The VAZ 2114 air filter is a key component of the internal combustion engine protection system. The filter does not allow dust, debris, or other foreign bodies to enter the working chambers of the motor; helps maintain its functional state.

The air filter is a consumable item: during operation it becomes clogged, is exposed to various influences and over time there is a need to replace it. The declared resource of the “air vent” is 30,000 km, but operational practice shows that in reality the filter is changed every 15-20 thousand mileage.

The “2114” model is equipped with panel-type air filters. In the era of carburetor engines, large round filters were installed on cars. The panel design made it possible to optimize the dimensions of the part and improve the performance properties of the filter element.

Air filter VAZ 2114: device, selection and replacement

The air filter for the VAZ 2114 is a device necessary to remove impurities from the air entering the engine. A clogged or damaged filter can lead to an incorrect composition of the fuel-air mixture, and, as a result, impaired engine operation.

Design and principle of operation of the air filter

The air filter on model 2114 consists of layers of filter paper, which are located in a panel-type plastic housing (as opposed to the round one on VAZ carburetor models). The filter layers are held together by polymer rings. The injection filter is more compact, but the level of air purification in it is higher compared to carburetor models.

A mass air flow sensor is installed at the outlet. Purified air is supplied to the engine intake receiver. Part of the air mass is used to maintain the operating pressure of the fuel hose. And the bulk enters the engine intake manifold. The operation of the feed system is regulated by an electronic control unit.

Thus, the air filter performs the following functions:

- Cleaning incoming air from small particles of dust and other impurities.

- Ensuring free flow of air into the intake receiver, and then into the engine manifold.

The filter needs to be periodically replaced every 10-15 thousand km. mileage, since all impurities from the air flow remain on the filter element. As a result of their accumulation, the filter becomes clogged and air has difficulty passing through it. If the car is used in dusty areas, or urban environments with heavily polluted air, the filters need to be changed more often.

How to tell if the filter is clogged

You can recognize that the air supply system is not working properly due to a clogged filter by the following signs:

- the “Check Engine” warning light is on on the on-board computer;

- the car loses power, engine speed drops;

- Gasoline consumption increases significantly - up to 3 liters per 100 km.

In addition to problems with engine operation, a dirty filter can lead to premature wear of the spark plugs and malfunctions of the ECU. Therefore, it is necessary to replace it as quickly as possible.

Replacing the filter

To remove and replace the air filter both on the VAZ 2114 and on other cars, you must first disconnect the terminals from the battery in order to de-energize the car. Then you should disconnect the air flow sensor. This is necessary to avoid accidental damage.

- Remove the inlet pipe, or lift the housing cover along with it.

- Remove the filter housing cover using a Phillips screwdriver.

- Remove the used filter.

- Remove accumulated debris from the housing.

- Install the new air filter, following the arrow indicating the correct location.

- If necessary, replace the rubber seal.

- Reassemble everything in reverse order. It is important not to overtighten the cover and ensure there are no cracks or distortions.

Thus, replacing the air filter on a VAZ 2114 is a fairly simple operation that does not require much time.

On car forums you can find advice to simply blow out a clogged filter instead of replacing it. But such purging can only be used as a temporary measure. In the future, the filter element still needs to be changed.

Which filter to choose

Since air filters are considered a vehicle consumable, they are generally inexpensive and widely available. But when buying a new filter, you should pay attention to the manufacturer and reviews of its products. The service life of the filter element and the performance of the vehicle depend on the quality of the filter element.

The following filters from the following domestic manufacturers have gained popularity among VAZ-2114 owners:

- BIG – the VAZ 2114 uses a filter marked GB 9597 C;

- AF – code of the filter used is 2112-1109080-02.

German filters are also recognized as high quality:

- MANN – filter C 22117 is used;

- HENGST – filter code E 22 L.

The quality of these air filters has been confirmed by experts as a result of tests and trials. There are other fairly high-quality filters suitable for the VAZ 2114.

When purchasing, you should evaluate the following parameters:

- Quality of filter material.

- Declared period of use.

- Reviews from car owners and test results of filter elements.

