Good day, dear readers! In this issue of the in-flight magazine we will talk about how to adjust the valves to 8 cells with your own hands. Lada Granta engine. I tried to compile detailed step-by-step instructions for adjusting the valves, which will help those who for the first time decided to do this on their own on their car. I would like to note right away that valve adjustment is carried out within the framework of TO-0, TO-1, TO-3, TO-5, TO-7.

This manual is applicable to adjust all 8 keys. engines of the VAZ family, starting with the VAZ 2108 and ending with modern LADAs (at the time of writing, 2022).

The valve adjustment was carried out on an editorial car LADA GRANTA 2022 model year, engine model 11186 (with a lightweight connecting rod and piston group); volume 1.6 l, 8-valve, power 87 hp. The mileage at the time of adjustment was 15,300 km.

Let me remind you that the previous adjustment was carried out at an official dealer at zero maintenance with a mileage of 2,920 km. But since it was decided to independently service the car (I wrote about the reasons in issue 5), all subsequent maintenance on this car will be carried out independently, with a detailed photo and video report, as well as the “price of the issue.” So let's get started.

Engines Lada Granta

The Lada Granta previously had 8-valve and two 16-valve engines installed. The eight-valve engines had a power of 82 and 87 l/s, respectively. Their indexes are 11183 and 11186. Power units with 16 valves with a capacity of 98-106 l/s had indexes 21126 and 21127

Lada Granta engines 8 valves

VAZ hp 132 Nm

The presented engine was installed until December 2014, then gave way to the ICE 11186, which was an injection 8-valve engine with a single camshaft and a timing drive. There were no hydraulic compensators, so the thermal clearances of the valves must be adjusted independently.

With the help of specialized holes made in the piston, when the valve belt breaks, it never bends. There are a lot of difficulties in using such an engine. The very first thing is a variety of noise and also knocking. A large number of problems are caused by unreliable electrics and an unstable thermostat. Very often, due to low-quality fuel, valve burnout occurs.

Sedan before restyling 2011 - 2022 1.6 l 11183 manual transmission5

| Type | injector |

| Fuel | gasoline AI-92 |

| Location | transverse |

| Cylinders | 4 in a row |

| valves | 8 |

| Working volume | 1596 cm³ |

| Power | 82 hp |

| Torque | 132 Nm |

| Acceleration to 100 km/h | 12.6 s |

| Speed (max) | 165 km/h |

| Ecological Class | Euro 4 |

| Consumption city | 9.7 l |

| Flow track | 6.1 l |

| Mixed flow | 7.4 l |

VAZ 11186 - 87 hp. 140 Nm

This engine variant is an improved model of the previous engine. A lightweight piston version with special anti-friction elements is installed here. The timing belt is from the manufacturer Gates, which has a resource of 180 thousand km. The throttle valve is of an electronic type. New cooling jacket and other improvements.

We managed to organize all this on a fairly old engine in accordance with accepted environmental standards. The pistons do not have special holes, so in case of problems with the belt, the valves almost always bend. In 2018, the manufacturing company equipped the motor with plugless pistons.

The list of faults of the presented motor is quite large. Car owners are constantly faced with various problems and difficulties related to valve burnout, malfunctions of installed sensors, oil leaks and unstable operation of the E-gas system.

Sedan before restyling 2011 - 2022 1.6 l 11186 manual transmission51.6 l 11186 automatic transmission4

| Type | injector | injector |

| Fuel | gasoline AI-92 | gasoline AI-92 |

| Location | transverse | transverse |

| Cylinders | 4 in a row | 4 in a row |

| valves | 8 | 8 |

| Working volume | 1596 cm³ | 1596 cm³ |

| Power | 87 hp | 87 hp |

| Torque | 140 Nm | 140 Nm |

| Acceleration to 100 km/h | 12.2 s | 14.2 s |

| Speed (max) | 167 km/h | 160 km/h |

| Ecological Class | Euro 4 | Euro 4 |

| Consumption city | 9.0 l | 10.4 l |

| Flow track | 5.8 l | 6.1 l |

| Mixed flow | 6.6 l | 7.7 l |

Lada Granta engines 16 valves

The Lada Granta car was equipped with 2 engines that had 16 valves. These are very common engines that were also installed on Priora. They have high performance parameters, but also certain disadvantages. The technical parameters of the engines that were installed on the Lada Granta car with 16 valves are as follows:

