The VAZ 2110 can already easily lay claim to the role of a classic VAZ car, given its age and genetic inextricable connection with previous generations of front-wheel drive cars. The tenth family did not cause such a sensation as 2108 did in its time, but is not inferior to it in popularity. Despite all the constructive archaism and unpretentious design, the top ten is respected by the public. It is easy to maintain, almost any repair can be carried out in a garage and with an average set of tools, and only the injection system, if this is the latest model, or the electronic engine control system requires special equipment. Although electronics, with the right approach, can be serviced independently. The main thing is the knowledge base. The base is not that big and not very tricky.

In the photo, the VAZ 2110 is a classic that is respected by the public

Repairing a VAZ 2110 with your own hands is easy only if you know exactly how the car works. Since the ten is not a particularly expensive vehicle, many people begin their acquaintance with automobile life with it. This is a fertile material for study, a good basis for tuning, and a practical means of transportation in space. But, of course, not without problems. The characteristic troubles that can be expected from this car have been studied far and wide, so there is no need to expect surprises from dozens, and the high degree of unification with other VAZ models makes any piece of hardware accessible, and in several versions at once.

For example, you can take advantage of the surging wave of tuning mania and the companies that have grown on its crest, which are already producing fairly high-quality modified spare parts, which could only be dreamed of five years ago. These are special timing camshafts, and drive gears of this same camshaft with a variable phase angle, and a whole bunch of power steering. Not to mention the suspension and optics, for which there are a great many options for components.

Video tutorial on how to remove and disassemble a VAZ 2110 generator with your own hands

In order not to get lost in this diversity, so that dozens of DIY repairs go smoothly and without surprises, we tried to systematize the main problems in the components and mechanisms of this car, where we will consider troubleshooting methods, options for replacing spare parts, tolerances, dimensions, shrinkage and their compliance or non-compliance with factory standards.

VAZ 2110 engine repair

More precisely, engine repair, since at different times completely different engines were installed on the car. Both carburetor ones, very close to eight and nine, and injection ones. With timely engine maintenance and compliance with regulatory maintenance standards, the engine can easily show the speedometer what 500 thousand mileage is. Not without surgical intervention, but even such figures are almost a feat for him, considering the kind of gasoline he has to pour into the tank. The Ford Focus starts to warp already at the 50th thousand mileage, and it requires a sanatorium-resort examination. The Ten can easily do without this, although it is still better to take care of the fuel system, especially the injection system.

VAZ 2110 comes with both carburetor and injection engines

Repairing the fuel system, as a rule, does not require any special expenses. Maintenance of the injector, fuel pump, timely replacement of the fuel filter and cleaning of the mass air flow sensor (MAF) are carried out in a garage without any particular problems. To carry out all maintenance and repair work on the VAZ 2110 fuel system, a special tool will rarely be required, and the only thing worth taking care of is a high-quality product for cleaning fuel system elements. They are inexpensive and can be useful when washing injectors, cleaning the air flow sensor, and on carburetor engines - when working with the carburetor, as well as when washing the lock and other hard-to-reach places. It should be borne in mind that the use of solvents and aggressive chemicals is extremely undesirable. If you handle them carelessly, you can destroy some rubber seals and cuffs, which are sufficient in both carburetor and injection systems.

Repair of the ignition module, ECU, and on-board computer can, in principle, be entrusted to services if necessary. Nowadays, it is not at all uncommon to find improved injection system control modules and ignition modules with prompt changes to their settings. Therefore, there is no need to carry out chip tuning of the 2110 on a full scale. Thus, the January injection system controller of the latest releases can provide the greatest opportunities for making changes to the operation of the fuel system and ignition system.

This is a very convenient thing. The January controls are located in the cabin, and in order to make changes to the settings mode, you just need to press the corresponding button, and the system will reprogram the injection and ignition algorithm, which will allow you to change the dynamic and operational characteristics of the engine in real time without any surgery or digging in the brains of the car. A module has been developed specifically for the tenth family, which allows you to simply switch the injection system to economy mode or sports mode on the go. And at any time you can reset the settings to standard factory settings.

Repair of the VAZ 2110 fuel system can be carried out within your garage

Repairing electrical equipment and power electrical devices - starter, generator and the relays that serve them, also does not present any difficulties. The main thing here is to know the location of the relays and fuses. In 2110 they are already more or less systematized and collected almost in one place, so there is no need to spend a long time searching for this or that relay. There are, of course, some oddities in their systematization, especially since the plant made changes throughout the entire production of the car. But there is still a certain logic in their placement.