Sometimes, in order to increase engine power, car owners install a so-called “zero filter” - a filter of zero resistance. To install it on a VAZ 2114, tuning of the intake system and flashing of the control unit are required. This filter is very demanding to maintain and requires impregnation with a special solution. It should also be carried out with caution to avoid contact with the DRV. Therefore, you should weigh the pros and cons before installing such a filter.

Thus, the air filter, despite the simplicity of its design, is a part necessary for the proper operation of the air supply system and engine. Therefore, filters should be changed promptly. You only need to replace it with a high-quality air filter suitable for this car model.

Useful video

You can glean additional interesting information from the video below:

When does the reason lie in the cylinder-piston group?

If the cylinders are destroyed or compression rings occur, then part of the energy of the explosion of the mixture in the cylinder will be directed directly into the crankcase along with the exhaust gases, which will create excess pressure in it. But in this case, the corresponding accompanying signs of such a malfunction will be observed:

- difficult engine starting;

- its unstable operation at idle;

- reduction in engine power;

- compression in the cylinders is lower than stated by the manufacturer;

- exhaust smoke;

- other.

Replacing the air filter on a VAZ 2114

Air filter VAZ 2114

Diagram and order of air movement in the VAZ 2114 injection engine

In an injection car engine, the air movement pattern is somewhat different from that of a carburetor internal combustion engine. Since the injection is controlled electronically, the system has built-in sensors connected to the on-board computer.

- The air driven through the cooling system fan enters a panel-type air filter, unlike the round, large-sized one that was on carburetor engines; this filter is small-sized, but effective in terms of cleaning and creating normal air flow. The fact is that injection engines are very responsive to the quality of the air entering the intake pipe.

- At the outlet of the air filter, between the filter and the corrugated hose of the intake pipe, there is a mass air flow sensor. The mass air flow sensor is designed to measure the amount of air that the engine sucks in, in kg/hour. If it overestimates the readings at low throttle, then the engine operates unstably at idle, stalls after a sharp application of gas, and even problems with starting are possible. If it underestimates the readings at high speeds, then traction drops and fuel consumption increases.

- After the sensor, the air enters the corrugated hose of the intake pipe and is supplied to the receiver. There are several more sensors in front of the receiver, such as the idle speed control and the throttle position sensor. The receiver itself is a mandatory accessory of an injection engine and is designed to accumulate air and compensate for fluctuations in the air mass. There are different receiver designs, including sports ones. It is believed that with the installation of such a design it is possible to achieve a significant increase in engine power. Air is taken from the receiver through a hose to the fuel pressure regulator located on the fuel rail.

Why does oil get in?

To understand why oil particles appear in the air filter, consider the following carburetor operation algorithm:

- When fuel burns, crankcase gases are formed;

- In the normal state of the engine, they are completely removed from the cylinders;

- If the engine is worn out, coked, or has other problems, some of the crankcase gases remain inside;

- This provokes the creation of high blood pressure;

- Due to increased pressure, the condition of the seals deteriorates and they cannot perform their functions properly;

- If the oil seals are damaged, oil consumption increases and it begins to flow into the VF.

Oil in VF

There are several main reasons why the VF becomes contaminated with oil.

| Cause | Nuances |

| The piston rings of the power unit are worn out | This leads to a disruption in the proper functioning of the collection of excess lubricant that enters the crankcase from the cylinder. Pressure increases, oil is squeezed out by the oil deflector and vent valve. A clogged oil deflector drain does not allow the lubricant to return back to the crankcase, so it escapes along with the gases |

| The crankcase gas outlet paths are clogged | If the paths are clogged, gases from the crankcase cannot fully escape the throttle limits. As a result, we get lubricant and gases in the air filter |

| Air cleaning material is clogged | The engine does not receive enough air, so it begins to suck it in from all available sources. Not rarely - from the crankcase. As a result, it turns out that the filter is flooded with oil. |

Piston rings

Replacing the VAZ 2114 air filter

The operation of replacing the air filter on a VAZ 2114, according to technical documentation, should be carried out every 30 thousand kilometers. But depending on operating conditions, more frequent replacement of the filter element may be required.

To carry out the work you will need a new air filter. The most popular for VAZ 2114 are: S9661 (Bosh), C22117 (Mann), U505 (Champion), CA3399 (Fram). The only tools you need are a Phillips screwdriver or a screwdriver.

