It is very important that the engine operates correctly in any mode, including idling. However, many car owners are faced with a problem: when they release the gas, the engine speed does not drop. As soon as such a defect is discovered, it is necessary to immediately find out the cause and eliminate the malfunction for the smooth operation of the car. Also, the engine may slow down for a long time, which also does not contribute to proper operation.

Typically, upon reaching operating temperature, the speed should drop to its normal level. The manufacturer indicates the indicators for each specific vehicle model in the operating manual. They may vary slightly depending on the mileage and general condition of the car, but usually stay within the range of 650-1000 rpm.

In some cases, the speed drops very slowly or even stays at the same level of 1500-2000 revolutions. In this mode, not only does fuel consumption increase, which affects the driver’s finances, but it also contributes to engine wear.

The cause of the idle failure must be diagnosed by qualified technicians. However, you can also understand on your own why the engine speed does not drop.

Why does Lada Priora stall while driving when releasing gas?

With such a malfunction of the system, the following indications of its operation change: air and fuel consumption increases, its injection time changes, the idle speed control step increases to 75 units, the voltage at the terminals of electrical appliances changes.

A little about the reasons

The Lada Priora stalls while driving when releasing gas: the causes of this malfunction most often are a violation of the composition of the fuel mixture entering the car’s engine.

Having analyzed the methods of car owners of this car model to eliminate this malfunction, we can conclude that such a violation may be caused by improper operation of both the throttle system and some sensors and regulators. A complete diagnosis of the car at a car service center will help to identify the specific reason for the “floating” idle speed, although sometimes it is possible to find the source of the engine’s malfunction on your own. To do this, you need to sequentially disconnect or replace the following sensors and regulators with ones that are known to work correctly, removed from another vehicle.

So, let's figure out what to do first in case of such a malfunction.

Checking the operation of the throttle valve

Very often, the cause of idle “floating” is a malfunction of the throttle position sensor (TPS). The graphite track inside a standardly installed part wears out over time, so it is replaced with a sensor with a non-contact system. After replacement, you need to reset the sensor error. To do this, disconnect the terminals from the battery for 30 seconds or more.

It is also necessary to check the cleanliness and integrity of the pipe leading from the air filter to the throttle valve, and adjust the tension of the gas pedal cable going to it.

It is also possible that the gasket of the throttle assembly has become unusable or the assembly itself needs to be thoroughly cleaned (motor oil could have gotten into it) with special compounds for washing carburetors.

Changing the idle air control

Car service specialists admit that sometimes they have to spend a long time selecting a correctly working (despite the fact that it is new) idle air regulator to stabilize the idle speed of the engine. It is in this case that, before handing over your car for service, you should use an IAC regulator removed (temporarily) from a working car of the same brand.

It is advisable to replace the idle air regulator itself in conjunction with cleaning the vehicle's throttle system.

Replacing the mass air flow sensor

Determining the performance of this sensor (mass air flow sensor) is quite simple. You need to measure the voltage at its terminals with a multimeter with the engine off. It should be less than 1 volt. If it exceeds this value, then this sensor requires replacement.

Other reasons

In addition to the above malfunctions, Priora car owners resort to the following types of repairs to their car aimed at eliminating idle “floating”:

- replacing the knock sensor (DS) or crankshaft sensor;

- cleaning the speed sensor (DS), fuel grid or fuel filter;

- checking the integrity of the wires suitable for the sensors and the cleanliness of their terminals;

- adjusting fuel pressure or the operation of the vehicle's air intake system;

- increasing the power of the electric generator by adding another diode to its circuit;

- change the voltage regulator;

- adjust the correct operation of the absorber valve;

- check the carbon dioxide content in the fuel mixture and the correct functioning of the oxygen sensor (lambda), or turn it off programmatically;

- Reset the vehicle's electronic control unit (ECU). To do this, the battery is disconnected for a while, and then, after connecting it, the electronic system is “self-learning”;

- perform flashing of the car's electronic system.

In general, such a situation can arise even due to poor quality of the fuel being poured. In addition to changing the gas station, the fuel system may need to be cleaned.

The situation when the Lada Priora stalls while driving when releasing the gas can arise either for one of the above reasons or for a combination of them. Therefore, before purchasing new parts (to avoid unnecessary costs), it is recommended to diagnose the operation of the vehicle system at a car service center.

