Adjusting the VAZ 2107 carburetor with your own hands will not take you much time, since the VAZ is designed in such a way that it is easier to carry out repair work yourself.

Various types of carburetors were installed on VAZ cars, but since we are talking about 2107, the DAAZ 2107-1107010 unit was installed on them. Signs of malfunction of this carburetor can be determined by pressing the gas pedal with the car running. When you press the pedal, the car will start to stall (while idling it works fine). Before starting work on adjusting the carburetor, we clean it using a special Abro product, which is quite good and not expensive compared to other similar products. Then we proceed to adjust the DAAZ carburetor on the VAZ-2107, repair it slowly, fulfilling all repair requirements strictly according to the instructions. Don’t forget - the rhythm of your car’s engine depends on the quality of your work. We will also adjust the carburetor choke - this will greatly simplify starting the engine in the cold and warming up the engine in the future. Don’t forget about cleaning the carburetor filter, since in our country gasoline is not of particularly good quality, so often the filters quickly become clogged and the car stops working as it should. Let's look at the same nuance as cleaning the carburetor on the road. It will be interesting to read not only about adjusting the carburetor, but also adjusting the valves of the 2107 carburetor.

The main component in a car is the engine. You can safely put the carburetor in second place in importance. The main task of this part is to ensure normal operation of the power unit in a variety of operating modes (during acceleration, at idle, during starting and braking). It is in the carburetor that the air-fuel mixture is prepared, which is subsequently ignited in the combustion chamber.

A small violation in the adjustment of the device can lead to a number of negative consequences - problems with starting the engine, increased fuel consumption, deterioration in dynamics, decreased power, and so on. To prevent such problems, it is important to timely tune and adjust the carburetor.

Main types of DAAZ Carburetors

DAAZ 2107-1107010 - installed on the VAZ 2105, as well as the VAZ 2107.

DAAZ 2107-1107010-20 - installed, as a rule, on new VAZ 2106 VAZ 2103.

DAAZ 2107-1107010-10 – installed on VAZ 2106 or VAZ 2103 engines without a vacuum corrector with an ignition distributor.

At all times, VAZ cars were equipped with a variety of types of carburetors - Ozone, Weber, Solex and others. However, some of them are still popular today. Generally speaking, the types of carburetors are float, bubbler and needle.

In our article we will pay special attention to the “native” carburetor of the VAZ-2107 – “Ozone”. At the same time, I would immediately like to note that these devices come in different series. For example, DAAZ 2107-1107010 was most often installed on “fives” and “sevens”. In turn, the marking of carburetors on “sixes” and “threes” was slightly different - DAAZ 2107-1107010-20 (or a similar type, but with 10 at the end).

Setting up idle speed

First, you should make sure that the ignition adjustment is correct. The engine must be at operating temperatures. To adjust, you need to rotate the fuel mixture quality adjusting screw until the engine speed reaches maximum.

Next, you need to rotate the fuel quantity screw counterclockwise. An even higher speed should be achieved.

Now it’s worth turning the quality screw to add a little more speed.

The point of these operations is to ensure that the quality of the mixture is minimal, and the idle speed is from 850 to 900. These are the most optimal values for carburetor engines of cars of the “Classics” family. You should not make revolutions more or less than this value, as they will be considered unstable and will entail increased wear of the crankshaft parts.

We looked at several possible adjustment methods that you can do yourself. But if you are not confident in your actions, it is better to entrust your DAAZ 2107 (carburetor from the “seven”) to a specialist who is well versed in them.

The engine in a car is the most important unit. However, it will not start without a working carburetor. Even a slight inaccuracy in the adjustment of this device will be enough for the driver to experience serious problems. But many troubles can be eliminated on your own, without resorting to the expensive services of mechanics from a car service center. Repairing a DAAZ carburetor is quite feasible in a garage.

Design Features

The main parts of the carburetor include the exhaust shut-off valve, the burnt fuel assembly outlet compartment, the transition chamber system, the throttle valve, the dosing system, the econostat, the float chamber, as well as the autonomous exhaust system. Each of these nodes performs its own function. We won’t delve deeply into this issue - the knowledge you’ve already gained will be enough to set it up.