Replacing the VAZ 2114 air filter

1.Raise the hood and find the air filter housing.

2. Press the lock of the mass air flow sensor and disconnect it. This is done in order not to accidentally damage the wires, the replacement of which will require much more time, and in addition to this - additional financial costs.

3.Then you can disconnect the inlet hose by first loosening the clamp on it. This is also optional. If you think that the cover will not interfere with your further actions, then you can not disconnect it, but move it to the side along with the hose.

4.The cover is secured with four screws. Unscrew them and open the air filter housing.

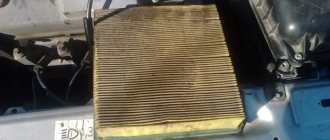

5.Remove the old element. As a rule, contaminants also accumulate in the internal cavity. They need to be cleaned by any convenient means (vacuum cleaner, compressor, damp cloth, etc.)

Installation procedure

- Before installation, remove the rubber support for the rear air filter mount from the housing hole. We replace the damaged rack.

Using a screwdriver, insert the rear rubber strut into the hole in the bracket.

Wet the rubber stand with soapy water. We install the air filter housing in place so that the strut fits into the hole intended for it, and the brackets for the front rubber struts are located under the hood lock rod. While pressing down on the filter housing, use pliers to pull the stand up until the housing is fixed in the annular groove of the stand.- We connect the air supply hose to the throttle valve to the mass air flow sensor.

- We connect the wiring harness block to the mass air flow sensor.

- We fix the hose tip in the bracket.

Replacing the air filter VAZ 2114

The main function assigned to the air flow filter of your VAZ 2114 car is to purify the air entering the engine cylinders. Atmospheric air, especially in big cities, contains a lot of dirt and dust, and if it gets into the liner-piston group, it reduces engine power and can even cause premature wear or breakdown. In addition, exhaust gases constantly enter the engine compartment of your car, which carry a lot of soot, which also does not have the best effect on the engine. The car engine air filter box is usually made of plastic, and inside the housing there are replaceable filter elements.

The filter element is often made of paper and may have specialized impregnation. To add density to the structure, paper filter elements are fastened with rings made of polymers or cardboard. Only such air, pre-cleaned by a filter, is suitable for engine operation.

Unfavorable environmental conditions negatively affect the condition of the air filter and it can quickly become dirty. A dirty, old air filter not only does not perform its function of cleaning the air, but can also throw already accumulated dirt into the engine cylinders. The engine will begin to lose power and the instrument panel may display fault messages.

The detachable metal structure of the VAZ 2114 engine air flow filter, coated with special paint, has two parts: front and rear. At the junction of the air filter parts there is a rubber seal that prevents the entry of extraneous air flows and drops of moisture. The direction of air intake in the engine air flow filter is oriented in the direction of travel of the vehicle. This design allows you to effectively supply the engine cylinders with purified atmospheric air. The process of removing and replacing the filter element in a VAZ 2114 car is quite simple and can be done even by untrained drivers.

The car manufacturer recommends replacing filter elements after 30 thousand kilometers. However, if your car was operated in dusty and dirty conditions, the service life of the filter element may be reduced. During operation, we recommend checking the condition of the air filter and, if necessary, cleaning it mechanically. To do this, the replacement element can be shaken or blown with compressed air.

Instructions for replacing the air filter

In order to replace the air flow filter on a VAZ 2114, disconnect the wiring from the battery.

The filter box cover is secured with four screws - unscrew them. After this, disconnect the air flow sensor wiring block. Lift the box cover and remove the replacement filter element. Thoroughly clean the filter box of accumulated dirt. When placing a new filter element, pay special attention to its orientation, directing the filter pleats along the arrows indicated on the bottom of the box. After replacing the filter, reassemble the structure in reverse order.

We change the air filter on a VAZ-2114 with our own hands: a painfully familiar replacement

All VAZ-2114 models were equipped with injection-type engines. This definition can be understood as a continuous supply of fuel to the injectors, and then into the intake pipe of the manifold in order to create an ideal air-fuel mixture. It is this mixture of gasoline and air, determined in a certain quantity, that is supplied to the cylinders.