16 grant valves

| Name | Characteristic |

| Brand | 21126 |

| Marking | 1.6 16V |

| Power | 98 horsepower |

| Type | Injection |

| Fuel | Petrol |

| Valve mechanism | 16 valve |

| Number of cylinders | 4 |

| Fuel consumption | 7.5 liters |

| Piston diameter | 82 mm |

| Resource | 180 - 200 thousand km |

| Name | Characteristic |

| Brand | 21127 |

| Marking | 1.8 16V |

| Power | 106 l. With. |

| Type | Injection |

| Fuel | Petrol |

| Valve mechanism | 16 valve |

| Number of cylinders | 4 |

| Fuel consumption | 8.2 liters |

| Piston diameter | 82 mm |

| Resource | 200 - 250 thousand km |

Which is better: 8 or 16 valve engine system?

8 grant valves

It is necessary to make a choice in favor of a specific motor taking into account how the car will be used. Motors need to be compared taking into account the operational features of a particular car. In terms of performance, 8-valve engines are better than 16-valve engines. Their main advantage is quick start-up and relatively low fuel consumption. For urban conditions, this motor is better suited. One of the disadvantages is the high noise from the engine in the interior of a Granta car.

The 16-valve system is suitable for long distance driving. It is possible to develop a fairly high speed when compared with a car with 8-valve engines. At high engine speeds it makes a lot of noise - this is due to their lack. Considering these features, it is possible to draw a certain conclusion:

For each car owner, the question of choosing a valve system is individual and depends on the specific use of the car. If you constantly monitor the car, then you can avoid engine malfunctions and major repairs for a long time and drive a 16-valve engine. In other cases, it is better to purchase a car with an 8-valve engine.

Car owners have problems and difficulties related to unstable engine operation when driving at low or high speeds. Adjustment of installed valves is required exclusively on 8-valve power units, which are installed as standard on Lada Granta vehicles.

Incorrectly performed valve adjustment will cause a significant gap to appear between various engine elements, which over time can lead to depressurization.

Let's sum it up

Which engine to choose - 8 valves or 16 - is a matter for each individual client. If the future owner of a LADA Granta likes an engine with 8 valves, then he will need to be concerned about routinely checking the condition of the timing belt and be inclined to periodically adjust the valves in order to ensure the “health” of the unit. Fans of the 16-valve engine will be deprived of the need for adjustment. The timing belt here does not have such whimsicality due to a more durable belt, but this does not relieve the owner of a LADA Granta from a similar verification procedure regarding the components of this “capricious” unit.

Signs of valve mechanism failure

There are many points that indicate the fact that it is necessary to adjust the valves installed in the Lada Granta, some of them are:

- Shaking when starting the engine.

- The appearance of noise and crackling. They can be determined by listening to the engine.

- Engine detonation when stopping.

- An increase in gasoline consumption and a decrease in car power.

How to correctly set the piston on the compression stroke?

Setting the piston of the first cylinder to the TDC position - top dead center - is necessary when carrying out work related to the timing belt. Violation of the valve timing is unacceptable, since the power unit will not start.

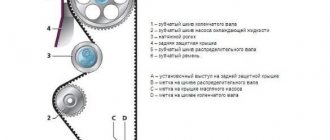

TDC is set according to the timing mark on the Lada Granta. There are 8 valves on the pulley of the first and fourth cylinders. To control accuracy, check the alignment of the marks on the flywheel and crankshaft toothed pulley. If the indicated marks do not match, then the valve timing is disrupted. Rotate the crankshaft pulley until the marks match exactly.

- We activate first gear in the car.

- We hang the wheel and turn it until the mark matches.

- Disconnect the terminals from the battery.

- Unscrew the three screws of the timing cover. Remove the plastic casing.

- We turn the crankshaft until the marks on the camshaft and the drive belt cover coincide.

- We remove the rubber plug from the clutch housing and check that the mark on the flywheel matches.

- If the timing belt marks do not match, then remove the engine protection (described below).

- Remove the timing cover and turn the crankshaft until the marks match.

Does the Granta engine tend to bend the valves when the belt breaks?