- Float chamber.

- Econostat.

- Autonomous idle system.

- Idle clearance valve.

- Throttle valve.

- Dosing system.

- Transitional system of two chambers.

- Crankcase gas removal department.

What do we have after proper adjustment of the carburetor unit of the “six”?

Checking the adjustments of the fuel mixture preparation unit is the same important maintenance step as monitoring the condition of the car battery . An integrated approach to setting up the carburetor guarantees not only a comfortable mode of movement, but also a lot of useful points:

- An increase in power and a confident increase in speed.

- No failures in the operation of the internal combustion engine in the low and medium speed sector.

- Improved dynamic characteristics - the car picks up speed faster and accelerates in a short time.

- Optimal engine response, which is expressed in the responsiveness of the gas pedal.

The listed qualities make it possible to effectively use the combustible mixture, which is necessary both in urban traffic jams and on country roads. Therefore, proper adjustment of the carburetor unit will help the car gain speed in a timely manner and complete the planned maneuver.

Setting up the DAAZ carburetor on a VAZ-2107

Please note that the adjustment process will take some time. It is necessary to work slowly and strictly follow the instructions. Please note that the characteristics of your engine and its “gluttony”, and therefore your further costs, depend on the accuracy of the settings. The general operating algorithm is as follows:

— inspect the part for damage and defects;

— clean and rinse all parts from dirt and debris;

— clean the mesh filter;

— wash the float chamber;

— clean the air jets;

— adjust the XX carburetor, trigger mechanism and float system.

Now let's look at each stage in more detail:

- Restoring the mesh filter is performed in the following sequence:

— using a gasoline pump, pump fuel into the carburetor chamber until the shut-off valve closes;

— move the filter “cap” to the side and remove the valve;

— rinse the valve in solvent and dry (you can use a source of compressed air).

Please note that the presence of “dips” during engine operation, decreased power, and “dullness” of the car are often associated precisely with filter contamination.

- Clean the float chamber. For these purposes, use a special rubber bulb. After this, dry the product. Wiping the bottom of the float chambers with ordinary rags is prohibited. Otherwise, pieces of lint may remain at the bottom of the carburetor, which is likely to clog the jets and lead to a number of problems.

- Check the tightness of the locking needle. This can be done using a special pear. Make sure the floats are on top and replace the lid. Press down on the bulb and listen to see if air is leaking anywhere. If there is a leak, the valve body or needle may need to be replaced.

- Adjust the float system. For this:

— check what position the float is in. If it is displaced, then straighten it using a special holder;

— make sure the needle valve is closed;

— open the chamber “hatch” and move the float. Next, lightly pull the “tongue” of the bracket towards you;

— set the required distance between the float and the hatch gasket. The optimal parameter is 6-7 mm. If the measured value does not fall within this range, then adjustment is necessary. In case of immersion, the gap should be no more than one or two millimeters. Otherwise, the needle can be rejected;

- measure the gap that actually appears between the float and the needle. When the valve is open, this value should be 15 mm.

The above checks can be performed without dismantling or with dismantling the carburetor.

- Adjust the starting system. To do this job you must remove the air filter, start the car and pull the choke out about a third of the way. Your task is to achieve 3,200-3,600 rpm. As soon as this parameter is set, release the air damper and set the rotation to about 300 rpm less.

- Adjust idle speed. Tighten the quality screw completely, and then make 2-3 turns to the side in a clockwise direction. Check that the quantity screw is not fully tightened. Next, warm up the engine to operating temperature (the choke should be open). As soon as the engine has warmed up, remove the choke and listen to the operation of the power unit. If the engine starts to stall, then slightly turn out the quantity screw. If the speed is too high, then, on the contrary, screw the screw back in a little.

Your task is to set 900 rpm. By rotating the quality screw, achieve the minimum speed during stable operation (in this case, the speed may increase). After this, use the quantity screw to return to the 900 rpm parameter. If necessary, use the quality regulator again.

