Under the hood of the "six"

Adjusting the idle speed of the VAZ 2106 is intended for:

- restoring proper engine operation if idle speed is lost - maintaining stable crankshaft speed;

- adjusting the emission of toxic substances and carbon dioxide into the atmosphere, reducing these indicators to a minimum.

The adjustment will eliminate excess fuel consumption and normalize the amount of CO2. If the content of harmful substances in the exhaust gases of a vehicle is critical, its operation is prohibited.

If the idle speed of a VAZ 2106 is lost, this may indicate the following problems:

- the idle fuel jet is clogged;

- the solenoid valve is damaged if it is installed on the XX jet;

- The carburetor is not adjusted.

The breakdown is accompanied by unstable operation of the engine at low speeds. It may stall after heavy braking or while driving.

One of the elements of the carburetor on the VAZ 2106 is the idle fuel jet, which can be made with or without a solenoid valve. In the second case, a blank holder is installed instead of the EMC.

Briefly about the features and structure of the “six” carburetor unit

Before adjusting the carburetor on a VAZ 2106, it doesn’t hurt to know its design features. After 1980, Ozone and Solex began to be installed on Tolyatti cars. The purpose of the unit’s operation is to prepare a combustible mixture before feeding it into the car’s cylinders. Down to the subtleties, this is not a driving school, we will not disassemble the design, it is enough to familiarize yourself with the main components that ensure optimal operation of a carburetor internal combustion engine:

- Fuel dosing system.

- Mechanisms for controlling throttle valves and enriching the mixture.

- Idle system.

- Accelerator pump and econostat.

- Float chamber.

A chamber with a float and a needle valve is responsible for the stability of the fuel level. Next, gasoline, flowing through the spray tube, enters the chamber, where it mixes with air from the inlet pipe. The amount of mixture is adjusted by the throttle valve, which is connected to the accelerator pedal.

Precise adjustment allows you to prepare the correct mixture of gasoline and air in a ratio of 1:15. During long-term operation of the car, the settings get lost and you have to think about how to adjust the carburetor on a VAZ 2106 on your own. The adjustment technology is the same for both Solex and Ozone.

How to adjust the carburetor

As a rule, after removal, all parts of the carburetor are thoroughly cleaned of dirt and deposits. Let's look at the main stages of cleaning.

Cleaning the jets

Jets are thin channels in the carburetor through which air and fuel are supplied. Mechanical cleaning of these channels is strictly prohibited, so the jets can only be cleaned with compressed air. To purge the channels, motorists use a tire pump. As a rule, this is enough.

Electric car pump, which is convenient for cleaning the jets in the DAAZ 2107 carburetor

But if the carburetor is very dirty, place it in a container with kerosene for half an hour. After soaking in kerosene, even the most stubborn stains are easily removed.

Cleaning the float chamber

The best tool for cleaning the carburetor float chamber is a rubber medical bulb, with the help of which all remaining fuel, along with accumulated contaminants, is carefully pulled out of the chamber. Do not wipe the float chamber with fluffy materials, as fluff may get into the jets.

It is convenient to clean the float chamber of the DAAZ 2107 carburetor with a rubber bulb

Flushing the throttle valve

The throttle valves in DAAZ 2107 carburetors are cleaned using various cleaning compounds purchased at auto stores (most often this product is WD40 liquid).

The damper itself and all adjacent structural elements are washed with liquid: small channels, valves, etc. And the crankcase ventilation channel should also be washed.

Video: cleaning the throttle valve on a VAZ 2107

When is adjustment needed?

Adjusting the carburetor unit is no more difficult than adjusting the clutch drive on a VAZ 2107 , since it only involves adjusting the jets. In some cases, they need to be cleaned of resins and other contaminants; the presence of contaminants is felt by power dips in the process of accelerating. Many car owners claim that Ozone carburetors are not a very good option and recommend replacing them with Solex.

