurs with the engine turned off, but with the ignition on.

The sensor is removed from its place, and oscilloscope probes are applied to its contacts. Polarity doesn't matter here. Next, a metal object is passed in front of the end part of the sensor (you can use the same wrench). The coil should fire on metal, but instead of removing the back seat and listening to the sound of the fuel pump, the response will be visible on the oscilloscope screen.

Checking DPKV with an oscilloscope

A more accurate test can be performed with the engine running by connecting an oscilloscope parallel to the DPKV terminals. Then the program will show not only the reaction, but also a complete picture of the controller’s operation. The amplitude of the electromagnetic field will be displayed on the screen. It should have even upper and lower boundaries, as well as equal separation intervals indicating the passage of the control section. If there are more such pauses or the edges of the oscillogram are not smooth, it means that some of the flywheel’s teeth are broken off or severely worn out. This leads to incorrect sensor response. Then the issue is not a malfunction of the crankshaft sensor, but a mechanical part. The flywheel crown will need to be replaced.

Multimeter

Checking the crankshaft sensor with a multimeter is performed in resistance measurement mode. To do this, the step switch is set to the appropriate position. The DPKV is removed outward, and the multimeter probes are inserted into the contacts.

Checking the sensor with a multimeter

Most sensors have a coil resistance range of 500-700 Ohms (you can find out more precisely from the characteristics of a specific model and the manufacturer’s data). Therefore, the device must be set to the upper value of 2000 Ohms. If the tester shows lower values, then the insulation of the coil winding is damaged. Such a malfunction requires replacement of the sensor. The absence of readings on the tester means that the circuit is broken and the DPKV is unsuitable for use.

In addition to resistance, some multimeters can test inductance. For the crankshaft position sensor, this indicator should be 200–400 mH. A significant deviation from the specified range indicates a controller malfunction.

Diagnostic scanner

Those who take a more professional approach to repairing their car have a diagnostic scanner in their tool kit. It helps to check not only the sensor, but also other parameters of the gasoline engine. Among products of Korean origin, OBD–2 Scan Tool Pro scanners are very popular.

Diagnostic scanner

The device is inserted into the car's standard connector and communicates with the ECU. Using a laptop, phone or PC, pairing occurs via Bluetooth or Wi-Fi network. A special program will be required. Collected errors are displayed on the screen. Among the fault codes related to the crankshaft position sensor: P0336 and P0335. Checking with a scanner consists of the presence of a signal from the position sensor and the ability to determine the reference mark to synchronize the subsequent operation of the engine.

Checking with an ohmmeter

If you don’t have a multimeter at hand, but have an ohmmeter, then that will also work. With the engine off, you will need to remove the crankshaft electric sensor and touch the device leads to the contacts in the connector. The operating parameters of the DPKV should be in the range of 500–700 Ohms. If the resistance is very high, it means that somewhere there is interference with the passage of electric current. If the indicator is too low, the integrity of the winding is compromised.

How to troubleshoot DPKV

DPKV is one of the most important car sensors, because Without it, the car simply won’t start.

Let me remind you that the Crankshaft Position Sensor (CPS) transmits the received current pulse to the controller, which in turn regulates engine operation. Read more about DPKV in the article: DPKV on VAZ. Operating principle, signs of malfunction.

The sensor is a simple mechanism, so there is nothing to break there. But nevertheless, nothing lasts forever, and the sensor fails.

How to repair DPKV?

Unfortunately, DPKV cannot be repaired, BUT! Most often, the fault occurs not in the sensor itself, but in the sensor circuit. In other words, if the DPKV is broken, then it needs to be replaced with a new one, but before replacing it, you need to check the wiring suitable for the sensor.

If the sensor is faulty, the on-board computer or diagnostics generates the following errors:

- Error 0335 - incorrect DPKV signal.

- Error 0336 – Crankshaft position sensor signal error.

- Most often, wires break in the connector area. Moreover, the insulation remains unharmed, so it will not be possible to determine a wire break by eye. In this case, we do the following: remove the wiring block from the sensor, and try to pull out the wires one by one, applying a little force. If a break occurs, you will tear the insulation and pull out a piece of the broken wire.

- DMRV malfunction. Yes, Yes, That's it! If the mass air flow sensor is faulty, error (0335) of the crankshaft position sensor appears when the ignition is turned on. The fact is that when we turn the ignition key, the DPKV diagnostic process starts using the air flow signal.

- Also, error 0335 can occur as a result of pulse noise created by the generator wiring.

- The damper rubber on the pulley, or the pulley itself, has worn out. In this case, the pulley will rotate in a figure eight.

- The teeth on the pulley have broken, so the sensor receives an impulse that is incompatible with engine operation.

- Malfunction of the sensor itself - check the DPKV (How to check and replace the DPKV?).