There is a special offer on our website. You can get a free consultation with our corporate lawyer by simply submitting your question in the form below.

Floating speed

In addition to slowly falling revs, car enthusiasts may encounter a phenomenon called floating revs, when they drop and then rise sharply. The reason is excessive air supply into the system, which causes the engine to spin up to 2 thousand revolutions at idle.

This often happens in cars that have a fuel injection sensor. It calculates how much air the mixture needs. When its operation is disrupted, different amounts of oxygen are supplied at different times, as a result, speed jumps are observed approximately every 3 seconds.

Faced with a similar phenomenon, the same computer diagnostics will be a prerequisite

It is very important that this and all subsequent work is carried out by experienced, qualified specialists. By contacting a service that does not specialize in breakdowns of this kind, you may be faced with the need to carry out expensive engine overhauls ahead of time.

Today, when starting from a stop, I let off the gas and the revolutions do not fall, and sometimes even rise to 3 thousand. After a few seconds everything returns to normal. I suspect either the idle air control valve or the throttle position sensor. How to find out what exactly?

Comments 25

I have the same. I'm already so angry that today I posted an advertisement for sale. really fucked up .suka.

At traffic lights it stopped, the rpm was 1200 or 1000. Sometimes when you accelerated, they would drop, but not always. Turned it off, started it, everything is fine.

I changed the IAC and it lasted for three days. suka. I cleaned the DZ and IAC with carb cleaner. At the same time I changed the TPS.

Result: three days later the same thing happens again. However, today the revolutions themselves dropped several times to 840-880-920 or something.

Error 0507 (high XX) and error 0422 (Converter not effective) occurred

ZAEBALA ONA SUKA MENYA. PRODAU.

Buy a dpdz, it costs around 250 rubles, and rxx 400. It was the same. First I bought a phx, it didn’t help, I cleaned the throttle and it didn’t help. I changed the DPZ, now I drive normal) on mine the mileage is 65k 2008

The VAZ Priora (2170) slows down its speed poorly. Hi all. On my Priore, the speed does not drop when switching and can even rise on its own and hold on for a long time, 10 seconds or more. If you gas, it throws off. I cleaned the throttle - didn't help, changed the IAC - didn't help, changed the throttle valve regulator didn't help either. I tried to remove the chip from the air flow and start it, but the revolutions did not rise to 1600 as in theory they should. I sit and think what else could happen.

- The speed rises on a warm VAZ Priora engine - 13 answers

- No charging at idle - 4 answers

- Engine shutdown at idle, VAZ Priora – 3 answers

- The VAZ Priora engine is shaking at idle speed - 2 answers

- The car does not respond to gas, VAZ Priora – 2 answers

I suffered for 3 months with the same problem - on a warm engine the revolutions increased to 2000 and held for 5-10 seconds, tinkered with the guys, changed the throttle, IAC, temperature sensors, changed spark plugs, tinkered with the ignition - it didn’t help, I went to the service center a couple of times but since the “check” did not light up, there are no errors and even if it cracks. And then the other day I went to check the fluid level in the power steering barrel, everything was ok there, my gaze fell on the intake manifold on which some kind of lump was hanging on the back side (from the cabin side). I look exactly at the place where the hoses are placed under the air conditioner and there are plugs. One itself fell off somewhere and there were scraps left, the second stood in place, but I took it off - it was oak and burst along the length. I changed it while the engine was running - the increase in speed stopped, but it stopped starting. After that, I took them off, started them, and it floats. I removed the battery terminals for about 3 hours, installed the plugs, connected the terminals, everything worked and no longer floats!

Lada Priora sedan › Logbook › They float at cold speeds, warm up a little and everything is fine?

In general, it all started about three weeks ago. When starting in the morning, the revolutions rose to 1500, then 500 and the speed became normal, then slowly it got worse and worse, the lower the temperature and the longer the car sits, the longer the revolutions float, when you start in the morning, you have to keep on accelerating to keep it from stalling. Before that, when I didn’t apply the accelerator once, it blinked, and then the check light came on and started flashing. While I was traveling on business, the check went out, I went to the diagnostician, he said that there were misfires in cylinder 4. Maybe the coil is moving? Priora with an electronic pedal and throttle by the way!