Device

First of all, you should know the very structure of the heating system in order to clearly understand what and how to repair, because for the VAZ 2110, interruptions in the operation of the heater are a typical phenomenon, and from time to time requiring the intervention of reliable hands - be it a driver or a service station worker.

So, the heating system consists of: 1. The actual heater unit, which provides heating for the interior. It is represented (by importance of details):

- An electric motor on which a fan is also attached to pump hot air;

- A radiator, without which the entire system does not work. Moreover, unlike the old heater, the radiator of the VAZ 2110 stove of the new model does not have a tap that shuts off the flow of antifreeze (antifreeze) through the radiator. Thus, it is always (whether in winter or in summer) heated. This was done supposedly in order to eliminate leaks that were often observed through this tap, and also to heat the interior as quickly as possible when necessary. In the summer, the supply ventilation goes past the radiator, but still some VAZ 2110 owners, when repairing the stove, add this tap to the system;

- There are three dampers. One is responsible for air intake recirculation, the second opens/closes the heater duct, the third, the most important for the interior, controls the heater;

- A resistor that regulates the blowing speed.

Heater parts VAZ 2110

All parts are packaged in a block with additional valves, shields, and fittings. This entire device is housed in a housing and is located under the hood closer to the instrument panel.

2. The next block represents the air ducts of the VAZ 2110. They extend directly from the stove and provide:

- Interior ventilation through central nozzles;

- The air distributor works to supply heat (or regular air for ventilation);

- Two air ducts are directed to the rear of the cabin;

- There is a whole system of five nozzles for heating the feet;

- Two side air ducts provide heating for the side windows and part of the interior, providing better heating;

- Two nozzles for ventilation.

The principle of operation of the heater

This, in brief, is the principle of distributing hot or cold air inside the VAZ 2110.

3. The electronic control unit for the stove operates from the passenger compartment. It includes:

- Controller handle. This device allows you to set the temperature in the cabin that the stove unit should produce. It turns on by turning the knob and sets the temperature from the air, the temperature of which will correspond to that outside, up to 30°C. Most often, this part is called the ACS controller (automatic heater control system);

- The temperature sensor is responsible for turning on the heater when the temperature in the cabin drops by 2 degrees against the set one. The sensor has a microfan, and if the control knob is in position A, then the micromotor in the stove block turns on and the damper begins to operate, ensuring proper heating. Therefore, before starting repairs of the heating system, the operation of this sensor is usually checked. It is located next to the heating lamp on the ceiling of the VAZ 2110. Since it is not repairable, in the event of a breakdown this device should be replaced immediately.

Ceiling interior air temperature sensor

VAZ 2110 suspension repair

The simple, understandable and reliable suspension 2110 does not require any special or costly measures for maintenance and repair. Chassis repair involves, first of all, eliminating the consequences of driving on our less than ideal road surfaces. In this regard, the top ten also compares favorably with more recent and much more expensive foreign cars in the budget segment. If you have a lift or, in extreme cases, an inspection hole, any part of the front suspension can be easily replaced or repaired with your own hands using basic tools. There are some peculiarities in the repair of front struts, support bearings and stabilizer bars, but they are present in every car.

Steering rack repair requires special attention. Its dismantling is simple, but the reassembly process itself can cause some difficulties, since there is a need for some pullers and calibrated samples. But it is enough to disassemble it yourself once, and in the future its maintenance will not cause problems. When repairing a steering rack, it is imperative to use the correct repair kits. And full. They can be sold either as a simple set of seals and a bushing, or as a complete repair kit with a bearing, corrugations, the same bushings and seals, as well as retaining rings. Considering that you will have to spend a good half day replacing a repair kit, it is better to replace the complete set.

How to extend the life of the bottom

The body on all VAZ models is not a high-strength unit. To maximize the life of the main part of the car, it is recommended to systematically carry out preventive maintenance. It is impossible to completely eliminate the aging process of metal, but every driver can increase the service life of a new underbody.

- Prevent water from entering the cabin through depressurized moldings on the windshield and side doors.

- Systematically remove the rubber mats under the driver's seat and check the floor for dryness. Systematically clean drains in thresholds and doors. Particular attention is paid to the area under the battery: under the influence of the electrolyte, the drainage holes on the platform become coked.