Trouble-shooting

The check may show the inability of the electric sensor to detect the condition of the crankshaft. In this case, if the failure of the DPKV is confirmed, it will need to be replaced with a new one. But if the breakdown happened on the road and the nearest car shop or service station is far away, you can try to find and fix the problem yourself. Sometimes the problem lies not in the coil of the induction device, but in the contacts.

Cleaning from dirt

For example, a common problem is contamination of the working part with grease from the flywheel. The latter flies onto the sensor and covers it with a thick layer of dirt. Dust and sand, as well as metal shavings, stick to the top. All this creates interference with the operation of the element. In this case, you will need to unscrew one or two holding bolts, remove the DPKV out and thoroughly wipe its body protruding after the stop. Then return the device back and try to start the engine again.

Dirty PCV sensor

Broken contact

Another common problem is a broken wire. It often happens before the contact chip. At this point the wires bend, which leads to gradual refraction. Visually, a violation of the integrity of the conductor may not be noticeable, since the outer insulation remains intact.

To resolve the problem, remove the connector and pull the contact pins lightly towards you. The tattered one will come out and remain in your hands.

Repairs will require stripping the insulation and tying off the exposed ends. Then the area is insulated (you can use cambric or electrical tape). But this measure is temporary and will require subsequent soldering.

Contact contamination

Although the connector is protected by a rubber seal, it gradually loses elasticity and tightness. Because of this, moisture and dust penetrate inside. The corrosion process begins. The contacts oxidize and the circuit is interrupted. As a result, a serviceable DPKV ceases to detect the condition of the crankshaft and the engine stalls.

Dirt on DPKV contacts

To solve the problem, try cleaning the contact pins. They are located in the recesses and can be reached with a thin file or sandpaper rolled into a tube. Blow out any dust that has accumulated inside, restore the connection and try to start the engine.

Related Issues

If the DPKV “rings” and there is no violation in the integrity of the contacts, the breakdown may be associated with missing teeth on the flywheel. The electric sensor simply “confuses” the ECU, responding to additional “tags” formed. Only a mechanic at a service station can determine this. To repair, you will need to replace the flywheel crown.

The MAF (determines the mass air flow) also affects the operation of the DPKV and causes deviations in the readings. The problem is diagnosed in the service.

A figure-eight bend of the flywheel can mislead the crankshaft electric sensor, and this will require removing the box and replacing the deformed part.

crankshaft sensor error

Welcome to ChipTuner Forum.

Theme Options

Andreyas

VAZ error codes (MP7.0H “Bosch”, etc.) VAZ P0335 Incorrect crankshaft position sensor signal

Code P0335 is entered if: the crankshaft turns; For one rotation of the engine crankshaft, the controller reads less than 58 or more than 60 teeth on the crankshaft pulley master disk. If a permanent malfunction occurs, the “CHECK ENGINE” lamp lights up after 2 drive cycles. WHAT TO CHECK: 1. Check the crankshaft position sensor wires and resistance. Resistance may change slightly as temperature increases. 2. The output signal of the sensor should have an alternating current voltage amplitude of about 0.3 V when the crankshaft is cranked by the starter. VAZ P0335 Incorrect signal from the crankshaft position sensor HOW TO CHECK: 1. Using the “Errors” menu, clear the error codes. Crank the crankshaft for 10 seconds or until the engine starts. Code P0335 - Intermittent If it does not set and there are no other codes, analyze the conditions under which the code occurs. Check the drive disc on the crankshaft pulley for missing teeth, runout or other damage. Failure of contacts in the sensor or controller block can cause the intermittent code P0335 to be entered. Also setting an intermittent code P0335 can cause a damaged sensor harness shield. 2. Turn off the ignition. Disconnect the harness connector from the controller. Using a multimeter, measure the resistance between contacts “48” and “49” of the harness block. If the resistance is 550 Ohms or less, the sensor wires are shorted to each other or the sensor is faulty. If the resistance is 750 Ohms or more, the connections are faulty or the sensor is faulty. 3. If the resistance is between 550-750 ohms, prepare a multimeter to measure the AC voltage. While turning the crankshaft, monitor the voltage between contacts “48” and “49” of the harness block. If the voltage is below 0.3V, the connections are faulty or the sensor is faulty. If the voltage is higher than 0.3 V, connect the harness connector to the controller. With the engine running, clear the error codes using the Errors menu. Crank the crankshaft for 10 seconds or until the engine starts. If code P0335 is entered again, check the condition of the drive disc on the crankshaft pulley for missing teeth, runout and other damage. If the drive is faulty, replace it. With the engine running, clear the error codes again. Crank the crankshaft for 10 seconds or until the engine starts. If code P0335 is re-entered, replace the controller. After repair, start the engine, reset the codes and make sure there is no signal from the “CHECK ENGINE” lamp.