In short, I found the reason, the rings on the receiver seemed to have fused, I replaced them with new ones and everything was fine!

Why does Lada Priora stall while driving when releasing gas?

With such a malfunction of the system, the following indications of its operation change: air and fuel consumption increases, its injection time changes, the idle speed control step increases to 75 units, the voltage at the terminals of electrical appliances changes.

A little about the reasons

The Lada Priora stalls while driving when releasing gas: the causes of this malfunction most often are a violation of the composition of the fuel mixture entering the car’s engine.

Having analyzed the methods of car owners of this car model to eliminate this malfunction, we can conclude that such a violation may be caused by improper operation of both the throttle system and some sensors and regulators. A complete diagnosis of the car at a car service center will help to identify the specific reason for the “floating” idle speed, although sometimes it is possible to find the source of the engine’s malfunction on your own. To do this, you need to sequentially disconnect or replace the following sensors and regulators with ones that are known to work correctly, removed from another vehicle.

So, let's figure out what to do first in case of such a malfunction.

Checking the operation of the throttle valve

Very often, the cause of idle “floating” is a malfunction of the throttle position sensor (TPS). The graphite track inside a standardly installed part wears out over time, so it is replaced with a sensor with a non-contact system. After replacement, you need to reset the sensor error. To do this, disconnect the terminals from the battery for 30 seconds or more.

It is also necessary to check the cleanliness and integrity of the pipe leading from the air filter to the throttle valve, and adjust the tension of the gas pedal cable going to it.

It is also possible that the gasket of the throttle assembly has become unusable or the assembly itself needs to be thoroughly cleaned (motor oil could have gotten into it) with special compounds for washing carburetors.

Changing the idle air control

Car service specialists admit that sometimes they have to spend a long time selecting a correctly working (despite the fact that it is new) idle air regulator to stabilize the idle speed of the engine. It is in this case that, before handing over your car for service, you should use an IAC regulator removed (temporarily) from a working car of the same brand.

It is advisable to replace the idle air regulator itself in conjunction with cleaning the vehicle's throttle system.

Replacing the mass air flow sensor

Determining the performance of this sensor (mass air flow sensor) is quite simple. You need to measure the voltage at its terminals with a multimeter with the engine off. It should be less than 1 volt. If it exceeds this value, then this sensor requires replacement.

Other reasons

In addition to the above malfunctions, Priora car owners resort to the following types of repairs to their car aimed at eliminating idle “floating”:

- replacing the knock sensor (DS) or crankshaft sensor;

- cleaning the speed sensor (DS), fuel grid or fuel filter;

- checking the integrity of the wires suitable for the sensors and the cleanliness of their terminals;

- adjusting fuel pressure or the operation of the vehicle's air intake system;

- increasing the power of the electric generator by adding another diode to its circuit;

- change the voltage regulator;

- adjust the correct operation of the absorber valve;

- check the carbon dioxide content in the fuel mixture and the correct functioning of the oxygen sensor (lambda), or turn it off programmatically;

- Reset the vehicle's electronic control unit (ECU). To do this, the battery is disconnected for a while, and then, after connecting it, the electronic system is “self-learning”;

- perform flashing of the car's electronic system.

In general, such a situation can arise even due to poor quality of the fuel being poured. In addition to changing the gas station, the fuel system may need to be cleaned.

The situation when the Lada Priora stalls while driving when releasing the gas can arise either for one of the above reasons or for a combination of them. Therefore, before purchasing new parts (to avoid unnecessary costs), it is recommended to diagnose the operation of the vehicle system at a car service center.

There is a special offer on our website. You can get a free consultation with our corporate lawyer by simply submitting your question in the form below.

Spontaneous increase in speed: we understand the reasons

Increasing engine speed while driving without the driver pressing the accelerator pedal can lead to an emergency situation, increased fuel consumption, and an arbitrary increase in the speed limit. If such a situation arises, the driver must take measures to eliminate it. Let's look at the possible reasons.