However, the signs that the device has begun to prepare an enriched mixture and needs to be adjusted are the same for both types of units:

- Increased fuel consumption.

- Frequent overheating of the motor.

- Black smoke from the exhaust pipe and pops.

- Loss of power.

The preparation of a lean mixture is characterized by the following characteristics:

- Popping sounds in the carburetor.

- Loss of power.

- Engine overheating.

Of course, you don’t always need to immediately grab a screwdriver and turn the adjusting screws - perhaps it’s something else. For example, when the idle speed floats, air may leak through the intake manifold gasket, or there may be a breakdown of the brake booster diaphragm. But even the reasons listed are not all the options, so specific recipes for eliminating certain problems cannot be given. The issue should be addressed comprehensively, taking into account the connection between vehicle systems.

Preparing the carburetor for adjustment

VAZ 2107 - in the photo - the car is carburetor and is sensitive to fuel quality, therefore sometimes it needs to correct the capacity of channels and gaps

If the engine starts and runs stably at any speed and under any load, fine adjustment is unlikely to be needed. As a rule, this must be done in cases where the engine's fuel consumption exceeds the nominal values, when the engine is difficult to start, and dips appear in transient operating modes during sudden acceleration. Absence or instability of idle speed can also be treated by adjusting or cleaning channels and cavities.

Sometimes there are situations and clear symptoms that it is necessary to adjust the ignition timing or adjust the valves of the VAZ 2107, but the carburetor may be quite serviceable. Therefore, it is worth adjusting it only when there is confidence in the serviceability of the ignition system, the accuracy of setting the thermal clearances of the valves, after checking the functionality of the fuel pump, and good compression in each of the cylinders.

Adjustment may not bring results if the carburetor is clogged or has obvious mechanical problems or leaks. Therefore, a thorough inspection and assessment of the external condition of the device is necessary. Adjustment and configuration begin only when all these conditions are met.

Preliminary stage

Before you properly adjust the carburetor on a VAZ 2106 with your own hands , it is important to carry out a number of work steps:

- Adjust the thermal clearances of the gas distribution mechanism.

- Set the optimal ignition timing.

- Open the air damper completely.

All work on setting up the carburetor unit is carried out on a warm engine. Do not forget that during the process you may need new parts and rubber products, so it is better to purchase a repair kit in advance.

Checking engine systems

The car engine runs on gasoline; the composition and quality of the fuel does not always meet the standard requirements. A clogged carburetor can lead to unstable engine operation. Depending on how clogged the carburetor is, this can manifest itself in different ways, even to the point that the engine may stall.

Reasons for unstable idling of the VAZ 2107 car:

- the air filter is clogged;

- the strainer, jets and their channels are clogged;

- incorrect fuel level in the float chamber;

- difficulties or limitation of valve travel in the EPH;

- air suction through tubes, membranes or damaged gaskets;

- incorrect gap between contacts or their burning;

- bad candles;

- incorrectly adjusted ignition.

Before you start adjusting the idle speed, you need to eliminate the problems listed above, if any, otherwise you will not be able to achieve the result.

Float adjustment

One of the main stages in setting up a carburetor unit. A high level will produce a “rich” mixture, and more of it will be supplied to the cylinders, but there will be no expected dynamics. Only fuel consumption will increase, as well as its toxicity.

The float tongue must be installed so that its stroke is no more than 8 mm. In some cases, the problem may be the needle valve. Then you need to remove the float, pull out the needle and check the patency of the holes.

Carburetors used on the VAZ-2107, or those whose use is possible

Fundamentally, all these devices can be divided into only two groups.