- If the first rust is found on the bottom of the interior, clean it, fill it with epoxy resin, and treat it with an anti-corrosive agent with the effect of preserving corrosion areas.

- Clean chips and renew the paintwork on the sills immediately after detection: the sills and fenders begin to rot first.

- It is necessary to lift the car with a jack only with the doors closed.

Body and transmission repair

The VAZ 2110 gearbox very rarely causes any complaints. Most often, the cause of difficult gear shifting is wear or breakage of the linkage. This is not the worst problem, and it can be solved quite simply. Moreover, you need to make it a rule to inspect the condition of the gearbox and rocker bearings during every repair or maintenance of the clutch. It often requires attention, especially if a disc with low-quality friction linings is installed. They wear out many times faster than branded ones, and rivets can damage the working surface of the flywheel and clutch basket.

In a VAZ 2110 you need to check the condition of the gearbox very often

Body work can be carried out with a minimum of experience, which is gained as the same body work is carried out. So this vicious circle must be broken and learn to independently replace thresholds, treat the bottom and cavities with anti-corrosion compounds, wheel arches and internal door cavities. There are now all the conditions and necessary anti-corrosion mastics and compounds for this. Epic Movil and construction bitumen mastic are a thing of the past, so there will be no problems with choosing such products. And if you do a complete anti-corrosion treatment of the body at least once every two years, then you can forget about rust for a long time.

This is interesting: Video of repairing a VAZ 2107 generator with your own hands

Repairing the bumper and other plastic body elements, covers, panels, and heater casings can be done independently, using several methods. This does not require any special skills or material costs, and saving a damaged bumper or plastic body kit with your own hands is much cheaper than buying a new one. These issues can be solved with the help of a powerful soldering iron, plastic electrodes and a hair dryer. The entire work, depending on the size of the injury received, may take no more than two hours. And the money saved on repairs can be spent on purchasing good putty and a set of spatulas, which will undoubtedly be useful for minor repairs to the body or the same bumpers.

There are archaic and some imperfect solutions in the design of car brakes, but taking into account their simplicity and the availability of components, everything can be solved in the conditions of an average garage. Front disc brakes are repaired in extreme cases and when the brake disc is critically worn, and the brake pads can be selected to suit your preferences and driving style. If the driver prefers a softer and more leisurely driving style, then it is worth choosing soft pads.

They are less noisy, operate softer, and do not wear out the brake disc as much. If your driving style is aggressive, then with soft pads you will have to change them quite often, and the braking force at high speeds may be insufficient. In this case, you should pay attention to the so-called sports brake pads. They are noisier, harsher and grip very sharply; with active use they wear out the brake disc. The rear brakes are a separate matter, since their design goes back to the days of the Fiat 124.

The design of the VAZ 2110 brakes has some imperfections

The factory never bothered to replace them with disk ones. Under normal operating conditions, they do not cause leaks, they just need much more attention than they deserve. As a last resort, there is always the option of replacing it with a disc brake with some modifications. Nothing is impossible.

The reliable, well-made, but somewhat outdated VAZ 2110 has not yet finished its song, and it may well be useful and teach a novice car enthusiast to hold a screwdriver in his hands and distinguish a switch from a radiator. And for an experienced driver, this is an indispensable car for every day and a reliable assistant.

Installing additional keys

Please note that additional control units may be required when installing additional accessories. It is possible to install keys on the central panel. This can be done quickly and easily.

The procedure for performing the work is as follows:

1. The front panel is disassembled. 2. Excess plastic is cut off. 3. The edges of the frame are processed to a minimum size. 4. To place the keys, you should create a special base made of plastic. 5. In order for the structure to be sufficiently rigid, stiffening ribs should be created. 6. Buttons can be taken from any car. It is worth noting that, if necessary, you can make the buttons backlit as an indication. 7. If necessary, you can repaint the color of the key to match the interior design.

The result of the above changes is a significant increase in the functionality of the car interior. The keys can be responsible for various additional functions. If necessary, you can create a niche for a multimedia system, which will be responsible for many functions in the car: playing music, watching videos, navigation, and so on. You can purchase various multimedia systems, the cost of which varies from several tens to hundreds of dollars. If necessary, you can modify the front panel almost beyond recognition.

In conclusion, we note that before carrying out work you should always create a work plan. It will eliminate the possibility of problems and errors during tuning.