1. Accelerator pedal cable sticking

. The cable in the system for transmitting the position of the gas pedal to the throttle valve was used mainly in cars before the year 2000. During the operation of the car, the metal strands of the cable gradually wear out and break. The cable loses its geometric integrity and becomes frayed. As a result, the force of the return spring is not enough to close the throttle valve when the accelerator pedal is released, and the speed remains elevated. The repair consists of replacing the cable.

2. Wear of potentiometers (rheostats, variable resistors) in the accelerator pedal sensor.

Resistors have a limited service life, their working surface wears off. In this case, violations of the resistance parameters are possible, which can lead to either an arbitrary increase or decrease in the engine speed. The parameters of the potentiometers are controlled using a multimeter.

3. Air filter clogged.

Failure to promptly replace the air filter leads to an increase in the fuel/air ratio, and as a result, an increase in crankshaft speed. To check the air filter's capacity, it can be temporarily removed.

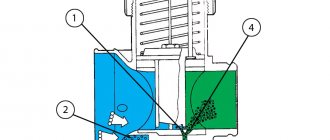

4. Malfunction of the idle air control.

Failure of the regulator can lead to jamming of the throttle valve, changing the size of the bypass (bypass) channel, which leads to an arbitrary increase in speed. The malfunction can be eliminated by cleaning with carburetor cleaner.

5. The electric throttle actuator is stuck.

This problem can occur if the air filter is very worn. It needs to be replaced and the damper mechanism washed.

6. Clogged jets in carburetor engines.

Carburetors in the intake systems of power units are currently installed on special equipment. If the jets become clogged or waste oil gets into the carburetor, the crankshaft rotation speed may change. Repairs are carried out by cleaning with special means and purging the jets.

7. Worn injectors.

When using low-quality fuel, accelerated wear of the injectors is possible. At the same time, a poor-quality combustion torch is formed and the speed increases. Injectors are checked on a special stand.

8. Timing belt (chain) stretching.

This leads to a change in the ignition angle, “floating” speed. The belt (or chain) needs to be changed.

Important: checking sensors

The answer to the question why the idle speed on a Priora fluctuates can often be this: one of the three sensors (IAC, TPS, MAF) is faulty. It's quite easy to check:

- Start the power plant.

- Disconnect the IAC power supply and analyze: the IAC frequency remains the same or the motor stalls - the sensor needs to be replaced. If the frequency has increased, the sensor is working.

- Restore power to the regulator.

- Remove the chip from the mass air flow sensor and observe: the speed has increased - the mass air flow sensor is working; the engine has stalled - the mass air flow sensor should be replaced.

- Connect power to the TPS.

- Disconnect the block from the mass air flow sensor and analyze: the crankshaft rotation speed has increased - the mass air flow sensor is working, the engine stalls - the throttle position sensor is faulty.

- Attach the chip to the mass air flow sensor.

For your information. Often the problem is caused by a poor connection of the terminals of both the “negative” and “positive” wires.

How to stabilize floating speed

- Penetration of foreign air into the engine. It is necessary to check the tightness of the air system channels with the intake manifold. For such purposes, it is necessary to dismantle each hose separately and pump it with a pump or compressor, but you can try spraying liquid -40 on the hoses, where it will quickly evaporate; there is most likely a crack in the hose. In such a situation, it is better to replace the damaged hose with a new one rather than wrap it with electrical tape.

- Replacement of IAC. The condition of this device is checked with a conventional multimeter, which needs to check its resistance. If the resistance readings are in the range of 40-80 Ohms, the regulator is faulty and such a device requires immediate replacement.

- Cleaning the valve and elements of the engine ventilation system. In this case, you will have to disassemble the oil sump and get to the ventilation valve. It should be pulled out and washed in a product for cleaning engine elements from an oil film. You can use regular kerosene. Next, dry the valve thoroughly and then put it in its place.

- Replacing the air flow sensor. This is the most delicate part and most often cannot be repaired. Therefore, if the cause is the air flow sensor, then it is advisable to replace it. It is known from practice that even professionals cannot repair a hot-wire anemometer.