The former trace their history back to the Weber carburetor modified for the first VAZ cars. This is a structural division of the Italian company Magneti Marelli, which works closely with the FIAT concern. Namely, this is where all the VAZ classics came from. After significant reconstruction, the family received the generic name “Ozone”. They were installed on the VAZ-2107 on the assembly line. The second direction consists of more advanced, yet simple, French Solex devices, produced in Russia by the same factories for the next generations of VAZ cars. The change in the vector of development had an effect, when the first front-wheel drive cars were developed with the participation of German and French companies. As more economical, these carburetors were also adapted to the families of Tolyatti cars with a longitudinal engine. For VAZ-2107 with 1.5 and 1.6 liter model 21053-1107010-20 ; the car will become more economical, although engine output will decrease in some modes. But this is a completely different carburetor; it was not used on production cars, and its adjustment is completely different.

- 2107-1107010 — the carburetor is equipped with a number of parts for working with the electronic forced idle system (EFI). Configured for the operation of a vacuum ignition timing regulator.

- 2107-1107010-10. The same device, but much simpler, does not have a vacuum supply tube to the regulator and is not equipped with a valve and switch for the EPHH system.

- 2107-1107010-20. The most common modification. Controls a vacuum regulator, not intended to work with capricious EPHH.

All these models are structurally very similar, but differ in a number of calibration data; accordingly, the difference in adjustments is mainly numerical in nature.

Setting idle speed

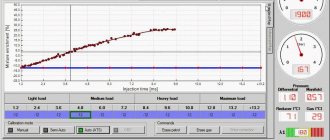

The process involves two screws that set the quantity and quality of the mixture. For high-quality settings, having a gas analyzer will not hurt. Before adjusting the carburetor on a VAZ 2106, you need to know about the restrictive plastic bushings that are pressed onto the adjusting screws. These plugs do not allow you to violate the factory settings. If this factor prevents you from setting XX normally, then you should break them out with a slotted screwdriver.

Idle speed control technology:

- With the air damper open, set the crankshaft speed screw to 800-900 rpm.

- Rotate the quality screw to set the maximum engine speed.

- Using the quantity screw, set the speed on the tachometer to 950-1030 rpm.

- Use the quality screw to set the maximum speed again.

- Repeat these operations until the speed of 950-1030 rpm does not coincide with the maximum speed set using the quality screw.

- After the moment of coincidence, return the quality screw to the position where the engine speed was 800-900 rpm.

If you have a gas analyzer, use a quality screw to achieve a CO concentration in the exhaust gases of 0.5-1.2%. The final position of the screws must be secured with plastic sealant to prevent spontaneous unscrewing.

Why do you have to adjust the idle speed?

For proper adjustment, you need to know how to adjust idle operation. If everything is done correctly, the procedure will not take much time. However, to do this you need to understand how the carburetor works and how it works. The main trouble associated with this problem is not the lack of idle speed, but the fact that the engine cannot operate stably and stalls.

Why can't the engine hold idle?

If the engine does not hold idle, first, you need to check the solenoid valve. However, it is not installed on all types of carburetors used in the VAZ 2106. If it is, then most often the problem is hidden in it.

In its operation, the valve is similar to a starter solenoid relay, it is even designed in the same way: there is a winding, a spring, a stator, but the overall dimensions are much smaller. The solenoid valve is needed to open fuel access when the throttle valve is in the closed position (gas pedal released). When the ignition is turned off, the valve should block fuel from reaching the carburetor.

Malfunctions of the solenoid valve that cause problems with stable idle speed include the following breakdowns:

- the winding is broken, the rotor does not move, and fuel does not enter the float chamber;

- the fuel nozzle is clogged with dirt;

- the rotor is deformed and jammed.

There is no need to contact specialists to diagnose valve problems. To check, just take a piece of wire and strip it from both sides of the insulation. One end of the wire must be connected to the positive terminal of the battery, the second is connected to the contact of the solenoid valve. There should be a click when connected. If this does not happen, the valve is faulty and should be replaced. There was a click - then you need to remove the wire and turn on the ignition, and then connect the terminal block to the valve terminal. If a click is not heard, this indicates a wire break in one of the sections of the circuit.

There are three ways to solve a problem with a faulty solenoid valve.