Reasons for repairing a VAZ 2110 with your own hands

- Relatively low prices for spare parts.

- Aerodynamics of high quality.

- Galvanized metal body.

- Soft suspension.

Do-it-yourself maintenance and repair of the VAZ 2110 is accessible and inexpensive. Buyers' interest is also caused by relatively low fuel consumption. The car is represented by a five-seater cabin with a front engine in the car, the drive is located on the front wheels. The body has a supporting structure of an all-metal welded type.

When does a generator need repair?

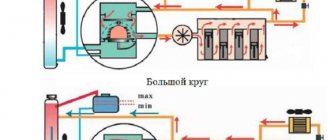

Scheme of operation of the device on a VAZ

Before disassembling and remodeling, let's figure out why we have to make repairs.

So, what are the reasons why a driver needs repairs:

- Modification of the VAZ 2110 16 valve generator or its repair is necessary if, while the engine is running, the light is constantly on or simply blinking, indicating the need to charge the battery.

- The mechanism is heating up. If you notice that the generator is heating up, and there are no other visible reasons for its damage, for example, wear of brushes, mounting brackets or rings, then you need to take time to diagnose. As a rule, the generator gets hot for various reasons. In any case, if it gets hot, it needs to be repaired.

- Another symptom of a malfunction is complete discharge or boiling off of the electrolyte in the battery of a car with a 16- or 8-valve engine.

- The need to remove and disassemble it yourself also appears if the device produces a small charge. That is, the light of the low and high beam headlights has become dimmer. Also, a too quiet steering horn may indicate malfunctions and the need for repairs and disassembly.

- When running a 16- or 8-valve injector engine, the generator revs too high, and the brightness of the lights may also change. This is quite possible when the speed level increases from idle, but the lights, after they light up brightly, should not increase their brightness in the future. That is, the intensity of the headlights should remain at the same level.

- Uncharacteristic sounds for the operation of the device (the device howls and hums). If you notice that the device not only produces less voltage, but also hums and howls, this indicates the need to remove, disassemble and repair the generator with further assembly. When the generator hums, this is the first sign of the need for repairs (the author of the video about generator repair is TexAs 64 rus).

Types of repair work

Important repair stages are scheduled and seasonal repairs. Mandatory vehicle maintenance includes diagnostics, repairs and adjustments. There is a simple, non-labor-intensive job that you can easily do yourself. For difficult work you will need additional equipment and good tools. If the machine is operated in particularly harsh conditions, experts recommend reducing the mileage for routine maintenance to 5 thousand km. Routine car repairs include:

- replacing used oil;

- replacing filters (oil, fuel, air);

- engine diagnostics with inspection of the brake system;

- replacement of steering mechanisms with chassis.

If necessary, after inspecting the VAZ 2110 car, the following is carried out:

- injector cleaning work;

- economizer adjustment;

- replacing brake pads;

- adjustment of wheel camber angles;

- replacement of brake cylinders with hoses;

- replacement of shock absorbers.

Repair and operation of VAZ must be carried out in strict accordance with the rules. A seasonal inspection is done every six months. The repairman is not limited to replacing tires on a car during the season. VAZ repairs can be carried out both in showrooms by qualified specialists and on our own. Based on work experience, year of manufacture and condition of the car, the master can easily tell the approximate mileage before subsequent repairs.

Device

Periodic malfunctions in the operation of the heating system for the VAZ 2110 are an ordinary and common thing. Therefore, the owners of this model from the Russian automaker have to dig around in their own garage every now and then or send the car for repairs to specialists from service stations.

Heater circuit diagram

To understand exactly how to carry out repair and preventative measures, you first need to familiarize yourself with the diagram of the stove and its components.

| Element | Peculiarities |

| Electric motor | A fan is mounted on it. Both elements contribute to the injection of heated air into the cabin |

| Radiator | The entire operation of the heating system is based on this component. Remove the radiator and the heater will not work. Interestingly, the new model stove does not have a valve that shut off the flow of coolant through the radiator. Older devices have a faucet. The faucet was removed in order to avoid leaks, which were common on old stoves. Plus, they got rid of the tap for faster and more efficient heating of the interior. Although many owners of new tens do not agree with this decision, therefore, during repairs, they install a faucet on the stove |

| Dampers | In total, the stove has three of them. The first is responsible for air intake recirculation, the second is for opening and closing the heater duct, and the third is intended for control and is considered the most important |

| Resistor | This element is responsible for the speed of blowing hot air into the cabin. |

All elements, including additional valves, shields, fittings, are combined into a single unit. It, enclosed in a housing, is located in the engine compartment near the dashboard.