- Flushing the throttle valve and then installing it in the correct position. There are two methods for cleaning the throttle valve from oil contaminants: without removing it from the car, and also with removing the throttle valve. When removing the damper from the car, you must disconnect all wires and hoses from the damper, loosen it and pull it out. Next, place it in a container and fill it with cleaning aerosol. If the oil stains on the surface of the throttle valve are already old, you can clean them with a brush. Next, dry the damper surfaces with a rag and put them in place, connecting all the wires and hoses. If the damper is not removed from the car, then it can be washed on a hot power unit with a similar aerosol. Before spraying cleaning agent, disconnect power from the throttle valve. First you need to pour the product inside the throttle valve, wait a few minutes and start the engine. With the power unit operating, continue cleaning the damper with the same product. If, during such cleaning, white smoke comes from the damper, then this is normal, since oil contaminants are cleaned in this way. At the end of the work, you should connect the wires and adjust the operating order of the throttle valve on the computer, setting the required opening gap.

- Idle speed adjustment. This procedure can be carried out using a regular screwdriver, adjusting the screws for the quality of the fuel mixture and the number of engine revolutions.

- Replacing the solenoid valve. If the carburetor idle valve malfunctions, the engine can only operate when the choke handle is pulled out. Therefore, in order to prevent idle speed fluctuations, it is advisable to replace the valve with a known good one or a new one.

- Cleaning the idle air jet. Even in the old days, cleaning the jet from oil deposits was considered a very labor-intensive task. Currently there is no need to remove the jet from the carburetor. To do this, you just need to pour a specialized product into it, designed for cleaning carburetors, and wait in this state for several minutes. Then you need to clean the nozzle from dirt using compressed air.

- Treatment of parts of the fuel pump on a diesel engine from rust. To perform this task, you will need a specialized corrosion cleaning agent. This can be either an imported or a domestic product. It is simply sprayed into the fuel tank by opening its neck before refueling with diesel fuel at a gas station. The cleaning agent will clean the pump parts from rust on its own. In order to prevent similar corrosion of the high-pressure pump in the future, it is recommended to pour a glass of motor oil into the tank, which can form a protective film on the surface of the pump parts when moving.

We recommend: Non-contact ignition system (BSI)

You need to know that if uneven engine speed occurs at idle, you must immediately contact a service station and carry out detailed diagnostics of the operation of all engine systems. Timely detection of faults will protect you from costly repairs.

Recommendations

Comments 32

The guys will laugh, but the fact is the fact, I have the same thing! Observation: there was no such problem until I installed a grid (blades) similar to that of the creator of the topic!

No, exactly, the fuel consumption on the highway is 6.0 - 6.3, I drive long distances at 120-140 km per hour, the temperature sensor was also changed to a new one half a year ago. I thought about it too, most likely I’ll buy a new one to check, thanks)))

The temperature sensor may be faulty, hence the ECU reads the readings incorrectly and slowly lowers the speed. Consumption should increase, haven’t you noticed?

It looks like this is the firmware, maybe it was already flashed by someone? The speed there is fixed based on temperature.

I adjusted the firmware myself to set the speed I wanted at any engine temperature.

Class. I want that too. What do you need to have for this?

You don't need to know much. Open the firmware file on your computer, for example in the Chiptuning program, configure what you need, and then upload the saved firmware to your brain. I have Bosch 7.9.7+

yes you need to solder to flash it

It’s clear, I know how to solder, but I’m afraid I’ll have to buy new ones later))) I’d rather pay the master 2.5 thousand)))

Here, as they say, the master is the gentleman. I actually tried different firmware and in the end I liked the stock Priora B174DT07 (Euro-4)

wow, cool, but do you have 2 oxygen sensors?

yes, the stock firmware was Euro 3

This happens to everyone even on staff to warm up the engine

no, not everyone is wrong, the revolutions should gradually drop when warming up, but for me they normalize when fully warmed up to 90 only, this is not correct))

It’s good in winter, it heats up quickly, it’s built into the firmware, but if there’s air leaks, then the revs will be low and it’ll stall.

oh exactly, thank you))) in winter, yes, but in summer it’s very unpleasant when the idle speed is higher than normal, it’s annoying because there’s no smoothness and when changing gears the car jerks as if I’m behind the wheel for the first time in my life, and in winter I’ll skid everywhere) ))

Read more: Replacing handbrake cables for Skoda Octavia A5

It's installed in the firmware, and it's the same for me.