- If the valve is destroyed, you need to, firstly, unscrew it, and secondly, remove the fuel nozzle. This way you can get to the nearest auto parts store and buy a new valve. It costs mere pennies (no more than a hundred rubles).

- If the wiring is broken in a section of the electrical circuit, you can connect the valve output to the positive terminal of the battery using a wire and then drive to the store.

- The most effective temporary solution is to connect the valve contact using a suitable wire to the ignition coil contact. This way, voltage will be supplied to the valve only when the ignition is turned on. When the ignition is turned off, the valve will close.

If the problem is not the solenoid valve

Problems with idle speed can also occur due to low-quality fuel, a malfunction of the ignition system, or dirt. These factors appear both separately and together. Idle speed may become unstable or disappear completely. If you decide to diagnose the problem globally, then it is better to start troubleshooting by checking or replacing the air and fuel filters (including the fine filter on the fuel pump). If there is heavy contamination, the fuel-air mixture will flow into the carburetor intermittently.

You should also pay attention to the filter installed at the mixture inlet to the carburetor. If there is contamination, the filters must be replaced. If the problem XX still remains, it means that the search circle is expanding significantly. The next step is to check the spark plugs. If the spark plugs were last changed more than 30,000 km ago, they must be replaced. You should pay attention to the carbon deposits, or more precisely, to its color. If the service life has expired, the gap between the electrode and the spark plug will increase due to severe wear. After replacing the spark plugs, you need to check the stability of the idle speed again.

If replacing the spark plugs does not help, then you should check the ignition system. For a contact system, first of all, the breaker gap (slider) is measured and the correct ignition timing is set. In the case of a contactless system, you need to check the serviceability of the switch and Hall sensor. As a rule, these parts fail first, although nothing else can break there.

It would be a good idea to inspect high-voltage wires. If they are wet or dirty, they should be wiped down and inspected for damage, as well as checking that the insulation is intact and that there is no loss of spark. You can also inspect the distributor cover; it should not be damaged. And finally, you can measure the resistance of the resistor on the breaker; it should be within 5.5 kOhm.

Adjusting the rods

An equally important stage in the process of adjusting the “six” carburetor is performed through the transitions:

- Remove the air filter and its housing.

- Measure the distance between the central points of the tips, it should be 80 mm .

- To change the length of the rod, release the tip with a screwdriver and unscrew the lock nut with an “8” wrench, and then perform the adjustment by rotating the tip.

- Tighten the fasteners and install the rod in its original place, start the engine and press the gas pedal all the way. If the throttle does not open completely, the damper has a travel reserve.

When asked how to further adjust the carburetor on a VAZ 2106, experts recommend performing a few more simple steps:

- Remove the end of the longitudinal linkage and unscrew the locknut.

- Reduce the length of the rod, secure it and again check the degree of opening of the damper by pressing the gas pedal to the floor. The damper must be completely closed.

- If it is necessary to increase the rod length, you need to loosen the throttle cable.

VAZ 2106 carburetor maintenance

During the operation of the carburetor, the narrow channels of the jets become clogged. This usually happens when using low-quality fuel, untimely replacement of the air filter, etc. The composition of the fuel-air mixture is disrupted and its flow into the engine is difficult. As a result, the power unit begins to operate intermittently, and its dynamic characteristics decrease. In such cases, it is necessary to flush the contaminated jets with a special cleaning compound and then blow them with air.

If the carburetor jets become clogged, they should be washed with a special agent and blown out with air.

In addition, it is recommended to periodically adjust the composition of the fuel-air mixture to the optimum using special adjusting screws. Otherwise, the engine will run unstably.

What do we have after proper adjustment of the carburetor unit of the “six”?

Checking the adjustments of the fuel mixture preparation unit is the same important maintenance step as monitoring the condition of the car battery . An integrated approach to setting up the carburetor guarantees not only a comfortable mode of movement, but also a lot of useful points:

- An increase in power and a confident increase in speed.