Air ducts

Air ducts are another block of the heating system. They come from the stove and perform several different functions at once:

- The interior is ventilated through central nozzles;

- Distribute the air through an appropriate distributor that supplies heat or air for ventilation;

- Another pair of air ducts serve to heat the rear row of seats;

- The system, which includes five nozzles at once, warms the feet;

- A pair of side air ducts take over the functions of heating the glass and partially heat the interior. This makes heating more efficient;

- A pair of nozzles are used for ventilation.

Electronic stove control

This electronic control unit operates directly from the passenger compartment. It consists of two main elements.

- Pen. Using the controller knob, the user sets the required temperature, which the stove then generates. Control is carried out by turning the knob in one direction or another, depending on what degree of heating you require at the moment.

- Temperature sensor. It is responsible for activating the stove when the temperature drops by more than 2 degrees compared to the value set on the controller. The sensor is equipped with a micro motor. When the handle is in position A, the micromotor in the stove block turns on, the damper is activated, thereby causing proper heating.

Control block

Before starting repairs of the entire stove, it is strongly recommended to check the condition of the sensor. You can find it near the heater lamp on the ceiling of the car. The device cannot be repaired. Replacement only.

Car repair tips

To carry out ordinary simple repairs of a VAZ 2110 on your own, you need to have a minimum of tools. Repair includes the following operations.

- Adding used fluid (brake, coolant, for washing external windows) or new oil to the engine.

- Adjusting the headlights.

- Replacing filters.

- Replacing brake pads

- Recharging batteries, replacing sensors, checking tire pressure.

To carry out routine repairs, you will need an inspection ditch (pit) and a special lift. To carry out complex repairs, where it is necessary to replace parts of all suspensions, you will have to invite competent and physically trained assistants. You need to use a professional tool. The most labor-intensive and expensive are the major repairs of the body and engine.

Experts do not recommend performing this work in artisanal conditions. This is especially true for those who do not have practical skills, the necessary special equipment and the necessary tools. It may be impossible to eliminate the consequences of incorrectly and unprofessionally performed major repair work on an engine; it is often necessary to replace it completely.

Final processing

After welding work, it is necessary to clean the seams with a grinder, carry out anti-corrosion treatment, and install new sound insulation panels. The bottom of the VAZ 2110 must be treated with anti-corrosion agent both from the outside and from the inside. Bottom finishing:

- The welds are cleaned until they shine, a grinder is used, and at the final stage, sandpaper R-80 is used.

- The seams are covered with bitumen-based mastic.

- The bottom surface is primed outside and inside the cabin.

- An oil-based anti-corrosion agent is applied to the inner surface. The composition penetrates into all hidden grooves and pockets.

- The outer part of the body is treated with anti-gravel protection.

- Sound insulation panels are cut to the required size, heated with a hair dryer, and placed on the bottom inside the cabin.

- Doors are being installed.

The work on replacing the bottom is completed, all that remains is to mount the interior, install the trim elements, and connect the electrical wiring.

Purpose

The wheels are attached to the front suspension; the unit provides shock absorption for the “front” of the car, is responsible for stability while driving, wheel adjustment, camber, and toe-in.

The front suspension design of the VAZ 2110 is quite complex, but any of you can figure it out. The main thing here is to arm yourself with an instruction manual, as well as understand the essence of the main angles.

Main front suspension components

The main element of the front suspension is considered to be a hydraulic telescopic strut , which is simply irreplaceable in the matter of shock absorption and ensuring a comfortable ride on the car. The car won’t shake much, and going through every hole won’t turn your trip into a nightmare.

To change the wheel camber, there is a strut in the front suspension. To be more precise, the steering knuckle and the upper bolt, which has an eccentric washer and a belt, are responsible for this process.

Mounted on the rack:

- Special springs;

- Buffer to limit the compression stroke. On the VAZ 2110 this element is made of polyurethane;

- Upper support. It is attached to the rack, to which, in turn, the mudguard is attached. Please note that only self-locking nuts are used for fixing. Therefore, ordinary nuts will not work for repairs;

- Bearing to ensure rotation of the stand together with the wheels;

- Shock absorbers with spring and plunger.