The video below shows in detail the process of replacing the air filter on a VAZ-2114:

The best air filters for VAZ-2114

Every year, various tests are carried out that can clearly demonstrate to all car enthusiasts the ability of certain air filters to work for the longest amount of time while maintaining high performance indicators. Based on this, we bring to your attention the best elements for the VAZ-2114, which will easily allow you to choose a clear favorite for you.

MANN is a favorite among filters.

- “MANN” article C 22117, price 300-350 rubles.

- “HENGST” article E 22 L, price 200 - 250 rubles.

- “BIG” made in Russia, its code is GB 9597 C, the average price is 100 rubles.

Other types of air filters

It is now popular to install zero-resistance filters instead of the stock filter, the use of which is expected to increase motor power.

However, before carrying out such work, you should know that such an element requires much more attention and maintenance , due to its treatment with special impregnation and constant cleaning. Also, when installing it, you may need some modification to the intake system.

This is what an installed zero resistance filter looks like.

How to replace the air filter

The air filter needs to be changed after every 10-15 thousand kilometers, and regardless of the condition in which it is. The thing is that visually it may be clean, but after prolonged use, its filter elements will certainly become dirty.

- Before you start replacing the filter, make sure that the new element is at hand, as well as a tool and a clean rag.

- Next, open the hood and, for safety, disconnect the negative terminal from the battery.

- Disconnect the power supply from the mass air flow sensor.

Remove the block carefully so as not to break the latches.

The bolt installation locations are marked with a marker.

We remove it carefully so as not to scatter all the accumulated dirt.

Despite such a precise sequence of work, the whole process is unlikely to take you more than 5-10 minutes of time. Having done such work once, you will remember this process, and in the future you will perform it without difficulty.

Purpose of the filter

The main and most important task facing the air filter is to clean all incoming air mass from impurities of sand, dust, and moisture.

In addition, it is capable of trapping various harmful particles that can move through the air, and at the same time providing a very high flow of air masses. These two parameters are the maximum for control and are displayed on the box from the manufacturer.

Working principle of the air filter

The air that enters the system first passes through the filtration of the air filter.

Unlike the round analogue of a carburetor engine, this filter has a square shape and much smaller overall dimensions. However, such indicators are in no way inferior in terms of cleaning, and can most effectively ensure the cleanliness of the air entering the system. This is the case because injection engines are very sensitive to the quality of the incoming air.

- Immediately after the air filter, before the corrugated hose, a mass air flow sensor is installed, which measures the amount of air that gets inside the engine; measurements are taken in the form of kg/hour.

- If it is faulty, then with a small force on the gas pedal it overestimates the readings, and the engine begins to idle unstably, some starting problems may occur, and fuel consumption may only increase.

- Bypassing the mass air flow sensor, the air goes through a corrugated hose to the receiver, first reaching the idle air control valve and the throttle position sensor.

Air filter design

Air filter structure

The air filter itself is made of paper elements fastened together with special polymer rings, and the housing is made of plastic.

Compression check

After checking the compression, you can breathe a sigh of relief or worry, since the cost of the repair depends on the result.

Impaired compression often causes the presence of oil in the VF, and also causes a number of other problems.

Compression check

To work you will need:

- Compressometer;

- A rag in oil, which you will use to determine the compression stroke;

- Adapter for spark plug holes. It is used when checking the combustion chamber for leaks;

- Compressor.

Now let's start checking.

- Warm up the engine to operating temperature, then turn off the fuel supply.

- In the case of a carburetor, you need to remove the hose, clamp or squeeze it with something, or lower it into a container.

- If you have an injector, remove the fuel pump fuse, start the engine and let it run. As soon as the fuel in the fuel rail runs out, it will stall on its own.

- Disconnect the ignition system by removing the center wire from the distributor (on the carburetor). The crankshaft position sensor at the injector must be disconnected.

- Remove all debris from the spark plug wells so that it does not end up inside the cylinders. Unscrew the spark plugs.

- Insert the compression gauge fitting while an assistant starts the engine. The starter should rotate the engine until the pressure gauge needle stops in one position.

- By analogy, measurements are carried out on each cylinder, the results are recorded on paper.