Engine operation before and after adjustment

Preventive and regulatory measures must be carried out in a certain sequence.

Carburetor maintenance steps:

- external cleaning of the device;

- visual inspection of the unit, which may reveal some problems;

- dismantling and cleaning the mesh filter element (this must be done every 60 thousand mileage).

- cleaning air jets;

- if necessary: setting the XX, PU and float assembly.

As a result of such simple measures, the engine will start easily, there will be no interruptions in its operation, the car’s dynamic characteristics will improve, no dark smoke will be visible from the exhaust pipe, fuel consumption will return to normal, and the engine noise will decrease.

Of course, many types of car maintenance work are not so easy to do at home. However, this does not apply to the system for preparing and supplying the fuel-air mixture.

Knowing what the carburetor diagram looks like, the principle of its operation, as well as the installation standards for the main parameters, each car owner of a car on which the DAAZ 2022 is installed is able to carry out most of the work on adjusting and repairing the device independently. This allows you to save material resources and time that you have to spend on trips to the service.

Solex carburetor VAZ2107, how to adjust the float system with your own hands

To adjust the float chamber, you must perform the following actions:

- We check the position of the float and pay attention to the shape of the mounting bracket - if it is deformed, it needs to be aligned. This is quite important, since otherwise the float will not sink into the chamber normally.

- We adjust with the needle valve closed. It is necessary to open the float chamber cover and move it to the side. Next, carefully pull the tongue of the bracket. You should ensure that there is a distance of six or seven millimeters between the float and the cover gasket. After immersion, the distance should be approximately one or two millimeters. If it is significantly larger, the needle must be replaced.

- When the needle valve is open, the distance between the float and the needle should be about fifteen millimeters.

It is worth noting that it is not necessary to remove the carburetor from the engine to perform these steps.

Now let's look at how the carburetor works, ensuring the distribution of the fuel-air mixture:

- Acceleration pump.

- Econostat system.

- Maintains constant fuel level.

- Idle support.

- Support for engine starting and warming up.

- Jets (air and fuel), diffuser, VTS atomizer, well and emulsion tube are located in the main metering chamber.

The carburetor is adjusted after cleaning and assembly. Before you start disassembling and cleaning, I suggest you remember the main saying of any auto mechanic - “Don’t make a fuss while it’s quiet,” meaning that you shouldn’t get into a place where everything is in order or disassemble something that has nothing to do with the breakdown.

Setting the carburetor choke

How much trouble does incorrect carburetor choke adjustment bring to drivers, especially in winter. In some cars, you pull the choke all the way, but the engine does not hold speed, you have to hold the gas pedal until it warms up. For others, on the contrary, you pull the choke to the end, and the engine screams like crazy, although during warm-up such high engine speeds are unnecessary.

The whole point is that the lever for forced opening of the carburetor throttle valve is incorrectly adjusted when the choke is pulled.

All this is easy to fix; in the photo above the arrow shows the thrust for forced opening of the throttle valve at the moment the choke is pulled out. If the engine does not hold speed, then it is possible that the rod is on the lower hole of the throttle lever; the photo shows two holes for the throttle rod. Move the rod into the upper hole of the lever.

If the engine is spinning very quickly on the choke, then use pliers to slightly bend the rod shown by the arrow; it bends easily without removing it from the carburetor; if the engine speed is low, straighten this rod. In this way, you can easily adjust the desired engine speed when starting on choke.

Setting the choke engine speed in a VAZ 2108 carburetor is even simpler; the photo above shows boot 3; by tightening it, the choke engine speed will increase, and unscrewing it will decrease.

I hope that after reading this article, you can easily adjust the carburetor on your car yourself.

Adjusting the fuel level in the float chamber

The free play of the float should be 6.5 mm on one side and 14 on the other. This can be adjusted using a checking template by placing the camera vertically. In this position, the float slightly touches, but does not press on the valve ball.