By the way, the cross member of the front suspension of the VAZ 2110 is a bar to which the lower arms are connected. In the center it is attached to the body using a rubber cushion.

This is a brief diagram of the front suspension of the VAZ 2110, your instruction manual will help you get to know it better. Many motorists underestimate the importance of this literature, which the manufacturer attaches to each of its cars. But in fact, the necessary, useful and important information about each component, unit and system of the machine is presented in detail and in all colors. Including the front suspension, of course.

Wireless charger

Modern business class cars have many useful options, for example, wireless charging of a mobile device. Many people have phones that are charged from a special unit. You can make a similar base yourself in the car in question. Let's consider all the features of such a modification.

Wireless power supply occurs via the QI channel. This standard can be used to transmit energy over a distance of up to 4 centimeters. The technology involves transferring energy between two induction coils.

A fairly popular option for installing wireless charging is to embed the unit into a tunnel. In this case, the mobile phone will be charged almost constantly, and the phone can be picked up during a call quite quickly.

In order to tune the interior of a VAZ 2110, you will need the following parts:

1. A charging module that transmits current according to the standard in question. 2. A converter that can lower the voltage from 12 V to 5 V. 3. A heat gun that will be used to mount the power supply.

Please note that the charger model is powered from a 5 V network. That is why the connection should be made through a converter. You can create a special niche for the charging module, which will eliminate the possibility of the phone slipping while turning. The mobile phone power base is attached to the base using thermoplastic. In order to monitor charging, you can display the LED in a visible place.

In a similar way, you can create a special unit to power a mobile phone. You can also purchase special holders that are designed for charging a cell phone in a car. However, their use is quite inconvenient.

Typical faults

The front suspension is characterized by certain breakdowns, which are determined by two phenomena:

They should be considered separately, since the reasons for their appearance are different.

Knocks

If you start to hear knocking noises coming from the front suspension, this could be caused by several reasons:

- The rack has certain faults;

- The ties on the cross member, the cushions are worn out or the bolts are loose;

- The attachment to the body was not strong enough;

- The springs have failed;

- The hinges are worn out;

- The rubber part of the suspension has broken its integrity. The knock should be clear, like the impact of metal on metal;

- Wheel alignment is out of balance.

If you do not hear a knock, but a noise, then the causes of front suspension problems may be as follows:

- The bolts that secure the stabilizer bar to the body have become loose;

- The rubber components in the strut support have collapsed;

- The rubber pads of the coupler or rod are worn out;

- The suspension spring has broken or violated its geometry;

- The wheels are unbalanced;

- The compression stroke buffer has collapsed.

Increased tire wear

If you are not a fan of fast acceleration, harsh braking, or do not overload the car, then the reasons for increased wear may be:

- The wheel alignment angles are incorrect;

- The hinges are worn out;

- Wheel balance is off.

Installing the clutch disc and basket

We install the clutch disc and basket on the flywheel. The clutch disc must be centered in relation to the internal bearing of the shaft cranks using a special shaft. On which there are two surfaces, one corresponds to the inner diameter of the bearing, the other corresponds to the inner diameter of the splined part of the clutch disc. The clutch disc is located with its protruding part towards the basket. After centering, install and tighten the clutch basket.

Why does the car pull to the side?

Sometimes drivers notice how, when driving in a straight line, the car begins to pull to the side. There are several reasons for this phenomenon:

- Each spring has its own specific compression ratio. If it loses elasticity, the element must be replaced;

- Tires may have different pressures. Check this first;

- A rubber component on one of the strut supports has collapsed. In such a situation, a characteristic knock may appear. The situation can be corrected by simply replacing the element;

- The wheels are set at the wrong angle. A common cause of tire wear. It is better to trust such a problem to a specialist, since it is difficult to repair the front suspension on a VAZ 2110 with your own hands in case of such a malfunction.

This is interesting: Replacing a 402 engine with a 410

Installation of pistons and connecting rods

The next step is to install the pistons on the connecting rods. Pistons and connecting rods have a certain direction in relation to the engine. The arrow on the pistons indicates the forward direction, that is, they should be directed from the flywheel towards the front cover.

There are numbers on the connecting rods; they should face forward in the same way.

Taking this direction into account, we connect the piston and connecting rod using a piston pin. Before installing the pin, the piston must be heated; just place it in hot water for a few minutes. In the piston, the pin is locked on both sides by retaining rings.