The engine runs erratically or stalls at idle Lada Priora

| The engine runs rough or stalls at idle | ||

| List of possible faults | Diagnostics | Elimination methods |

| Unreliable connection of electrical circuits of engine control and power supply systems | Check the connection of the electrical connectors of the wiring harnesses, the reliability of the contacts in the wire lug blocks | Troubleshoot connector connections |

| The gap between the spark plug electrodes is not normal | A gap of 1.0–1.1 mm is checked with a round feeler gauge | Set the required gap or replace the spark plugs |

| A lot of carbon deposits on the spark plug electrodes; ingress of carbon particles into the gap between the electrodes | Inspection | Check and replace spark plugs if necessary |

| Spark plugs are faulty: current leakage through cracks in the insulator or carbon deposits on the heat cone, poor contact in the central electrode | The absence of external damage and sparking between the electrodes on the inverted spark plug does not allow us to draw a conclusion about its functionality | Replace spark plugs |

| Damage to the insulation of high-voltage devices and circuits | Using an ohmmeter, check for open or breakdown (short to ground) of the ignition coil windings | Replace damaged ignition coil |

| Disturbed valve timing | Check the alignment of the marks on the crankshaft and camshaft pulleys | Establish the correct relative position of the shafts. Check compression |

| Low compression in the engine cylinders (less than 11 bar): wear or damage to valves, their guides and seats, stuck or broken piston rings | Check compression | Replace faulty parts |

| Faulty: phase sensor, throttle position sensor, injectors (break or short circuit of windings, nozzles are very dirty) | Check the timing sensor, throttle position sensor, injectors Check whether +12 V is supplied to the controller, injector operation, electrical circuits and sensor | Replace faulty sensors, wires, injectors. Contaminated injectors can be washed at a special stand at a service station |

| The idle speed controller or its circuits are faulty | Replace the regulator with a known good one. | Replace faulty regulator |

| Suction of foreign air into the intake tract | Inspect the joints, check the fit of the hoses, fittings, and the tightness of the clamps. During start-up, turn off the vacuum brake booster by plugging the intake manifold | Replace torn gaskets, parts with deformed flanges, faulty vacuum booster |

| Fuel pressure regulator is faulty | Check the pressure in the fuel system with a pressure gauge (at least 3.6 bar) | Replace the faulty regulator |

| The adsorber is faulty, the connections of the hoses of the fuel vapor recovery system are leaking | Check the adsorber for damage, the serviceability of the purge solenoid valve and the tightness of its connections | Replace faulty adsorber, purge valve, hoses and tubes. Eliminate leaky connections |

| Sticking of the throttle valve or its drive. Under these conditions, the controller does not regulate engine idle speed. | Check the ease of movement of the damper | Adjust the drive, throttle position. Replace the throttle assembly |

| The control oxygen concentration sensor is faulty | The Check indicator is on. You can evaluate the performance of the oxygen concentration sensor and the reliability of its electrical circuit connections using diagnostic equipment | Restore damaged electrical circuits. Replace faulty sensor |

| Camshaft cam wear | Inspection after partial disassembly of the engine | Replace camshaft |

| The hydraulic pushers in the valve drive are faulty | Check compression | Replace faulty hydraulic pushers |

| Vehicle speed sensor is faulty | After stopping the car, the engine runs unevenly, but soon the idle speed stabilizes | Replace the vehicle speed sensor |

Video on the topic “Lada Priora. The engine runs erratically or stalls at idle.”

Unstable idle on Priora, what is the reason

Priora's revs float - one of the solutions

idle speed disappears. stalls at traffic lights. in neutral. cause found

Conclusion

Many car enthusiasts do not know the reasons for the appearance of the effect of high idle speeds, and especially the methods for eliminating them. So, naturally, experts and car mechanics advise contacting a car service right away, but our man, until he tries it himself, don’t slow down.

There are many reasons for the appearance of the effect of high speed, from faulty sensors to an error in the electrical control unit. You can also fix the problem at home, which is what owners of VAZs and other Russian cars do. But owners of foreign cars will have to contact a car service center, where repairs can cost a large amount.