- No failures in the operation of the internal combustion engine in the low and medium speed sector.

- Improved dynamic characteristics - the car picks up speed faster and accelerates in a short time.

- Optimal engine response, which is expressed in the responsiveness of the gas pedal.

The listed qualities make it possible to effectively use the combustible mixture, which is necessary both in urban traffic jams and on country roads. Therefore, proper adjustment of the carburetor unit will help the car gain speed in a timely manner and complete the planned maneuver.

Self-adjustment of the carburetor

As a rule, when setting up a DAAZ 2107 carburetor, car enthusiasts adjust fuel consumption and idle speed. Let's look at these stages.

Idle speed adjustment steps

Setting up the carburetor in this mode is easy:

- A carburetor with a properly adjusted idle speed allows the car engine to operate stably even with very low CO levels. To do this, the car engine warms up for 10 minutes. After this, the fuel quality screw in the carburetor is turned out as much as possible.

Symptoms of a problem

If the carburetor begins to produce a rich mixture, you will understand this by the following signs:

- Fuel consumption increases

- Loud exhaust is heard from the muffler and the smoke turns black

If the engine receives a lean mixture, you will understand this by the following sign:

- Loud bangs are heard from under the hood.

In both cases, the engine heats up noticeably more, and its power is also lost.

If you encounter a similar problem, remember that it is a natural consequence of using the carburetor. Any element of the car requires care, regular inspection and maintenance. Therefore, the VAZ 2106 carburetor must be adjusted from time to time.

Before proceeding with the adjustment, you need to make sure that the cause of the breakdown is not the failure of any element inside the device. You need to disassemble it, wash it and clean it. And only after you are convinced that all components of the structure are in full working order, you can begin adjustment.

The easiest option is to send the car to a specialist. Carburetor technicians have a special tool - a gas analyzer. Using this device, you can achieve the most efficient system setup. However, the services of specialists in this profile are not cheap. You may want to do all the work yourself, using available materials. Next we will look at how to set up a carburetor step by step.

Air leak

It is one of the most difficult problems and can be caused by several reasons:

- Crooked seat

- Gasket failure

- Throttle valve not closed

To make sure that this problem exists, you need to check the color of the spark plugs and the number of idle speeds. If the speed is too high and the spark plugs have a white coating, then the mixture is lean, which means more air is coming in than it should be.

In this case, the check begins by treating the carburetor-manifold joints with a throttle valve cleaner. Start processing from the intake manifold, then move to the junction of the carburetor and manifold and complete the EPH. A change in the speed will indicate the presence of air leaks. It should be located at the joints of the gaskets.

However, the gasket may not always be the cause. If carburetors are installed and dismantled incorrectly, irregularities may form on the surface of their connections, through which air is sucked in.

Another reason is an open throttle. More precisely, not completely closed. This would be more correct, because at the bottom of the top carburetor cover there is a bolt for adjusting the throttle clearance. If it is unscrewed, the damper opens slightly and a very large amount of air passes into the diffuser, reducing the gasoline content. This is why the consumption becomes less, but the speed is too high, so it needs to be adjusted.

To fix, you need to remove the top cover and adjust the throttle position. The problem will disappear immediately.

What malfunctions can occur in the carburetor?

It is worth noting that many problems in the carburetor are very similar in their symptoms to those that appear when the fuel supply and ignition systems break down. For example, if an internal combustion engine operates unstably, the speed constantly fluctuates, and sometimes it even begins to stall, then you should not immediately blame the carburetor directly. Most likely, the reason for this behavior lies in the fuel supply system to the carburetor.

Very often the electric valve, which is mounted in the housing, fails. Its winding may burn out, which is why the fuel supply from the fuel pump does not occur. Therefore, before you start adjusting the carburetor, you need to make sure that the electric valve is working normally, its winding is intact, and the jet is not clogged. But for all other troubles, you can blame the carburetor of the VAZ 2105 - its settings are most likely out of order.