The main concern of the owners of the Lada Granta, which has an 8-valve installation, is the risk of “getting” to overhaul the “heart” of the car after a break in the timing belt drive. This model is built on the basis of the time-tested Kalina, which has valves with increased strength parameters, which allows minimizing damage after a belt break. However, the unit will still have to be repaired due to this unpleasant situation.

One of the important problems for owners of Lada Granta cars is the risk of major repairs if the timing belt breaks. This car model is made in such a way that there are high strength damage indicators when the timing belt breaks. In 16-valve engines, unlike 8-valve engines, there is a special design of pistons with recesses on the bottom, so belt rupture does not cause damage to the engine. This point should be strictly understood and taken into account when choosing a motor.

The main concern of the owners of the Lada Granta, which has an 8-valve installation, is the risk of “getting” to overhaul the “heart” of the car after a break in the timing belt drive. This model is built on the basis of the time-tested Kalina, which has valves with increased strength parameters, which allows minimizing damage after a belt break. However, the unit will still have to be repaired due to this unpleasant situation.

When adjusting valves, it is also necessary to check the condition of the timing drive elements, especially the belt. It is prescribed to carry out adjustment measures regardless of the type of valve mechanism design.

Which engine is more profitable: a vintage 8-valve engine or a fashionable 16-valve unit?

It is worth starting a comparison if important aspects of operation are taken into account, including: driving style and the ability to service the unit.

The 8-valve version is more suitable for repair procedures. In terms of timing design, the 16-valve unit does not require adjustment of the valve mechanism, since it is equipped with a progressive solution - hydraulic compensators.

Buyers who intend to use their “horse” in urban conditions in the future are inclined to purchase Lada Granta cars, which have an 8-valve power plant. For them, the main advantages of the engine include lower fuel consumption (compared to 16-valve versions), as well as unpretentiousness in terms of design simplicity and applicability to independent repair procedures. The only measure that allows you to save the nerves of the Lada Granta owner and the integrity of the engine is a timely check of the condition of the timing belt drive. The 16-valve version is perfect for long-distance voyages. The motor allows you to reach a higher speed limit.

Necessary tool

Necessary tool

The tool that will be required to carry out the process of adjusting the installed valves in a Lada Granta car. The very first thing is a special set of washers for adjustment. These washers can usually be purchased in thicknesses of 3-4.5 mm, with intervals of 0.05 mm.

In addition, the vehicle owner must have a special device for performing the adjustment process, which is reliable and can significantly save time. Also, take tweezers that have a clamp and a 17 key.

Reviews

| № | Positive |

| 1. | Victor: adjusted the timing belt independently, without outside help. First time tuning at 65,000 km. Before this, systematic prevention at the service station according to the instructions. |

| 2. | Vasily: the valve knocked at 50,000 km. I visited the service station and ordered preventive maintenance. The guys set everything up very quickly. |

| 3. | Sergey: I have driven over 70,000 km, there are no complaints about the timing belt. The engine runs quietly and smoothly. |

| 4. | Vladlen: at 45,000 km the first valve knocked, I opened it myself and adjusted it. I didn’t change the metal washer, I limited myself to tightening it. |

| 5. | Vladimir: the engine began to knock when cold, I thought the valve was on, but it turned out that the fuel was of poor quality. |

| Negative | |

| 1. | Vyacheslav: My third piston has already flown at 30,000 km. I visited the workshop and replaced all the others. The service life of 30,000 km is very short. |

| 2. | Gennady: I don’t recommend buying the 8-valve Lada Granta. Better add some money and get a 16 valve. |

| 3. | Ivan: the quality of workmanship and assembly is low, already at 40,000 km I replaced the second and third valves. |

Sequence of actions when adjusting Lada Granta valves with your own hands

The 8-valve system is designed so that each cylinder has 2 valves. One is responsible for supplying a special mixture, and the other for releasing working gases. The entire system is balanced using a timing belt.

The adjustment process must be performed when the car engine has completely cooled down. This point is very important and should be strictly understood and taken into account. Using a jack, you will need to hang the car on the front wheel. We remove the cover where the valve mechanism is located.

We place a “fork” (that is, a specialized device) above the engine head, which is necessary to carry out the process of adjusting the valves installed in the car. Put the gear in the manual transmission position and rotate the car wheel. When the piston has reached boiler 1, to the TDC position. Before starting the adjustment, you will need to use a syringe to pump out the oil from the “bath” installed around the pusher. Before doing this, it is very important not to forget to unscrew the spark plugs.