Examination

- Experts recommend paying special attention to the protective covers of the joints, monitoring their condition, and also checking the front suspension for mechanical damage.

- Make sure that neither the front suspension arm of the VAZ 2110 nor any other element has cracks or other visible damage. Pay attention to checking the connection points of the elements.

- If the components are deformed, the angle of the wheels will most likely be disrupted and they will no longer be able to be adjusted.

- Check ball joints, hinges, upper stack mounts, cushions. If there are breaks in the rubber elements, they must be replaced.

- Measure the distance between the lower arm and the brake disc. This way you can check the condition of the suspension joint. If the distance is more than 0.8 millimeters, the hinge must be replaced with a new one.

- If the buffer shows signs of destruction, it should be replaced immediately.

- The spring is replaced if it has failed or sagged.

- Ball joints are replaced when they are worn or deformed. Other hinges must be replaced if they or the stabilizer bar struts are worn out.

- All rubber elements change under conditions of deformation or failure.

- If the fastening of the upper strut mount to the body is loose, simply try to tighten the fastening. Most likely, no major intervention will be required.

Understanding the structure of the front suspension, as well as audibly or visually identifying its malfunctions is quite simple, despite the apparent complexity of the assembly. But you should approach the issue carefully and periodically check the condition of the suspension, even if its malfunction is not indicated by any noise, knocking or behavior of the car on the road.

For any car, it is better to organize preventive maintenance than to later pay exorbitant prices for a full repair. Like a disease, it is better to prevent problems with the front suspension of the VAZ 2110 from occurring. It is cheaper, simpler and more correct on the part of the car owner.

Installing piston rings

Now you need to install the piston rings on the piston. As a rule, three rings are installed on one piston. The upper and middle compression and lower oil rings are removable. The rings have an engraving, the inscription should be facing up,

if it is not there, then you can navigate by the chamfer, which is located either along the inner or outer diameter of the piston rings. This chamfer acts as a stiffening rib, which creates resistance to the loads that arise when gases expand in the combustion chamber. If there is a chamfer along the inner diameter, then the ring is placed with the chamfer up, if along the outer diameter, then with the chamfer down. The oil slip rings also have an engraving that should face up; if it is not there, then the direction of the ring does not matter.

The rings on the pistons must be placed in such a way that the ring connectors are not located under each other and do not fall into the groove under the pin. Since, for example, the middle ring connector is located on one side of the piston, the upper and lower ring connectors must be on the other side of the piston, and must be spaced apart from each other, but not fall into the piston pin recess

Tags: repair, maintenance, VAZ tuning, faq

Comments 52

Good afternoon everyone! I ran into trouble that circumstances forced me to install an unloading relay on the starter, but I have a question about the correctness of the circuit that I used in this community: www.drive2.ru/c/48003/ why is it better or worse than this www.drive2.ru /c/595839/ There is no selenium in the electrics, I’m afraid of burning the car

Have a good time everyone. Need help, the dashboard lights are constantly on, when you turn on the ignition, not a single light comes on. Maybe someone had this.

hi all! Tell me what to do, I changed the sensor, drove 500m, and everything is new (the check light is on) ps there are no deviations in the car, everything is normal. NOT troit,

maybe the hall sensor is working, if only the switch or coil?

VAZ 2110 carburetor at first troubled then everything, tried with A3-1, thought hall sensor, silence

here not long ago there was a 2112 that had a muzzle and rear arches made under the coupe, I can’t find it, help

I just have the first ten, I don’t really know anything about it, I just found the manual from you)

Yes, I have. If viburnum or Priora, or. you'll find it too

thank you, a lot of useful and necessary information) I wish there were more such wonderful people)))

that's exactly why) good luck

Add a topic! Replacing the foam lamp socket with a cigarette lighter. In my blog, here is the link www.drive2.ru/cars/lada/2…3/glebing/journal/202385/

There are no priors in the family yet. I’ll definitely take the advice. Thanks

Thanks for the info. I downloaded it on both Kalina and 10.

I saw an electronic version of Murzilka somewhere, but I can’t find it anymore, can anyone tell me? Not PDF, but in program form.

Whoa! Like this! In fact, I forgot that I needed it.))) I’ll go look for it on the tracker. Py-Sy. Here, I hope it will be useful to many! yadi.sk/d/JBFUaKkqdD5GW

What about removing and installing the internal combustion engine? Also a useful topic: How to do what, you can look in my blog

how to pull the power wire through the elastic band of the hydraulic corrector?