If the distance does not correspond to the required 6.5 mm, then you need to slightly bend the tongue of the valve (needle-shaped), adjusting the size to the required one, indicated in the figure by the arrow under the letter “A”.

The next step is to adjust the degree of opening of the needle valve through which gasoline enters the float chamber. When the chamber is filled, the float rises and the flow of fuel decreases; when you sharply press the accelerator pedal and open the throttle, the fuel goes into the cylinders, the float drops and gasoline enters the float chamber.

Next, we adjust the deflection of the float in the opposite direction. To do this, move it away from the lid as much as possible and measure it with a template, the thickness of which should be 14 mm with a certain tolerance (Fig. above, picture on the right).

If the distance is greater or less, you need to bend the stop of the float mounting bracket and set it to no more than 14 mm.

Now, after the adjustments have been made, the free play of the float should be within 8 mm. Adjusting the VAZ 2107 carburetor also includes checking fuel filters and incoming screens to maintain a good supply of fuel.

Carburetor filter, how to clean the strainer

By pumping, fill the float chamber with fuel. As a result, the shut-off valve will close, after which it is necessary to move the upper section of the strainer, remove the valve and clean it with a solvent. To get the most optimal result, it is advisable to use compressed air to purge the valve.

When cleaning the bottom of the float chamber, do not use a rag, as this may cause fibers to appear on the bottom, causing the carburetor jets to become clogged. For cleaning, it is advisable to use compressed air or a rubber bulb.

When checking the shut-off needle for leaks, a bulb is also used, since the pressure that appears due to squeezing this object with the hands approximately corresponds to the pressure of the gas pump. When installing the carburetor cover, check whether the floats are set up. Significant pressure will be felt during installation. At this moment, the carburetor needs to be listened to, since air leaks are unacceptable. Even with the most minimal leak, the needle and valve body need to be replaced.

Symptoms of a device malfunction

Carburetor failure can look different. The most common situations in which the driver should pay attention to the condition of this unit:

- The car engine does not start even after several attempts. There may be two reasons for this: either there is no fuel-air mixture in the float chamber, or the proportions of this mixture are incorrect and it cannot ignite in time;

- the engine stalls at idle or its operation is unstable. The most common reason for this is a clogged nozzle. In addition, interruptions in the operation of the motor may occur due to damage to any o-ring or hose. Finally, such malfunctions can be caused by a malfunctioning solenoid valve in the carburetor;

- Engine idle speed is too high. This malfunction may occur due to incorrect carburetor adjustment or due to loose air dampers. It also occurs due to too high pressure in the float chamber, resulting from oxygen entering through damaged hoses or sealing joints.

How to clean a carburetor on the road

Sometimes it happens that the main jet in the carburetor gets clogged, if the carburetor in the classic is easy to clean, since the jet is easy to pull out, then in the VAZ 2108-2109 carburetor the jet is deep and can be pulled out for cleaning by removing the carburetor and turning it over. On the road this is of course a very long time.

There is an easy way to clean the VAZ 2108-09 carburetor jet without removing the carburetor, but you only need to remove the top part of the carburetor. In order to remove the jet from the carburetor you will need a toothpick or a finely planed stick.

To get to the jet, you need to remove the air filter pan, unscrew the bolt holding the choke cable (it is shown with an arrow in the photo below), disconnect the fuel hoses and the five bolts holding the top of the carburetor.

Next, unscrew the air jet, use a thin screwdriver to unscrew the main jet, stick a toothpick into it and pull out the jet.

After removing the jet from the carburetor, inspect the jet; there may be a speck in it; blow it out; blow it into the hole from which the jet was removed with a pump; if there is a speck in it, it will fly out into the carburetor's float chamber.

The carburetor float chamber can be drained of gasoline with a rag, then wiped well with the rag, removing debris, or blown out with a pump.

That's it, the main jet is cleaned, you can reassemble everything in the reverse order. This cleaning is easy to do on the road yourself, not to mention at home.

Sign of a clogged jet in the first chamber of the carburetor

The sign of a clogged first chamber of the carburetor is very simple: the engine runs fine at idle, but as soon as you lightly press the gas pedal, the engine stalls.