The adjustment process requires a certain sequence, which looks like this: 1-3, 5-2, 8-6, 4-7. The very first number indicates the valve number, and the other number indicates the intake element.

When the exhaust valve is prepared for the adjustment procedure, you will need to measure the clearance readings. When this clearance is optimal, then the feeler gauge will pass between the camshaft cam and the installed valve with little interference. We carry out a thorough inspection and look at the markings that are located on the surface itself.

After this, we make a simple calculation of the recommended thickness values and select the optimal size of a special washer for adjustment. It must be remembered that the clearance indicators on the valves (exhaust) are set by a certain parameter (regulated), which is 0.25 mm. In this case, the permissible error is no more than +/- 0.05 mm.

Having selected a washer of the thickness we need, we should immerse it in the pusher. This action is also performed using a fork to recess the valve.

The same steps will need to be carefully performed on all remaining valves of the car. To carry out the adjustment process, you will need to put the piston in the correct position, which will simplify the process of performing the necessary actions. Using the crankshaft, it is possible to quickly and fairly easily set the piston to the desired position to begin adjustment. In addition, it can be installed using a high gear of the manual transmission and manually moving the car wheel when placing the car on a jack.

Now let’s pay attention to the “plug” from the installed engine block head. This element is installed on special studs, which are necessary to “fit” the valve covers into their original place. This cover will need to be thoroughly cleaned. The special gasket that is required for installation between the valve cover and the head must be replaced with a new one. This should be taken into account when you have completely completed the adjustment process and are reassembling the motor to its original state.

It is necessary to note such an important point that after the washer is put in place, you will need to check its rotation along its axis. These steps must be completed without fail.

Conclusion

The timing system, which is installed on a Lada Granta car with an 8-valve engine, is a rather weak link where various problems and malfunctions arise on a regular basis. But, with systematic and correct maintenance of this component of the car, a calm driving style, the period of use of the timing belt makes it possible to drive from 5 to 10 thousand kilometers.

At the same time, it is recommended to use high-quality gasoline, as well as oil with a viscosity of at least 10W-40, which will significantly increase the service life of the engine. The interval required to complete the timing adjustment process is at least 15 thousand kilometers. Which engine to choose in a Lada Granta car should be decided by each car owner, depending on the specific use of their car.

If the owner is suitable for an engine with an 8-valve system in a Lada Granta car, then it will be necessary to periodically check, repair and adjust the timing belt, which is very important and will avoid unexpected and quite expensive engine overhauls.

How often are adjustments made?

If we talk about mileage, then it is 20-30 thousand km. Adjustment of the thermal clearances of the valves should be carried out even if you do not experience a loss of power, increased fuel consumption and black smoke from the muffler (you should not wait for the first symptoms to appear). It is best to carry out the procedure in a car service center, but if you have the appropriate tools, equipment and experience, this can also be done in your garage.

The design of a four-stroke internal combustion engine is, in principle, quite simple and understandable. The air-fuel mixture from the intake manifold enters the combustion chamber through the intake valves. Then, the valves close and the process of compressing the mixture begins, which occurs due to the upward movement of the piston.

Further, at a certain moment, approximately near the top dead center of the cylinder, the mixture is ignited, which is carried out by the spark plug. Obeying the laws of physics, the mixture expands under the influence of temperature and pushes the piston back down, converting thermal energy into mechanical energy. The last stroke of the piston is the release of exhaust gases into the exhaust system through the opened exhaust valves.

As you can see, everything is simple.

In this description, there was twice a mention of valves, inlet and outlet, which require periodic adjustment of the so-called thermal clearances. Let's see together what it is and why it is needed.

So, the thermal gap is a special gap left between the camshaft cam (or rocker arm) and the valve stem. Its necessity is very simple - when the engine heats up, the metal, obeying the same physics, begins to expand, and the valve (more precisely, its stem) lengthens. The gap is designed to level out this expansion.

Everything seems to be simple and clear again. However, over time, approximately every 40,000 km, the valve clearances “go away” and become (as a rule) larger than required. In this case, they need to be adjusted and returned to the original value, because the resulting excessive gap will lead to wear on the rocker arm or camshaft cam, since an impact load will appear on them.