Source

Signs of a faulty crankshaft sensor

There are a number of reasons why a crankshaft position sensor can fail, and a number of symptoms associated with this failure. Crankshaft position sensor problems often manifest as engine timing problems. Here are some common symptoms of a bad crankshaft sensor that can help you determine if it has failed. Problems

problems with the crankshaft sensor may be due to several reasons. 2 common ones include:

1. Engine overheating

.

Excessive engine heat may damage the sensor by melting the plastic coating. 2. Wiring problems

. Incorrect voltage or loose, frayed or damaged wiring can interfere with the transmission of signals to and from the DPCV, causing problems. Typically, a faulty sensor will cause any of the following symptoms, which alert the driver to a potential problem that needs to be fixed.

Problems starting the car

The most common and most common symptom is difficulty starting the engine. The crankshaft sensor monitors the position and speed of the crankshaft, as well as other parameters that play an important role when starting the engine. If the sensor is faulty, the car may have intermittent problems starting or may not start at all, which is more likely. A faulty sensor can affect your vehicle's ignition timing. This can result in no voltage being supplied to the spark plugs, resulting in an inability to start. If only one or two cylinders are affected, the problem may be with the ignition coil.

Intermittent stop

If there is any problem with the sensor or its wiring, it may cause the crankshaft signal to be cut off while the engine is running, resulting in the engine stalling. Problems with the sensor worsen at low engine speeds. Sometimes the engine can even stall completely at low speeds if the fuel injectors are not delivering the fuel it needs. This is usually a sign of a wiring problem. However, a faulty crankshaft sensor can also cause this problem.

Uneven vehicle acceleration

Due to the inaccurate input signal from the crankshaft position sensor, the engine control unit is unable to adjust ignition timing and fuel injection as engine speed increases. Slow or uneven acceleration may result from a lack of precision and make it difficult to maintain a constant speed.

Misfire or engine vibration

If you feel vibration in the engine, this may be a sign of misfire in the cylinders due to a faulty crankshaft position sensor. Therefore, it cannot provide correct information about the position of the piston in the engine, which results in the cylinder misfiring. This can also occur due to improper spark plug timing.

Rough idling and engine vibration

Another sign of a faulty DPKV is rough idle. When idling at a red light or otherwise stopped, you may notice a grinding or vibration from the engine. The sensor does not monitor the position of the crankshaft, resulting in vibrations that affect the overall engine power.

Increased fuel consumption

Without accurate timing information from the crankshaft position sensor, the fuel injectors cannot effectively deliver fuel to the combustion chamber. The engine will use more fuel than it needs on short and long trips, reducing overall fuel economy.

Check Engine light comes on

If the computer detects a problem with the crankshaft position sensor signal, it will activate the Check Engine

to alert the driver of the problem.

Check Engine

Light can also be caused by a variety of other problems. It is highly recommended that you perform troubleshooting. DPCV is critical to proper engine operation and performance due to the important signal it provides for engine calculations. Problems with the sensor can quickly lead to problems affecting the vehicle's handling.

Purpose, device and principle of operation

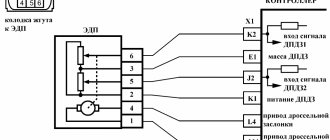

The crankshaft position sensor is the main regulating function of the fuel injection system on a vehicle. Its presence ensures synchronous operation of each engine injector and the entire ignition system.

The driver consists of the following components:

- 1 — device of a nylon frame;

- 2 - magnetic circuits, these elements are made of steel;

- 3 - winding kit, for which thin copper wire is used;

- 4 - a layer of electrical circuit insulation, most often in the form of enamel or resin.

Unstable operation of the controller causes temporary interruptions in the fuel supply. During operation of the device, the vehicle control module, which is a microcontroller, ensures the correct piston position at a given time for each cylinder of the internal combustion engine.

To ensure adjustment using the device, the process is based on the following algorithm:

- The crankshaft of the power unit is equipped with a special gear. There are no two gears on it, this was done on purpose.

- When the machine's engine crankshaft begins to move, all the teeth move in close proximity to the controller. This contributes to strong distortions of its magnetic field.

- Signals are generated in the induction coil of the regulator when the shaft moves. Packet pulses are transmitted to the information base, which is located in the memory of the microcontroller. The two gears missing from the shaft are considered the starting point and also the zero point. Due to the absence of these gears, the microprocessor unit diagnoses the initial position of the crankshaft.

- The microprocessor in the car then counts the number of signals sent by the device. Then, after a certain time, the position of the crankshaft is determined.

- The processed pulse data is then sent by the control unit to the controller used to activate the fuel injector. The latter supplies fuel to the ignition system.

The device and where the crankshaft position sensor is located

The electrical sensor plays an important role in the proper operation of the power plant, so all car manufacturers place it within easy reach for inspection and repair. The DPKV is located on the right side of the engine, next to the flywheel in the area of the cylinder block. You need to look above the pan, closer to the starter and coolant outlet pipes.