But there is a very similar sign that indicates a malfunction of the spark plugs or ignition coil; more often this sign appears in damp weather or heavy fog. You're driving a car, the engine starts to twitch, you give it gas and it accelerates, but as soon as you let off the gas the engine stalls, if you give it a little gas the engine doesn't react, if you press it into the floor or pull out the choke the engine starts to drag. It looks very much like the jet in the carburetor is clogged, but it’s not the jet, it’s the spark plugs that are failing. You can check this way: unscrew the spark plugs; if they are covered in dry black soot, then the spark plugs are to blame; if the spark plugs are very old with a lot of deposits, then such spark plugs need to be replaced or calcined on a gas stove.

Why does the VAZ engine stall at low speeds at 90c and not start?

There may be two reasons for this; the carburetor produces a very rich mixture. The rich mixture may be due to the carburetor needle (not holding the level), the float has a leak and has collected gasoline, the float level is incorrectly set, or the jets are incorrectly set to the calibers. While a cold engine needs a richer fuel mixture, which can be provided by an overflow carburetor, a hot engine needs a leaner fuel mixture, which is why the engine stalls when warming up.

The second reason is not related to the carburetor, but this is a sign that the ignition coil (bobbin) is faulty. Due to a malfunction of the ignition coil, a warm engine may also stall at low speeds and not start until it cools down.

Adjusting the throttle drive

If this drive is incorrectly configured, the car's engine response drops and acceleration dynamics deteriorate. The setup is done with an assistant.

You will need the following tools: a screwdriver, an 8-mm open-end wrench, a flashlight, a ruler or a caliper.

- Turn down the “choke” (air damper drive) completely.

- Have your assistant press the gas pedal all the way to the floor. The throttle valve will open completely, as shown in the picture below, you can shine a flashlight into the first chamber. When you release the pedal, the damper should completely close the first chamber without any gaps. If there are gaps, then proceed to the next step.

- Next, we measure the length of the rod with a caliper; it should be exactly 8 cm. To adjust the length of the rod to the required size, rotate the tips by unscrewing the lock nuts.

After all these operations have been completed, put the rod in place and repeat the check. Nowadays, rods are made of low-quality plastic, which shrinks over time. Therefore, you need to check the operation of the traction after a week or two.

We looked at all the ways to adjust the carburetor yourself. We hope this article helped you, if you have any questions, ask them in the comments and we will definitely answer.

Setting up the PU (starting device)

To begin the stage of setting up the launcher (starter), first prepare a piece of wire with a cross-section of 0.75 ± 0.05 mm and a cardboard (plastic) template 5.0-5.5 mm wide. After this, remove the air filter and clean the outside of the carburetor.

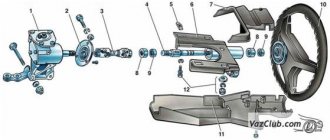

1 — three-arm air damper control lever; 2 - air damper; 3 — thrust of the starting device; 4 - rod; 5 - adjusting screw; 6 — throttle valve of the first chamber; 7 — throttle drive rod

We close the air intake completely, while the end of the rod that connects the air intake lever with the PU rod should be at the end of the groove of this rod. Then we fully retract the PU rod and, using a template or caliper (ruler), control the size of the gap between the chamber wall and the edge of the air intake. It should be 5.0 + 0.5 mm.

Now we adjust the air intake opening gap. The adjustment is made using a special screw, which is closed with a stopper. Therefore, first we unscrew the plug with a slotted screwdriver, and then we correct the opening of the air intake.

Remote control opening control

To perform this operation, you must first remove the carburetor. Then we scroll the 3-arm lever counterclockwise and use a wire to check the gap, the value of which should be within 7.5 ± 0.5 mm. If necessary, carefully bend the rod or move its tip to another hole.

Setting XX

To properly configure the XX, you will need a gas analyzer and a multimeter. Pre-warm the engine. The speed in idle mode should be within 860 ±40 rpm. First we set the lead angle.