- To calculate ideal compression, use the formula - 1.2 * Compression ratio.

See your owner's manual for the compression ratio of your engine. Please also note that measurements may have some error.

What you need to know about verification

- If the indicator is 12 atmospheres, this indicates that your engine is almost in perfect condition.

- When checking the compression on a cold engine, the compression readings will be significantly lower. Perform the test only on the engine at operating temperature.

- If the battery is partially discharged, the test data will also not be accurate.

- The increase in compression occurs due to the combustion of oil in the cylinders.

What the results say

We take the paper where you wrote down the data of the check, carried out according to all the rules, and study what is wrong with the motor.

- Indicators in the range of 0-4 atm indicate a high probability of burnout of the piston, head gasket or valve.

- Compression of 4-6 atmospheres indicates that the piston rings or the partition between them have broken.

- If you get about 8-10 atm in each cylinder, the cylinder-piston group is worn out. Major repairs will soon have to be carried out.

- 12-12.5 atm - these are the indicators that occur in a new, run-in power unit.

- If the car has serious mileage, and the check data shows numbers equal to or exceeding the norm, oil has probably entered the cylinders due to wear of the cylinder-piston group or valve liners.

Obviously, the presence of oil in the filter does not bode well. But the problem can still be prevented if measures are taken in time.

Air filter VAZ 2114, what is it for and how often to change it

Welcome, friends, to the DIY car repair website. The air filter VAZ 2114, VAZ 2115 or some other plays an important role in the operation of the engine.

It catches various particles, even the smallest ones, and prevents them from getting inside the engine, which has a positive effect on its operation, that is, it significantly extends its life.

Air filter VAZ 2114

Although modern cars are equipped with a good quality filter element, timely replacement is simply necessary, the same applies to oil and fuel filters.

As previously mentioned, the air filter serves to clean the air entering the engine cylinders, but such filtration entails a loss of engine power, since quite serious resistance to air flow arises, and all this is due to the density of the filter element.

It follows from this that the more the filter becomes clogged, the more the power decreases; in addition, deformation of the filter element can occur and all the dust will begin to penetrate into the inside of the engine, which will lead to rapid wear of the motor.

The main signs of a clogged air filter:

- Significant increase in fuel consumption.

- Decrease in engine power.

- There is an increase in CO2 in the exhaust gases.

This immediately raises the question, how often do you change the air filter? If you open the hood, then on the housing where the filter is located it is written that it should be replaced every thirty thousand kilometers.

But this is not entirely true, because its service life depends on operating conditions; it breaks down faster on dirt and dusty roads than when driving on asphalt.

Therefore, when to change the air filter is up to you, but on the good side, it is better to replace it more often, because its price is not at all high. Read how to replace the cabin filter here.

Many experienced car owners recommend replacing them within ten to fifteen thousand kilometers.

I would like to say right away that there is no point in going to a service station (service station), since everyone, even a novice car owner, can change the filter in just a few minutes.

Self-replacement of the VAZ 2114 air filter

So, open the hood and unscrew the four screws of the air filter housing with a figured screwdriver (Phillips).

We lift the housing up, pull out the unusable air filter and insert a new one; the ribs of the filter element should correspond to the direction indicated inside the housing.

That's all for the entire repair, or rather, it only took a couple of minutes to service the car. Have a good trip.

Repair work

If you discover the presence of oil in the air filter of your VAZ 2109, you should definitely take immediate action.

Ignoring the presence of oil in the VF can lead to serious damage, including the need for major engine repairs. I don’t even want to imagine how much it will cost.

- Check the compression of your engine. If there are problems with it, the piston rings or the piston system are worn out, this can be determined by blue or dark smoke. Plus, the level of lubricant, that is, oil, will constantly drop.

- If the compression test shows that everything is fine, then you can breathe a sigh of relief. This suggests that the problem is not that complex.

- Most likely, the filter element is clogged or the hoses for removing crankcase gases from the crankcase are clogged. You will have to change the filter, wash or replace the output hoses.

The most important recommendation is periodic maintenance of all engine components and auxiliary mechanisms. It is better to prevent a disease than to eliminate its consequences later.