And also, I have a proposal to create a topic on consumables, what kind of oil, brake pads and timing belt, etc. I can even fill it out myself

Thank you, the manual has been added to the community FAQ. Everything is well written and the photos are on point! We need a topic regarding consumables; the same type of questions are asked every day. Will you do it?

I’ll do it, but the topic will need to be fixed in the same way as the faq.

And also, I have a proposal to create a topic on consumables, what kind of oil, brake pads and timing belt, etc. I can even fill it out myself

+1. suspension, pads, calipers, tips and all that from me

I would like to know something about the power steering and rack, otherwise the Murzilkas don’t have anything on the power steering, mine is leaking, I plan to sort it out when it gets warmer. I would like to know what to prepare for and where the difficulties are.

on the treatment of outgoing corners on the dashboard near the air intakes

How to distinguish original MAFs from fakes, a very useful link

Maybe someone will be interested in what an absorber is. The feedback injection system uses a fuel vapor recovery system. It consists of an adsorber installed in the engine compartment, a separator, valves and connecting hoses. Fuel vapor from the tank partially condenses in the separator, and the condensate is drained back into the tank. The remaining vapor passes through gravity and two-way valves. The gravity valve prevents fuel from leaking out of the tank when the vehicle rolls over, and the two-way valve prevents excessive increase or decrease in pressure in the fuel tank.

Then the fuel vapor enters the adsorber, where it is absorbed by activated carbon. The second fitting of the adsorber is connected by a hose to the throttle assembly, and the third to the atmosphere. However, when the engine is turned off, the third fitting is closed by an electromagnetic valve, so that in this case the adsorber does not communicate with the atmosphere. When the engine starts, the injection system controller begins to send control pulses to the valve with a frequency of 16 Hz. The valve communicates the adsorber cavity with the atmosphere and the sorbent is purged: gasoline vapors are sucked through the hose into the receiver. The greater the engine's air consumption, the longer the duration of the control pulses and the more intense the purging.

In an injection system without feedback, the system

DIY VAZ 2110 repair

In the photo there is a red Lada Ten - a four-door front-wheel drive domestic sedan.

VAZ-2110 is a small class car made in Russia. Production began at the VAZ plant in 1995. In 2007, the last car, model 2110, rolled off the assembly line.

The model was produced under the VAZ 2110 and Lada 110 brands. The “folk” names of the model are Zhiguli, Desyatka.

Initially, the VAZ 2110 was produced only as a sedan with four doors. The car was equipped with front-wheel drive and an electronic engine control system. For the first time, an on-board computer was installed on a Russian car model.

Engines

On the domestic market, the model could be purchased with one of three engine options:

- 1.5-liter 8-valve engine, 69 hp. Model 2110 base carburetor powertrain;

- 1.5-liter 8-valve engine, 79 hp. Accelerates to hundreds in 14 seconds;

- 1.5-liter 16-valve engine, 94 hp. The most powerful version of the power unit. Acceleration to 100 km/h takes 12.5 seconds.

8-valve engines have valve protection - they do not bend if the timing belt breaks. There is no such protection on a 16-valve power unit.

All VAZ engines require timely maintenance. Failure to meet replacement deadlines may result in major repairs.

During operation, the intake manifold fails. Repairing a problem yourself requires a lot of time and effort. Repairs at a service station will cost twice as much. If you have no experience in such work on your own, it is better to turn to specialists.

How to choose a part: average prices

To weld the bottom of a car at a car service center, the minimum price is 25,000 rubles. This applies to minor floor defects in all customer materials. A complete overhaul and update can cost up to half the cost of a car. Considering that the price of a VAZ is minimal, such repairs are not profitable for most drivers.

Many people prefer to carry out repairs and replacements on their own, buying a solid bottom. The repair kit is produced by AvtoVAZ, the element is suitable for models 2110, 2111, 2112, 2170, 2171, 2172. The cost does not exceed 4,000 rubles. Cold-rolled steel 0.8 mm thick is used in production.

There are options on the market to buy bottom elements: panels, amplifiers, connectors and cross members. The cost of each element is from 900 rubles. Parts of the bottom are chosen instead of metal patches if local repairs are necessary without welding out the entire bottom.