- We switch the multimeter to the speed measurement mode and connect one probe to the primary winding of the short circuit (ignition coil), and connect the second to ground.

- We insert the gas analyzer sensor into the exhaust pipe and turn on the device.

- We start the engine and control the speed . If necessary, use the quantity screw to adjust their value to 860 ±40 rpm.

- Using the quality screw, we achieve a carbon dioxide content within 0.85 ± 0.35%. If you do not have a gas analyzer, we monitor this parameter for stable engine operation.

When configured correctly, if you sharply press and release the gas pedal, the engine should smoothly increase and then decrease speed.

Setting up the VZ drive

After dismantling the air filter, take the damper handle with your hands and move it away from you so that the air intake becomes vertical. If it was not possible to install it vertically, proceed to adjustment.

Using a 7mm wrench, hold the bushing and at the same time unscrew the screw securing the damper rod. Under the action of the spring, the air intake should be in a vertical position. Then tighten the screw.

Adjusting the air damper drive

If you don't take care of the drive, the car may stall. To do this, you will need a simple Phillips screwdriver and a 7 mm open-end wrench.

The positions of the damper are shown above with the “suction” extended and recessed.

To adjust the drive, do the following:

- drown the “suction”;

- Unscrew the rod fixing screw with a screwdriver (the spring will push it out vertically)

- Tighten the screw;

- Check the valve stroke.

Why do I adjust the carburetor myself?

Self-adjustments save money and time. There are types of work that cannot be done with your own hands without special equipment. But I am capable of servicing a carburetor, which does not have a complex design.

Therefore, I am happy to do this process myself, without outside help. After correct adjustment, there is a feeling of pride and satisfaction for the result obtained. My car runs like a clock, which is nice.

Source ru.megasos.com prosedan.ru vipwash.ru mylada.net make-1.ru

Preliminary stage

Before you properly adjust the carburetor on a VAZ 2106 with your own hands , it is important to carry out a number of work steps:

- Adjust the thermal clearances of the gas distribution mechanism.

- Set the optimal ignition timing.

- Open the air damper completely.

All work on setting up the carburetor unit is carried out on a warm engine. Do not forget that during the process you may need new parts and rubber products, so it is better to purchase a repair kit in advance.

Signs of carburetor problems

Dust, contaminants and foreign particles that enter the carburetor with fuel and air settle on the internal walls of the channels, of which there are many in the design of the unit, which leads to malfunction. The carburetor design includes a number of components, the components of which wear out and become damaged over time, which affects its performance. Signs indicating a carburetor malfunction:

- Difficulty starting the engine;

- Decrease in acceleration dynamics;

- Jerks, failures during acceleration;

- Unstable idle speed;

- Unauthorized stop of the engine;

These signs are also given by other engine systems (the same ignition system), but if the carburetor has not been serviced for a long time, then the reason for poor engine performance lies in this unit.

Disassembling and cleaning the unit

Considering that the amount of impurities in our gasoline is simply off scale, cleaning the VAZ 2107 carburetor turns into a necessary procedure. It can be carried out without dismantling and disassembling, or it can be done with complete disassembly of the device.

Cleaning without dismantling, video.

Many car owners periodically treat the carburetor with special cleaning agents (carbocleaners). These aerosols do a good job of removing deposits in gaps, unless, of course, they are perennial “growths.”

- The engine must be turned off and cool before starting work;

- Remove the air filter housing;

- Using a wrench, unscrew the idle speed solenoid valve on the carburetor;

- Use a carb cleaner to treat the carburetor: external surfaces, jet channels (through a thin tube), chambers, air dampers, etc., as far as you can get;

- Leave for 10 minutes for the aerosol to dissolve deposits;

- Run the engine for a couple of minutes. A stream of gasoline will wash away the residue;

- If necessary, repeat the procedure, first waiting until the engine cools down.

If such cleaning does not produce results after twice use, the carburetor will have to be removed and cleaned “like an adult”, with disassembly.

Cleaning with removal, video.