Air filter VAZ 2114

The air entering the combustion chamber must be cleaned of dust and abrasive particles. For these purposes, a special filter is provided in the design of the VAZ 2114. Its presence significantly increases the resource of the power unit.

The operation of the car is accompanied by gradual contamination of the filter. Its throughput is reduced.

This leads to a decrease in engine power, a deterioration in the dynamic performance of the vehicle, as well as an increase in gasoline consumption. Therefore, for normal operation of the motor, periodic installation of a new filter element is required.

Article number and cost of the original VAZ 2114 air filter and its analogues

The branded air filter for the VAZ 2114 has catalog number 2112-1109080. Its price ranges from 240 to 300 rubles. When purchasing an original consumable, the car owner knows for sure that the filter will fit well into the seat and there is no need to use an adapter. In this case, the filter element is attached in the normal way.

In addition to the branded air filter on the VAZ 2114, it is possible to use its analogues. Some of them are of very good quality and attractive prices. The table below shows the best alternatives to native consumables in terms of cost to quality ratio.

Table - Alternatives to branded air filter 2112-1109080

| Brands of analogues of the original air filter | Article number | Estimated cost, ruble |

| Febi | 1510 | 260-300 |

| Champion | CAF100505P | 350-450 |

| Knecht-Mahle | LX220 | 450-550 |

| Japan Cars | B2W004PR | 120-160 |

| JC Premium | B2W004PR | 320-430 |

| Bosch | 1457429061 | 370-410 |

| Starline | SFVF2246 | 150-220 |

| Denckermann | A140027 | 160-190 |

| Filtron | AP006 | 200-270 |

Frequency of replacing the air filter on a VAZ 2114

The service life of the filter element is directly related to the operating conditions of the vehicle. According to official recommendations, replacement of consumables is required every 20-30 thousand km. In this case, for a number of reasons, there may be a need for an unscheduled installation of a new filter element.

An indirect sign that the filter needs to be changed is a deterioration in the dynamic performance of the vehicle. A “strangled” engine is not capable of energetically accelerating the car. In addition to the drop in power, the engine begins to consume more fuel. Therefore, if such symptoms appear, you should check the condition of the air filter and, if necessary, replace it.

During the operation of the vehicle, for one reason or another, the filter element may be damaged. Through the resulting hole, dust and abrasive particles enter the combustion chamber. Therefore, if damage is detected, a completely new filter should be installed immediately.

Deformations of the filter element often lead to deterioration in throughput. The injector operates with a lack of air, which affects the proportions of the working mixture. In this case, the filter element should also be replaced without waiting for a deadline.

A clogged air filter is a common culprit for unstable operation of the power unit. There are many reasons for floating speed, but it is better to start checking with the condition of the air filter. If the consumable is clogged with dust and dirt, then a new filter element should be installed instead.

The filter should be replaced immediately after purchasing a used car. This is due to the fact that it is unknown how the previous owner carried out maintenance, as well as at what mileage the consumable was previously installed.

Making your own adapter

If you are confident that you can make an adapter yourself, this will allow you to save a lot of money, which you can spend on purchasing a good carbon filter element. First, you need to find the adapter manufacturing diagrams on the Internet (taking into account the fact that this product is designed for installation in a VAZ-2114, since there are a great many such diagrams on the Internet for a wide variety of cars).

It is advisable to first make a paper model according to the diagram with exact dimensions - this will allow you to understand which part fits to which and in what order. To make the case you will need galvanized or stainless steel sheets. Plastic is also not bad, but processing it will require a special tool, and working with polyvinyl chloride itself is much more difficult than with metal, especially if curved surfaces and bends are required.

Since you have already cut out the parts for the layout, you should have no difficulty reading the drawing. All the required bends can be made using a large vice and a rubber (or, alternatively, a wooden) mallet. To connect metal parts, you can use either rivets or bolts. Rivets are good because they do not require drilling holes, but you need to know how to work with them - otherwise there is a risk of damaging the thin-walled metal.

When assembling the adapter, it is advisable to treat all connections, holes and other similar places with sealant, which is an excellent sound insulator and will not allow vibrations to occur when driving at high speed or on uneven roads. If you have enough experience, the process of making an adapter will take you a maximum of 5-6 hours, not counting the time spent searching and studying the circuits.