Crankshaft position sensor location

It is usually secured with one or two bolts (depending on the modification) and has a small wire with a contact chip. The element is coated with an elastic polymer that is resistant to oils and high temperatures

DPKV position relative to the mark

The shaft position is determined by two missing teeth or a dedicated control one (depending on the type of flywheel). DPKV “notices” this visually and using electromechanical processes. There are three types of controller.

With Hall sensor

Works with a magnet mounted on the flywheel. Whenever it passes the sensor, a direct current is excited in the DPKV. This is recorded by the synchronizing disk and the information is transmitted to the engine control unit.

DPKV with Hall sensor

Optic

The device has an LED. Works in conjunction with a receiver. The beam always leaves and is reflected. When the glow is interrupted, it means that the control tooth has passed by the controller. It is used to determine the position of the crankshaft.

Optical DPKV

Inductive

Contains inside a magnetized coil that responds to an electromagnetic field. When the indicators change, a mark is recorded indicating the specific position of the pulley on the shaft.

Inductive DPKV

The last type is the most common and is installed on all modern cars with a fuel injection system into the engine. In addition to the position of the crankshaft, it is able to determine the rotation speed, therefore it is more functional.

Main symptoms of DPKV malfunction

A faulty sensor or a faulty device sensor can be recognized by the following symptoms:

- The vehicle's propulsion system began to detonate. When the engine is idling or increasing engine speed, a knocking sound occurs from the hydraulic compensators. The so-called pins may knock when driving uphill at low engine speeds.

- The car engine is no longer as stable as before. The engine speed may drop sharply at idle or shift to a higher speed. A car can become stuck idling if it is stuck in traffic or at stop lights.

- The drive may not rotate at the correct speed even if it is running at maximum power.

- The machine's engine power may drop and then increase. In this case, the driver will not take any action.

- The aerodynamic properties and characteristics of the machine are significantly deteriorated.

- The generator may not start. The engine may not start or may catch fire and shut down suddenly.

- No spark when ignition. It may not appear at all or occur with a certain frequency.

If the vehicle owner detects three or more “symptoms” of an internal combustion engine malfunction, the device must be replaced.

It should be noted that the described malfunctions do not always indicate a controller malfunction. They may also indicate other problems with the drive. For example, a sharp change in engine power and a drop in speed indicates a clogged fuel pump or lines connected to it. Symptoms of incorrect operation of the combustion chamber may appear due to contamination of the sensor connection socket.

The Govorun4eg Auto channel showed signs of a faulty high pressure control valve in practice.

Symptoms of a problem

To understand what signs of a malfunction may relate to the DPKV, let’s briefly consider its participation in engine operation. Asymmetrical projections on the crankshaft sequentially act on the connecting rods, pushing the pistons in the cylinders. The latter compress the air and pump up the compression. At the same time, the timing belt supplies the required amount of air to the cylinders through the cylinder head.

The engine control system “understands” the position of all participants, based on the DPCV data (provided that the timing drive is installed correctly), and opens the injectors to release gasoline. A spark is supplied from the ignition coils to the spark plugs, and the air-fuel mixture ignites. The engine runs smoothly and does not jerk.

If the crankshaft sensor malfunctions, the synchronization of the process is disrupted. The engine ECU does not know at what point to supply gasoline, which affects the operation of the internal combustion engine.

Diagnostics will help you find the cause of the breakdown, but more on that below.

Among the signs of malfunction indicating a possible breakdown of the DPKV there are:

- the Check Engine icon lights up on the dashboard;

- loss of vehicle dynamics;

- unstable engine speed;

- the engine stalls spontaneously;

- detonation when pressing the accelerator pedal;

- The engine jerks and shakes.

If the crankshaft sensor fails completely, the engine cannot be started at all. But this can only be established by checking, where the diagnostics will show the condition of other participants in the ignition system.

Popular brands:

Hyundai Creta

How to check DPKV for performance?

You can check the operation of the DPKV in three ways:

- using a multimeter or similar test device;

- using a multimeter or similar test device; - using a combined test;

- Using an oscilloscope.

Diagnostics of the crankshaft position sensor with an ohmmeter

You can use an ohmmeter to test the regulator winding to measure the resistance value. If an ohmmeter is not available, multimeters can be used. As a result of diagnostics, on a working sensor the resistance value should be in the range of 550-750 Ohms.

The testing process itself consists of measuring the resistance of the inductive regulator coil. If this equipment fails, the failure will affect the operating resistance parameter. Therefore, before starting the test, you should set the appropriate range and diagnose the correct operation of the device using measuring sensors.

The method of checking the crankshaft sensor with an ohmmeter is considered the simplest to perform, but does not give a 100% result.