How to remove the carburetor is already clear. Now the sequence of its disassembly:

- Remove the top cover by unscrewing the five mounting screws;

- Unscrew the jets and remove the emulsion tubes;

- Remove the accelerator pump nozzle - unscrew it, pry it off with a screwdriver and remove it;

- Remove the seal located under the valve;

- Remove the diffusers from the chambers using pliers or carefully knock them out with the handle of a screwdriver;

- Unscrew and remove the accelerator pump screw;

- Unscrew the adapter system nozzle holder and remove the nozzle itself;

- Unscrew and remove the idle fuel jet;

- Remove the accelerator pump cover: unscrew the 4 screws in the corners, remove the cover and the pump itself (diaphragm, pusher, spring);

- Remove the return spring from the pneumatic drive lever, then the rod clamp, after which remove the spring from the throttle valve drive lever;

- Remove the pneumatic drive by unscrewing the fasteners;

- Unscrew the 2 screws that secure the lower part of the carburetor to the body, remove the lower part; Remove the economizer and economizer microswitch with bracket;

- Unscrew the screws for adjusting the quantity and quality of the mixture.

This completes the disassembly of the carburetor. After this, you can start cleaning. The parts and body of the carburetor, including the jets, can be washed with kerosene, the seats of the jets and the jets themselves can be blown out with a compressor. It is advisable not to clean the jets with wire; it can damage the holes and then the jet will have to be replaced.

When the layers are washed off the metal, you can inspect it for corrosion, wear and defects. All parts that show signs of wear must be replaced with new ones. The carburetor is assembled in the reverse order, then adjustments are made and you can put it in place.

Types of service

Maintenance of Ozone carburetors can be partial or complete. The first is flushing the unit without removing it from the engine. This is done using special cleaning products such as “Carb Cleaner”. We use the product according to the instructions and continue to operate the car. But the effect of partial maintenance is short-lived and does not always help. Eventually you will have to perform a full service.

Full setup of Ozone carburetors comes down to complete disassembly of the unit, cleaning of the channels, checking the functionality of the mounted units, troubleshooting parts, assembly using spare parts and subsequent adjustment.

Purpose and design of the carburetor

The main function of the unit is to ensure the preparation and dosage of the air-fuel mixture in all engine operating modes without the participation of electronic systems, as is implemented in more modern cars with an injector. The DAAZ 2105 carburetor, installed on the mounting flange of the intake manifold, solves the following problems:

- provides a cold start of the engine;

- supplies a limited amount of fuel for idling;

- mixes fuel with air and directs the resulting emulsion to the manifold at operating modes of the power unit;

- doses the amount of mixture depending on the opening angle of the throttle valves;

- organizes the injection of additional portions of gasoline during acceleration of the car and when the accelerator pedal is pressed “all the way” (both dampers are maximally open).

The unit is equipped with two chambers, the secondary one is opened by a vacuum drive

The carburetor consists of 3 parts - the cover, the main block and the throttle body. The lid contains a semi-automatic starting system, a strainer, a float with a needle valve and an econostat tube. The upper part is attached to the middle block with five M5 screws.

A fitting is pressed into the end of the cover for connecting a gasoline pipe.

The structure of the main part of the carburetor is more complex and includes the following elements:

- float chamber;

- main metering system - fuel and air nozzles, large and small diffusers (shown in detail in the diagram);

- pump - accelerator, consisting of a membrane block, a shut-off ball valve and a sprayer for fuel injection;

- transition system and idle channels with jets;

- secondary chamber damper vacuum drive unit;

- channel for supplying gasoline to the econostat tube.

The middle block of the carburetor contains the main metering elements - jets and diffusers

At the bottom of the unit there are axles with throttle valves and main adjusting screws for the quality and quantity of the air-fuel mixture. This block also contains the outputs of many channels: idle speed, transition and starting systems, crankcase ventilation and vacuum selection for the ignition distributor membrane. The lower part is attached to the main body with two M6 screws.

The design provides for different sizes of chambers and chokes