Source: avtodvigateli.com

When releasing the gas, the speed is increased or “freezes”: common malfunctions

Let's start with the fact that on many cars with an injector, the ECU raises the speed while the internal combustion engine is warming up. This is necessary to ensure that the power unit operates stably after a cold start.

However, after the temperature rises, the control unit reduces the idle speed, bringing it to normal. On many cars with a carburetor, the driver independently increases the speed during warm-up, using the so-called “choke”.

Moreover, after the engine is warmed up, the normal idle speed is, on average, 650-950 rpm. If you press the gas and release the accelerator, the speed should increase, and then decrease again to the specified values.

Also, a situation often arises when the speed drops slowly or is constantly kept at around 1.5 thousand rpm, 2 thousand revolutions, etc. Naturally, in such cases, consumption increases and the internal combustion engine wears out more, which indicates the need for diagnostics.

So, let's start with common carburetor problems. Often the engine speed does not drop due to problems with the throttle valve. For example, when the driver steps on the gas, the throttle must be opened wider to allow more air to enter the cylinders to burn fuel. After the gas pedal is released, the throttle closes and the speed decreases.

If the damper does not close completely, an over-enriched mixture enters the cylinders, and the speed is increased. The cause may be severe contamination of the throttle assembly or damage to the valve itself (deformation). First you need to clean the damper; carburetor cleaning liquid is suitable as a cleaner.

We also note that the damper does not close tightly even when the drive cable is worn out. In this case, the cable must be replaced. On carburetor cars, engine speed often does not drop even if the gasket between the carburetor and the cylinder head has failed. The culprit may also be an intake manifold that is damaged.

It should be noted that after cleaning the carburetor and fuel system, the engine speed slowly drops due to a failure in the adjustments of the idle system itself. In other words, after any manipulations with these components, the carburetor should be separately configured and adjusted.

The main task is to find the correct ratio of fuel and air. Often, a high level of fuel in the carburetor float chamber also leads to increased speed. The check should begin with the needle valve.

Now let's move on to the injector

Please note that on many injection cars, after cleaning the throttle valve, the assembly also needs to be additionally “trained”. As for problems, the injection system itself is more complex, that is, there are more reasons for high speeds compared to a carburetor

As a rule, problems with speed can be caused by problems with both mechanical elements and electronic components. In the list of main malfunctions, experts highlight malfunctions of the coolant temperature sensor, which is installed in the cooling system.

Currently reading

UMZ-4218

Oil is flowing from under the oil filter: why does this happen...

In simple words, if the specified sensor gives an incorrect signal, the ECU considers that the engine is cold and activates the warm-up mode. In this case, the control unit raises the speed so that the power unit operates stably and reaches operating temperature faster.

Also, problems with speed can begin due to problems and malfunctions in the operation of the IAC (idle air regulator). It also happens that the throttle cable gets stuck and becomes wedged. The spring that closes the throttle valve may also become stretched or damaged.

Special attention should be paid to gaskets, since air leaks can lead to disruption of mixture formation. This means that you need to separately inspect manifold gaskets, injector seals, etc.

Let's sum it up

As you can see, in order to accurately determine why the engine speed is not reset, in many cases in-depth diagnostics may be necessary. For carburetor engines, cleaning and adjustment of the carburetor itself is often necessary, while the injector will require computer diagnostics.

If the problem is not on the surface (the throttle cable has become sour, after washing or dry cleaning, the carpet in the cabin is not installed correctly, which presses the gas pedal, etc.), then it is better to take the car to a service center.

The most complex situation is when the design of the power system involves the presence of a large number of sensors and actuators. In this case, even the use of diagnostic equipment does not always allow you to quickly and accurately determine the problem.

Ignition system

This is another fairly common option and the reason why the Priora has difficulty starting when cold. Almost regularly, due to sudden and constant temperature changes, various microcracks form in the ignition coils. When the coil heats up, it tends to expand. If there are cracks between the walls of the coil, then there is no hot breakdown, since the gap in the crack will be minimal. When it is cold, the microcrack will be larger and as a result there will be a breakdown. There will be no spark on the spark plug. There is no ignition of the mixture, the car does not start well.

The problem exists not only with the ignition coils, but with any other components that operate in the Priora ignition system. This could be a distributor, wires, spark plugs. In this case, there is nothing better than replacing the coil and other elements.